Fiberglass motorcycle fairings are not merely a popular aesthetic upgrade; they represent a crucial advancement for performance, safety, and rider personalization. Designed with high-performance capabilities, these components enhance speed and handling, serving as an ideal solution for both street and track enthusiasts. By focusing on significant benefits like aerodynamics and customization possibilities, businesses can capitalize on the increasing demand for fiberglass fairings. Through exploring each facet—from performance enhancements to market accessibility—owners can better understand how to embrace and promote this vital upgrade in their motorcycle offerings.

Contours of Speed: Aerodynamics, Weight, and the Performance Edge of Fiberglass Motorcycle Fairings

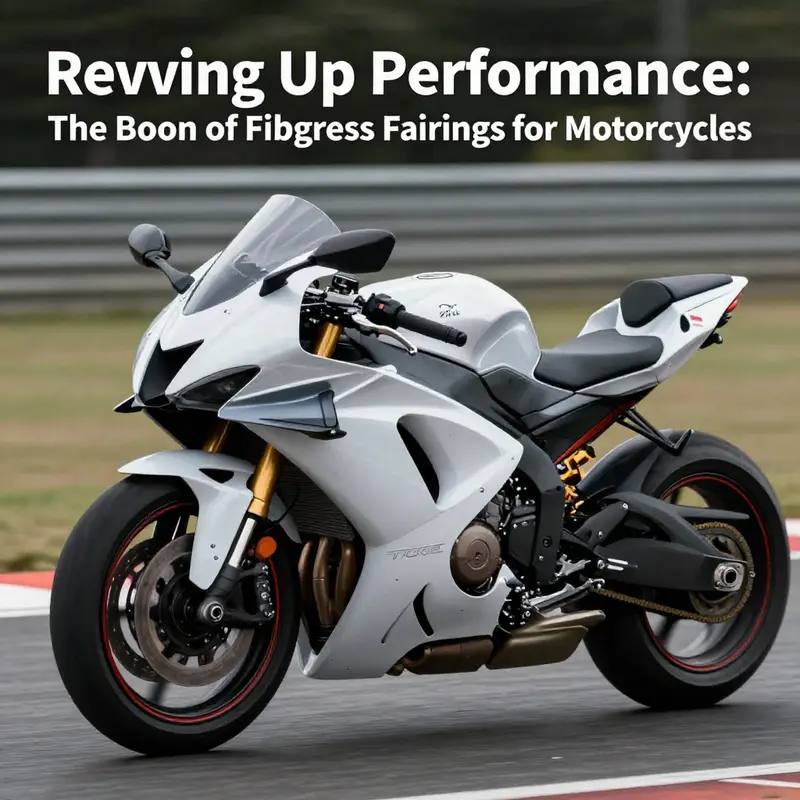

A motorcycle’s performance hinges on a delicate balance between power, grip, and the way air interacts with the machine and rider. Fiberglass fairings, far from being mere shells, act as a carefully engineered interface between the bike and the atmosphere. They shape the flow of air around the rider and chassis, guiding it in ways that reduce drag, stabilize at high speeds, and protect valuable components from road debris and weather. When crafted with intent, fiberglass panels can deliver a meaningful reduction in wind resistance while preserving the strength needed to withstand the daily rigors of street riding or the demands of the track. The result is a composite that helps a bike feel quicker, more planted, and more responsive to rider input, especially when the throttle is pressed into the upper ranges where the air forces are strongest. The story of these fairings begins with how air behaves around a streamlined body and how fiberglass, as a fabric of fibers and resin, can be shaped to follow the contours of a rider and engine with precision.

Air moves in patterns that science can describe but experience turns into practice on the road and in the wind tunnel. A well-designed fairing reduces the size of the wake behind the bike, pushes turbulent separation further away from critical surfaces, and helps the bike slice through air with less energy wasted in churn. Fiberglass, unlike rigid plastics that can fatigue under temperature swings and impact, offers a combination of moldability and rigidity that lets designers craft complex curves and tight radii without sacrificing strength. Each contour is an attempt to manage the boundary layer—the thin layer of air that clings to the surface—and to avoid abrupt transitions that invite flow separation. When the surface geometry is locked in, the rider experiences steadier handling, less oscillation in crosswinds, and a smoother ride through gusts, rain, or coarse road surfaces.

The direct performance implications of these aerodynamic choices are often expressed in two practical currencies for riders: speed and efficiency. Drag reduction translates into higher top speed potential and improved throttle response at mid- to high-velocity ranges. In everyday terms, that means a bike can accelerate with less effort and sip fuel more frugally on long highway stints, because the engine is not fighting a relentless headwind every time it climbs to highway velocities. But the benefits are not simply about raw numbers. High-speed stability matters as well. A refined fairing aims to channel wind away from the rider’s chest and helmet, reducing fatigue and allowing a rider to focus on line choice and braking points rather than bracing against buffeting. Even small gains in stability can extend the window of comfortable, precise control, which is a subtle but meaningful aspect of performance on sportier, wind-sensitive machines.

In the realm of fiberglass, the material’s role is not just to form a shape but to maintain it under load. Lightweight, rigid, and crack-resistant, fiberglass composites provide a strong canvas for aerodynamic design. The weight advantage matters because every extra kilogram added in the body panels translates into marginally more inertia the bike has to move and overcome during acceleration, braking, and cornering. Fiberglass can be engineered to be significantly lighter than traditional plastic options, while still enduring the cracking risks that come with road debris and occasional misadventures off the tarmac. The resulting stiffness contributes to predictable handling, especially when the rider is pushing the machine near its limits. A stiffer panel resists flex that could otherwise alter the intended airflow, preserving the designed aerodynamic characteristics even as road conditions and riding styles vary.

Yet fiberglass is not simply a straight line to speed. It offers the designer a tolerance for details that matter in real-world riding. The surface finish, the transition between panels, the gaps around mounting points, and the way the fairing can be tuned with minor adjustments all contribute to aerodynamics in ways that factory-level testing might not fully capture. In practice, a well-executed fiberglass fairing system is a synthesis: a carefully contoured exterior, built around the bike’s geometry, that works in harmony with the rider’s posture and riding rhythm. It is this harmony that translates theoretical drag reductions into tangible benefits such as improved high-speed stability, smoother drafting behavior, and easier management of windblast during long rides.

The configurations of fiberglass fairings further shape their aerodynamic and performance profile. Full fairing kits envelop the front and sides of the bike, creating a unified shell that reduces exposed area and channels air efficiently around the rider and engine compartment. The larger surface area demands careful attention to the interface between the fairing and the frame, as well as the integration with other components like mirrors, windscreen, and radiator scoops. When these elements come together with precision, the result is a cohesive silhouette that minimizes drag while offering substantial wind protection for the rider. Semi-fairings, by contrast, cover only the upper portions of the bike—such as the headlight area and the top line of the fuel tank—delivering aerodynamic benefits without the weight and bulk of a full kit. The choice between full and semi-fairings often hinges on the rider’s goals: sport performance and ramped-up aerodynamics on the track, or enhanced protection and comfort on long-distance and street riding. The beauty of fiberglass lies in its adaptability; it can be tailored to emphasize one goal without compromising the other.

To many riders, the allure of fiberglass lies not only in the performance edge but also in the practicalities of customization. A fiberglass shell can be molded, repaired, and refinished with relative ease compared to other composites. This flexibility is crucial for riders who want to tailor a bike’s appearance while maintaining aerodynamic integrity. Finishes can be painted or wrapped to match a rider’s aesthetic without altering the underlying aerodynamics. This balance between form and function makes fiberglass a popular choice among enthusiasts who demand both performance and personal expression from their machines. As with any aftermarket component, the quality of the raw material, the precision of the mold, and the craftsmanship of the fabrication process determine how much aerodynamic advantage is realized in practice. A high-quality fiberglass kit that fits well and aligns with the mounting points will deliver the intended contours, while a poorly fitted panel can introduce gaps, misalignments, and unexpected airflow disruptions that erode performance gains.

Beyond the physics, there is a safety and durability dimension that cannot be overlooked. Fiberglass fairings, when produced to recognized safety standards, provide meaningful protection to the bike’s vital internals. In a crash or impact with road debris, a robust fiberglass shell can absorb and distribute some of the energy, reducing the likelihood of damage to the engine, fuel system, or electrical harnesses. The rigidity of the material also helps maintain panel integrity during repeated vibrations, which are commonplace on long trips and at high speeds. In practice, riders value these properties because they translate into fewer panel failures, fewer maintenance interruptions, and more predictable behavior after minor bumps. The result is a composite that not only slices through air with less resistance but also stands up to the realities of riding, weather, and road imperfections with a reliability that is essential for everyday use as well as competitive environments.

The journey from concept to road-ready performance with fiberglass fairings is inherently collaborative. Designers, engineers, and riders work together to refine the geometry, ensure accurate fitment, and verify that the finished product complements the motorcycle’s chassis dynamics. This collaboration often involves iterations that consider the rider’s posture, the cockpit’s ergonomics, and the fitment of key components such as instruments and headlights. The aim is to deliver a surface that maintains smooth airflow across a wide range of speeds and rider positions. In practice, even small changes in the line of a fairing or the radius of a corner can influence the transition of air from the nose to the sides, altering the drag profile and the lift characteristics around the front wheel. The result is a nuanced, integrated system rather than a simple add-on. When done well, fiberglass fairings become an enabler of performance, a practical embodiment of aerodynamic science that translates into noticeable gains in speed, efficiency, and confidence on the road or the track.

For riders exploring upgrade options, the landscape is populated with a spectrum of choices that balance aerodynamic performance, weight savings, and cost. Some kits emphasize the race-inspired silhouette and high-speed efficiency, while others prioritize touring comfort, with better wind management and reduced fatigue on long rides. The available variants reflect a practical philosophy: you do not have to sacrifice aesthetics to achieve performance, and you do not have to accept excess weight to gain protection. The fiberglass approach offers the possibility of tailored aerodynamics—optimizing the surface for the rider’s typical speeds and riding style, while maintaining the visual presence that makes a machine feel alive on the road. In this sense, fiberglass fairings represent a pragmatic intersection of science and art, where aerodynamic theory meets the realities of street and track riding, and where the rider’s experience is shaped by both the wind and the work that went into shaping it.

As riders consider fitment and compatibility, a decisive factor becomes the alignment of the fairing with the bike’s mounting points, brackets, and surrounding components. Precision fitment ensures the intended aerodynamic performance is realized. A fairing that sits off by a few millimeters or that leaves uneven gaps can introduce chatter, create unexpected aerodynamic disturbances, or cause rubbing between panels. Consequently, reputable manufacturers and suppliers emphasize not only the weight and rigidity of the fiberglass itself but also the accuracy of the mold and the care taken during assembly. A well-fit kit will align with the bike’s frame geometry and will integrate cleanly with existing features such as the windshield, instrument cluster, and headlight nacelles. This alignment matters as much as the material properties because, even with excellent fiber composition, a misfit is a drag in more ways than one—literally increasing drag and visually breaking the intended silhouette.

For riders choosing fiberglass fairings, the design, material quality, and craftsmanship determine longevity and performance. The feasibility of maintenance and repair is an often overlooked advantage. If a panel is damaged, fiberglass parts can often be repaired or reshaped without the need to replace the entire kit. This practical flexibility reduces downtime and keeps the bike on the road while still preserving aerodynamic integrity. The process of repair can also be a way to correct minor misalignments or scuffs that occur during aggressive riding or casual use alike. The enduring appeal of fiberglass in this context lies in its capacity to be tuned and repaired with the same care that goes into its original design, preserving the performance benefits over the long term and ensuring that the rider continues to enjoy the intended balance between speed, efficiency, and protection.

In the marketplace, buyers encounter a spectrum of options that reflect the diversity of riding styles and priorities. Some kits are designed to be bolt-on replacements that preserve original mounting points and require minimal modification, while others are intended for more extensive customization, demanding a higher degree of fitment expertise. Regardless of approach, the prudent rider recognizes the importance of quality materials, precise manufacturing, and reliable fitment guarantees. When a kit is backed by a fitment guarantee and a documented build standard, it offers peace of mind that the aerodynamic goals and protective functions will hold up under the stresses of high-speed riding and rough roads alike. For the curious shopper, a practical path involves comparing the weight savings, the expected drag reduction, and the compatibility with the rider’s typical riding environment. The result is not simply a matter of grabbing the lightest panel but selecting the combination of contours, rigidity, and finish that best aligns with the rider’s needs and the bike’s characteristics.

For readers exploring the topic further and seeking model-specific options, a curated catalog of fairing options provides a direct pathway to assess how the geometry translates into real-world performance. The catalog emphasizes how each contour, each edge transition, and each mount point is engineered to preserve the intended aerodynamic behavior while accommodating the rider’s seat height, posture, and line through corners. This approach reinforces the idea that fiberglass is not a one-size-fits-all solution but a versatile platform that can be tailored to exercise the aerodynamic potential of a given chassis. In practice, the most satisfying results come from a careful pairing of design intent with the rider’s preferences and riding conditions, producing a setup that feels fast and stable in equal measure. When this harmony exists, the rider experiences that elusive combination of lightness, speed, and control—the hallmark of a well-executed fiberglass fairing upgrade.

From an instructional perspective, understanding the core ideas behind fiberglass fairings helps riders make informed decisions about fitment, finish, and maintenance. It begins with recognizing that performance is a system property: the effect of a single contour depends on how it integrates with the entire bike, including the rider’s position. It continues with appreciating material behavior under load, temperature, and impact, and how that behavior translates into both performance and durability on the road. Finally, it involves acknowledging the practical realities of ownership—repairability, customization potential, and the availability of fitment guarantees. When these elements come together, fiberglass fairings emerge as a thoughtful, performance-oriented upgrade rather than a cosmetic adornment. They are a blend of physics and craft, carefully tuned to improve aerodynamics, reduce fatigue, and enhance the riding experience while maintaining the resilience required to withstand the everyday demands of motorcycling.

To connect these ideas to a practical starting point, riders often look for model-specific fitment options that ensure the contours and mounting points align with the bike’s geometry. A curated catalog or a trusted supplier can be the doorway to a fairing system that respects both aerodynamic intent and the realities of on-road use. For readers who want a direct route to explore a model-focused collection, the following catalog entry provides a focused path to evaluate the available fiberglass options and their attributes: honda-cbr600rr-fairings-2005-2006.

In sum, fiberglass fairings offer a compelling blend of aerodynamic efficiency, weight savings, and protective capability that can enhance both sport and touring applications. By shaping the air around the rider and the chassis, these panels reduce drag, improve high-speed stability, and make long rides more comfortable. Their lightweight construction and rigid, crack-resistant properties contribute to sharper handling and better energy efficiency, while their finish options and repairability support customization and longevity. The right choice—carefully matched to the rider’s goals, riding style, and vehicle geometry—transforms a bike into a more confident, more capable machine. When approached with a clear sense of how the contours interact with air and with real-world riding demands, fiberglass fairings become a practical, engineered path to performance that does not require trading aesthetic appeal for speed, nor sacrificing durability for lightweight design. And for those who want to begin with a strong, model-conscious option, a direct link to a model-focused catalog can guide the search toward a fitment that truly respects the bike’s lines and the rider’s ambitions. External reading can also supplement this exploration, offering a broader view of how the market supports fiberglass fairing upgrades and how shoppers evaluate the balance of weight, cost, and aerodynamic payoff. A widely used external resource provides further context for buyers seeking fiberglass fairing kits and related components: https://www.ebay.com/sch/i.html?_nkw=fiberglass+motorcycle+fairings+kits

Beyond the Look: How Fiberglass Fairings Elevate Safety, Strength, and Personal Style on the Move

Fiberglass motorcycle fairings are more than a styling cue or a lightweight accessory. They are intentionally engineered components that influence safety, durability, and the rider’s self-expression in equal measure. When a rider chooses fiberglass for fairing upgrades, they are opting for a material that blends strength with flexibility, weight with protection, and artistry with aerodynamics. The conversation around fiberglass begins with safety, but it does not end there. It unfolds as a cohesive narrative about how a well-crafted shell can shield vital systems, absorb and redirect energy during mishaps, and still carry a rider’s personal mark through color, texture, and finish.

To understand the safety advantages, it helps to start with the material’s intrinsic properties. Fiberglass stands out for its tensile strength, which is the measure of how much stretch a material can endure before it fails. In practical terms, this means a fiberglass fairing can resist deformation under high heat and during mechanical stress more reliably than many common ABS plastics used in OEM parts. The fibers themselves act as a reinforcing lattice, distributing loads across a broad surface and reducing the likelihood that a single impact will crack the structure. This distributed resistance is particularly valuable in the context of riding dynamics, where a fairing encounters heat from the engine bay, radiant sun, and the occasional stray rock or curb during a sidestep maneuver on a bend or a moment of hard braking where the front end experiences abrupt loads.

Beyond raw strength, fiberglass has a track record for resilience in the face of impact. A well-laminated fairing can absorb and dissipate some of the energy that would otherwise transfer directly to more fragile components such as the fuel tank, radiator shrouds, and instrument cluster. The result is a protective envelope that keeps the most critical elements shielded from the kind of minor collisions, tip‑overs, and road debris that riders occasionally encounter. For those who ride aggressively, or who venture into less-than-perfect road conditions, this protective aspect becomes a meaningful safety multiplier. It is not a guarantee against damage, but it is a durable line of defense that can make a difference when a crash or a harsh encounter with the terrain is unavoidable.

Certified fiberglass fairings are engineered to meet rigorous industry standards for impact resistance and longevity. Certification is not a mere checkbox; it is a careful, documented process that tests how the material behaves under repeated stresses, temperature cycles, and environmental exposure. This assurance matters because a fairing is not just a one‑off cosmetic piece. It is part of the bike’s bodywork that endures wind stress at highway speeds, UV exposure that can degrade surfaces, and the physiological aging that comes with years of riding. A quality fiberglass laminate resists heat-induced softening, resists cracking after a subtle collision with a guardrail or a tree root, and maintains its protective rhythm across a broad range of operating temperatures. In practice, this translates to fewer random fractures, more predictable behavior during an off‑season storage period, and a more reliable return to service when the road conditions improve.

The safety story extends to how fiberglass fairings coexist with the bike’s most sensitive systems. Modern motorcycles rely on a carefully tuned balance between airflow, engine cooling, and radiator efficiency. A properly designed fiberglass fairing can be contoured to minimize drag while still directing air toward the radiator and beneath the engine bay where heat tends to accumulate. The result is not only a cleaner silhouette and a sportier look but also more stable temperature management in sustained high‑speed riding. The aerodynamic profile that fiberglass can be molded into—curving smoothly around the front, tapering along the sides, and integrating with the bike’s existing lines—contributes to a calmer air wake behind the rider. A calmer wake reduces buffeting and can improve overall stability at speed, which in turn supports safer handling, particularly in windy conditions or when a rider is navigating a twisty road or a highway crosswinds situation.

Durability follows safety in importance because consistency over time is a rider’s best ally. Fiberglass is naturally resistant to cracking under normal riding stresses, and its repairability is a practical advantage for many enthusiasts. Unlike some plastics that become brittle with UV exposure or heat cycling, fiberglass surfaces can maintain their stiffness and resist microfractures that might otherwise propagate into larger damage. When damage does occur, repair options range from patching a superficial surface crack to re‑laminating damaged sections. The repair process is compatible with the layered architecture of fiberglass: fabric layers, resin, and a protective gel coat can be restored, keeping the fairing’s protective function intact and preserving its original alignment with mounting points. This reliability matters for riders who use their motorcycles in demanding environments—sport routes, track days, or long tours—where occasional impact or abrasion is an inevitability rather than a hypothetical.

The guardrails of safety and durability also hinge on how the fairing is finished and protected. A quality fiberglass shell is typically finished with a gel coat or a composite top layer that guards the fibers from moisture, UV degradation, and chemical exposure. UV resistance safeguards color fidelity and gloss, which matters for visibility—the glossy finish can reflect light in a way that makes the bike more noticeable to other road users. A well finished surface also reduces the likelihood of micro-scratches that can harbor dirt and moisture, which in turn helps extend the life of the fairing and reduces the need for frequent refinishing. Maintenance routines, such as gentle cleaning with non-abrasive solutions and avoidance of harsh solvents, support the long‑term performance of the shell. For riders who value safety as a daily practice, this is more than skin deep; it is a commitment to preserving the protective envelope that fiberglass provides.

If there is a practical takeaway from the durability narrative, it is that fiberglass fairings are not wooden sleds of yesterday. They are adaptable, resilient, and designed to endure a rider’s evolving needs. This is especially true when the fairings are selected with fit and finish in mind. Precision fitment matters because a loosely mounted shell can vibrate, rub against mounting points, or rub other components, which compromises both safety and aesthetics. Model‑specific fitment is more than a matter of alignment; it is a safeguard that ensures mounting hardware engages in well‑defined, tested contact points. A fairing that aligns precisely with the frame and bodywork maintains predictable airflow, reduces flutter at speed, and minimizes the risk of failure at critical junctures such as the upper headtube area or near the instrument cluster. In other words, the durability promise multiplies when a fiberglass shell is chosen not only for its material properties but also for its integration with the bike’s architecture.

A further layer to the safety and durability conversation is weight. The aim of fiberglass in this context is to offer a robust shell while keeping the overall mass down, yielding real world benefits in handling and responsiveness. Lightweight construction translates to quicker steering inputs, more agile neck for cornering, and less inertia when changing directions or correcting line on a curve. It also translates to a more efficient ride in everyday use; reduced weight can contribute to lower rolling resistance and, in turn, improved acceleration and fuel efficiency under certain conditions. The total system gains from weight reduction are not isolated to a single moment but accumulate across performance, safety margins, and rider confidence. A rider who feels the bike responding more promptly to steering input, who experiences a more planted front end under braking, or who perceives improved feedback from the chassis, is often a rider who perceives fairing upgrades as a meaningful safety enhancement as well as a performance enhancement.

Turning from safety and durability to customization, fiberglass shines in a different light. This material is inherently moldable, which makes it the preferred choice for riders who want to translate personal taste into the bike’s exterior personality without sacrificing functional performance. The production method enables complex aerodynamic shapes to be formed with a smooth, continuous surface. Riders can select finishes that suit their aesthetic—glossy for a deep, reflective look; matte for a understated, modern vibe; or textured for a rugged, tactile feel that can hide dirt and scuffs while adding grip in contact areas around the knee or thigh. The surface treatments extend beyond color. Finish options include not only paint and decals but also wraps and hydrographics that provide a nearly limitless palette of visuals, from carbon fiber replicates to bold two-tone schemes that emphasize the bike’s lines. Importantly, these finishes are not mere cosmetics. They contribute to the rider’s sense of ownership and identity while preserving the shell’s protective function. A well sealed and finished fiberglass surface is more resistant to moisture intrusion and environmental wear, sustaining the fairing’s look and feel over time.

The customization journey also includes structural details that riders often overlook when planning a makeover. Edge reinforcements at mounting points, ribbing along large panels, and carefully placed stiffeners can maintain rigidity during high‑speed riding or in the event of a minor tip. In a well‑engineered fiberglass system, the same design choices that enable a striking appearance also support reliable handling. The backstory here is that customization is not a trade‑off with safety; rather, it is an opportunity to reinforce the very attributes that safety and durability rely upon: alignment, rigidity, and resilience of the shell under real world stresses. When a fairing is designed with both aesthetics and engineering in mind, it becomes a single, cohesive system rather than a cosmetic add‑on that sits on top of the bike. The rider benefits from a package that reflects personal taste without compromising the bike’s core protective envelope.

Optimal selection then becomes a matter of fitment compatibility, material certification, and a realistic assessment of riding needs. For riders seeking model‑specific fitment, the right fiberglass fairing should align with the bike’s frame geometry and mounting points, accommodate engine and radiator clearances, and allow unobstructed access for maintenance and service. Certification and testing are not afterthoughts; they provide the assurance that the pieces will behave as expected when subjected to heat, vibration, and the occasional impact. Certification markers such as CE, BV, and ISO are indicators that the component has undergone automotive grade evaluations, offering a level of confidence in safety and performance that goes beyond appearances. In practice, this means that a purchaser can select components that not only look the part but also work harmoniously with the bike’s structural and mechanical architecture. For riders investing in a fiberglass upgrade, the combination of precise fitment, certified materials, and a thoughtful finish translates into a reliable enhancement rather than a transient modification.

The story of fiberglass fairings would be incomplete without acknowledging the practical realities of ownership. Weight savings and aerodynamic benefits are meaningful, but the true value shows up in maintenance and repair. A fairing that is easy to inspect after a ride, simple to clean, and straightforward to repair in the event of a scuff or crack is one that a rider will feel comfortable relying on for the long haul. Regular maintenance routines—gentle cleaning with non abrasive products, prompt attention to any signs of fiber bloom or resin separation, and timely repairs when laminate damage appears—keep the fairing performing its protective function across seasons. The repair ecosystem for fiberglass is well understood: damaged panels can be repaired with patches, relamination, or even full panel replacement when necessary, with the result being a restored surface that continues to shield the bike and preserve the rider’s visual expression.

All these factors—safety, durability, and customization—coalesce into a single practical takeaway. Fiberglass fairings offer a compelling blend of protective function and personal expression without forcing riders to choose between performance and aesthetics. They enable riders to tailor weight, aerodynamics, and appearance to match riding style, local conditions, and personal taste. Whether a rider values a race inspired look, a rugged touring aesthetic, or a sleek modern silhouette, fiberglass makes it feasible to achieve that vision while maintaining the structural integrity required for real world riding. It is the kind of upgrade that respects the bike’s original design intent while extending its capabilities in a thoughtful, integrated way. In this light, fiberglass becomes less about replacing a part and more about enhancing a system—one that protects, adapts, and expresses the rider’s voice on the road.

For readers who want to explore materials and options further, it is useful to consider the supplier landscape and how it affects safety and performance. Reputable suppliers typically offer OEM certified components with standardized documentation, giving buyers confidence in product consistency, fitment accuracy, and the long term viability of the fairing. While the specifics of each model and year differ, the underlying principles of safe design, durable construction, and flexible customization remain constant across the spectrum of fiberglass fairings. A careful buyer will evaluate the balance of these factors alongside practical concerns such as ease of installation, compatibility with existing wiring and mounting hardware, and the potential for color matching to the rest of the bike’s bodywork. In the end, the best fiberglass fairing is the one that acts as a reliable shield, a responsive surface for dynamic riding, and a canvas for the rider’s individual style—all rolled into a single, well engineered piece of bike anatomy.

External resource for deeper context on certified fiberglass components and market standards can be found here: https://www.alibaba.com/product-detail/2005-2006-Honda-CBR600RR-Fiberglass-Motorcycle_1601384997545.html

Global Gateways: Navigating Market Access and Availability of Fiberglass Fairings for Motorcycles

Fiberglass fairings sit at the intersection of engineering ambition and practical accessibility. Their journey from a factory floor to a rider’s bike hinges on a nuanced network that blends material science, manufacturing scale, logistics, and the digital marketplaces that connect buyers with suppliers around the world. When riders consider upgrading their machines, they are not just choosing a lighter, stronger shell; they are tapping into a global system that makes sophisticated composites available beyond the walls of local dealers. In this sense, market access becomes a condition of performance as much as a matter of aesthetics. The story of fiberglass motorcycle fairings is a story about how a technical choice—lightweight strength, aerodynamic refinement, and durable protection—travels through channels that extend from the factory to the curb, then onto the highway, and into the garages of enthusiasts who demand both function and flair.

A core driver of this accessibility is the global composer of supply—manufacturers who produce fiberglass components at scale and distributors who translate factory output into a language that diverse markets can understand. The manufacturing advantage is clear. Fiberglass composites offer an excellent balance of weight and rigidity. When designed with aerodynamics in mind, these parts can reduce drag and improve handling without adding the brittleness that sometimes accompanies other lightweight materials. The numbers cited in industry discussions—roughly thirty percent weight reduction relative to traditional plastics and drag reductions in the mid-teens in optimized shapes—are not merely marketing claims. They reflect iterative improvements in resin systems, fiberglass layups, and finishing processes that together yield a part that performs consistently on track and remains practical for street use. This combination of characteristics makes fiberglass fairings a compelling option for riders who want more speed, more control, and a more cohesive appearance from their bike’s profile. The market response to these technical benefits has been widespread and resilient, especially as riders increasingly view upgrades as investments in ride quality and long-term durability, rather than quick cosmetic patches.

The pathways to market are as varied as the models of motorcycles themselves. On one end of the spectrum, there is direct sourcing from manufacturers who specialize in fiberglass composites. These suppliers often serve a global clientele, offering certified parts that come with documentation attesting to material composition, structural integrity, and finish quality. Certifications such as CE, BV, and ISO are frequently highlighted to reassure buyers about consistency and adherence to safety standards. This assurance is not merely about compliance; it is about confidence. When a rider purchases a fairing that has been certified for impact resistance and performance, the user experience—in terms of reliability, return on investment, and the quiet assurance of a part that will fit correctly and stay in place—becomes markedly better. The implication, then, is that the market is not only accessible but also trustworthy, provided buyers conduct due diligence and rely on suppliers that publish credible certifications and test data.

Meanwhile, large online marketplaces play a central role in shaping what is available and how easily it can be obtained. Platforms that connect buyers to sellers globally expose customers to a breadth of options that were inconceivable a decade ago. On e-commerce sites, for instance, buyers can search for full fairing kits or semi-fairings and then compare options based on fitment guarantees, weight, and estimated delivery times. The presence of “guaranteed fit” features on some listings helps mitigate the perennial concern that aftermarket parts may not align with a specific motorcycle’s geometry or mounting points. This guarantee, paired with seller channels that offer consistent after-sales support, transforms an after-market upgrade from a speculative purchase into a confidence-building decision. The effect on the market is measurable: a wider customer base, faster decision cycles, and reduced friction in the post-purchase phase where customers often worry about fit, color matching, and subsequent maintenance.

Direct sourcing also remains a vital route, particularly for buyers who prioritize cost efficiency and customization. Alibaba, a platform that connects buyers directly with manufacturers, has become a focal point for those seeking cost-effective, high-quality options that can be tailored to regional needs. The ability to verify suppliers, review product certifications, and negotiate terms in multiple currencies gives buyers in Western Europe, Africa, and North America access to a broader spectrum of designs, finishes, and configurations. The export volumes reported by suppliers on these platforms reflect a mature global trade in fiberglass fairings. For buyers, this translates into options that range from standard configurations to model-specific, factory-style shells that mimic the appearance and aerodynamics of original equipment, all while maintaining a competitive price point. Yet, with breadth comes responsibility: buyers should scrutinize the supplier’s QC processes, confirm that the fairings meet the necessary standards for impact resistance and endurance in varied climates, and verify that packaging and shipping terms will protect the component from moisture, vibration, and mishandling during transit.

What emerges from this ecosystem is a market that is both highly accessible and carefully governed by quality controls. Model compatibility, or fitment, remains a central criterion for both sellers and buyers. Because motorcycle geometry and mounting points can vary, even subtle design differences can make a kit incompatible with certain years or trims of a given model. This is why model-specific diagrams, templates, and support from manufacturers or retailers matter. For riders, the ability to confirm fitment before purchase reduces the risk of costly returns and the downtime associated with incorrect parts. The market responds to this need with detailed product descriptions, measurement charts, and, increasingly, interactive fitment guidance powered by digital catalogs and user forums. These tools enable riders to identify a suitable option without leaving their workshop, creating a smoother cycle from decision to installation.

The availability of fiberglass fairings also interacts with regional demand patterns and logistics infrastructure. In regions with strong motorcycle cultures and a robust network of repair shops and performance shops, aftermarket fairings are highly accessible. Dealers in such markets often maintain a curated selection of kits and semi-fairings that can be perched on the counter or ordered with quick turnaround. In regions where riders value long-term durability and ease of maintenance, suppliers emphasize finish quality and repairability. Fiberglass tends to respond well to field repairs, which can extend the life of a fairing and reduce the total cost of ownership—an important consideration for riders who ride extensively or operate in areas with limited access to professional services. The global supply chain also demonstrates resilience. Even when freight costs rise or supply constraints appear, the market can pivot toward standard sizes, compatible mounting kits, and finish options that preserve a legible aesthetic while preserving performance benefits. In this sense, availability is not simply “in stock” and ready to ship; it is a dynamic capability, shaped by the interplay of manufacturing lead times, batch production, and the efficiency of distribution networks that feed into regional warehouses and delivery hubs.

Quality assurance remains a recurring theme in the market conversation. The fiberglass used in fairings is typically a composite of glass fibers embedded in resin, crafted to achieve a predictable balance of stiffness, impact resistance, and surface finish. The industry standardization around material composition does not erase the importance of supplier-specific processes. Some customers demand full transparency about the resin type, the fiber layups, and the curing process because these details influence the final weight, the resistance to micro-cracking, and the adhesion of paint and decals. The right supplier will present test data or third-party certifications that verify the performance claims and welfare of the fairing over time. In turn, buyers gain access to products that are not only lightweight and aerodynamically tuned but also durable under road conditions that expose bikes to temperature fluctuations, road debris, and frequent maintenance cycles. The result is a more confident market where riders can select from a spectrum of finishes, from unpainted fibers with a natural matte texture to fully finished shells that have been painted to match a bike’s color scheme or committed to a bold, race-inspired look.

From a consumer perspective, the breadth of availability can be both a boon and a challenge. On the one hand, the sheer number of configurations—ranging from complete fairing suites that encase the front and sides to lighter upper-shells designed to improve wind protection while preserving weight—allows riders to tailor the upgrade to their riding style, climate, and budget. A sport rider focused on performance and downforce might prioritize full kits that streamline the bike’s silhouette and pay particular attention to the aerodynamics of the chin, windscreen, and side panels. A touring rider, conversely, could favor semi-fairings that balance wind protection with ease of maintenance and compatibility with existing luggage or seating arrangements. The design intent behind each configuration—whether full or semi—cascades into practical outcomes: improved rider comfort on long stints, reduced fatigue at high speeds, and a more composed high-speed ride that respects the bike’s original handling cues. The market recognizes this diversity of needs and has organized itself around it, offering a spectrum of options that can be aligned with a rider’s goals without forcing an all-or-nothing decision.

To navigate this spectrum wisely, riders should consider several practical steps. First, verify the supplier’s credibility through the platform’s trust signals and by requesting test data or customer references when possible. Second, examine fitment guides and measurement diagrams—these documents are essential for ensuring that a kit aligns with the bike’s mounting points, fairing attachment hardware, and the instrument cluster. Third, assess post-purchase support, including return policies, warranty terms, and the reliability of shipping to your country. These elements significantly affect the total cost of ownership and the time-to-ride that a buyer can expect after ordering. The market’s maturity is evident in the emergence of guarantees and after-sales services that align with consumer expectations for a long-term upgrade rather than a transient cosmetic change. This shift—from mere availability to dependable, full-service access—marks a maturation point in the fiberglass fairing market and underscores why the segment has grown beyond a niche into a staple for riders who demand performance without sacrificing reliability.

The global access dynamic also shapes and is shaped by regional distribution strategies. In Europe and North America, for instance, logistics networks have adapted to handle multiple language requirements, currency options, and warranty norms. Import duties and certification requirements can influence the total landed cost of parts, but the market has learned to respond with transparent pricing, standardized documentation, and predictable lead times. In Africa and parts of Asia and the Middle East, where riding culture is vibrant and expanding rapidly, the availability of affordable, certified fiberglass fairings has helped broaden the aftermarket ecosystem. This expansion often includes partnerships with regional distributors who understand local road conditions, climate considerations, and the demand for finishes that hold up under intense sun and heat. The result is a marketplace that is not only wide in its scope but also nuanced in its adaptation to local realities.

An important facet of this market access is the importance of model-specific fit and the way it guides consumer choice. Even in a world of universal access, the precise geometry of a motorcycle—its rake, trail, mounting points, and fairing contours—dictates compatibility. This reality encourages a careful, informed shopping approach. Buyers typically cross-check fitment data with official service manuals, dealer schematics, or supplier-provided CAD templates. When a listing promises model-specific compatibility and provides clear guidance on the years or variations it covers, buyers gain confidence that the fairing will align with the bike’s structure and instrumentation. In addition, some listings offer color-matching envelopes and paint-ready surfaces that reduce the friction of customization and finishing work after installation. The combination of fitment reliability, finish quality, and finished appearance contributes to a higher rate of satisfaction and a lower probability of post-purchase complications.

The accessibility narrative is ongoing. As packaging innovations, faster logistics, and digital tooling converge, buyers will experience even more seamless pathways from inquiry to installation. The market’s trajectory suggests a future where virtual fitment checks, augmented reality overlays, and more sophisticated product configurators help riders preview how a given fairing will look and perform on their specific bike. Already, many suppliers provide high-resolution images, install guides, and performance data that empower buyers to visualize the upgrade before committing. The ongoing maturation of the market also invites new entrants: smaller ateliers and regional producers who can deliver highly customized, hand-finished shells while retaining the price-to-performance value that makes fiberglass composites attractive. In a sense, the market access for fiberglass fairings has moved beyond a simple supply-and-demand dynamic; it has evolved into a collaborative ecosystem where manufacturers, marketplaces, distributors, and riders contribute to a shared knowledge base about fit, finish, and performance.

For readers seeking concrete paths to explore, a practical starting point is to engage with the broader catalog of model-focused components available through online retailers that host a wide range of aftermarket parts. By it, riders can compare finish options, gauge weight differences, and assess the perceived aerodynamic impact of various configurations. When price, performance, and fitment align, the upgrade can be a straightforward exchange—yet the underlying marketplace remains complex and layered, reflecting the global scale and diversity of rider needs. The market’s ability to maintain competitive pricing while preserving quality underscores a balancing act that benefits customers: a broad selection of choices, credible certification, and reliable distribution that keeps riders on the road rather than waiting for orders to arrive.

As the narrative returns to the rider’s workshop, the significance of access becomes clear. Availability is not an abstract concept; it translates into practical outcomes—faster procurement, safer rides, and more expressive customization. The fiberglass fairing market’s maturity is evident in its ability to meet a spectrum of rider preferences. It accommodates the race-inspired aesthetic sought by some and the practical, weather-protective needs favored by others. The blend of lightweight design, aerodynamic refinement, and robust durability means that this aftermarket upgrade can deliver meaningful improvements in handling, fuel efficiency, and ride quality without forcing riders to adopt a one-size-fits-all approach. In this sense, market access becomes a enabling force that makes high-performance engineering tangible for a broader community of motorcyclists.

If you’re exploring options, consider how a particular package aligns with your riding goals. Do you prioritize a comprehensive look that minimizes wind blast and provides comprehensive engine shielding? Or is your focus on maintaining a lighter, more agile feel for daily commuting and weekend cruising? The answer depends not only on the fairing’s weight and rigidity but also on the availability and reliability of the supporting ecosystem—the certifications, the fitment guarantees, and the after-sales confidence that back every purchase. With a mature supply chain at your fingertips, you can pursue upgrades that are both technically sound and practically accessible. The market, in essence, has learned to translate performance engineering into real-world accessibility, so that riders from diverse regions and with varied budgets can experience the benefits of fiberglass composites without compromising longevity, safety, or aesthetics.

To close this chapter with a practical connective thread, consider the following gateway into the market: collections that organize options by model families can provide a structured starting point for comparison, while the broader marketplaces offer breadth and pricing flexibility. For a tangible reference, you can explore a catalog that aggregates model-specific fairings in a centralized listing, which helps with side-by-side evaluation of fitment, finish, and price. This approach supports informed decision-making and reduces the guesswork that often accompanies aftermarket upgrades. As the market continues to evolve, the core message remains consistent: fiberglass fairings offer a compelling blend of performance, protection, and style, and the pathways to access them are now wider and more dependable than ever before. The result is a more confident rider, a more capable machine, and a market that supports both repair needs and performance-driven customization in a global context.

Internal reference for further exploration: collections/honda-fairings

External resource: Alibaba product page

Final thoughts

Fiberglass fairings for motorcycles represent a significant opportunity for business owners aiming to elevate their product offerings. Not only do these fairings enhance performance and rider safety, but they also provide customization avenues that resonate with a broad range of motorcyclists. Understanding the benefits across aerodynamics, durability, and market accessibility positions businesses to meet the growing demand for high-quality aftermarket parts. As riders seek options that not only maximize performance but also reflect their personal style, your offering of fiberglass fairings will certainly position you as a trusted supplier in this evolving marketplace.