Motorcycle fairings play a pivotal role in enhancing the performance and aesthetics of motorcycles, making them a crucial consideration for business owners in the industry. Understanding the nuances of motorcycle fairing com reviews is essential for selecting high-quality products that meet customer expectations. This article delves into the intricacies of motorcycle fairings, highlighting their functionality, the key factors influencing reviews, and insights into top-rated brands and materials. Each chapter will equip business owners with the knowledge needed to navigate the motorcycle fairing market with confidence, ensuring they make informed purchasing decisions that align with their customer needs and branding strategies.

null

null

Riding the Edge: Decoding Motorcycle Fairing Reviews for Real-World Value

When riders sift through motorcycle fairing reviews, they want a narrative that goes beyond looks. A fairing is an aerodynamic envelope that shapes the rider’s experience and protects the engine. Reviews should translate materials, construction, and fit into a clear sense of whether a kit will withstand highway gusts, weather, and daily riding. A good review tells how a product behaves when the bike leans into a curve, when sun heats the paint, and when a rider’s hands stay steady behind a shield that is protective and unobtrusive. In this sense, trustworthy analyses read like a careful audition of performance, durability, and practicality, anchored by how a piece of plastic will live with the rider over miles and seasons rather than hours in a showroom. The aim is not to crown a favorite but to illuminate patterns that separate credible, maintenance-friendly offerings from those that look good in photos but fall short in the field.

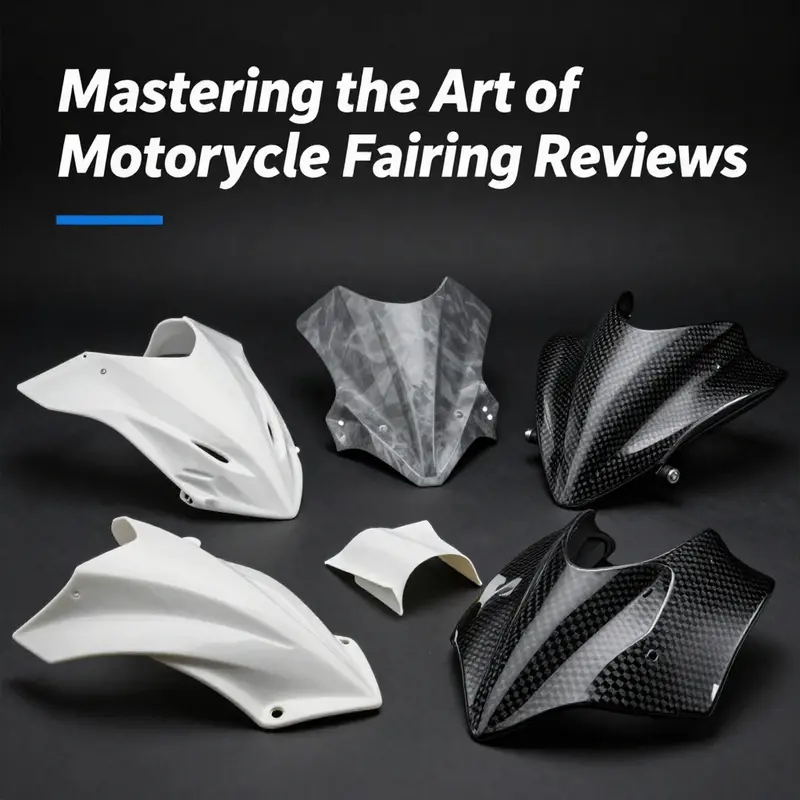

Material quality and durability sit at the core of any robust evaluation. Reviewers emphasize what a fairing is made from and how that material behaves under stress. ABS plastic, fiberglass, and carbon fiber composites each carry a distinct profile of stiffness, impact resistance, and UV tolerance. Carbon fiber offers high strength and light weight but comes with a premium price and tougher repair. ABS plastic provides affordability and easier repair, but its scratch resistance and UV durability depend on grade and finish. Fiberglass sits between, enabling complex shapes at lower cost than carbon while demanding attention to resin quality. The best reviews place material choices in a lifecycle context: how does a panel resist stone impacts, hold color after sun exposure, and survive temperature swings without warping?

Aerodynamic efficiency and wind protection also matter because rider comfort, bike stability, and fuel economy hinge on how a fairing channels air. Reviewers report subjective outcomes like reduced wind noise and calmer highway riding, but they frame these with observable factors such as wind deflection, smooth airflow around edges, and how a taller screen aligns with the rider’s posture. Half fairings deflect wind around the torso while leaving legs and knees exposed; they can be easier to live with for maintenance. Full fairings offer more comprehensive protection and a cleaner profile but may raise repair costs and maintenance complexity. A careful review explains not just that a full fairing looks protective, but how its shape interacts with the bike’s geometry, rider height, seating position, and windscreen.

Fitment and compatibility are the hinge between theory and reality. Real-world testing shows premium-looking fairings can fail to align with mounting points or require modifications. Precise fit matters for performance. Reviews reference OEM alignment, mounting points, and how easily a kit bolts on without bending metal or altering the chassis. The influence of manufacturing discipline matters too: high-tolerance regions tend to deliver tighter cut lines, bracket placements, and pre-punched holes, translating into smoother installation and better long-term alignment. Credible reviews connect compatibility notes to the actual assembly experience and to the kit’s ability to fit around mirrors, exhaust, and maintenance panels.

Ease of installation and maintenance access is the next lens. A well-designed kit should snap into place and allow routine access to components without dismantling the entire shell. Reviews favor clear instructions, compatible mounting points, and consistent hardware. The half-vs-full fairing distinction becomes clear here: half fairings preserve easier access to the engine and wiring, while full fairings can complicate routine checks but provide better protection. A thoughtful review maps these realities to the rider’s lifestyle and highlights trade-offs between comfort and upkeep.

Value for money and supplier reliability frame the economic and logistical side. Riders want to know if price aligns with quality, materials, and brand support. Reviews weigh durability against cost, aesthetics, and after-sales support. Geographic origin can surface, since some regions offer faster delivery or better parts availability. The best analyses link material quality, fit, and performance to a fair price and a reliable supply chain, while also noting potential issues such as shipping damage or color matching. They point readers toward broader resources like community forums for long-term satisfaction and owner experiences.

In credible testing, established outlets conduct repeatable evaluations. They frame conclusions as informed judgments that consider model-year variations and typical riding loads. For readers who want deeper material and performance metrics, technical overviews provide baseline references. See an external overview linked at the end for foundational material considerations that inform fairing design and testing.

As readers, we also benefit from installation experiences and user-submitted photos that populate review databases. Real-world observations help verify that theoretical advantages translate into riding benefits. If you want a broader sense of fit across models, you can explore OEM-inspired collections and installation guides to visualize how a fairing will look on your bike. A collection like Honda fairings demonstrates this connection between words and fit.

In sum, effective fairing reviews knit together material science, aerodynamics, and practical usability into a rider-centric narrative. They help readers appraise not just theory but real-world performance when the bike is loaded with luggage, when wind tests stability, and when a rider carves a corner with calm air around them. The strongest analyses acknowledge trade-offs between half vs full, carbon vs plastic, and OEM-inspired replicas, recognizing that different riders prioritize different outcomes. For those seeking a clearer, more reliable picture of aftermarket fairings, these reviews offer a measured, transparent lens. External reference: https://www.motorcyclefairingguide.com/technical-overview-material-grades-and-performance-metrics-2025

Top-Rated Brands in Motorcycle Fairing Reviews: Leading Names, Materials, and Real-World Fit

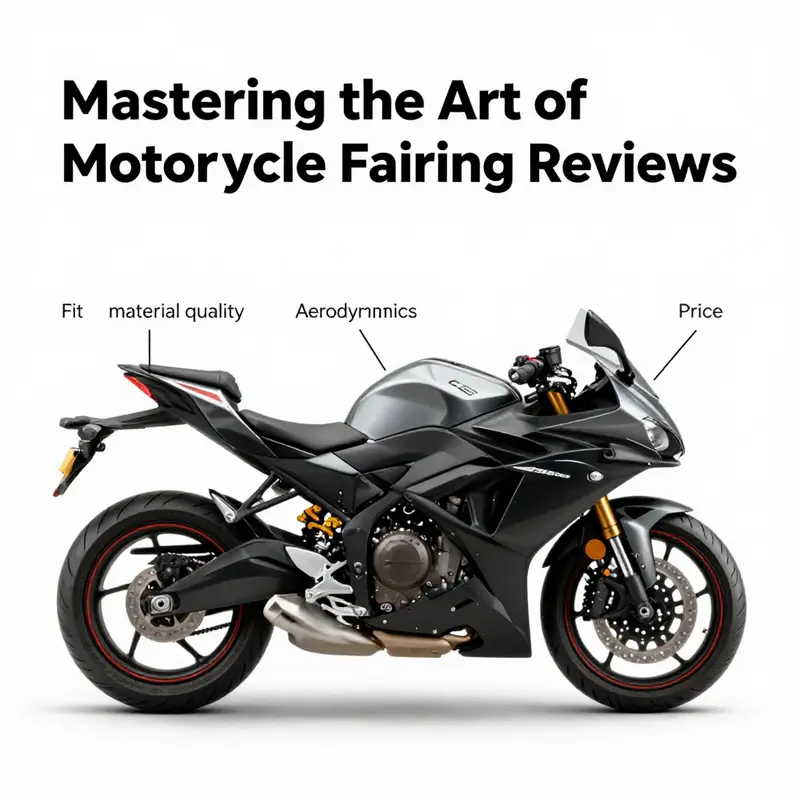

Top-rated brands in motorcycle fairing reviews are evaluated on fit and finish, material quality, aerodynamics, and real-world performance. Reviewers emphasize that a fairing should integrate with OEM mounting points, minimize gaps, and include clear hardware and documentation to avoid misalignment or irreversible modifications. Material choices—ABS plastic, fiberglass, and carbon fiber—each bring trade-offs in weight, cost, and durability, with carbon fiber offering superior strength-to-weight at a premium. Aerodynamics are judged by wind noise reduction, rider comfort, and high-speed stability, not just looks. Ease of installation and robust after-sales support often tip the balance, since a well-engineered kit should install without altering the bike’s geometry. Price vs value is a recurring theme: the best options balance build quality, performance gains, and service, rather than chasing the absolute lowest price. In practice, readers tend to trust brands that publish precise fitment charts, provide supportive installation guides, and offer model-specific guidance. For riders pursuing Yamaha-based projects or similar platforms, brand fitment resources and community galleries help verify compatibility before purchase. In summary, the strongest fairings feel like intentional upgrades that improve ride quality and confidence at speed, with comprehensive product storytelling and dependable after-sales service. For further expert comparisons, refer to established review hubs such as Motorcycle.com reviews.

Wind, Weight, and Wear: How Material Choices Shape Motorcycle Fairing Reviews

Fairings do more than dress a motorcycle; they shape how a bike cuts through air, how much vibration a rider feels, and how a panel ages over miles of riding. In the world of fairing reviews, the material behind the shell often quietly decides the verdict before a tester even starts counting the bolts. Reviewers look for a seamless blend of performance and durability: a shell that sits flush, that can be painted to match the bike, that withstands sun, rain, and road grit, and that can be repaired or replaced without a wholesale rebuild. The choice of material—ABS plastic, fiberglass, or polycarbonate—frames every other factor reviewers measure. It dictates weight, rigidity, impact resistance, and even how easily a kit can be installed or customized. The best review scores tend to go to fairings that deliver a credible combination of fit, finish, and long-term value. They are not fooled by glossy surfaces alone; they consider how the material behaves under stress, at speed, and after exposure to the elements. In this sense, material science is the quiet backbone of rider comfort and safety, shaping how a fairing performs as much as how it looks when the bike sits in a showroom or on a driveway after a weekend ride.

ABS, fiberglass, and polycarbonate each bring a distinct set of strengths and trade-offs to the shop bench and the road. ABS is the familiar workhorse for OEM and many aftermarket lines. It is lightweight, easy to shape, and forgiving to color-match, which helps when a fairing needs to blend with an existing bike’s styling or when a rider wants a clean, uniform appearance. Reviewers consistently note its ease of repair—scratches can often be buffed out or filled with conventional plastic repair methods—and its resilience in everyday use. Yet UV exposure is an ever-present caveat. Over months and seasons, long-term sun can make ABS surfaces brittle or cause slight color shifts unless a UV-protective coating or clear layer is applied. Those small, almost invisible changes can tilt an otherwise favorable review toward a more cautious verdict if the panel begins to show microcracking or chalking after a few summers of sun exposure. Still, for most riders who see fairings as a practical investment, ABS hits the sweet spot of cost-to-performance, provided the material grade is sound and the finish is properly protected.

Fiberglass, by contrast, speaks to a different set of priorities. It is stiffer and can be tuned for high rigidity, which matters when a rider pushes a motorcycle toward high-speed stability or aggressive cornering. For performance-oriented builds and custom modifications, fiberglass often earns praise for its structural integrity. Reviewers value the precision with which fiberglass shells can be molded and reworked, especially when unique shapes or large panels are required. The downside comes in weight and finishing. Fiberglass is heavier than ABS, which can erode marginal gains in acceleration and handling if weight savings are the goal. It also demands skilled craftsmanship to finish and paint correctly; improper sanding or resin work can lead to imperfect seams that ruin aerodynamics and aesthetic appeal. Cracking under sharp impact is another risk that reviewers parse in owner feedback and field testing. When fiberglass is done well, though, it presents a compelling choice for riders who demand stiffness and a tailored look without stepping up to the premium cost of carbon fiber.

Polycarbonate brings another axis into the comparison. Known for exceptional impact resistance and toughness, polycarbonate is favored when safety and resilience take priority. The material’s shatter resistance translates well into windshields and fairing sections that face the brunt of road debris, off-road dust, or the occasional tumble. Reviewers who test passenger protection or crash scenarios often note polycarbonate’s ability to absorb energy and resist catastrophic failure better than traditional plastics. The trade-offs are clear: polycarbonate can be more prone to scratching than ABS and may require protective coatings or harder finishes to maintain clarity and gloss. UV resistance is better than bare glass in some formulations, but aging can still produce subtle hazing or yellowing if coatings degrade over time. Price typically sits between ABS and fiberglass, offering a middle ground for riders who want extra durability without the weight penalty of fiberglass or the premium cost of carbon fiber. In real-world reviews, polycarbonate often earns praise for durability in tough riding environments and for its protective role, while reviewers remind readers to consider long-term maintenance, such as scratch repair and coating upkeep.

A careful reader of fairing reviews quickly notices that material choice interacts with several other factors that determine overall performance. The fit and finish of a panel—how precisely it aligns with mounting points, how evenly the edges mill, and how seamless the color or texture is with the rest of the bike—will either amplify or undermine the material’s innate properties. A well-made ABS shell with tight tolerances and a high-quality paint job gains from the material’s molding flexibility, turning a potentially bulky aftermarket addition into a near-OEM look and feel. Conversely, a fiberglass shell with a generous thickness but uneven sanding can trap air and create micro-turbulence that offsets any gains in stiffness. Reviewers routinely evaluate how well mounting points align with existing hardware and whether additional modifications are required. Ease of installation can determine whether a kit earns a thumbs-up for daily riders or a cautionary note for weekend hobbyists, and that assessment often hinges on whether the base material supports a straightforward, tool-light fit.

Beyond fit and installation, the material’s behavior over time matters. ABS’s forgiving repairability is a boon for riders who want to recover a fairing after a mishap or a stone strike on a long highway run. The same characteristic that makes ABS appealing to maintainers—its workable nature—also means finish and resilience depend heavily on the protective coatings that accompany the panel. A clear UV layer or a robust paint system can extend the life of an ABS fairing significantly, preserving color and gloss. For fiberglass, long-term durability is a function of resin quality and the skill put into sealing and finishing joints. The stiff, chassis-like nature of fiberglass helps with aerodynamic stability, but the potential for cracks under sharp impact remains a legitimate concern. When a reviewer sees a damaged but repairable fiberglass section, the narrative shifts to the skill required to restore structural integrity, the cost of materials, and the potential downtime. For polycarbonate, the chapter on wear is often tied to scratch resistance and clarity, especially for windshields and shields. A protective coating may be essential, and reviewers frequently push readers to consider the environment in which they ride—dusty, rocky, or heavily UV-exposed conditions where polycarbonate’s strength should be paired with proactive care.

The practical implications of these material choices extend into the realm of maintenance and value. Reviewers consistently frame value as a function of initial cost plus expected lifespan, repairability, and ease of return on investment. ABS often wins on upfront affordability and ease of refinishing, making it attractive for stock replacements and daily commuters who want reliable performance without a large upfront risk. Fiberglass appeals to enthusiasts chasing rigidity and a more aggressive look, with the caveat that the extra stiffness may come with added upkeep and potential repair costs. Polycarbonate’s strength lies in durability and crash protection; riders who value resilience in harsh environments may see long-term savings even if the initial price is higher. Across all three materials, guidance from manufacturers about proper care and maintenance can influence long-term outcomes. UV protection, proper coatings, and cautious handling all help maintain the shell’s integrity, color, and gloss, reinforcing a reviewer’s sense that the kit will stand up to real-world riding rather than merely looking good in photos.

For readers who are weighing options themselves, the material decision should align with riding style, climate, and how much maintenance they’re prepared to invest in. A daily commuter in a sun-drenched corridor might prioritize UV stability and cost-effectiveness, pushing toward ABS with a protective clear coat. A rider who pushes a sport or custom build toward track-like performance might favor fiberglass for its stiffness, provided there is technical skill available to finish and repair. A rider navigating rugged routes or frequent debris exposure could lean toward polycarbonate for enhanced impact resistance, as long as they’re willing to maintain scratch protection. In all cases, the material choice is not a single-factor decision. It intertwines with fit, mounting compatibility, and the level of care a rider can commit to in order to preserve appearance and performance.

To explore concrete examples of how these materials play out in real builds and to see how fit and finish compare across aftermarket lines, readers can browse a broad range of options in the Honda fairings collection. This resource illustrates how a well-designed kit can complement a bike’s styling while maintaining precise fit and finish across different model generations. It also highlights how color matching and surface texture work in practice, offering a tangible sense of how material properties translate into daily usability. Honda fairings collection serves as a practical touchstone for readers seeking to connect the theory of material properties with hands-on choices and installation realities.

Looking ahead, the conversation about fairing materials in reviews will continue to evolve as new composites and coatings enter the market. Advances in resin chemistry, surface hardness, and UV stabilization are likely to shift the middle ground between weight savings and durability. Reviewers will increasingly weigh lifecycle costs—resale value, repairability, and the cost of protective coatings—alongside raw performance metrics. Even as the aesthetics of a fairing remain important, the underlying material science will keep shaping how riders perceive value, how they judge fit, and how they judge long-term reliability. For readers seeking deeper technical grounding, external resources offer a rigorous look at how manufacturers test and specify materials for fairings, from impact resistance to weathering and structural performance. A detailed external reference can be found here: https://www.suzukimotorcycles.com/fairing-guide-material-properties

null

null

Final thoughts

As business owners explore the domain of motorcycle fairing com reviews, the insights provided in this article serve as a comprehensive guide for making informed purchasing decisions. Understanding the importance of fit, material quality, and brand reputation, along with the critical evaluation of price and value, will empower businesses to enhance customer satisfaction and brand credibility. By prioritizing these factors, owners can ensure they provide their customers with optimal products that not only meet but exceed expectations, fostering loyalty and long-term success.