Understanding fiberglass motorcycle fairings is essential for business owners in the motorcycle industry. These components offer a unique combination of durability, cost-effectiveness, and customization potential, which can significantly boost product offerings and customer satisfaction. As we delve into the advantages of fiberglass motorcycle fairings, their aerodynamics and aesthetic designs, the market availability for sourcing compatible variants, and their applications in motorsport and beyond, it becomes clear that embracing fiberglass fairings can enhance both performance and profitability in your business.

Fiberglass Fairings: Strength, Lightness, and Savings for Modern Motorcycles

Fiberglass fairings occupy a unique niche in motorcycle engineering. They sit between the hard, high-cost materials used in some factory designs and the more basic plastics that weather the rough realities of everyday riding. The result is a composite that can be molded into aerodynamic shapes, finished with a glossy surface, and finished off with decals or custom graphics—all while delivering a combination of durability, weight savings, and affordability that many riders find appealing. This chapter explores how fiberglass fairings achieve their signature balance, why durability and cost-effectiveness matter as performance factors, and how these attributes translate into real-world riding, modification, and maintenance.

At the heart of fiberglass fairings is a reinforced fiberglass composite, typically glass fibers embedded in a polyester resin matrix. The glass fibers provide the structural backbone, lending stiffness and impact resistance, while the resin binds the fibers into a cohesive, shape-retaining shell. The resulting material is not a single uniform block but a layered system. A typical fairing may combine multiple plies of fiberglass with tuned resin content to achieve the desired balance between rigidity and flexibility. This layering gives the fairing the ability to absorb and distribute energy from minor impacts, vibrations, and road debris without cracking or delaminating as quickly as cheaper plastics can. The outcome is a panel that behaves predictably under stress, which is especially important for performance riding where fairings must maintain a clean aerodynamic profile even after a few nicks or dings.

One of the most tangible advantages of this construction is weight. Fiberglass fairings are commonly lighter than traditional ABS plastic counterparts by up to about 30 percent. The exact savings depend on the thickness and the number of layers, but in general, this weight reduction translates into measurable performance gains. Lighter fairings reduce the overall mass that must be moved with every engine revolution, which translates into crisper throttle response, quicker acceleration, and improved maneuverability. Weight savings also play into fuel efficiency, not by turning a heavy touring bike into a fuel-sipping machine, but by reducing the work the engine must do to push the machine through wind resistance. In practical terms, riders experience a smoother, more responsive ride at highway speeds where aerodynamic drag dominates inefficiency. The fairing’s shape—often tailored during the molding process—also helps manage airflow more efficiently, reducing turbulent wake behind the rider and the bike’s silhouette. While those shaping decisions are nuanced, the end result is a shell that contributes to stability and a calmer ride at high speeds and during prolonged highway exposure.

Durability, closely tied to the fiber-resin matrix, is another cornerstone of fiberglass fairings. The glass fibers confer high impact resistance. If a rock or a piece of debris strikes the surface, the energy can be dispersed across the fiberglass layers rather than concentrated at a single point, which lowers the risk of cracking. This toughness matters for daily riding, track days, and weekend adventures alike. Compared with standard plastics, the fiberglass composite tends to be more forgiving when subjected to road hazards. It can resist minor chips and scratches without propagating damage that would require immediate panel replacement. That resilience reduces downtime and the frequency of parts-mastering repairs, which is a practical consideration for riders who rely on their machines for commuting, training, or weekend sport.

The durability story also includes fatigue resistance. Even under repeated cycling loads—such as those produced by buffeting, wind pressure, and the flex of a bending fairing at highway speeds—a well-designed fiberglass panel maintains its shape and integrity. Shops and manufacturers can tune the layup to emphasize impact resistance or stiffness as needed for a particular model and riding purpose. For riders, this translates into a more predictable, stable experience when weather conditions, road texture, or aggressive cornering add dynamic stress to the fairing surface. The net effect is a panel that not only protects internal components from the elements but also contributes to the rider’s confidence and control on the bike.

Aesthetics are part of the durability conversation, too. Fiberglass panels take finishes very well. Their surface can be ground, polished, and painted to a high-gloss standard, and the underlying fiberglass field responds well to finisher treatments, clear coats, and decals. Because fiberglass is readily moldable, designers can craft streamlined shapes that optimize airflow without creating prohibitively complex tooling. This moldability is where performance and style converge: the same process that yields a wind-slick profile can also accommodate intricate details, vents, and cutouts that personalize a bike while maintaining an aerodynamically efficient form. For riders who seek a custom look—whether a race-inspired livery, a retro appearance, or a bold, modern graphic—fiberglass fairings offer a practical path to achieve it without a prohibitive price tag.

Cost-effectiveness is the other side of the durability narrative. Fiberglass fairings typically cost less to produce than carbon fiber equivalents and are more affordable than high-grade OEM panels. The raw materials themselves are less expensive, and the tooling and prep work associated with fiberglass layups are generally more forgiving and quicker to execute. This combination translates into substantial savings across the supply chain, from aftermarket manufacturers to repair shops that service a large fleet of bikes. For a rider purchasing a replacement panel or an entire set, the lower upfront cost of fiberglass can be a deciding factor when considering a full aesthetic or aerodynamic upgrade. It also means that enthusiasts can pursue more ambitious customization projects without risking a budget spiral. When paired with a finish that holds decals well and resists UV degradation, fiberglass fairings deliver long-term value, balancing initial outlay with the convenience of maintenance and renewal over time.

Industry standards and quality assurance add another layer of value. Many manufacturers produce certified fiberglass fairings that meet stringent performance and safety benchmarks. These certifications cover impact resistance, dimensional accuracy, and endurance under various temperature and humidity conditions. In practice, this means a buyer can expect a fairing that fits the mounting points with reliable tolerances, holds its shape across riding conditions, and withstands the regular heat and weather exposure an engine bay experiences. Certification provides a level of trust that helps riders select components with confidence, even when the price point is more accessible. The combination of durable construction, reliable fit, and a sensible price point helps fiberglass fairings remain a practical choice for both new builds and restorations.

Beyond raw materials and testing, the repairability of fiberglass contributes to its cost-effectiveness. Minor damage to fiberglass panels can often be repaired rather than replaced. A skilled shop can address small cracks or chips by smoothing the damaged area, applying patch material, and refinishing the surface. This repairability not only lowers long-term ownership costs but also aligns with the DIY spirit that many riders enjoy. The ability to restore a fairing’s appearance and performance without sending the bike to a precision shop makes fiberglass a compelling option for weekend project cars and bikes alike. It also means that riders can maintain their bike’s look and aerodynamic performance without waiting months for a replacement part to arrive from a factory or aftermarket supplier.

Customization remains a hallmark of fiberglass fairings. While durability and cost are important, the way a rider experiences the bike’s personality matters too. Fiberglass can be finished in a variety of ways—from high-gloss clear coats to matte textures—and is well suited to graphic application, color matching, and custom airbrushing. The surface accepts decals and wraps with predictable adhesion, which helps preserve the aesthetic over time. For riders who want a particular color scheme, emblem, or visual theme, fiberglass provides a pragmatic path to realize that vision without incurring the higher expenses typically associated with more exotic materials. The result is a bike that looks as good as its performance feels, reinforcing the idea that performance aesthetics can be accessible and enduring.

The practical realities of choosing fiberglass come with some caveats. While fiberglass can deliver excellent strength-to-weight characteristics and a favorable cost profile, it is not inherently as stiff or light as carbon fiber for the most extreme performance applications. For track-only builds or bikes that push to the upper limits of aero optimization, carbon fiber or advanced composites may still be preferred. Yet for the vast majority of riders—whether they are upgrading an aging sportbike, restoring a classic, or pursuing a custom project—the fiberglass option offers a compelling balance. It provides a robust, repairable, and visually versatile solution that can withstand daily use, occasional track days, and the social and practical demands of riding, all while keeping a lid on total ownership costs.

The broader market context reinforces fiberglass’ appeal. Aftermarket ecosystems are thriving with fiberglass offerings designed to fit a broad spectrum of models and riding styles. Manufacturers emphasize fitment accuracy, surface finish quality, and the ability to deliver ready-to-paint panels that are compatible with common repair and painting workflows. This reliability is crucial for shops and individual buyers alike, who want a straightforward path from purchase to installation and style realization. The availability of ready-to-ship options and a scalable manufacturing approach means that fiberglass fairings can serve both one-off restorations and small shop operations with equal efficiency. The economics of scale come into play here as well: when larger volumes are involved, prices can become even more favorable, further widening the appeal for riders who want to upgrade without overextending their budgets.

To illustrate the practical implications for riders, consider how fiberglass fairings align with the broader goals of customization, performance, and affordability. A rider might choose fiberglass to reduce total bike mass, rework aerodynamics, and refresh the exterior with a high-impact finish that resists fading in sunlight. The ability to rework the surface for decals, artwork, or a brand-new color palette makes fiberglass a versatile canvas for self-expression, whether the intent is to mimic a race-inspired look or to create a personalized street-bike silhouette. Additionally, the relative ease of repairing minor damage supports ongoing maintenance as part of a rider’s routine rather than an exceptional event that requires a large budget or extended downtime.

For readers seeking more information on compatible options and model ranges, a practical path is to explore category-specific collections that organize fairings by fitment and design cues. As a starting point for model-agnostic exploration, the broad availability of fiberglass options remains a strong incentive for riders who value both durability and customization. When compatibility matters, and the goal is to minimize downtime while maximizing rider satisfaction, fiberglass fairings often deliver a compelling mix of performance, aesthetics, and economics that few competing materials can match.

For readers who want a direct pointing resource on compatible options, you can browse the Honda fairings collection for a sense of how fiberglass shapes and finishes translate across different bike families. This internal link helps connect the discussion to a concrete assortment of products while keeping the focus on the general principles described above. Honda fairings collection

In sum, fiberglass motorcycle fairings offer a durable, lightweight, and cost-effective path to upgrading a bike’s performance and appearance. Their material makeup supports tough, impact-resistant shells; their weight advantages contribute to acceleration, handling, and fuel efficiency; and their market availability enables affordable customization and easier maintenance. While no single material is ideal for every racing or riding scenario, fiberglass stands out for riders who want to balance performance with value. This pragmatic blend of properties makes fiberglass fairings a versatile option for aftermarket upgrades, race replicas, and personalized builds. The result is a practical, aesthetically pleasing, and economically sensible solution that aligns with the everyday realities of riding and the long-range goals of customization. A rider can envision a tailored look without breaking the bank, knowing that the same panel contributes to better aerodynamics, weather protection, and resilience against the inevitable bumps and bruises of road life.

External resource for further background and industry context: https://www.alibaba.com/product-detail/CFRP-Fiberglass-Motorcycle-Fairings-for-CBR600RR_1601478899244.html

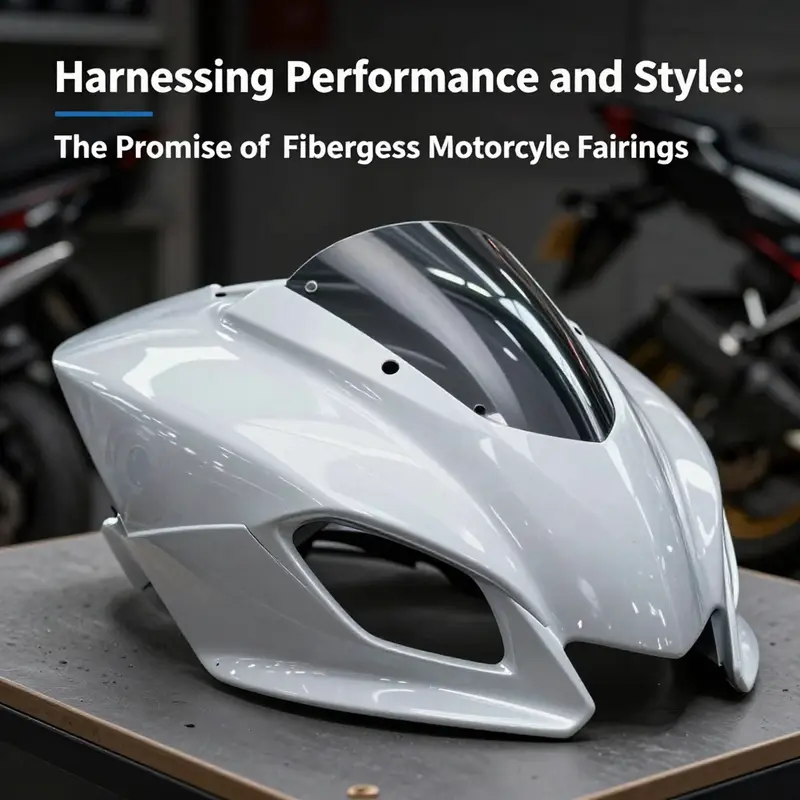

Weaving Air and Identity: Aerodynamics and Aesthetics in Fiberglass Motorcycle Fairing Design

Fiberglass fairings are more than simply covers; they are a deliberate conversation between the rider, the machine, and the air around it. In a sportbike, where every curve is a statement about speed and control, the fiberglass shell plays the role of both shield and guide. Its popularity rests on a practical balance: durability that resists scuffs and impacts, a low weight that preserves handling, and the ability to tailor aesthetics without forcing a heavy price tag. This chapter looks at how the design of fiberglass fairings blends aerodynamic function with personal expression, and how that blend translates into real-world performance on the road and on the track.

At the heart of fiberglass fairing design is the material system itself: a glass-reinforced resin matrix that can be laid up in complex shapes, cured, and finished to a high gloss or a muted tone. The typical setup uses polyester resin reinforced by layers of chopped or woven glass fiber. This combination yields a favorable strength-to-weight ratio while remaining relatively forgiving in the layup shop. The mold forms the vehicle’s silhouette, and skilled craftsmen steer the layup to ensure each contour responds to air in a predictable way. Because fiberglass can be molded around features like instrument clusters or line up with chassis brackets, designers can preserve the bike’s original proportions while adding fairing edges that align with the rider’s needs for protection and comfort. The result is a shell that is stiff enough to hold its shape at high speeds, yet forgiving enough to absorb subtle impacts without shattering into sharp fragments.

Aerodynamics is a central driver in shaping fiberglass fairings. The shapes are not ornamental afterthoughts; they are tuned instruments that channel air to minimize drag and manage pressure distribution around the rider. Smooth, continuous surfaces reduce flow separation, allowing the air to stay attached as the motorcycle advances. Where a fairing meets the head, the design can guide the slipstream around the helmet and shoulders, reducing buffeting and steering torque. Side panels steer air toward radiator intakes and frame cavities, avoiding wake regions that would otherwise sap speed or stability. In wind tunnel simulations and real-world testing alike, well-contoured fiberglass fairings have demonstrated meaningful drag reductions, often in the mid-teens depending on the baseline geometry and the rider’s position. That drag reduction translates into faster acceleration, higher top speeds, and a more consistent ride at highway and race-track velocities. It also improves fuel economy at sustained high-speed cruising, because the engine works less hard to push air aside and through the chassis openings. Importantly, the aerodynamic gains come without a commensurate increase in weight, preserving the bike’s reactiveness and steering feel.

Beyond function, fiberglass fairings offer a platform for personal design language. The material’s inherent moldability makes it feasible to craft distinctive lines, integrate graphic channels, and provide press-fit or bonded finishing options. Finishes range from high-gloss lacquer to matte textures, with clear weave showing through in certain aesthetic treatments to celebrate the fabric-like interior of the composite. Artistically minded builders can apply decals, airbrushed artworks, or embedded color gradients that respond to lighting as the bike moves. The result is a shell that can be as striking as it is efficient, turning a performance modification into a statement of taste and identity. Because the resin system accepts paint readily, and because fiberglass can hold surface details well, the durability of the finish holds up to daily use and to the occasional track-day session. This synergy between form and function is a key reason fiberglass remains a preferred option for riders who want both a competitive edge and a unique look without resorting to more expensive materials.

Of course, safety and protection must accompany style. The fairing forms a protective envelope around critical components, guarding the wiring, radiator, and electronics from wind-blast and minor impacts. Modern fiberglass systems are engineered to meet impact resistance and durability criteria that matter in both street and track scenarios. While no shell can replace good riding technique, a well-finished fairing can distribute impact forces and help keep fairings intact long enough to avoid additional damage. In practice, the resin, glass content, and layup schedule are chosen to deliver predictable deformation and energy absorption characteristics. When integrated with correct mountings and fasteners, the fairing contributes to rider safety by maintaining line of protection without introducing unpredictable points of failure. Because fiberglass is relatively forgiving during crashes, it can crack or dent while still preserving the rider’s protection and the bike’s integral structure, a feature that adds to the overall resilience of the package. These considerations are part of the design brief that guides both aftermarket manufacturers and restoration shops toward a fairing that performs as well as it looks.

Weight remains a central consideration, especially for riders chasing nimble handling. Glass-reinforced systems deliver a favorable stiffness-to-weight ratio compared with many other plastics, while still offering an economical path to enhancement. The impact on handling comes through reduced inertial load in the front-end assembly and a more balanced mass distribution around the steering axis. When paired with appropriate windshields and fasteners, a fiberglass fairing can lower the rider’s fatigue on long rides by directing airflow toward protected zones and away from the rider’s upper body. A modest weight gain or savings translates into better acceleration and braking response, which in turn improves control. That is particularly important in the aftermarket and racing contexts, where precise fitment and surface finish are paramount to realizing the aerodynamic and protective benefits without compromising stability. In this sense, fiberglass fairings act as a careful compromise: light enough to aid performance, rugged enough to resist the day-to-day demands of riding and racing, and flexible enough to accommodate the rider’s evolving sense of style.

Achieving a seamless integration with the motorcycle’s original architecture is perhaps the most nuanced aspect of fiberglass fairing design. The process begins with accurate measurement of the frame and fairing mounting points, followed by a review of clearance around the engine, fuel tank, and exhaust. The layup is then tailored to keep the finished shell within tight tolerances for fitment. When the fairing bolts into place, gaps and contours should align with the bike’s frame lines so that the eye reads a single, coherent silhouette rather than a mismatch of shapes. A well-fitting fairing maintains the intended aerodynamic profile while safeguarding controls and indicators from weather and branches of airflow that could cause flutter at speed. The design also must consider heat sources, such as the engine and radiator, so that panels do not bend, warp, or trap heat in ways that degrade performance or comfort. For riders seeking specific compatibility with a broad catalog of models, a wide range of mold-formed options exists, and careful selection ensures the skin remains faithful to the bike’s visual language. For a broad range of model-specific options, see the Honda fairings collection.

From a production perspective, fiberglass fairings are appealing because they support both small-run customization and larger-scale manufacturing. The layup process, when executed with care, can produce robust shells with consistent thickness and surface quality at a reasonable cost. The resin system and glass content determine not only strength but also cure time, resin bleed, and ease of sanding. Skilled technicians can achieve a near-flawless surface ready for priming and painting, with minimal filler. The economics of fiberglass versus carbon fiber become clear in this context: fiberglass offers significant cost savings, easier repairability, and broader accessibility for riders who want to customize or restore. As the marketplace for aftermarket components expands, vendors can deliver ready-to-ship fairings that fit a wide range of models and weather conditions. The emphasis is on reliable fitment, predictable results, and a finish that holds up to weather, sun, and the occasional crash repair. In short, fiberglass fairings balance manufacturing practicality with the demands of performance on both street and track, making them a practical choice for builders and enthusiasts who value a hands-on, craft-centered approach to biking.

Riders who choose fiberglass are often looking for a canvas as much as a shell. The design process becomes a collaboration between intention and constraint: performance targets drive contouring, but the rider’s taste drives color, texture, and graphics. There is room for customization that ranges from subtle refinements to bold graphic statements. The performance implications of a given aesthetic choice are real but manageable; a cooler color scheme or a unique finish does not inherently undermine the streamlining of airflow so long as the geometry remains true to the airflow path. This is why builders emphasize the importance of a thorough fit-check, a careful paint job, and a robust finish. They know that the fairing must survive repeated exposure to sun, rain, and road grit while continuing to deliver the experience of a bike that feels fast, smooth, and well-deserved. In practice, a fiberglass fairing becomes a record of a rider’s journey, a tangible marker of both the machine’s capability and the owner’s vision. The chapter’s discussion has sketched the space where engineering goals and creative expression meet, and it invites readers to imagine how a well-made shell can transform everyday rides into extended conversations with wind, light, and speed.

Ultimately, fiberglass fairings stand as an accessible gateway to a sport that blends art with engineering. They are the result of an iterative design language that respects aerodynamic truth while inviting personal customization. The path from raw glass to finished shell is one of careful planning, precise fabrication, and patient finishing work—an arc that many riders know well because it mirrors their own process of upgrading a bike. In this sense, the fairing becomes more than a protective cover; it is a disciplined interface that channels air, frames the rider’s silhouette, and communicates intent with every mile traveled. And as the market evolves, the core message remains: the fiberglass shell offers a practical, versatile platform where performance can go hand in hand with expression, enabling riders to honor the machine’s heritage while shaping its future.

External resource: https://www.alibaba.com/product-detail/2005-2006-CBR600RR-Fiberglass-Motorcycle-Fairings_1600743782242.html?spm=a2700.gallery-internal.0.0.1a1c7e91LdXgIv&urlPrevPage=1

Between Fit and Finish: Sourcing Fiberglass Motorcycle Fairings in a Global Market

Fiberglass motorcycle fairings sit at a crossroads of practicality and expression. They are not merely shells that cover the bike; they are engineered surfaces that shape aerodynamics, shield critical components, and carry the rider’s personal language in color and graphic design. In the modern market, fiberglass fairings offer a compelling blend of durability, lightness, and customizability. They are made from glass-reinforced polyester resin, which provides a strong strength-to-weight ratio that many riders find ideal for track-ready builds or street machines that demand both performance and curb appeal. The moldability of fiberglass makes it possible to craft aerodynamic shapes with smooth transitions, clean lines, and precise contouring that can significantly reduce wind buffeting and rider fatigue on long rides. Yet the story of fiberglass is not only about performance. It is also about accessibility. Compared with higher-cost alternatives like carbon fiber, fiberglass maintains a more approachable price point while still delivering robust protection for the engine, frame, and instrumentation. This balance makes fiberglass fairings a staple in aftermarket upgrades, race replicas, and personalized builds where a rider seeks both form and function without breaking the bank.

In the global marketplace, the availability of fiberglass fairings is broad and surprisingly efficient. Buyers today have multiple routes to source complete kits or individual panels, enabling restoration projects, mid-range performance pivots, or highly customized aesthetics. As a result, the decision to adopt fiberglass is increasingly framed not just as a material choice but as a sourcing strategy. Platforms that aggregate sellers—whether they are large-scale manufacturers or smaller shops specializing in niche models—allow riders to compare fitment, finish, and price across a spectrum of options. An essential driver of this accessibility is the compatibility specificity that accompanies many listings. The market recognizes that fit is not a guess but a verification activity. The more precise the product description—model year range, engine size, frame type, and even sub-variants—the greater the likelihood of a smooth install and a reliable aesthetic outcome. In this sense, fiberglass fairings are less a single product and more a modular ecosystem in which fabricators, retailers, and end users converge around standardized reference points to ensure harmony between bike and body panels.

The sourcing landscape is anchored by two broad channels, each with its own rhythms and implications. First, consumer-facing marketplaces host an extensive range of full fairing kits and individual panels for a diverse set of motorcycles and scooters. Marketplaces are particularly valuable for riders seeking options with flexible return policies, community feedback, and buyer protection programs. They also offer confidence-enhancing features like compatibility guarantees, which can be a decisive factor when a rider faces a nonstandard build or a project bike that has seen a few iterations. Second, wholesale platforms and factory-direct corridors connect buyers with manufacturers capable of scaling orders, customizing finishes, or tailoring designs to specific performance or aesthetic objectives. In this space, fiberglass fairings are not only sold as off-the-shelf parts but also as components in a collaborative process aimed at achieving precise fit and a shared vision for appearance and performance. The important takeaway is that fiberglass is no longer a niche choice limited to DIY enthusiasts; it sits at the heart of a robust, interconnected supply chain that can support everything from quick repairs to bespoke builds.

Compatibility remains the linchpin of successful sourcing. The market emphasizes the importance of exact model year, engine size, and frame type as core compatibility axes. While many listings promote broad categories like “universal” or “sport bike,” the safest route in practice is to interrogate the seller about these dimensions with a precise checklist in hand. For a restoration or a performance-oriented rebuild, even small discrepancies in mounting points, rake, or fairing hole spacing can complicate installation and degrade the intended aero profile. To mitigate these risks, buyers are advised to gather as many specifics as possible before committing. In addition to model year and engine displacement, factors such as mounting hardware compatibility, secondary attachment points, and the contour of the tail section can influence how a panel aligns with the radiator shroud, windscreen, or frame braces. The broader implication is clear: fiberglass fairings reward careful upfront verification with a smoother, more durable outcome, whereas hasty purchases can lead to misfit and rework.

The material advantages of fiberglass are tangible in real-world riding scenarios. High rigidity translates into stable aerodynamics at higher speeds, where a well-fitted fairing maintains predictable airflow and reduces the buffeting that often troubles riders on longer journeys. The crack resistance of fiberglass also contributes to longer service intervals between repairs, an especially meaningful consideration for riders who use their machines in demanding environments or who push toward track days. Light weight remains a critical asset, as every gram shaved from the vehicle’s exterior can influence handling, acceleration, and fuel efficiency—especially when fairings are integrated with lightweight brackets and clamps. Yet the same properties that endow fiberglass with strength also demand careful handling during installation and finishing. Unlike some more forgiving plastics, fiberglass surfaces respond to weather exposure, impact, and UV rays. Protective coatings, UV stabilizers, and occasional refinishing are prudent measures to preserve gloss and edge integrity over time. In practice, the best installations combine clean preparation, proper mounting sequences, and a balanced approach to finish work that honors both aesthetics and durability.

Economic considerations shape the purchasing mindset as much as engineering factors. Fiberglass fairings typically sit between ABS or polycarbonate plastics and carbon fiber in the spectrum of cost versus performance. They offer durability and rigidity without the premium price tag associated with carbon fiber, making them particularly attractive for those who want a strong shield for the bike without resorting to more fragile or heavier composites. For midrange projects, fiberglass can deliver substantial value through a combination of resilience, ease of repair, and broad compatibility with aftermarket graphics and paints. The pricing landscape, however, can still vary with volume, customization, and the degree of finish applied by the supplier. Premium finishes, color-matched gel coats, and graphic detailing can elevate the perceived value and the eventual resale potential of a fiberglass kit, while factory-direct or factory-run facilities may offer more consistent fitment and standardized coatings that reduce post-purchase refinishing work. The interplay between cost, fit, and finish is the daily arithmetic of a fiberglass fairing purchase, and the buyer who negotiates this balance well often lands with a package that both looks sharp and performs under pressure.

For buyers who want a guided path through options, a curated catalog approach can be especially helpful. One practical step is to explore a dealer or retailer that maintains model-specific collections designed to align with broad model families rather than bespoke single-year variants. Such catalogs can dramatically simplify the verification process by presenting a standardized reference set that corresponds to a family of bikes already known for shared geometry. For example, a catalog page dedicated to a brand’s fairings can serve as a reliable compass for compatibility across multiple years and minor revisions, reducing the risk of a misfit that can derail a restoration or tune. If the project requires a more hands-on approach to fitment, the buyer can complement catalog-based decisions with conversation threads, seller-provided fitment notes, and, when possible, firsthand photos from other builders who completed similar installations. In this ecosystem of options, the role of the buyer evolves from a passive selector to an informed collaborator who communicates clearly about model, year, and desired finish so the final product aligns with both mechanical realities and aesthetic ambitions.

Within this market, several practical steps can help a rider move from concept to installation with confidence. First, define the project goals: restoration, performance optimization, or personalization. Each goal shapes the criteria for rigidity, finish, and fit. Second, assemble a precise parts checklist that includes mounting hardware, grommets, and any frame spacers that may be required for proper alignment. Third, request high-resolution photos and, if possible, dimensional diagrams from the seller to confirm critical distances and contour lines. Fourth, verify the finish options, including gloss level, paint compatibility, and whether the kit comes pre-primed or requires additional priming. Finally, factor in shipping considerations, international duties, and the potential for customs delays if ordering from overseas suppliers. These steps, while seemingly meticulous, are instrumental in turning a fiberglass fairing purchase into a seamless upgrade experience.

A practical takeaway for riders seeking immediate opportunities is that there is value in engaging with communities and retailers that maintain focused, model-conscious inventories. The availability of ready-to-ship kits and the ability to order in small quantities from wholesale platforms can be a meaningful difference for repair shops and individual enthusiasts alike. When a buyer finds a compatible kit with a glossy finish and a coherent color option, it often signals a combination of design alignment and production quality that reduces the amount of post-purchase modification needed. Even in these moments, the market continues to benefit from a cross-border ecosystem that enables designers and manufacturers to respond quickly to demand for specific lines or colorways, while riders can access a broader array of finishes than ever before. The end result is a more dynamic and responsive marketplace where fiberglass fairings are not merely aftermarket add-ons but strategic components in the ongoing evolution of how riders customize, protect, and optimize their machines.

For readers seeking to explore current options and perhaps expand their research into a hands-on catalog, a curated starting point can be found through an internal resource that gathers model-focused offerings. This portal compiles a broad range of fairing sets and panels that align with widely used body configurations, providing a helpful cross-section of available choices while illustrating the practical realities of compatibility. By reviewing such a catalog, a rider can gain a sense of what is realistically achievable within a given budget and timeline, while also identifying gaps where custom fabrication or professional finishing might be required. In this context, fiberglass fairings become less a single product and more a strategic asset—one that can be tailored to fit a specific bike’s geometry and a rider’s expressive intent. The materials, the suppliers, and the methods converge to empower riders to achieve a result that is both technically sound and visually compelling.

To connect this discussion with practical access points, consider a cross-section of offerings that aligns with common preservation and modification goals. A connected, model-aware catalog can serve as a reliable reference for what is feasible within typical repair-shop workflows and home-garage projects. This approach emphasizes not only the immediate fit but also the long-term maintenance and repair considerations that will accompany any fiberglass installation. With good fitment data, rigorous preparation, and attention to finish quality, fiberglass fairings can deliver consistent performance and enduring aesthetics across a broad spectrum of bikes and riding styles. In this light, the sourcing and compatibility narrative becomes a craft, blending engineering insight with the realities of supply chains and the practicalities of daily riding. The result is a durable, adaptable, and visually engaging outer shell that riders can rely on whenever the road demands both protection and personality.

Internal link note: For readers exploring model-conscious options within a curated dealer catalog, a focused gateway can help locate compatible fairings across a range of popular platforms. See the Honda fairings collection for a representative example of how a structured catalog can streamline selection and ensure proper fitment while preserving the rider’s vision. Honda fairings collection

External resource: For an overview of current listings and guarantees on compatibility from major marketplaces, consult the eBay Motorcycle Fairings category as an external reference point: https://www.ebay.com/b/Motorcycle-Fairings/160574/bn_2032893

Racing Lightweight Armor: Fiberglass Fairings as Precision Tools in Motorsport and Custom Culture

Fiberglass motorcycle fairings occupy a unique niche in the engineering landscape of two wheels. They are not merely shells that shield the engine from weather and debris; they are active participants in a motorcycle’s performance envelope. The balance they strike between lightness, durability, and the freedom to shape air flow makes them a core technology for both professional racers and the vibrant world of aftermarket customization. In this space, fiberglass is both material and philosophy: a proven, moldable platform that can be tuned for speed without sacrificing the rider’s sense of control or the bike’s reliability. The essence of fiberglass fairings lies in their composition, where glass fibers are embedded in a polyester resin matrix. This combination yields a structure that is stiffer than simple plastics yet forgiving enough to absorb minor impacts that might occur in rough pit lane maneuvering or a casual misjudgment on a windy road. The result is a panel system that can take the heat of a race weekend while still offering enough flexibility to handle the irregularities of real world riding. The characteristic lightness of the system is not an abstract benefit; it translates directly into throttle response, suspension behavior, and tire load management. For riders chasing agility, every gram saved in the fairing reduces the rotating mass and the drag footprint, sharpening the bike’s overall dynamic profile. Yet fiberglass does not demand the exclusivity of premium composites. Its manufacturing ecosystem supports rapid prototyping, repair, and iterative design changes, all of which are essential for both race teams and DIY builders who want to experiment with aerodynamics or mass at minimal cost. The moldability of fiberglass makes it possible to craft complex, multi-curve contours that would be difficult or expensive to reproduce with other materials. Designers can incorporate aggressive noses, scooped tails, and integrated air channels that guide flow around the rider and the engine bay. These contours, when validated through CFD and wind tunnel testing, reveal aero benefits that extend beyond mere looks. They contribute to more stable handling at high speeds, better rider comfort in crosswinds, and a broader operating envelope that can be tuned to track conditions or street riding preferences. The aerodynamic gains arise from a careful balance: a smoother external surface reduces skin friction drag, while a shape that manages separation zones lowers form drag and helps maintain downforce where it matters most. These advantages are frequently quantified through computational simulations and validated in controlled wind tunnel environments. In the best case, a fiberglass fairing set can be designed to shave drag by a measurable margin while maintaining or slightly reducing weight compared with plastic counterparts. When such gains are realized across a full fairing package, riders experience faster lap times and improved fuel efficiency during endurance runs, where every second and every watt counts. The weight advantage is particularly meaningful in mid to high power machines, where small reductions in mass at the front end translate into crisper steering and more predictable front-end behavior during aggressive cornering. It is worth noting that the weight reduction figures cited in industry chatter and case studies are typically benchmarked against conventional plastic panels. The magnitudes can vary with the specific layup, resin system, and the exact fiber volume fraction chosen by the fabricator. Still, the overarching trend is clear: fiberglass can offer substantial weight savings without sacrificing the structural integrity needed to withstand the demands of racing and aggressive street riding. Alongside the performance math, fiberglass fairings bring a practical dimension that resonates with shop owners, restoration enthusiasts, and builders who value maintenance-friendly components. The repair story of fiberglass is straightforward compared with carbon fiber or advanced thermoplastics. A crack can often be repaired with resin and cloth layups, restoring much of the original stiffness without requiring a full replacement. This repairability reduces downtime and keeps a project or a race program on track during tight schedules. It also supports the ongoing lifecycle of a bike that sees heavy use or frequent cosmetic customization. The aesthetics of fiberglass are another asset. The material accepts paint and finish work with relative ease, enabling bold graphics, subtle candy-clear coats, or matte textures that suit a rider’s personality. The ability to customize is not incidental; it is a design discipline in its own right. In markets that value individuality, a rider can tailor each panel to a specific color scheme, theme, or sponsor arrangement, all while preserving aerodynamic efficiency and protective capability. A well-executed fibreglass kit balances form and function, turning a functional component into a statement piece that complements a bike’s lines and stance. Beyond the cockpit, the modular nature of contemporary fiberglass fairing kits has transformed how riders approach upgrades. Modern families of body panels are designed to be swapped piece by piece. Front fenders, side panels, fairing stays, and rear sections can be replaced or upgraded without reconstructing the entire shell. This modularity is a boon for racers who need to adjust the aero package for different circuits or for enthusiasts who want to refresh the look of a bike after years of use. It also enables creative experimentation: a rider can mix and match shapes, textures, and finishes to craft a distinctive silhouette while preserving the performance benefits of a high-quality layup. This approach aligns with the broader ecosystem of aftermarket components that revolve around model families and compatibility, ensuring that a single kit can fit multiple generations or variants of a bike with appropriate mounting hardware and brackets. The upshot is a robust, adaptable platform that invites iterative design work without demanding wholesale replacements each season. In the race paddock, the fiberglass fairing is not an ornamental layer but a performance instrument. Teams routinely marry fiberglass bodies with refined internal features such as bulkheads and guiding structures to maintain torsional stiffness and to integrate cooling ducts and intake paths. Even if a fairing is primarily cosmetic in appearance, its internal channels can be engineered to reduce plume interaction with the engine bay, guide air toward radiators, or stabilize the flow around a rider’s legs. The interplay between exterior contours and internal pathways exemplifies how precision fabrication and engineering discipline translate into competitive advantage. To quantify the performance potential, consider the idea of a fairing package that is designed with CFD insights and wind tunnel validation. When the contour is optimized to minimize flow separation at the splitter and around the elbows of the fairing, the observed drag reduction can reach the order of a few percentage points. While seemingly small, these gains compound with speed, contributing to better acceleration, higher top speed reserve, and more efficient engine operation on longer stints. In practice, this translates to faster lap times, steadier cornering dynamics, and more predictable handling through high-G, mid-corner situations. The physics is complemented by the structural reality that fiberglass bodies offer a generous margin for crash protection. While riders should not rely on them as crash barriers, the materials used in well engineered fairings provide credible energy absorption and resistance to impact. The fact that these parts are designed and certified to meet industry safety standards adds a layer of assurance for riders who push the edge of performance and who seek a reliable, shielded cockpit. For those pursuing customization outside the race track, fiberglass fairings serve as a fertile ground for creative reinvention. The modular system invites artists and builders to reimagine the surfaces, apply bold graphics, and experiment with different finishes without compromising the structural health of the mount points or the panel interfaces. The ability to apply decals, airbrushed art, or layered textures merges artistry with engineering, reinforcing the culture of individual expression that defines motorcycle communities. In this context, the fairing becomes a canvas as much as a shield, a convergence point where aesthetic intent meets aerodynamic strategy. As riders explore different aesthetic directions, the underlying engineering remains anchored by the core advantages of fiberglass: a light, strong, and adaptable material that can be formed into shapes that optimize airflow while accommodating the realities of maintenance, repair, and ongoing upgrades. The broader marketplace supports this approach with ready-to-ship options that maintain a balance between cost and quality. For riders who value access to OEM-certified quality and efficient logistics, suppliers and platforms that provide model-specific fitment data, material certifications, and responsive service play a central role. These capabilities help a rider or repair shop secure panels that align with the bike’s mounting points, fairing stay geometry, and instrument cluster positioning, ensuring that upgrades do not compromise safety or electronics alignment. The practical side of this ecosystem is the ability to source components that are designed for direct compatibility, reducing the friction of installation and minimizing the risk of fitment issues that can occur with more generic fiberglass sheets. For the performance-minded and the aesthetically oriented alike, fiberglass fairings offer a compatible path to both speed and style. They support aerodynamic optimization within a realistic budget, enabling teams to iterate designs quickly and riders to realize personal visions on a scalable platform. The modern fiberglass kit is not a static, one-time purchase but a living system that can be refined, expanded, and reinterpreted as the bike evolves and as new circuits, classes, and rules shape the competitive landscape. The ongoing dialogue between design, testing, and user feedback ensures that fiberglass fairings remain relevant across a spectrum of riding contexts. In this sense, fiberglass is more than a material; it is a design language that harmonizes performance science with the art of customization, a bridge between the track and the street that keeps a bike tuned for speed while inviting personal expression. For riders seeking tangible sources of these options, model-specific kit families exist that align with a bike’s geometry and mounting architecture, offering a coherent route from showroom shape to race-ready configuration. Where the market shows breadth, the important criteria remain consistent: reliable material quality, verified fit, and careful attention to the integration of fasteners, brackets, and seals to preserve weather protection and electrical integrity. This is where the value of OEM-certified or OEM-equivalent components comes into play, delivering confidence that a given kit will perform in demanding conditions and that it can be serviced and repaired in a straightforward manner when wear or damage occurs. In the end, fiberglass fairings bring together several threads that riders value: lightness, strength, adaptability, and cost efficiency. They translate wind tunnel and CFD insights into real-world gains that can be felt in the ride—from the instant the throttle opens to the moment the rider weights the outside peg in a hard corner. They also invite a broader audience to participate in the sport’s fabric, from race teams mapping aero packages to enthusiasts who want to reimagine a bike’s silhouette. This is the core reason fiberglass remains a durable and evolving choice across motorsport and the culture surrounding high-performance street riding. External access to ongoing developments, materials science advancements, and supplier networks continues to shape how riders approach this technology. For those who wish to explore a tangible option in the marketplace, online platforms offer ready-to-ship fiberglass fairings with OEM-certified quality and scalable quantities that suit both repair shops and individual riders. A practical perspective on sourcing notes that these kits can be highly compatible with a broad range of popular sport bike families, allowing a single kit to serve multiple generations or variants with appropriate mounting hardware and adjustments. If you want to investigate a concrete example of how these kits translate into performance on a race weekend or a long canyon ride, you can explore model-specific kit families in the wider ecosystem, including dedicated sections for a well-known sportbike lineage. The combination of precise fitment, robust engineering, and the freedom to customize makes fiberglass fairings a continuing cornerstone of both the professional race scene and the personal project culture that defines modern motorcycling. Internalized through practice and tested on real machines, fiberglass fairings demonstrate that lightweight, durable, and craft-friendly engineering can coexist with bold design and practical maintenance. As the sport evolves and as riders pursue ever more efficient aerodynamics, the fiberglass fairing remains a reliable platform from which new ideas can spring. This synergy of performance, safety, and style is what keeps fiberglass fairings at the heart of both racing strategy and the culture of customization that follows the sport from track to street. For readers who want to see how a particular kit aligns with a bike family, the following collection page offers a snapshot of the kinds of options that experience has produced in the market: Kawasaki Ninja ZX-14R fairings (2012-2021). The reference category underscores the broader principle that compatibility and performance can be pursued in tandem, enabling riders to design a fairing package that respects the bike’s geometry while unlocking new aerodynamic potential. As a practical note, when exploring these options, it helps to review fitment data, mounting hardware requirements, and finish options to ensure a seamless install and a durable outcome across seasons. Ultimately, fiberglass fairings deliver more than just a skin; they deliver a disciplined approach to optimizing a machine’s aero profile, preserving rider comfort, and supporting a culture of creative expression that thrives at the intersection of engineering and artistry. External link for further reading and procurement considerations: https://www.alibaba.com/product-detail/Alibaba-Com-CBR600RR-2005-2006-Fiberglass1601749829227.html?spm=a2700.galleryofferlist.pdefault&buyerdst=1601749829227&isB2B=true&isShowVideo=false&from=productDetail

Final thoughts

Fiberglass motorcycle fairings represent a pivotal element in modern motorcycle design and customization. Their balance of durability, cost-effectiveness, and design versatility makes them an appealing choice for business owners looking to enhance their offerings. Whether aiming to boost the performance of motorcycles or enhance their visual appeal, investing in fiberglass fairings can pay dividends in customer satisfaction and brand loyalty. As you consider expanding your product lines, keep fiberglass fairings in mind as a robust option that successfully merges quality and affordability.