Introduction

The demand for high-quality carbon fiber motorcycle fairings continues to rise as riders seek lightweight, durable, and aesthetically superior parts. For business owners entering or expanding in the motorcycle parts market, a thorough understanding of the production process is essential. This guide explores the critical stages involved in making carbon fiber motorcycle fairings, providing insight into each production phase from design and mold creation through to assembly. The first chapter delves into shaping and mold preparation, laying the foundation for precision parts. The second chapter uncovers techniques for fiber layup and resin application. The third chapter examines curing methods and quality control vital for structural integrity. The fourth chapter focuses on finishing touches and UV protection that ensure longevity and style. Finally, the fifth chapter clarifies adhesive choices and assembly strategies to maximize durability and performance. Together, these chapters offer business owners a holistic perspective on delivering premium carbon fiber fairings that meet market demands.

Tables of Contents

Chapter 1: Design and Mold Creation in Making Carbon Fiber Motorcycle Fairings

- Balancing Aerodynamics and Structure: The Art of Designing Carbon Fiber Motorcycle Fairings and Their Molds

- Precision Mold Fabrication: Cutting-Edge Techniques and Materials for Carbon Fiber Fairings

- From Concept to Mold: The Critical Pathway Shaping Carbon Fiber Motorcycle Fairings

- Advanced Technologies and Industry Strategies Elevating Carbon Fiber Fairing Molds

Chapter 2: Mastering Layup and Resin Techniques for Carbon Fiber Motorcycle Fairings

- Optimizing Carbon Fiber Layup: Material Preparation and Structural Strategies for Superior Fairings

- Precision in Resin Application: Balancing Wet Layup and Prepreg Techniques for Optimal Fairing Performance

- Optimizing Fiber Orientation and Resin Integration for Structural Excellence in Carbon Fiber Fairings

- Precision Crafting and Rigorous Quality Control in Carbon Fiber Layup and Resin Techniques

Chapter 3: Curing Techniques and Quality Control in Making Carbon Fiber Motorcycle Fairings

- Precision Curing Strategies Enhancing Strength and Longevity of Carbon Fiber Fairings

- Mastering Epoxy Resin Application for Optimal Strength and Durability in Carbon Fiber Fairings

- Precision in Environmental and Process Control: Enhancing Bond Strength and Surface Finish in Carbon Fiber Fairings

- Mastering Defect Prevention and Longevity: Quality Control from Curing to UV Protection

Chapter 4: Finishing and UV Protection for Durable, High-Performance Carbon Fiber Motorcycle Fairings

- Elevating Durability and Shine: Autoclave Curing and UV-Resistant Clear Coats in Carbon Fiber Fairings

- Balancing Cost and Longevity: The Economic Advantage of Multi-Layer UV Protection on Carbon Fiber Fairings

- Navigating Supply Chain and Geopolitical Challenges in Sourcing UV-Resistant Resins and Adhesives

- Enhancing Longevity and Visual Appeal: Societal Influence and Maintenance Strategies in Carbon Fiber Fairings

Chapter 5: Adhesives and Assembly Strategies in Making Carbon Fiber Motorcycle Fairings

- The Essential Role of Epoxy-Based Adhesives in Bonding and Repairing Carbon Fiber Fairings

- Balancing Strength and Precision: Integrating Mechanical Fastening with Adhesive Bonding in Carbon Fiber Fairings

- Seamless Manufacturing and Surface Preparation Techniques for Superior Adhesive Bonding in Carbon Fiber Fairings

- Innovations in Automation and Quality Assurance for Carbon Fiber Fairing Adhesives and Assembly

Chapter 1: Design and Mold Creation in Making Carbon Fiber Motorcycle Fairings

1. Balancing Aerodynamics and Structure: The Art of Designing Carbon Fiber Motorcycle Fairings and Their Molds

Designing carbon fiber motorcycle fairings demands a precise balance between aerodynamic efficiency, structural strength, and striking visuals. The process begins with shaping fairings to optimize airflow and reduce drag using tools like computational fluid dynamics (CFD) and wind tunnel testing. These technologies shape contours that smooth airflow, minimize turbulent wakes, and maintain rider comfort while channeling cooling air effectively. Carbon fiber’s exceptional strength-to-weight ratio allows the fairings to be lightweight yet rigid, ensuring they withstand aerodynamic pressures and minor impacts without compromising handling.

Once the design is finalized, molds are crafted with pinpoint accuracy to replicate every aerodynamic curve. Materials such as fiberglass or aluminum endure the curing temperatures needed for carbon fiber layup. The mold’s surface quality directly impacts the final product’s finish and performance, making precision essential. The carbon fiber sheets are carefully layered within the mold, oriented to reinforce critical stress points before curing under heat and pressure. This process solidifies the resin, bonding fibers into a stable, lightweight composite.

The synergy of aerodynamic design principles with meticulous mold creation produces fairings that are not only visually compelling but also enhance motorcycle speed and stability. For those interested, a deeper look into the mold fabrication and carbon fiber layup stages can be found at Summit Fairings’ extensive resource hub.

2. Precision Mold Fabrication: Cutting-Edge Techniques and Materials for Carbon Fiber Fairings

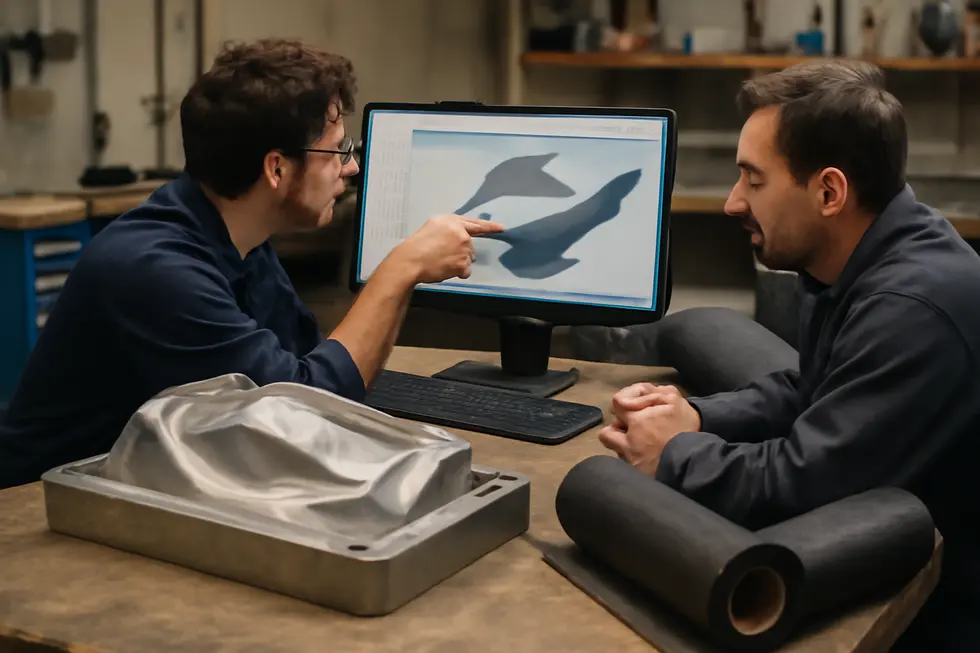

Creating high-quality carbon fiber motorcycle fairings hinges on precision mold fabrication that captures every intricate detail of the design. The process begins with refined CAD modeling, ensuring the digital fairing shape is exact. This design is then translated into physical molds through advanced machining techniques like high-speed CNC milling, which sculpts complex three-dimensional contours with tight tolerances and superior surface finishes critical for flawless carbon fiber layups. For harder mold materials, electrical discharge machining (EDM) and hard milling refine fine features and deliver impeccable precision. Mold materials are carefully selected to balance durability, thermal properties, and weight: aluminum molds offer excellent thermal conductivity and are ideal for prototypes or limited runs, while steel molds provide exceptional hardness and wear resistance for high-volume production. Composite molds, combining various materials, are occasionally utilized to optimize weight and heat management. Emerging additive manufacturing methods, such as stereolithography and selective laser sintering, complement traditional machining by producing tooling aids and prototype molds quickly, facilitating rapid iteration and cost efficiency. Every mold’s surface finish and dimensional accuracy directly influence the fairing’s structural integrity and aesthetic quality. Exploring more about production techniques and materials can enhance understanding of this critical stage in carbon fiber fairing manufacturing.

3. From Concept to Mold: The Critical Pathway Shaping Carbon Fiber Motorcycle Fairings

The creation of carbon fiber motorcycle fairings begins with a detailed design phase that transforms conceptual ideas into precise digital models using CAD software. This phase is essential to ensure the fairing fits perfectly on the motorcycle frame and adheres to aerodynamic and structural requirements. Once the design is finalized, the next pivotal step is mold creation, where materials like aluminum or steel are expertly machined to replicate the fairing’s exact contours. These molds serve as the foundation for shaping the carbon fiber layers, dictating the final dimensions and surface quality of the parts.

With the molds prepared, carbon fiber fabric sheets are carefully hand-laid or positioned using automated techniques within the mold, oriented strategically to optimize strength and stiffness. After layup, the assembly undergoes a curing process involving heat and pressure, typically in an autoclave or through vacuum bagging, which solidifies the resin and fiber matrix into a rigid, lightweight structure. Following curing, the fairings are demolded and refined through sanding and finishing coatings that protect against UV damage and enhance their visual appeal.

This seamless interplay of design, precise mold fabrication, and controlled curing is crucial to producing resilient and lightweight fairings that elevate motorcycle performance. For further exploration of the manufacturing nuances involved, visiting a comprehensive source like the explore the best motorcycle fairings at Summit Fairings can provide valuable insights.

4. Advanced Technologies and Industry Strategies Elevating Carbon Fiber Fairing Molds

The creation of precision molds is central to crafting high-performance carbon fiber motorcycle fairings, where accuracy and material choice dictate final quality. Designers begin with detailed 3D models generated through CAD software, enabling refinement of aerodynamic shapes and structural integrity before physical production. To bring these digital designs to life, manufacturers increasingly rely on innovative technologies like 3D printing to produce complex mold prototypes quickly, allowing rapid iteration to perfect form and fit. Complementing this, CNC machining is employed to deliver exact dimensions and smooth surface finishes essential for flawless carbon fiber layup.

Industry professionals integrate advanced composite processing techniques such as vacuum bagging and autoclave curing within mold design considerations to ensure even resin distribution, reducing defects like voids or warping. Additionally, principles like design for manufacturing help simplify molds by combining features, shortening production cycles and improving repeatability. Resources available within the composites sector further guide optimization of molds, materials, and processes to meet evolving demands for lightweight strength and aesthetic appeal.

These technological and strategic advancements harmonize to produce molds that not only form superior carbon fiber fairings but also streamline manufacturing workflows. For those interested in exploring a wider range of options and insights related to motorcycle fairings, there are comprehensive resources covering affordable and diverse fairing choices that complement knowledge on carbon fiber fabrication.

Chapter 2: Mastering Layup and Resin Techniques for Carbon Fiber Motorcycle Fairings

1. Optimizing Carbon Fiber Layup: Material Preparation and Structural Strategies for Superior Fairings

The foundation of producing high-performance carbon fiber motorcycle fairings lies in precise material preparation and strategic layup to optimize structural integrity. Starting with high-quality carbon fiber fabrics—either resin pre-impregnated prepregs or dry cloth—the key is ensuring proper adherence and coverage. Preparing the mold surface through careful cleaning and light sanding enhances bonding, while cutting fabric with generous overlap guarantees complete coverage of complex fairing shapes. During layup, resin application varies: wet layup involves saturating dry fabric manually, whereas prepregs come resin-ready, requiring only controlled curing.

Layer placement is meticulously planned to align fiber orientations—such as 0°, ±45°, and 90°—with expected load paths, strengthening resistance to tension, compression, and shear. Techniques like vacuum bagging or compression molding help consolidate layers, remove air pockets, and distribute resin evenly, resulting in superior mechanical performance and a smooth surface finish. Advanced simulation tools aid in designing optimal ply schedules, ensuring maximum strength-to-weight efficiency. Post-curing solidifies resin cross-linking, further enhancing durability.

This comprehensive approach produces fairings that are lightweight yet exceptionally strong, resistant to vibration and impact. Surface finishing with sanding and clear coating protects the composite and elevates appearance. For ongoing maintenance or repairs, specialized two-part epoxy adhesives maintain structural integrity despite operational stresses. Discover more about effective bonding and repairs in our detailed guide on motorcycle fairings.

2. Precision in Resin Application: Balancing Wet Layup and Prepreg Techniques for Optimal Fairing Performance

The application of resin plays a pivotal role in shaping the strength, durability, and finish of carbon fiber motorcycle fairings. Two main resin application techniques dominate this manufacturing stage: the wet layup and the prepreg methods. The wet layup process involves manually saturating dry carbon fiber fabric with resin directly in the mold. This approach offers flexibility and cost-effectiveness, making it ideal for small runs and repairs. However, achieving even resin distribution can be challenging, often risking air entrapment or resin-starved zones that compromise structural integrity.

In contrast, the prepreg method utilizes carbon fiber sheets pre-impregnated with resin under controlled conditions. These sheets are precisely laid into molds and cured under heat and pressure, typically within autoclaves. This controlled curing eliminates voids and ensures consistent resin content, which translates to fairings with superior strength, weight efficiency, and aesthetic quality.

While the prepreg technique demands specialized equipment and higher initial investment, its precision aligns closely with the high-performance requirements of premium motorcycle fairings. Wet layup remains a versatile alternative, especially when customization and lower production costs matter most. For those exploring quality carbon fiber components, understanding these resin application distinctions is essential. Further insights on achieving optimal resin application can be found in resources dedicated to motorcycle fairings craftsmanship.

3. Optimizing Fiber Orientation and Resin Integration for Structural Excellence in Carbon Fiber Fairings

Carbon fiber motorcycle fairings leverage the material’s unique anisotropic properties to achieve an exceptional strength-to-weight ratio essential for high-performance riding. The fibers provide tensile strength and stiffness in their oriented directions, allowing engineers to customize layup sequences that precisely align with anticipated stress paths—especially around mounting zones and impact-critical areas. Layering carbon fibers at multiple angles such as 0°, ±45°, and 90° helps balance torsional rigidity, bending resistance, and impact absorption, crucial for withstanding aerodynamic forces and mechanical loads during aggressive riding.

Sandwich construction augmentations, using lightweight core materials between carbon fiber skins, further improve stiffness and vibration damping without significant weight penalties. Selecting the right epoxy resin system is equally vital, as it bonds fibers firmly, transfers loads evenly, and shields the composite from environmental damage while providing excellent fatigue resistance.

Effective resin application techniques—hand layup, vacuum bagging, and resin infusion—ensure full fiber impregnation, minimize voids, and optimize the resin-to-fiber ratio to maximize mechanical performance. Following layup, controlled curing processes stabilize the composite’s microstructure, guaranteeing dimensional accuracy and long-term durability. By integrating tailored fiber orientation with precise resin application and curing, manufacturers produce fairings that excel in strength, durability, and lightweight responsiveness, delivering enhanced rider confidence and component longevity.

Explore more insights on premium motorcycle fairings and composite material strategies at the Summit Fairings blog.

4. Precision Crafting and Rigorous Quality Control in Carbon Fiber Layup and Resin Techniques

The creation of carbon fiber motorcycle fairings demands precision in both the layup of fibers and the application of resin to ensure optimal strength and durability. The layup stage involves carefully placing carbon fiber sheets within molds, aligning them meticulously to enhance mechanical properties like stiffness and impact resistance. This process often combines manual skill with automated precision to maintain uniformity and prevent fiber misalignment, a common source of defects. Following layup, resin application binds the carbon fibers into a solid composite, with techniques such as the wet layup method offering adaptability for different manufacturing scales. The chosen resin—typically epoxy—directly influences the fairing’s toughness, UV resistance, and environmental durability. To secure consistent high quality, manufacturers implement stringent quality control protocols, including visual inspections for fiber placement and microscopic analysis to detect voids or resin contamination. Advanced curing processes, often performed under heat and pressure in autoclaves, further enhance composite consolidation and dimensional stability. Post-curing, fairings undergo finishing treatments that protect against UV degradation and surface wear, extending service life while preserving aesthetics. These combined efforts in layup precision, resin application, and quality assurance are critical to delivering fairings capable of enduring the demands of high-performance motorcycle use. For detailed insights on expertly crafted motorcycle fairings, explore a reliable resource on unmatched choices in motorcycle fairings at Summit Fairings.

Chapter 3: Curing Techniques and Quality Control in Making Carbon Fiber Motorcycle Fairings

1. Precision Curing Strategies Enhancing Strength and Longevity of Carbon Fiber Fairings

Advanced curing strategies for carbon fiber motorcycle fairings are vital to achieving superior structural performance and durability. These methods revolve around meticulously controlling temperature, pressure, and time during the resin polymerization process to ensure optimal fiber consolidation and minimize defects like voids or delamination. Autoclave curing remains the gold standard, employing elevated heat and pressure to produce dense, high-strength laminates with reduced porosity. Alternatively, vacuum bagging paired with oven curing offers a cost-effective means to refine resin flow and enhance bonding without specialized equipment. Out-of-autoclave (OOA) techniques utilize engineered resin systems and tooling to cure at lower pressures while maintaining excellent mechanical properties, making them ideal for scalable production. Key to these processes is the use of prepreg materials, where carbon fabrics pre-impregnated with controlled resin content enable consistent wetting and cross-linking under heat and pressure, boosting impact resistance and overall durability. Throughout curing, rigorous quality control encompasses precise monitoring of temperature and pressure, alongside non-destructive testing methods such as ultrasonic inspection to detect internal flaws before assembly. Dimensional accuracy is verified using advanced 3D scanning, ensuring each fairing fits precisely and performs aerodynamically. Such integration of refined curing protocols and stringent inspections guarantees lightweight, resilient fairings that endure the mechanical stresses and environmental exposure intrinsic to motorcycle use. For more insights on high-quality fairings, explore this comprehensive motorcycle fairings resource.

2. Mastering Epoxy Resin Application for Optimal Strength and Durability in Carbon Fiber Fairings

Achieving maximum strength and durability in carbon fiber motorcycle fairings relies heavily on meticulous epoxy resin application and precise curing techniques. Choosing a high-quality, automotive-grade epoxy resin formulated exclusively for composites ensures excellent heat resistance and strong, resilient bonds capable of withstanding vibration, weather, and thermal stress. Preparing the surfaces by lightly sanding and thoroughly cleaning removes contaminants that could compromise adhesion, a foundational step to secure long-lasting bonds. Accurate mixing of the two-part epoxy resin in exact ratios is essential to complete polymerization, while firmly clamping parts maintains correct alignment throughout the typical 24-hour curing period.

Controlled curing environments, often at room temperature or with mild heat, promote complete resin hardening. Advanced post-curing methods, such as UV light exposure, further enhance bond strength and impact resistance by up to 30%, benefiting high-performance applications. In premium production, autoclave curing applies heat and pressure to optimize resin flow and fiber consolidation, improving mechanical performance and surface finish. Precise control over resin content during layup or filament winding balances rigidity and flexibility—prepreg materials excel here but require strict storage and handling.

Comprehensive quality control, including non-destructive ultrasonic inspection, detects voids or delamination early, ensuring structural integrity. Applying UV-resistant coatings after curing protects the fairings from sunlight degradation and enhances longevity, critical for exposed motorcycle components. These refined epoxy application and curing protocols are indispensable for producing carbon fiber fairings that meet the rigorous demands of both road and track use. For further insights on epoxy adhesives tailored to motorcycle fairings, explore detailed resources at the Summit Fairings blog.

3. Precision in Environmental and Process Control: Enhancing Bond Strength and Surface Finish in Carbon Fiber Fairings

The curing stage is pivotal in defining the structural integrity and aesthetic quality of carbon fiber motorcycle fairings. Environmental factors such as temperature and humidity must be tightly regulated, as excessive moisture can disrupt resin polymerization, leading to weak bonds and surface blemishes. Stable temperatures ensure consistent resin viscosity and complete curing, preventing voids or delamination that compromise durability under dynamic loads. Alongside, precise process controls—including cure time, pressure in autoclaves, and uniform resin application—are essential to achieve compact, void-free laminates with strong interfacial adhesion. Automated monitoring systems allow real-time adjustments to maintain ideal conditions, mitigating risk of defects that degrade performance and longevity. Chemical exposures from fuels or cleaners further necessitate selecting resins and adhesives with robust resistance, while UV-protective coatings safeguard the finish against degradation from sunlight and environmental wear. Quality control intertwines with these processes by validating resin ratios, inspecting lamination integrity, and conducting non-destructive testing to detect hidden flaws. The final finish’s smoothness not only enhances visual appeal but also improves aerodynamics and corrosion resistance, achieved through meticulous sanding, polishing, and multi-layer clearcoats with UV inhibitors. Ensuring every stage meets stringent standards guarantees fairings that combine high strength, lasting durability, and premium appearance. For more insight into advanced manufacturing and quality assurance practices, visit the comprehensive resources at Summit Fairings.

4. Mastering Defect Prevention and Longevity: Quality Control from Curing to UV Protection

The manufacturing of carbon fiber motorcycle fairings demands rigorous quality control to ensure structural integrity and long-lasting aesthetics. Central to this is the curing process, particularly autoclave curing, which applies precise heat and pressure to bond resin and fiber layers uniformly. This method significantly reduces critical defects such as delamination, resin voids, and warping that can compromise fairing strength and performance. Throughout curing, vacuum technology plays a vital role in eliminating air pockets, yielding a consistent composite structure.

Beyond curing, selecting appropriate adhesives is essential for assembly and repair. Epoxy-based adhesives are favored for their strong, flexible bonds that withstand vibration, temperature changes, and UV exposure without degrading the composite surfaces. Proper adhesive curing further prevents joint brittleness and delamination.

The final layer of quality assurance involves advanced UV protection. Carbon fiber composites are susceptible to fading and yellowing under sunlight, so manufacturers apply multiple layers of UV-resistant clear coats and paints. This not only preserves the fairing’s visual appeal but also helps prevent warping and surface degradation. Regular maintenance using mild cleaning agents supports the longevity of these protective finishes.

Comprehensive inspections—both visual and instrumental—are integrated at every stage to detect flaws early and guarantee precise fitment. These combined measures form the backbone of reliable, high-performance carbon fiber fairings, balancing mechanical strength with enduring aesthetic quality. For further insight into options and standards, explore detailed collections of high-quality motorcycle fairings at Summit Fairings.

Chapter 4: Finishing and UV Protection for Durable, High-Performance Carbon Fiber Motorcycle Fairings

1. Elevating Durability and Shine: Autoclave Curing and UV-Resistant Clear Coats in Carbon Fiber Fairings

The technology behind finishing carbon fiber motorcycle fairings has evolved to combine mechanical excellence with enduring aesthetics. Central to this advance is autoclave curing, a precision process where carbon fiber prepregs are cured under controlled heat and pressure inside a pressurized oven. This eliminates voids, ensuring a dense laminate that maximizes strength while minimizing weight. Such curing produces fairings with superior structural integrity and durability, essential for high-performance motorcycles exposed to extreme conditions.

Following curing, applying UV-resistant high-gloss clear coats further protects and enhances the fairings. These clear coats serve not only to shield the resin and fibers from damaging ultraviolet radiation—thus preventing yellowing and surface degradation—but also to impart a mirror-like finish that highlights the carbon fiber’s intricate weave. Typically formulated from polyurethane, acrylic, or two-component catalyzed systems, these coatings balance flexibility, chemical resistance, and UV stability. The multilayer application, combined with intermediate sanding and heat curing, ensures a flawless surface resistant to scratches and environmental wear.

Together, autoclave curing and advanced clear coatings extend the fairing’s lifespan, maintaining both the component’s mechanical performance and luxurious appearance despite prolonged sun exposure and road conditions. This integrated finishing approach reflects industry-leading standards for motorcycle carbon fiber parts, merging precision engineering with protective artistry. For more insights on durable motorcycle fairings, explore detailed resources at Summit Fairings’ blog.

2. Balancing Cost and Longevity: The Economic Advantage of Multi-Layer UV Protection on Carbon Fiber Fairings

Applying multi-layer UV-resistant paint systems to carbon fiber motorcycle fairings introduces a critical economic balance between upfront manufacturing costs and long-term value. These coatings require multiple stages—primers, UV-blocking layers, and clear coats—adding material and labor expenses due to their complexity and skilled application. However, the investment extends the fairings’ lifespan by shielding the carbon fiber from UV-induced yellowing, cracking, and structural weakening, thus minimizing maintenance and replacement needs. This durability reduces overall lifecycle costs for manufacturers and riders alike. Beyond protection, the rich, glossy finishes enabled by these coatings maintain aesthetic appeal, which significantly boosts market value and enhances consumer desirability, especially in premium segments. Moreover, as sustainability becomes a stronger market driver, durable and eco-conscious UV coatings align with contemporary environmental expectations, justifying higher price points and elevating brand reputation. Ultimately, while the initial costs rise due to multi-layer UV protection, the benefits—fewer warranty claims, improved customer satisfaction, and greater resale potential—outweigh expenses. This economic logic supports the adoption of advanced UV finishes in the competitive motorcycle fairing industry, delivering both financial and environmental advantages. For related insights on protective coatings and adhesives, explore comprehensive guidance on the Summit Fairings blog.

3. Navigating Supply Chain and Geopolitical Challenges in Sourcing UV-Resistant Resins and Adhesives

Securing UV-stable resins and adhesives is critical to the finishing and UV protection of carbon fiber motorcycle fairings. These specialized materials contain UV absorbers and stabilizers that shield composites from ultraviolet-induced yellowing, brittleness, and mechanical degradation. The global supply chain for such chemicals is concentrated within key regions like North America, Europe, Japan, China, and South Korea. However, geopolitical tensions and trade policies in these areas frequently introduce risks such as tariffs, export restrictions, and raw material shortages. Such disruptions can inflate costs, delay manufacturing timetables, and threaten consistent product quality. Moreover, the complex logistics environment heightens the vulnerability to shipping delays that impact just-in-time production frameworks. Manufacturers counter these risks through strategies like supplier diversification across continents, maintaining safety stocks, and investing in alternate resin formulations to reduce dependency on scarce petrochemical feedstocks. From a manufacturing perspective, UV-stable resins are integrated directly into the composite matrix or applied as advanced multi-layer clear coats, ensuring both protection and visual appeal. Adhesives must also balance strong, flexible bonds with UV durability, especially when joining carbon fiber to materials like ABS plastic. Navigating these intertwined supply chain and geopolitical challenges is essential for delivering carbon fiber fairings that maintain their strength and finish under prolonged sunlight exposure. For further insights into tailored fairing solutions and material technologies, consider exploring Summit Fairings’ expert resources.

4. Enhancing Longevity and Visual Appeal: Societal Influence and Maintenance Strategies in Carbon Fiber Fairings

Carbon fiber motorcycle fairings stand at the crossroads of performance, style, and sustainability, influencing both rider preferences and industry practices. Their exceptional strength-to-weight ratio elevates motorcycle handling and fuel efficiency, while their distinctive weave offers a sleek, high-tech aesthetic. Beyond these benefits, carbon fiber reflects a societal push toward innovative materials that emphasize environmental responsibility, even as the complexities of recycling composite products remain a challenge.

Proper finishing and UV protection not only preserve the fairings’ visual depth and gloss but also safeguard structural integrity against degradation from sunlight and environmental exposure. Maintenance practices underpinning longevity involve gentle cleaning with mild solutions and microfiber cloths to avoid surface damage, coupled with routine inspections for cracks or wear following intensive use. Applying UV-resistant coatings is critical in preventing premature yellowing and resin oxidation that compromise both appearance and durability.

User care extends to selecting adhesives designed for carbon composites, enhancing bond resilience against vibration and thermal shifts. Embracing eco-conscious maintenance products and mindful handling contributes to a sustainable ownership ethos, aligning with broader environmental priorities. Through attentive finishing and proactive upkeep, riders ensure their carbon fiber fairings remain vibrant and robust, simultaneously supporting evolving trends for quality, aesthetics, and material stewardship.

For further exploration of maintenance and protective strategies, discover affordable motorcycle fairings and related care insights at Summit Fairings.

Chapter 5: Adhesives and Assembly Strategies in Making Carbon Fiber Motorcycle Fairings

1. The Essential Role of Epoxy-Based Adhesives in Bonding and Repairing Carbon Fiber Fairings

Epoxy-based adhesives are fundamental to the assembly and repair of carbon fiber motorcycle fairings, providing strong, durable bonds essential for demanding riding conditions. These two-part resin systems offer exceptional compatibility with carbon fiber composites, ensuring that the structural integrity and aerodynamic form of the fairings remain uncompromised. Their mechanical strength withstands continuous vibration, thermal expansion, and environmental exposure common in motorcycle use. Water and solvent resistance further guard the bonds against degradation over time.

The application process requires careful surface preparation, such as sanding and cleaning, to maximize adhesion, followed by precise mixing and controlled curing, often under clamping to maintain alignment. Unlike quick-setting adhesives, epoxy formulations cure without shrinkage and can be sanded or shaped post-curing, preserving the fairing’s flawless finish. Some variants also provide electrical insulation, adding protection around sensitive components.

Preferred over alternatives like cyanoacrylates or silicones, epoxy adhesives extend the service life of carbon fiber parts by enabling reliable repairs and permanent assemblies. This not only supports high-performance requirements but also aligns with sustainable manufacturing practices by reducing waste. For detailed guidance on selecting and using epoxy adhesives tailored to motorcycle fairings, resources like the comprehensive posts on Summit Fairings blog offer valuable insights.

2. Balancing Strength and Precision: Integrating Mechanical Fastening with Adhesive Bonding in Carbon Fiber Fairings

Integrating mechanical fasteners with adhesive bonding in carbon fiber motorcycle fairings is essential to achieving durable, lightweight, and serviceable components. While epoxy-based adhesives offer uniform load distribution and sleek aerodynamic surfaces by eliminating visible fastener heads, they can be sensitive to environmental factors and limit ease of disassembly. Mechanical fasteners such as screws, bolts, and rivets complement adhesives by adding localized strength and allowing for reliable joint retention under vibration and thermal changes.

Optimal assembly involves designing mounting points that minimize the risk of fiber damage during fastening, utilizing careful hole placement and protective backing to prevent cracking or delamination. Quick-release mechanisms or strategically positioned fasteners facilitate maintenance without compromising structural integrity. Surface preparation prior to adhesive application — including cleaning and abrasion — ensures strong chemical bonding, while precise epoxy dosing prevents bond line weaknesses or surface irregularities.

This hybrid approach combines the chemical cohesion of adhesives with the mechanical security of fasteners, producing fairings capable of withstanding high-speed stresses while maintaining visual appeal. Understanding and executing these integrated techniques enables manufacturers to deliver superior assemblies that fulfill both functional and aesthetic demands. For a deeper dive into advanced fairing options and finishing techniques, explore premium motorcycle fairings available with customized solutions.

3. Seamless Manufacturing and Surface Preparation Techniques for Superior Adhesive Bonding in Carbon Fiber Fairings

The process of manufacturing carbon fiber motorcycle fairings hinges on meticulous layering and curing methods that ensure both strength and lightness. Prepreg carbon fiber sheets, pre-impregnated with resin, are laid into precision-engineered molds reflecting the fairing’s exact shape. This layup is cured under controlled heat and pressure, typically in an autoclave or oven, which firmly bonds fibers and resin, producing a resilient composite part. Post-curing, trimming and sanding refine the fairing’s edges and surface for optimal finish quality. Crucial to achieving durable adhesive bonds during assembly is rigorous surface preparation. Surfaces are first cleansed with degreasers or solvents to remove contaminants that would weaken adhesion. Following this, light sanding with 400 to 600 grit abrasives creates a microscopically rough texture, vastly improving mechanical interlocking with adhesives and coatings. Assembly employs structural epoxy adhesives tailored for carbon fiber, delivering exceptional strength and environmental resistance. Often, a hybrid joining strategy is used: adhesives combined with mechanical fasteners such as bolts to maximize joint durability while allowing maintenance flexibility. This ensures the bonded fairings withstand vibration, temperature changes, and dynamic stresses inherent to motorcycle use. By integrating meticulous manufacturing controls with detailed surface preparation and robust adhesive strategies, fairings gain enhanced longevity and performance. This comprehensive approach is foundational to high-quality motorcycle fairing production and can be explored further through detailed insights available at Discover affordable motorcycle fairings at Summit Fairings.

4. Innovations in Automation and Quality Assurance for Carbon Fiber Fairing Adhesives and Assembly

The integration of automation, rigorous quality control, and advanced adhesive technologies revolutionizes the assembly of carbon fiber motorcycle fairings. Automated systems, including robotic fiber layup and precise adhesive application, improve consistency by minimizing human error and ensuring exact resin placement. These technologies streamline the curing process, often conducted in autoclaves or ovens where temperature and pressure are meticulously controlled to optimize bonding and dimensional stability. Quality control measures extend beyond visual inspection to include ultrasonic testing and laser scanning, detecting hidden flaws like delamination or resin voids that could compromise strength. The adhesives themselves, largely high-performance epoxies and UV/LED-curable variants, deliver durable, lightweight bonds resistant to environmental stressors such as vibration and temperature changes commonly encountered in motorcycle use. The advent of flexible LED-curable adhesives significantly reduces curing times, enhancing production efficiency without sacrificing bond integrity. Assembly techniques blend these adhesives with precision mechanical fastening, balancing structural rigidity and overall weight to maintain aerodynamic design. Digital innovations like virtual twins and augmented reality support operator training and assembly validation, driving error reduction and consistency in final products. These combined strategies produce carbon fiber fairings that meet stringent performance demands while enabling scalable, repeatable manufacturing. For deeper insight into fairing options and production approaches, explore the comprehensive resources available at Summit Fairings.

Final thoughts

Creating carbon fiber motorcycle fairings demands precision and expertise throughout every step—from initial design and mold fabrication to the final assembly. Business owners who grasp the integrated nature of composite manufacturing processes can better ensure product quality, performance, and customer satisfaction. By mastering design accuracy, fiber layup techniques, curing processes, finishing protocols, and adhesive bonding strategies, your business positions itself for success in a competitive market. These combined efforts yield lightweight, strong, and visually striking fairings that meet the rigorous demands of riders and manufacturers alike. Investing in these core aspects ultimately helps deliver exceptional fairings that stand the test of performance and time. Understanding this holistic approach transforms production challenges into tangible business advantages.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined