Honda motorcycle fairings play a critical role in enhancing the performance and aesthetics of bikes. They are not just for looks; they improve aerodynamics, reduce wind resistance, and offer protection to riders. Full fairings encapsulate much of the bike’s body, while semi and front fairings provide flexibility for different riding styles. Understanding the materials used, like ABS plastic and carbon fiber, is essential for quality assurance and performance durability. Furthermore, aligning with current market trends, including pricing strategies and availability, is vital for business owners focused on maximizing their offerings. Each chapter delves deeper into these aspects, ensuring you have a well-rounded grasp of Honda motorcycle fairings.

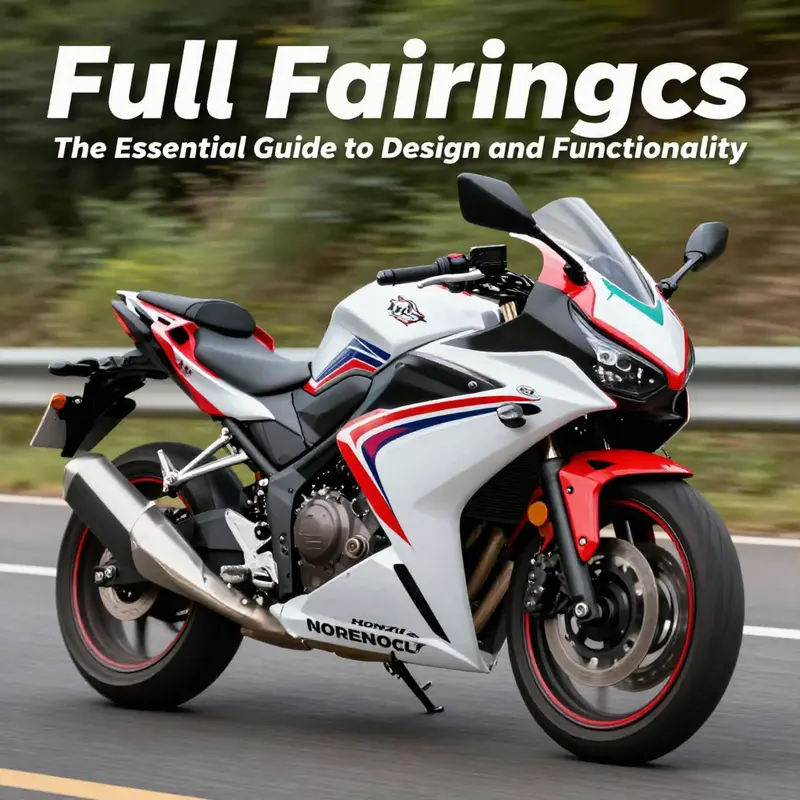

Full Fairings for Honda Motorcycles: Design, Aerodynamics, and Rider Protection

Full fairings are more than cosmetic covers on Honda motorcycles. They are engineered packages that enclose the engine and much of the frame, designed to tame air, shield the rider from weather and wind stress, and unify the bike’s visual language into a single, performance-driven silhouette. When you look at a modern sport or track-oriented machine, the lines of the fairing read like a map of deliberate choices: where air will speed up, where it will slow, where heat must escape, and how a rider’s posture will be supported by the airflow that flows around the machine. It is this orchestration of form and function that makes full fairings a defining feature of many Honda models, and a focal point for riders who seek both performance and a cohesive factory look. In practice, a full fairing does more than reduce drag. It creates a barrier against gusts that would otherwise buffet a rider at highway speeds, minimizes stray turbulence that can sap comfort over long distances, and contributes to track stability by shaping pressure zones around the bike. The result is a package that feels connected—engine, chassis, rider, and wind—working together rather than in opposition. The primary effect of this comprehensive coverage is aerodynamic efficiency. By streamlining the front end and wrapping around the sides, full fairings reduce parasitic drag and parasitic lift that can destabilize a bike at speed. Less drag means not only higher potential top speed, but better fuel efficiency and more consistent performance as conditions shift. The rider benefits too: wind Blast is redirected to places where it can be managed, reducing fatigue and allowing a more comfortable riding posture for longer stints on the road or in the saddle at the track. The look is unmistakable. There is a certain sonic identity to full fairings—the way the surface carries air into the wind, the way light catches the contoured panels, and the way aggressive lines converge toward the nose. This aesthetic is inseparable from the performance ethos that drives design in sports-oriented platforms. Yet elegance here is not purely about speed. The fairing’s shape often carries integrated features, and those integrations matter just as much as the external form. Headlight housings, indicators, air intakes, cooling ducts, and channeling paths for heat and air are frequently built into the fairing itself. The balance between cooling needs and aerodynamic cleanliness is delicate. When cooling ducts are too large, they compromise laminar flow and create unwanted turbulence; when too small or poorly placed, they can choke engine temperatures under load. In the right configuration, cooling becomes a backstage performer: the engine breathes easier, the rider remains comfortable, and the fairing’s lines stay taut and uninterrupted. The choice of materials is central to achieving this balance. ABS plastic has been a reliable workhorse for mass-produced full fairings. Its cost-effectiveness, impact resistance, and ease of fabrication make it an everyman option for OEMs and aftermarket suppliers alike. In everyday riding, ABS holds up well against road debris, minor scrapes, and UV exposure when properly treated with finishes and paints. For riders chasing lighter weight and higher stiffness, carbon fiber composites offer a different set of advantages. Carbon fiber’s high strength-to-weight ratio can improve high-speed stability and reduce unsprung weight, which translates to crisper handling and a more responsive feel at the limits. The trade-off, of course, is price, manufacturing complexity, and repair considerations. Carbon fiber panels can be repaired but often require specialized processes, making them a premium choice that sits outside the reach of all riders. Some builders and enthusiasts opt for blends—ABS as the structural backbone with carbon accents or reinforcement in high-stress zones—to capture weight savings without inflating cost beyond reason. Material selection also intersects with durability and weather resistance. A well-made full fairing must withstand sun, rain, heat, and the cycle of temperature changes without warping, losing paint, or developing micro-cracks that invite moisture. That is why manufacturers invest in UV-stable finishes, weather seals, and precise mating tolerances. The result is an outer shell that maintains its fit and finish across years of exposure to road salt, stone chips, and rapid temperature swings. A full fairing’s structural integrity is not just about the shell itself. It must cooperate with the bike’s chassis and mounting points. The fasteners, clips, duplicates of alignment tabs, and mounting brackets are chosen to preserve alignment across years of use and to allow for straightforward maintenance and repair. A well-designed fairing aligns with the bike’s instrument cluster, mirrors, and bodywork cutouts so that zero interference occurs during steering lock, wheel travel, or suspension travel. This is not a trivial achievement. Each year, new paint layers, weather seals, and mounting hardware are refined to maintain a precise fit. The process addresses not just the appearance of seamless panels but the functional integrity of the whole assembly. The design process for full fairings is a careful negotiation among performance, accessibility, and resilience. Aerodynamics drive the majority of the exterior geometry, but engineers must also account for rider ergonomics. The rider’s posture interacts with the shape and position of the seat, tank, and fairing. The windstream around the rider informs comfort and control. If a fairing creates excessive buffeting at a rider’s helmet or introduces a disruptive wind vortex at certain lean angles, the design must be adjusted. The result is a shape that remains compliant at wide ranges of angles and speeds, from calm city streets to the edge of the track. Another layer of complexity comes from integrative features. Modern fairings often embed light housings, signaling arrangements, and sometimes ventilation pathways that satisfy both performance and aesthetic needs. Strategically placed openings serve to shed heat from the engine, manage ram air for charge cooling, and prevent heat buildup in sensitive electrical components. Each opening is placed with care lest it disrupt the laminar flow or invite water intrusion. Even the edges and transitions of the panels are meticulously finished. Radii, seams, and joint gaps influence the bike’s overall feel and its visual cohesion. A crisp seam or an elegant transition can emphasize speed and precision, while a poorly executed junction can appear sloppy and undermine confidence. All these considerations matter because a full fairing communicates the bike’s purpose at a glance. It signals to the rider that the machine is designed with a performance objective in mind and that aerodynamics, protection, and aesthetics are harmonized. From a practical standpoint, owning a full fairing involves trade-offs. The most immediately audible advantage is wind protection. A rider behind a well-fitted full fairing encounters less direct wind pressure, which translates to a calmer upper body, reduced fatigue, and easier long-haul riding. For sport and track-minded riders, the fairing also helps establish a stable ride height and reduced windborne steering inputs when entering high-speed straights or negotiating sweeping curves. The flip side is the cost and complexity of repair. A fairing is a large, bonded or fastened shell. A single impact can crack or deform a panel that is not just cosmetic but structural in maintaining alignment. Repairing or replacing a full fairing can be an involved process that touches multiple panels, color matching, and fastener configurations. That is why many riders weigh the long-term value of OEM or OEM-compatible full fairings against aftermarket alternatives. The decision is rarely about one attribute alone. Riders weigh compatibility, weight, stiffness, and the ease of replacement after a crash against the budget and the long-term goal for the bike. For those seeking the most faithful restoration or the most integrated look, OEM-compatible full fairings provide a reliable baseline. They preserve the original geometry and color schemes and are designed to minimize fitment surprises during removal or reinstallation. On the other hand, aftermarket full fairings can offer unique aesthetics, weight savings through alternate materials, or simplified maintenance where panels are more readily accessible. In either case, the installation process benefits from accurate model-year matching and precise alignment with existing mounting points. The effort to achieve a perfect fit is one reason why many riders consult with specialty shops or skilled hobbyists who understand the intricacies of alignment, wind tunnel-inspired shaping, and the subtle balance between robustness and weight. For riders who are new to full fairings, the landscape can feel daunting. The critical first step is to determine the rider’s primary use: highway cruising, occasional track days, or a combination that leans toward sportier ambitions. This choice informs not only the color and aesthetic but the practical build: whether a lighter, simpler front fairing suffices for comfort in daily rides or a full, all-encompassing body wrap is desired to maximize aero gains and protection during high-speed runs. The available options are broad, and the market provides a spectrum of assembly configurations. The configuration options include full coverage that envelopes most of the engine and frame, semi-fairings that balance wind protection with accessibility, and front fairings that offer a lighter shield with more open access to the mid-portion of the bike. For riders who crave the most cohesive appearance and the highest potential aerodynamic gains, full fairings represent a complete solution. They present a unified surface that minimizes drag and presents an aggressive look, a visual cue that signals purpose and performance. Yet even within full fairings, the design language can vary. Some fairings emphasize razor-sharp lines that slice through the wind, while others favor rounded forms that reduce abrupt pressure changes. The choice hinges on the rider’s preferences for handling, the intended riding environment, and the aesthetic that matches the bike’s overall character. It is this balance—between science and style—that defines the value of a full fairing in Honda’s broader design philosophy. As with other components in a modern motorcycle, the prediction of how a full fairing will perform across weather, miles, and pressure systems benefits from data, testing, and feedback from the riding community. While lab measurements can predict drag coefficients and cooling efficacy, real-world experience reveals how panels behave under dynamic conditions: during lean angles, when hitting sudden crosswinds, and as the rider shifts weight to optimize balance. The ongoing dialogue between engineering and riding experience continues to refine every new generation of fairing. Within this dialogue, the notion of authenticity plays a role. For riders who want a factory-accurate look and feel, OEM-compatible or factory-inspired full fairings offer alignment with the visual and tactile language of the brand. For others, the aftermarket ecosystem provides opportunities to experiment with weight, stiffness, and aesthetics without compromising the essential aerodynamic benefits that full fairings deliver. The essence of a full fairing, at its core, lies in its ability to unite performance goals with practical riding realities. It is this union—from wind tunnel-informed drafting to field-tested durability—that explains why full fairings occupy such a prominent place in the history and future of Honda’s motorcycles. Those who choose them do so not merely for speed or looks, but for a holistic riding experience where every panel serves a purpose and every line communicates intent. In the end, a well-executed full fairing tells a story about the bike: it is a machine designed for calculated speed, confident handling, and enduring road presence. For riders, that story translates into fewer compromises on long rides, more confident control in demanding conditions, and a sense that the bike’s exterior is a faithful reflection of the performance ready to unfold beneath it. If you are exploring upgrades or replacements, consider how a full fairing will integrate with your riding rhythm, your preferred scenery, and your maintenance habits. A thoughtful selection—paired with careful fitting and appropriate materials—can elevate the bike’s aero efficiency, comfort, and enduring appeal. The journey from a bare engine and frame to a fully wrapped sculpture of aerodynamics is as much about engineering discipline as it is about the rider’s relationship with wind, speed, and the road ahead. For enthusiasts and everyday riders alike, the full fairing remains a central element of what makes Honda motorcycles feel precise, protected, and poised on the edge of performance. Availability and access to compatible full fairings have never been more convenient, with OEM-aligned options and carefully engineered aftermarket kits that honor the original design language while offering customization paths. For those curious about current offerings and where to begin, a look into the broader Honda fairings ecosystem reveals a continuum of products that can be tailored to different riding styles and budgets while preserving fit, finish, and function. A practical starting point is to consider the compatibility of the fairing with your model year and intended use, then weigh the benefits of integrated features versus ease of maintenance. Even as you consider these aspects, it is important to remember that the ultimate goal is not simply to cover the bike, but to harmonize its performance envelope with the rider’s needs. A well-chosen full fairing will maintain a clean, efficient silhouette at speed, support stable handling through the apex and into the straight, and deliver the kind of confidence that makes a long ride feel effortless. It is this synergy—air, heat, weight, and will—that makes full fairings a cornerstone of Honda’s design language and a central feature in any discussion about optimizing motorcycle performance through bodywork. For readers seeking practical options and user experiences, the availability of OEM-compatible kits and aftermarket variants can be explored through the Honda fairings collection, which gathers compatible shapes and finishes in one accessible place. Honda fairings collection .

External resource for further reading: https://www.bikeexif.com/honda-cbr1000rr-carbon-fiber-full-fairings/

null

null

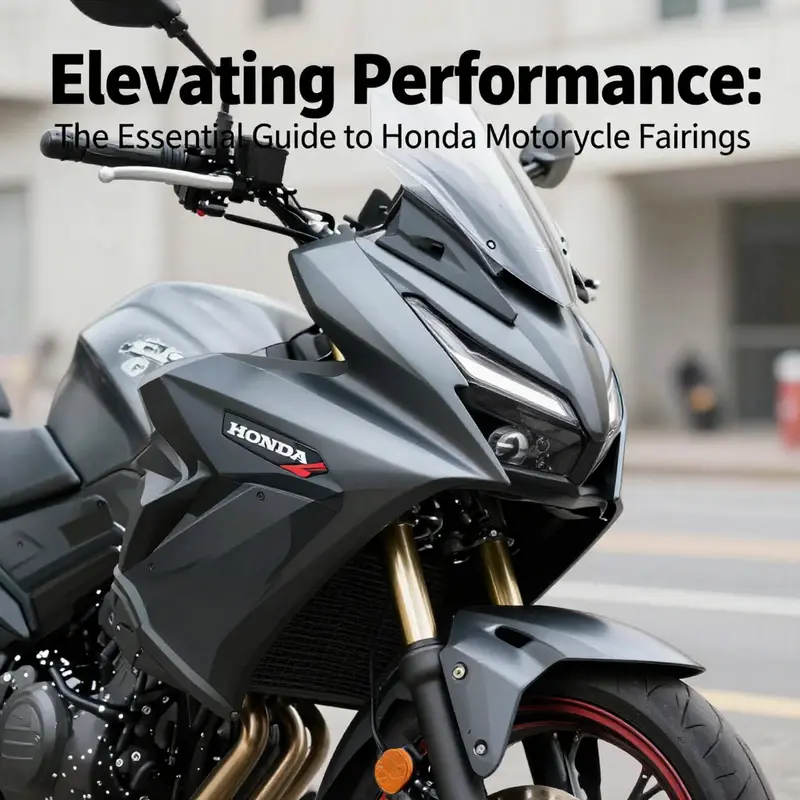

From ABS to Alloys: How Honda Fairing Materials Shape Durability, Aerodynamics, and Style

The fairing on a Honda motorcycle is more than a cosmetic shell. It is a carefully engineered body component that mediates air, rider comfort, and the bike’s overall stance on the road. Material choice sits at the heart of this balance. The small, almost invisible decisions about what the shell is made from ripple through every ride. They affect how cleanly air flows around the machine, how well the rider is shielded from wind and debris, how long the finish will last in sun and rain, and how practical it remains to repair or replace damaged panels after a misjudged curb or a stray stone. In short, the material system of a fairing is a critical enabler of both performance and practicality for Honda’s diverse lineup, from sport-oriented machines to urban commuters and touring machines. The story of these materials is a story of trade-offs, innovations, and the pursuit of a seamless synthesis between speed, protection, and visual impact.

ABS plastic remains the backbone of most fairings across OEM and aftermarket supply. Its dominance is not accidental. ABS brings a dependable blend of flexibility, toughness, and impact resistance that suits the unpredictable rhythms of road riding. Panels made from ABS can bend slightly under impact and absorb energy without cracking, which is crucial when a fairing brushes a rock, a pothole, or another rider’s luggage during an urban shuffle. The same material also holds up well under road debris and varying weather cycles. It resists the minor fading and chalking that can plague more brittle plastics, helping the fairing keep its shape and its lines after months or years of exposure to sun, rain, and temperature swings. The structural role of ABS is complemented by the way it accepts manufacturing processes and finishes. It readily takes consistent paint lines, is compatible with weather-resistant clear coats, and tolerates mass production tolerances that ensure a snug, repeatable fit across many identical units.

But durability cannot be measured in impact energy alone. The long life of a fairing surface under heat, sun, and moisture often comes down to surface treatments and the broader material stack. UV-resistant paints and coatings are commonly layered over ABS or other plastics to slow color fade and preserve the gloss, even after extended exposure to sunlight. These protective layers prevent yellowing, chalking, and micro-cracking that can dull edges and compromise aesthetics. Corrosion-resistant composites, used in high-end or specialized applications, add another layer of resilience by inhibiting the gradual chemical interactions that moisture and airborne pollutants can provoke. Even small structural improvements in the topcoat or the interface between paint and base plastic contribute to a more enduring appearance, which matters as much for the rider’s confidence and street presence as for resale value.

Where the conversation broadens beyond standard ABS, aluminum alloys begin to show up in select components. In some configurations, decorative covers and certain frame-adjacent elements may lean on aluminum for increased rigidity and a distinctive, premium feel. Aluminum’s strength-to-weight ratio provides a tactile rigidity that is noticeable in the fairing’s edge lines and panel transitions. It also offers opportunities for sleeker, more geometrically precise shapes that capitalize on aerodynamic rationales without adding excessive weight. Yet, given the scale and complexity of full fairings, aluminum tends to be reserved for particular parts rather than the entire shell. The practical upshot is a carefully curated mix: the mass and formability of ABS for the majority of the panels, augmented by aluminum where rigidity or a signature, alloy-based look is desirable. This combination can yield a fairing that looks and feels purpose-built, with a balance of lightness and structural trust.

From a performance perspective, the material system behind Honda fairings is closely tied to the air’s behavior around the bike. The contouring afforded by modern plastics and composites enables aerodynamic shaping that reduces drag and can stabilize the ride at higher speeds. In well-executed designs, the resulting drag reduction is not merely cosmetic; it translates into measurable gains in top speed, acceleration feel, and fuel efficiency, especially in touring or sport-touring applications where wind resistance compounds over longer distances. A well-designed fairing can lower drag by a meaningful margin—figures cited in some industry discussions suggest improvements on the order of up to fifteen percent relative to less-aerodynamic designs. While this is a broad figure and dependent on overall bike geometry and riding posture, the principle holds: a thoughtfully contoured shell made from quality materials makes riding easier at pace and more efficient for fuel-conscious riders.

Although the technology behind fairings has grown more sophisticated, the core relationship between material and performance remains intuitive. The weight of the shell matters, not just for the bike’s moment of inertia but for how the rider experiences handling, steering feedback, and even heat management around the engine bay. ABS’s intrinsic lightness compared with heavier alternatives is a practical benefit in most street-use scenarios. It reduces uncompressed mass on the bike’s front end, which can translate into more responsive steering and lower gyroscopic load during quick direction changes. When the fairing is designed with modularity in mind, the ability to swap panels without destabilizing the entire assembly becomes a meaningful cost and time saver for owners who dabble in maintenance or style changes. The modular approach also allows different material selections by section to be tuned for function—some areas may prioritize impact resistance, others aerodynamics, and still others aesthetics. In this sense, material strategy becomes a design language as much as a manufacturing choice.

The practicalities of real-world use reinforce that material selection is never about a single property in isolation. It is about how the panel behaves when confronted with road salt, splash, sun, and heat, how easily panels can be repaired or replaced, and how consistently the finish remains over time. The adhesive and fastener systems that join panels to the substructure must accommodate the chosen materials’ expansion and contraction cycles, resistance to creep, and susceptibility to surface scratches. A well-executed fairing system therefore embodies more than the raw material attributes; it embodies a design philosophy that promises dependable fit, predictable maintenance, and an enduring aesthetic. This philosophy helps riders keep their machines on the road rather than chasing cosmetic issues.

When riders consider OEM versus aftermarket options, the material narrative continues. OEM fairings are engineered to meet exacting standards for fit, finish, and durability within the constraints of a particular model’s architecture. Aftermarket options expand the material palette and finish choices, offering coatings and composite blends that push beyond stock performance in some cases. In both channels, the material platform is the foundation on which a rider can tailor the bike’s appearance and performance to suit their riding style and climate. For those who want a curated sense of continuity in a modern Honda, a fairing package that harmonizes with the bike’s lines, finishes, and color is not just a cosmetic upgrade; it is a performance choice anchored in material science.

The manufacturing and quality story behind these materials also speaks to safety and road legality. Modern fairings and their coatings are designed to meet weathering and durability standards, while finishes keep color fastness and gloss levels stable across years of daily riding. Some regions require certifications and conformity marks that ensure fairings do not degrade or shed materials that could compromise visibility or rider protection. The best suppliers align with global standards, including recognized safety and quality frameworks. For riders who source parts through online marketplaces, these assurances help ensure that a replacement panel is not only a good-looking match but also a reliable one in the real world. In practice, this means prioritizing products from entities that demonstrate consistent process control, material traceability, and robust finishing protocols, along with the ability to maintain precise fit across production runs.

For readers seeking a curated starting point, a practical way to explore options is to look at dedicated Honda fairing collections from reputable retailers. These collections reflect the brand’s intended lines and emphasize compatibility with the bike’s geometry and mounting interfaces. To view a representative lineup of Honda fairings, you can explore a curated selection at this source: Honda fairings collection on Summit Fairings. This resource presents a range of panels, finishes, and style choices that illustrate how material decisions translate into real-world appearance and performance.

As the discussion turns toward sourcing and materials, it is important to acknowledge the broader context. The market includes offers that blend plastic, composite, and metal elements to meet different rider priorities. For some riders, weight savings and aggressive aesthetics drive a greater emphasis on carbon-fiber-like composites, while for others the pragmatic durability and cost-effectiveness of ABS-based shells take precedence. In this spectrum, the material choice becomes a matter of balancing performance with practicality, a balance that reflects the intended riding conditions, maintenance habits, and budget of the owner. Beyond the material itself, the finish and protection strategies—UV resistance, corrosion inhibitors, and color-fast coatings—play a consequential role. When combined thoughtfully, these elements yield a fairing that remains visually compelling and functionally reliable through the highs and lows of riding life.

The story of Honda fairing materials is therefore not a single invention or a single panel. It is a layered conversation about how to marry science with riding experience. It is about choosing a material system that can survive the daily grind of road riding while still looking sharp after miles of sun exposure. It is about the confidence a rider gains when the fairing’s finish looks good and the piece remains securely attached, even after a tough ride or a casual curb encounter. It is about the peace of mind that comes with knowing the bike’s aerodynamics are designed to perform under real-world conditions, not just in a wind tunnel. And it is about the enduring appeal of a well-executed fairing that communicates a rider’s identity through its lines, its finish, and its quiet, reliable performance underneath.

External resource: https://www.alibaba.com/product-detail/Honda-CBR400RR-NC29-1990-1998-white1600743228169.html?spm=a2700.1.root.dtitle&productDetailTab=specifications

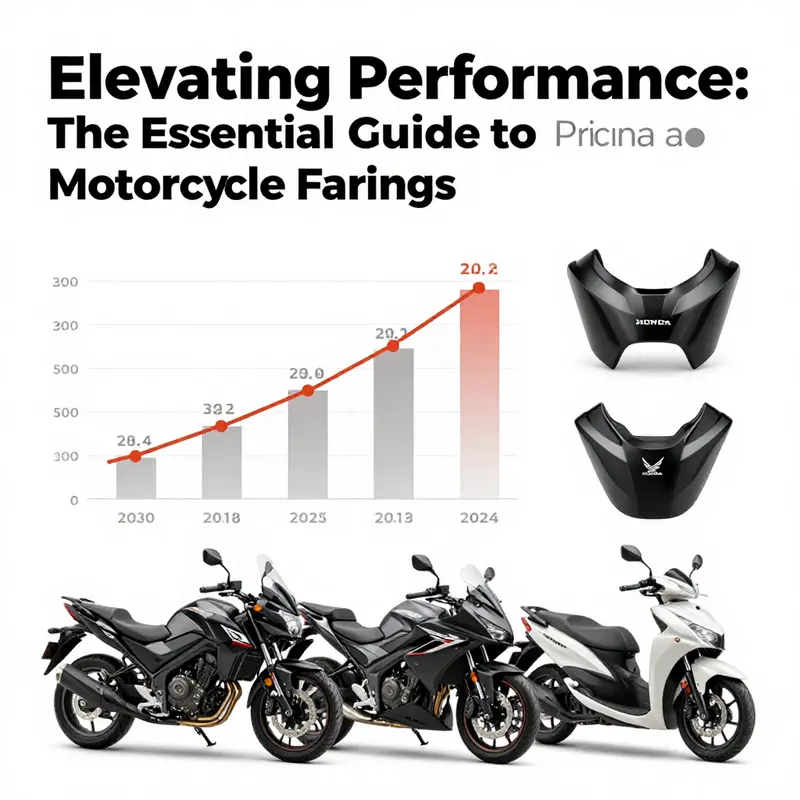

Riding the Curve: Pricing Dynamics and Availability of Honda Motorcycle Fairings in 2026

The market for Honda motorcycle fairings in 2026 reads as a spectrum of choices rather than a single product line. OEM fairings offer guaranteed fit, factory finishes, and seamless integration with lighting and electronics, typically at higher prices. The aftermarket ecosystem expands options on materials, finishes, and price, with typical aftermarket price ranges from about $150 to $600 for standard sets, and higher for premium carbon fiber or sport-touring kits. Durability, fitment precision, and finish quality are key differentiators, and buyers should consider long-term maintenance and resale implications when comparing options. Availability mirrors model life cycles and distribution dynamics: mainstream bikes stay in stock more reliably, while limited editions and late-life runs can constrain supply and push secondary-market prices.

Material choices drive both price and performance. ABS plastics deliver impact resistance and cost efficiency, while carbon fiber offers weight savings and stiffness at a premium. The carbon option requires careful handling and precise installation but rewards riders chasing speed and maneuverability. OEM sets tend to be priced higher still—roughly $400 to $1,200 per complete kit—reflecting fit guarantees, warranty, and a consistent finish across panels. Availability for OEM parts aligns with Honda’s production and parts cycles, with bulk-order discounts influencing fleet purchases for shops and teams.

Riders’ decision calculus ties directly to riding philosophy and use case. Touring riders may prioritize wind protection and aerodynamic efficiency, favoring full fairings, while commuters might opt for lighter, modular front skins that ease maintenance. The market increasingly supports modular solutions—half fairings and front fairings—as a way to balance protection, airflow, and serviceability without a full-body redesign. Pricing and value now mean more than sticker price; buyers consider installation labor, color-matching options, repaint costs, and the long-term cost of ownership.

To navigate the landscape, buyers should consult reputable suppliers and catalogs that emphasize fitment accuracy and finish consistency. Collections of Honda-compatible fairings and trusted aftermarket distributors can guide comparisons, while external market coverage helps place Honda fairings within the broader ecosystem of performance upgrades and styling choices. See Cycle World and other industry outlets for ongoing analysis that complements specific product pages (e.g., https://www.cycleworld.com/).

Final thoughts

Honda motorcycle fairings are more than just aesthetic enhancements; they are vital components that improve performance, safety, and the overall riding experience. By understanding the different types of fairings, the materials that constitute them, and the current market landscape, business owners can make informed decisions regarding their motorcycle offerings. Opting for high-quality, suitable fairings not only adds value to the motorcycle but also aligns with customer expectations for both performance and design. This comprehensive understanding empowers business owners to optimize their inventory and provide riders with options that meet their needs.