Introduction

Motorcycle fairing bolt kits represent a vital yet often overlooked component in the aftermarket and OEM motorcycle parts market. For business owners, understanding the nuances behind these kits—from their innovative materials to precise installation techniques—can unlock opportunities to enhance product offerings, improve customer experiences, and expand revenue streams. This comprehensive overview covers key aspects such as material innovations that drive weight savings and durability, stylistic choices that influence aesthetics and functionality, streamlined installation methods ensuring ease and reliability, expanded kit contents that provide all-in-one solutions, brand-specific options tailored to unique models, and the customization and performance benefits that appeal to discerning riders and enthusiasts. Together, these insights form a robust foundation for evaluating and optimizing your motorcycle fairing bolt kit inventory or service offerings.

Tables of Contents

Chapter 1: Material Innovations in Motorcycle Fairing Bolt Kits

- Advances in Lightweight Alloys and Corrosion Protection for Motorcycle Fairing Bolt Kits

- Economic Impact and Market Trends Fueling Material Innovation in Motorcycle Fairing Bolt Kits

- Navigating Global Supply Chains: Geopolitical Influences on Material Sourcing for Fairing Bolt Kits

- Enhancing Rider Safety and Maintenance Through Durable, Lightweight Bolts

Chapter 2: Styles and Designs of Motorcycle Fairing Bolt Kits

- Innovative Materials and Finishes Elevating Motorcycle Fairing Bolt Kit Styles

- Distinctive Head Styles That Define Motorcycle Fairing Bolt Kits

- Tailored Kit Contents and Model-Specific Compatibility in Motorcycle Fairing Bolt Designs

- Blending Style and Performance: The Dual Role of Motorcycle Fairing Bolt Kits

Chapter 3: Installation Techniques for Motorcycle Fairing Bolt Kits

- Mastering Sequential Tightening and Precision Tool Usage for Fairing Bolt Kit Installation

- Optimizing Material Choices and Precision Fitment for Seamless Fairing Bolt Installation

- Enhancing Fairing Protection: The Role of Anti-Scratch Washers and Lubricants in Bolt Kit Installation

- Precision Disassembly and Reassembly: Ensuring Perfect Fit with Motorcycle Fairing Bolt Kits

Chapter 4: Content and Coverage of Motorcycle Fairing Bolt Kits

- Innovative Materials and Precision Fasteners: Technological Foundations of Motorcycle Fairing Bolt Kits

- Balancing Cost-Effectiveness and Accessibility in Motorcycle Fairing Bolt Kit Offerings

- Global Manufacturing and Supply Chain Dynamics Shaping Motorcycle Fairing Bolt Kits

- How Installation and Customization of Fairing Bolt Kits Shape Rider Safety and Style

Chapter 5: Brand-Specific Motorcycle Fairing Bolt Kits and Options

- Innovations Driving Precision and Performance in Brand-Specific Fairing Bolt Kits

- Economic Influences and Emerging Market Trends Shaping Brand-Specific Fairing Bolt Kits

- How Global Political Dynamics Shape Production and Distribution of Motorcycle Fairing Bolt Kits

- The Intersection of Customization and Quality in Model-Specific Fairing Bolt Kits

Chapter 6: Customization and Performance Benefits of Motorcycle Fairing Bolt Kits

- Innovations in Materials and Precision Enhancing Motorcycle Fairing Bolt Kits

- Economic Dynamics and Emerging Market Trends Shaping Motorcycle Fairing Bolt Kits

- How Geopolitical Dynamics Shape Customization and Performance of Motorcycle Fairing Bolt Kits

- The Cultural Pulse and Performance Edge of Motorcycle Fairing Bolt Kits

Chapter 1: Material Innovations in Motorcycle Fairing Bolt Kits

1. Advances in Lightweight Alloys and Corrosion Protection for Motorcycle Fairing Bolt Kits

Modern motorcycle fairing bolt kits leverage cutting-edge materials like aluminum and titanium alloys to drastically reduce weight while enhancing strength. Aluminum offers significant weight savings with excellent corrosion resistance thanks to anodized finishes available in customizable colors. Titanium alloys, often aerospace-grade, provide exceptional durability and even greater corrosion resistance, ideal for high-performance and long-lasting applications. These kits frequently feature advanced chemical coatings—such as anodizing and plating—to protect fasteners from rust and environmental degradation. Precision machining and surface treatments ensure bolts withstand vibration and aerodynamic stress, preserving fairing integrity. Some innovations even explore composite-metal hybrids to push boundaries further. These technological strides create faster, lighter, and tougher bolt kits that elevate both aesthetics and performance. For deeper insights into corrosion-resistant materials and machining, refer to Modern Machine Shop.

Explore more about motorcycle fairing options in our detailed guide on Summit Fairings.

2. Economic Impact and Market Trends Fueling Material Innovation in Motorcycle Fairing Bolt Kits

Material innovations in motorcycle fairing bolt kits have reshaped cost efficiency and market dynamics. Advances like precision-molded ABS plastics for fairings and powder-coated steel brackets improve durability and simplify assembly, reducing labor expenses and replacement frequency. This streamlining benefits both manufacturers and riders seeking reliable, affordable upgrades. Concurrently, growing consumer demand for lightweight, strong, and customizable components drives adoption of advanced composites such as carbon fiber, despite their higher upfront costs. These materials offer long-term economic gains through enhanced performance and durability. Additionally, universal adjustable mounting kits respond to a trend favoring versatility, broadening market appeal and increasing sales. Together, these factors enable manufacturers to meet evolving rider preferences with competitively priced, high-quality fasteners. For deeper insights on composite trends influencing this market, see the comprehensive overview at CompositesWorld. Explore more on lightweight and durable motorcycle component choices at Summit Fairings blog.

3. Navigating Global Supply Chains: Geopolitical Influences on Material Sourcing for Fairing Bolt Kits

The development of advanced motorcycle fairing bolt kits is deeply shaped by geopolitical factors tied to global material sourcing and supply chain dynamics. Critical metals like titanium and aluminum, essential for lightweight yet durable fasteners, are mined primarily in a limited set of countries including Russia, China, and Australia. This concentration creates vulnerability to trade restrictions, tariffs, and political tensions, which can delay production or increase costs. Furthermore, manufacturing processes span multiple countries, exposing bolt kit supply chains to disruptions seen during global crises. To safeguard innovation and availability, manufacturers often diversify suppliers or localize production. Such strategies not only mitigate risk but also align with evolving trade policies and regional technological leadership. These geopolitical realities play a crucial role in how material innovations reach riders worldwide. For further context on advanced manufacturing and material sourcing challenges, detailed analyses from institutions like Politecnico di Torino provide insightful perspectives.

4. Enhancing Rider Safety and Maintenance Through Durable, Lightweight Bolts

Material advancements in motorcycle fairing bolt kits greatly improve installation efficiency and long-term durability, directly enhancing rider safety and reducing maintenance demands. Precision-molded components from advanced plastics ensure exact OEM fitment, minimizing installation errors and speeding up repairs or upgrades. The introduction of lightweight composites like carbon fiber blends lowers overall bike weight, boosting handling and reducing rider fatigue on extended journeys. Strong, corrosion-resistant fasteners prevent fairing detachment at high speeds, elevating safety standards on the road. These durable materials extend service intervals, decreasing waste and maintenance costs, while aerodynamic fairing designs complement sturdy mounts to lessen wind buffeting. Such innovations collectively foster a more reliable, cost-effective, and comfortable riding experience. For additional insights, explore motorcycle fairings and related fasteners.

Chapter 2: Styles and Designs of Motorcycle Fairing Bolt Kits

1. Innovative Materials and Finishes Elevating Motorcycle Fairing Bolt Kit Styles

Motorcycle fairing bolt kits have advanced through innovative materials and finishes that blend strength with visual appeal. Lightweight aluminum alloys feature vibrant anodized colors and matte textures, combining corrosion resistance with customization. Titanium bolts offer exceptional durability and a natural metallic sheen, often enhanced by colored anodizing in striking hues like blue and gold. Beyond metals, sophisticated finishes such as color-shifting chrome deliver dynamic, light-responsive effects, while faux carbon fiber and forged patterns mimic high-tech aesthetics without added weight or cost. These material and finish technologies empower riders to personalize their motorcycles, matching fairing bolts with aggressive race styles or refined custom themes. Such progress reflects the larger trend of lightweight, durable, and visually stunning hardware shaping contemporary motorcycle styling. Explore more on enhancing your bike’s look at Explore the Best Motorcycle Fairings at Summit Fairings.

For further insight into these trends, see detailed coverage at KingsMotorcycleFairings.com.

2. Distinctive Head Styles That Define Motorcycle Fairing Bolt Kits

Motorcycle fairing bolt kits feature a range of head styles thoughtfully designed to blend style, strength, and practicality. The low-profile dome head offers a smooth, sleek look favored for visible areas, providing broad load distribution and a polished aesthetic. In contrast, the tapered socket cap head suits tighter spaces, delivering a streamlined profile that maintains secure fastening without bulk. The truss head, often anodized, adds a sportier, aggressive edge popular in performance kits. These styles are not just about appearance; they address stress, vibration, and installation ease. Enhanced by anodized or DLC coatings and crafted from materials like titanium or aluminum, these heads enable riders to personalize their bikes while enjoying durable, corrosion-resistant hardware. For a deeper look into fairing options, explore this ultimate source for affordable motorcycle fairings.

3. Tailored Kit Contents and Model-Specific Compatibility in Motorcycle Fairing Bolt Designs

Motorcycle fairing bolt kits are carefully tailored to match specific bike models, ensuring perfect fitment and comprehensive coverage. These kits vary widely—from compact sets with a few anodized aluminum screws and washers to extensive collections covering every fairing component on popular models like the Honda CBR600F4i. Compatibility hinges on precise sizing and fastener types, encompassing screws, nuts, clips, and washers that replace original hardware seamlessly. Some universal kits offer versatility for multiple brands but require careful selection to match unique mounting points. The choice of materials and finishes, such as black anodized aluminum or polished stainless steel, enhances both durability and style. Selecting a kit matched to your motorcycle’s exact make and year is essential for safe installation and aesthetic consistency. For a deeper dive into fastener options and setups, explore detailed guides on motorcycle fairings and bolt kits.

Reference: Motorcycle Fairing Bolt Kit – 10pc Black Aluminum Screw Set

4. Blending Style and Performance: The Dual Role of Motorcycle Fairing Bolt Kits

Motorcycle fairing bolt kits masterfully unite aesthetic appeal with functional excellence. Crafted from advanced materials like aircraft-grade titanium, these fasteners ensure remarkable strength while reducing weight by up to 42% compared to traditional steel bolts. This not only enhances durability but also contributes to improved bike handling. Design-wise, kits feature polished or anodized finishes in vivid colors such as blue, gold, and purple haze, enabling riders to tailor their bike’s appearance with an eye-catching, customized look. Bolt styles range from sleek dome heads to practical quick-release types, balancing traditional OEM aesthetics with modern convenience. These kits often come complete with washers, grease, and tools for seamless installation. Paired with pre-drilled fairing panels, they provide a cohesive upgrade that improves both performance and style. For deeper insights, explore affordable motorcycle fairings and accessories. External reference: Pro-Bolt Titanium Fairing Kit Kawasaki ZX10R Ninja.

Chapter 3: Installation Techniques for Motorcycle Fairing Bolt Kits

1. Mastering Sequential Tightening and Precision Tool Usage for Fairing Bolt Kit Installation

Installing motorcycle fairing bolt kits demands a careful balance of alignment, protection, and precision. Start by loosely fitting the fairing panels using the supplied bolts to allow fine positioning, ensuring the fairing does not interfere with controls or cables. Rubber grommets and washers play a vital role in safeguarding fragile fairing materials by evenly distributing bolt pressure and preventing cracks. Gradual, sequential tightening of each bolt is essential to maintain even stress across the panels and avoid warping. Employ the correct tools—typically Allen keys or specific sockets—to match bolt heads precisely, while clamps can stabilize parts during any necessary hole adjustments. After securing the fairing, attach ancillary components like windshields or turn signals, verifying all fasteners sit correctly without strain. Final torque checks and clearance inspections confirm a durable, damage-free installation. For an in-depth visual guide on these steps, consult the detailed tutorial titled How Do You Install Motorcycle Fairings? – The Racing Xpert. For further insights on selecting the best fairings to complement your installation, explore Explore the Best Motorcycle Fairings at Summit Fairings.

2. Optimizing Material Choices and Precision Fitment for Seamless Fairing Bolt Installation

Selecting the right materials and ensuring precise fitment are critical for installing motorcycle fairing bolt kits that safeguard both aesthetics and durability. Commonly, stainless steel bolts provide strong corrosion resistance, while aluminum alloys offer lightweight strength. To protect delicate fairing plastics or fiberglass, rubber grommets and washers are essential—they distribute pressure evenly and absorb vibrations to prevent cracking. Matching the bolt kit to the motorcycle’s model and fairing design ensures proper alignment, with bolts initially tightened by hand to allow adjustments. Avoiding overtightening is vital; washers behind the grommets help shift clamping forces away from fragile panels toward the frame. When holes misalign slightly, careful modifications may be necessary to maintain integrity without forcing components. For deeper guidance on these installation principles, detailed demonstrations are available in specialized instructional videos. For adaptable and durable fairing solutions, explore the wide selection of motorcycle fairings tailored to diverse styles and models at Summit Fairings.

3. Enhancing Fairing Protection: The Role of Anti-Scratch Washers and Lubricants in Bolt Kit Installation

Using anti-scratch washers and lubricants is crucial when installing motorcycle fairing bolt kits to preserve fairing surfaces and ensure lasting fastener performance. These soft rubber washers act as cushions between bolt heads and delicate fairing panels, preventing scratches, cracks, and stress points during tightening. Often paired with additional washers behind the rubber grommets, they help shift pressure from fragile plastics to sturdier frame parts. Lubricants, such as anti-seize compounds, reduce friction on bolt threads to avoid galling and make future removal easier. They also protect against corrosion caused by moisture and vibration exposure. Adopting a gradual tightening sequence with fingertight starts and torque progression, combined with these accessories, guarantees secure fitting without damage. This approach maintains both the appearance and durability of fairings while simplifying maintenance. For expert tips on installation using these accessories, consult The Racing Xpert.

4. Precision Disassembly and Reassembly: Ensuring Perfect Fit with Motorcycle Fairing Bolt Kits

Achieving a flawless installation of motorcycle fairing bolt kits demands a careful, step-by-step disassembly and reassembly process. Begin by removing obstructive components such as the seat, cowl, and instrument panels to expose the original fasteners. Each bolt should be loosened and removed one at a time, preserving order and avoiding loss. With fairings detached, inspect and clean mounting points to ensure they are free of debris and damage. When reassembling, align new fairing panels meticulously with their mounting points, inserting each supplied bolt along with anti-scratch washers to protect the finish. Gradually tighten fasteners, applying the recommended torque to prevent stress or cracking. Finally, reinstall removed parts in reverse order. This methodical approach preserves structural integrity and cosmetic appeal, making the upgrade seamless and reliable. For detailed visual guidance on these techniques, explore comprehensive installation resources available online.

Chapter 4: Content and Coverage of Motorcycle Fairing Bolt Kits

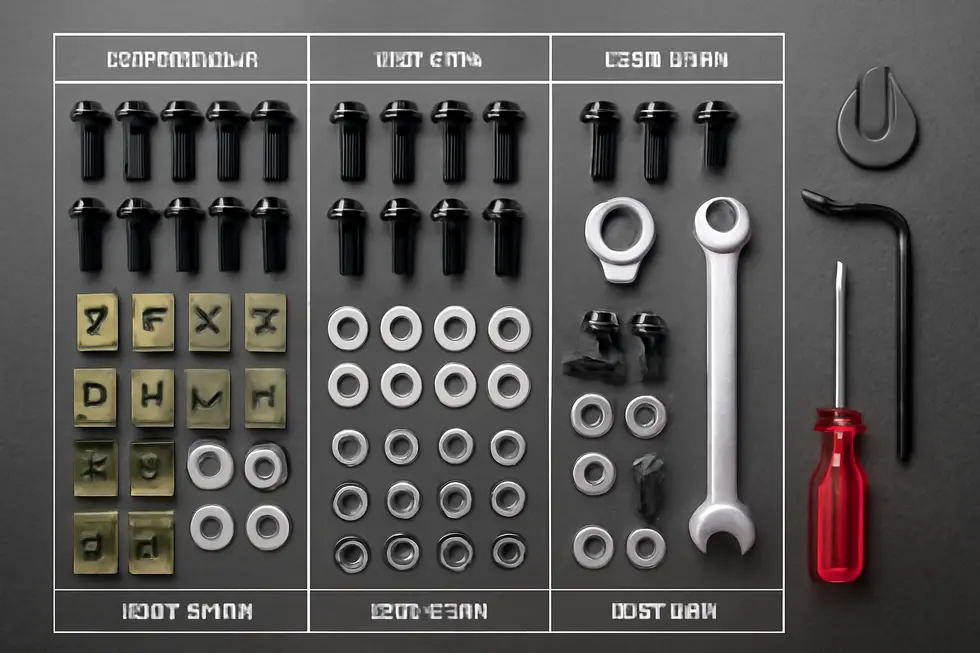

1. Innovative Materials and Precision Fasteners: Technological Foundations of Motorcycle Fairing Bolt Kits

Motorcycle fairing bolt kits combine advanced materials and precision engineering to improve both aesthetics and performance. Aluminum bolts, often anodized in vibrant colors, reduce weight by up to 60% compared to steel, enhancing handling while resisting corrosion. Stainless steel fasteners provide enduring durability with excellent rust resistance. Kits usually include various sizes like M6 to M8, featuring sleek dome heads or low-profile designs to complement bike styles. Precision is ensured through rolled threading, which strengthens the fastener and promotes secure mounting. Anti-scratch washers, nuts, and installation tools typically complete the kits, facilitating exact fitment with original or upgraded backing components. These thoughtfully engineered kits support both functionality and customization, striking a balance between lightweight efficiency and corrosion protection. For more insights on motorcycle fairing options, visit Explore the Best Motorcycle Fairings at Summit Fairings.

External resource: https://blog.summitfairings.com/explore-the-best-motorcycle-fairings-at-summit-fairings/

2. Balancing Cost-Effectiveness and Accessibility in Motorcycle Fairing Bolt Kit Offerings

Economic factors crucially shape the content and coverage of motorcycle fairing bolt kits. Selecting materials like 6061-T6 aluminum ensures durability and corrosion resistance while maintaining affordability, enabling manufacturers to offer competitively priced kits without sacrificing quality. Comprehensive sets include all essential fasteners and components tailored to specific motorcycle models, reducing the need for repeat purchases and ensuring consumers receive precisely what they need. Market availability is enhanced by wide model compatibility, covering various years and variants, which minimizes supply challenges and wait times. Streamlined production and distribution further lower costs and improve accessibility for riders. This integrated approach achieves cost-efficiency and broad reach, delivering value by combining material choice, complete kit coverage, and widespread market presence. For more insights on affordable options in motorcycle fairings, explore affordable motorcycle fairings at Summit Fairings.

3. Global Manufacturing and Supply Chain Dynamics Shaping Motorcycle Fairing Bolt Kits

Motorcycle fairing bolt kits are deeply influenced by global manufacturing hubs and their complex supply chains. Predominantly produced in Asia, especially China and Taiwan, these kits benefit from robust metal fabrication and plastic molding sectors that drive cost efficiency and material quality. The sourcing of raw materials spans continents, with assembly often localized near key markets to optimize delivery speed and reduce costs. Geopolitical factors such as trade tariffs, regulatory standards, and shipping logistics directly impact the availability, pricing, and design consistency of these kits. This global interplay results in a range of product quality—from precise OEM-level fitments to more economical aftermarket solutions—reflecting the manufacturers’ origin and the geopolitical climate. Understanding these dynamics clarifies why kit contents and coverage vary globally, shaping what riders ultimately receive. For deeper insights into fairing components and quality, explore affordable motorcycle fairings.

4. How Installation and Customization of Fairing Bolt Kits Shape Rider Safety and Style

Motorcycle fairing bolt kits significantly influence rider safety and bike aesthetics by securely fastening protective panels that enhance aerodynamics and guard against debris. These kits support diverse customization options through anodized finishes and lightweight materials, allowing riders to express individuality while maintaining performance. Their design, often including pre-drilled holes and comprehensive installation accessories, lowers barriers for both beginners and experts to upgrade bikes easily. This accessibility fosters greater rider confidence and engagement. Moreover, the growing demand for quality kits stimulates the aftermarket economy, encouraging innovation in materials and ergonomic features that improve comfort and ride quality. Such trends contribute to a cultural shift where motorcycles symbolize both functional transport and personal identity. For insights on tailored fairing options enhancing these benefits, explore affordable motorcycle fairings at Summit Fairings.

Chapter 5: Brand-Specific Motorcycle Fairing Bolt Kits and Options

1. Innovations Driving Precision and Performance in Brand-Specific Fairing Bolt Kits

Advancements in brand-specific motorcycle fairing bolt kits focus on precision-engineered materials and tailored fitment for enhanced durability and style. Modern kits predominantly use aerospace-grade titanium and lightweight aluminum, CNC-machined to exact tolerances that ensure secure fastening despite vibration and exposure to harsh elements. These pre-measured, model-specific kits simplify installation by including every necessary fastener, reducing errors and saving time during repairs or upgrades. Beyond performance, anodized finishes in colors like purple, gold, and black offer riders personalized aesthetic options that complement custom fairings. Drawing on technology adapted from aerospace and racing industries, these innovations provide corrosion resistance, weight savings, and increased strength. For riders seeking superior quality and customization, such kits deliver both reliability and visual appeal without compromise. Explore more on tailored motorcycle components at Explore the best motorcycle fairings at Summit Fairings.

Further product insights can be found at Pro-Bolt’s official site.

2. Economic Influences and Emerging Market Trends Shaping Brand-Specific Fairing Bolt Kits

The market for brand-specific motorcycle fairing bolt kits is increasingly driven by riders seeking both personalized style and precise fitment. Premium pricing thrives on high-quality, anodized finishes and exact-fit hardware that simplify installation while elevating aesthetics. Despite the growth in customization demand, traditional dealership networks face challenges like shrinking margins and rising e-commerce competition, impacting parts availability and pricing strategies. Meanwhile, online platforms expand consumer access, intensifying market competition and encouraging manufacturers to innovate with versatile finishes, color options, and corrosion-resistant materials. Segmented demand reflects diverse rider profiles—from track enthusiasts to daily commuters—each valuing functional appeal combined with brand loyalty. This dynamic interplay underscores a specialized aftermarket where economic pressures coexist with strong customization trends shaping kit development and distribution. Explore more on this evolving marketplace in our comprehensive motorcycle fairings blog.

For broader context on these economic factors and market evolution, see detailed analysis by industry experts here.

3. How Global Political Dynamics Shape Production and Distribution of Motorcycle Fairing Bolt Kits

The manufacturing and distribution of brand-specific motorcycle fairing bolt kits are deeply intertwined with global geopolitical forces. Asia Pacific’s dominance as a manufacturing hub benefits from supportive trade policies and regional agreements, enabling cost-efficient production and expedited shipping. Nonetheless, reliance on electronic components and rare materials exposes supply chains to risks amid trade tensions and diplomatic conflicts between major powers. Tariffs imposed by countries like the United States reshape cost structures and drive efforts toward domestic sourcing, affecting availability and pricing worldwide. Meanwhile, emerging markets in Latin America boost local demand, prompting customized product adaptations to meet regional preferences. Navigating this landscape requires manufacturers to diversify suppliers and adapt logistics strategically. For insights into motorcycle fairing solutions tailored to diverse needs, explore Summit Fairings’ comprehensive options. More on trade impacts can be found in this detailed overview of tariffs and supply chains.

4. The Intersection of Customization and Quality in Model-Specific Fairing Bolt Kits

Motorcycle enthusiasts increasingly seek fairing bolt kits that combine precise fitment with personalized style and durable materials. Riders value anodized fasteners offered in diverse colors and finishes, enabling them to highlight or complement their bike’s unique aesthetic. Matte, gloss, and even chrome chameleon coatings align with contemporary trends, while materials like aluminum and titanium deliver lightweight strength and corrosion resistance essential for both street rides and track performance. Exact match to specific motorcycle models is crucial, ensuring hassle-free installation with no modifications needed. These preferences reveal a broader consumer desire for functional upgrades that simultaneously enhance visual appeal, reflecting the evolving role of bolt kits beyond mere hardware replacements. For those exploring further, the Summit Fairings blog offers insights into stylistic options that complement these specialized kits.

Chapter 6: Customization and Performance Benefits of Motorcycle Fairing Bolt Kits

1. Innovations in Materials and Precision Enhancing Motorcycle Fairing Bolt Kits

Advancements in motorcycle fairing bolt kits revolve around superior materials like titanium and CNC-machined aluminum, which drastically reduce weight while boosting strength and corrosion resistance. These innovations enable smoother airflow by ensuring panels fit with exact precision, improving the bike’s aerodynamic profile and handling at speed. Custom anodized finishes bring new possibilities for personalized aesthetics without compromising OEM-level durability. Additionally, modern fastening solutions often incorporate anti-scratch washers and optimized nut-and-clip systems that secure fairings tightly, reducing vibrations and wear. Some kits integrate with performance mods such as improved inner-clearance mounting, aiding engine cooling and ride stability. These technological strides make fairing bolt kits vital for riders seeking seamless integration of style, performance, and long-term reliability. For more insights on top-tier fairings and related customization accessories, explore Summit Fairings’ expert guide.

2. Economic Dynamics and Emerging Market Trends Shaping Motorcycle Fairing Bolt Kits

The motorcycle fairing bolt kits market reflects a compelling convergence of customization desire and performance demands. Riders increasingly invest in aesthetically distinct finishes—ranging from matte to neon accents—while valuing bolt kits that ensure aerodynamic stability and structural integrity. This dual focus drives burgeoning aftermarket sales, with consumers preferring high-quality, OEM-equivalent fasteners tailored to both universal and model-specific applications. Online retail platforms have expanded accessibility, offering rapid delivery and a broad product range, fueling growth further. The pervasive influence of social media showcases unique builds that inspire demand for specialized hardware, making bolt kits a critical element in motorcycle personalization and efficiency. For riders exploring diverse options, discover affordable motorcycle fairings at Summit Fairings provides valuable insight into complementary customization products. This evolving market underscores how economic and stylistic trends collectively enable performance-enhanced and visually striking motorcycles. For more detailed analysis, see the research on customization trends and economic impact.

3. How Geopolitical Dynamics Shape Customization and Performance of Motorcycle Fairing Bolt Kits

Geopolitical dynamics significantly influence the customization and performance benefits of motorcycle fairing bolt kits through manufacturing capabilities, trade policies, and regional market demands. Countries with advanced production infrastructure ensure access to premium materials like aircraft-grade titanium, enhancing durability and weight savings, vital for performance. Trade tariffs and restrictions can limit bolt kit availability or increase costs, driving riders toward locally sourced options that may affect customization variety. Supply chain stability also impacts timely maintenance and upgrades, with well-connected regions enjoying wider choices. Cultural preferences and regulations further shape design trends, prioritizing either aerodynamic efficiency or aesthetic appeal in different markets. Consequently, geopolitical factors directly affect how riders customize and optimize their motorcycles. For a deeper understanding of customization options, explore affordable motorcycle fairings at Summit Fairings. See also Kings Motorcycle Fairings Blog for insights on global market tailoring.

4. The Cultural Pulse and Performance Edge of Motorcycle Fairing Bolt Kits

Motorcycle fairing bolt kits transcend basic hardware; they symbolize a fusion of performance enhancement and personal expression. Crafted from durable materials like 6061-T6 aluminum, these bolts secure fairings to improve aerodynamics and ride stability, directly impacting safety and longevity. Beyond function, customization with anodized finishes and color options allows riders to showcase individual style, reinforcing identity within diverse motorcycling communities. This expression fosters camaraderie and pride, highlighting how technical precision and artistic choice coexist in motorcycle culture. The industry supports this interplay by offering OEM-quality fitment combined with stylistic variety, maintaining performance while celebrating unique personal flair. Discover more insights about fairings and customization at Summit Fairings’ blog. For broader cultural and technical context, refer to Kings Motorcycle Fairings and SSNNUU bolt kits.

Final thoughts

Integrating motorcycle fairing bolt kits into your business offerings delivers tangible benefits that resonate strongly with consumers seeking enhanced durability, style, and performance. Material innovations like lightweight aluminum and aircraft-grade titanium provide the dual advantage of strength and weight reduction, directly impacting bike handling and aesthetics. The diversity in bolt styles caters to practical needs and visual preferences, while streamlined installation processes reduce service times and improve customer satisfaction. Comprehensive kit contents ensure retailers and service providers can supply complete solutions, elevating the end-user experience. Brand-specific options allow tailoring to key markets, maintaining OEM compatibility and boosting consumer confidence. Ultimately, embracing customization possibilities and tangible performance enhancements through quality bolt kits positions your business as an essential partner in the motorcycle aftermarket, fostering loyalty and driving growth.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined