Introduction

Heat management is critical for motorcycles, particularly for high-performance and touring models. As engines and exhaust systems generate considerable heat, motorcycle fairing heat protection becomes essential to safeguard the integrity of bodywork and to ensure rider comfort. This article delves into the materials and technologies that constitute effective heat shields, their crucial roles in improving performance and safety, the economic considerations of implementing effective solutions, an evaluation of popular products on the market, and future trends in heat protection engineering. Each chapter contributes to a comprehensive understanding of how proper heat protection can significantly benefit both motorcycle manufacturers and riders alike.

Tables of Contents

Chapter 1: Exploring the Thermal Advantages of Fiberglass in Motorcycle Fairings

- Harnessing the Insulative Power of Fiberglass in Motorcycle Fairing Design

- Innovative Carbon Fiber Shields: Protecting Performance with Cutting-Edge Heat Technologies

- Enhancing Performance: How Aluminum-Backed Thermal Shields Revolutionize Motorcycle Heat Protection

Chapter 2: The Role of Motorcycle Fairing Heat Protection in Performance and Safety

- Maximizing Performance and Comfort: The Essential Role of Heat Shields in Motorcycle Fairings

- Preserving Rider Comfort: The Impact of Fairing Heat Protection on Safety and Performance

- Optimizing Thermal Comfort: The Integration of Heat Protection for Endurance Riding

Chapter 3: Evaluating Financial Implications of Motorcycle Fairing Heat Protection

- Balancing Initial Investments with Long-Term Value in Motorcycle Fairing Heat Shields

- The Cost-Effectiveness of High-Performance Materials in Motorcycle Fairing Heat Protection Solutions

- Emerging Trends in Materials and Market Demand for Motorcycle Fairing Heat Shields

Chapter 4: Harnessing Heat Resistance: A Deep Dive into ABS Plastic Heat Insulation Solutions for Motorcycle Fairings

- Optimizing Motorcycle Fairings with Self-Adhesive ABS Plastic Insulation Pads for Heat Protection

- Reflective Aluminum Heat Shields: Revolutionizing Motorcycle Fairing Protection

- Harnessing Heat: An In-Depth Look at Consumer Preferences and Trends in Motorcycle Fairing Heat Protection Products

Chapter 5: Innovations in Motorcycle Fairing Heat Protection Engineering

- Harnessing Adaptive Technologies for Next-Gen Heat Management in Motorcycle Fairings

- Revolutionary Materials: The Future of Heat Protection Engineering in Motorcycle Fairings

- Harnessing Smart Materials and Connectivity for Enhanced Heat Protection in Motorcycle Fairings

Chapter 1: Exploring the Thermal Advantages of Fiberglass in Motorcycle Fairings

1. Harnessing the Insulative Power of Fiberglass in Motorcycle Fairing Design

Motorcycle fairings serve more than just a decorative purpose; they are essential components that provide protection against environmental factors, primarily heat generated by the engine and exhaust systems. Among various materials utilized in fairing construction, fiberglass emerges as a favorite due to its unique blend of strength, durability, and outstanding thermal insulation capabilities. This subchapter delves into how fiberglass functions as an effective thermal barrier, ensuring both rider comfort and structural integrity of the bike.

Fiberglass is highly regarded for its inherent resistance to heat transfer, making it an optimal choice for motorcycle fairings, especially in high-performance and touring models. The ability of fiberglass to inhibit the passage of heat plays a critical role in safeguarding vulnerable components like electrical wiring and fuel lines, while also shielding the rider from excessive thermal exposure. This is particularly vital for motorcycles with full fairings, where engine heat can accumulate rapidly. By implementing well-designed fiberglass fairings, manufacturers can significantly reduce the risk of heat-related issues that affect the bike’s performance and the rider’s comfort, especially on long rides.

Moreover, fiberglass offers remarkable advantages in terms of flexibility and design. It can be molded into complex aerodynamic shapes, enhancing airflow and reducing drag during operation. This aerodynamic efficiency complements its thermal properties, creating a scenario where the fairing not only protects the inner workings of the motorcycle but also contributes to a smoother and more stable ride. However, even with its superior heat resistance, fiberglass can still suffer from thermal degradation if subjected to consistently extreme temperatures over prolonged periods. Hence, OEMs and aftermarket manufacturers often incorporate additional technologies to fortify the insulating properties of fiberglass fairings.

One such enhancement is the integration of reflective coatings or specialized insulating layers within the fiberglass structure. These coatings, often made of ceramic materials or aluminum foil, augment the fairing’s ability to dissipate heat and reflect it away from critical areas near the engine and exhaust. This synergy between the core fiberglass material and supplementary heat shielding results in a comprehensive thermal management solution, ensuring maximum protection and efficiency. For instance, the application of heat-resistant adhesives and thermal blankets aids in maintaining an optimal thermal environment for the motorcycle components, which is crucial for overall performance reliability.

While the benefits of fiberglass are clear, it’s essential for riders and motorcycle enthusiasts to understand the importance of proper ventilation in systems with full fairings. Inadequate airflow can lead to heat build-up that undermines not only the fiberglass structure but also the integrity of various engine components. Therefore, a holistic approach to fairing design is necessary, combining high-performance materials like fiberglass with strategic airflow pathways and careful heat shield placement to combat the potential risks of heat accumulation.

In summary, fiberglass stands out as a versatile and powerful material in the realm of motorcycle fairing construction due to its exceptional thermal insulation properties. Its ability to provide a protective barrier against heat while enabling sleek aerodynamic designs differentiates it from other materials. As technology progresses, continuous innovations in combination with fiberglass promise to enhance heat protection features further, ensuring both rider safety and the longevity of motorcycle components. For those considering upgrades, a wealth of options can be found online, including an extensive range of motorcycle fairing heat shields, that underscore the necessity of quality materials in modern motorcycle design.

For riders seeking quality fairings, platforms offer a diverse collection of motorcycle fairings tailored to numerous motorcycle models, each engineered for optimal performance with careful attention to heat management.

2. Innovative Carbon Fiber Shields: Protecting Performance with Cutting-Edge Heat Technologies

The intersection of high-performance motorcycles and advanced materials like carbon fiber represents an evolving frontier in the realm of heat protection. As riders push their machines to the limits, the need for heat management becomes paramount, particularly for sport bikes and touring models where engine temperatures can soar. In this context, carbon fiber fairings stand out—not only for their lightweight and robust nature but also for the unique challenges they present regarding heat exposure.

Understanding Carbon Fiber’s Role

Carbon fiber, while celebrated for its incredible strength-to-weight ratio, is vulnerable to heat damage. Prolonged exposure to excessive heat can compromise the structural integrity of carbon fiber components, making effective heat shielding a critical consideration for manufacturers and riders alike. To address this, cutting-edge approaches to heat protection have been developed, ensuring that the lightweight benefits of carbon fiber can be realized without the risk of heat-related degradation.

One prominent solution involves the integration of innovative heat shielding technologies directly into the carbon fiber fairings. Manufacturers often utilize multi-layered composite shields that sandwich thermal barriers within the carbon fiber structure, supplying a bulwark against heat transfer from the engine and exhaust system. These innovations may also include ceramic-infused coatings that enhance the material’s resistance to high temperatures, offering protection and maintaining performance over extended periods.

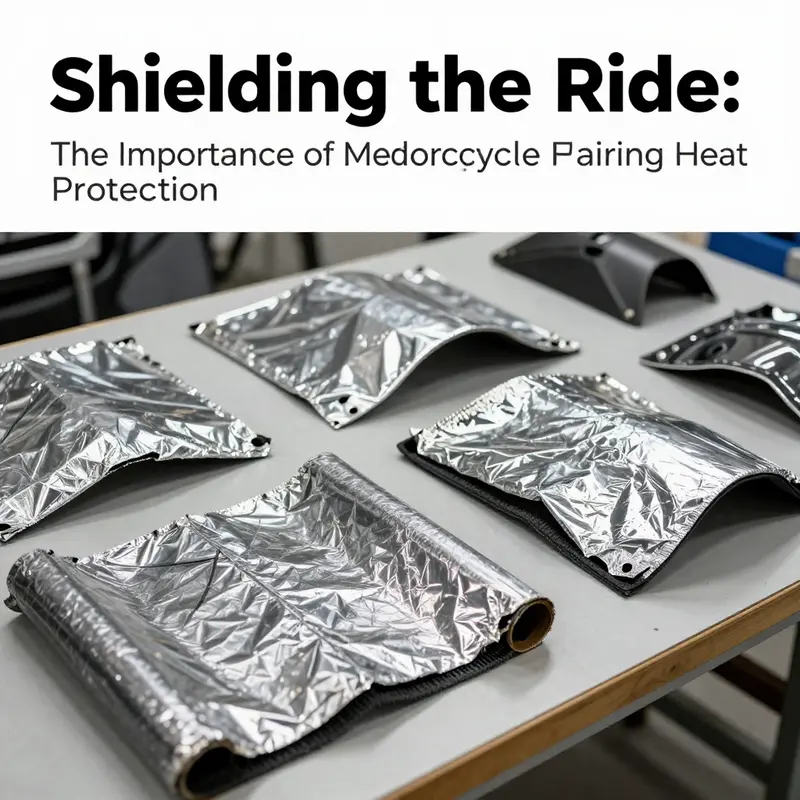

Another effective strategy involves the application of aluminum-backed aluminized self-adhesive heat shields. These materials are designed specifically for high-temperature applications, boasting a capacity to withstand temperatures exceeding 850°F. Designed with fiberglass-based thermal insulation, these heat shields are lightweight and can be easily applied to the inner surfaces of fairings, acting as a protective layer against radiating heat from critical engine components. The reflective nature of the aluminized surface helps minimize heat transfer, safeguarding not only the carbon fiber but also the sensitive electronic systems integrated within the fairing architecture.

Technological Applications Beyond Motorcycling

It’s worth noting that many of the thermal protection materials used in motorcycle fairings are not exclusive to the motorsport world. Similar technologies are extensively applied in sectors such as aerospace and automotive, where managing thermal loads is equally vital. This cross-industry practice underlines the efficacy of advanced thermal management technologies.

The principles at play in these applications involve the dual strategies of reflection and conduction resistance. While reflection involves preventing heat penetration through reflective materials, conduction resistance utilizes substances that hinder heat transfer capabilities. Together, these techniques ensure that absorbed heat is dissipated effectively, which is crucial for maintaining performance, especially during high-stakes riding scenarios where every degree of temperature control can enhance a rider’s experience.

For models such as the Honda CBR1000RR, the integration of high-performance heat shielding within carbon fiber fairings represents a harmonious balance between aesthetics and functionality. The half-fairing designs prevalent in sport-touring setups benefit immensely from these technologies, enhancing rider safety while optimizing aerodynamic performance. As heat management continues to be prioritized in motorcycle engineering, the role of innovative materials like carbon fiber coupled with advanced shielding will undoubtedly shape the future of motorcycle design.

As riders consider upgrades or replacements for their motorcycle fairings, options like those available on various online platforms can provide valuable resources. It is essential for enthusiasts seeking superior heat protection to explore compatible products such as aluminum-backed heat shields, guaranteeing sustained performance and safety in their riding endeavors. For more detailed specifications and product options, riders can explore the extensive range at Honda Fairings.

3. Enhancing Performance: How Aluminum-Backed Thermal Shields Revolutionize Motorcycle Heat Protection

In the world of motorcycling, where performance and efficiency intersect, the materials used in fairings play a pivotal role, particularly when it comes to managing heat. Aluminum-backed thermal shields have emerged as a standout solution, specifically crafted to address the challenges posed by excessive heat generated from high-performance engines and exhaust systems.

Aluminum-backed thermal shields not only serve to protect the structural integrity of fairings but excel in dissipating heat away from critical components, ultimately enhancing rider comfort and safety. The innovative fusion of lightweight composite materials with aluminum effectively increases the efficacy of heat dissipation while maintaining aerodynamic integrity. This combination is particularly critical in sport bikes and touring models, where engine temperatures can soar, risking not only the fairing itself but also the rider’s experience during long rides.

One of the most compelling advantages of aluminum-backed heat shields is their durability under extreme conditions. Unlike traditional ABS plastic fairings that can suffer from warping or deformation due to heat exposure, these aluminum-backed products maintain their shape and performance, even under the most strenuous riding conditions. This resilience not only safeguards the aesthetic appeal of the motorcycle but also ensures that functionality is preserved. In applications where heat management is non-negotiable, such as in competitive racing or long-distance touring, the robustness of aluminum-backed fairings becomes a crucial factor.

The ease of installation further adds to the appeal of these thermal solutions. Many aluminum-backed shields are designed with self-adhesive backing, facilitating quick application without the need for specialized tools or expertise. This feature is exceptionally beneficial for DIY motorcycle enthusiasts who wish to enhance their bikes without incurring high labor costs. It also empowers riders to take control of their motorcycle maintenance, allowing for periodic upgrades or repairs as needed.

Blending technological innovation with practicality, manufacturers have developed multi-layered thermal barriers that take advantage of reflective coatings and insulating materials beneath the aluminum layer. These designs not only maximize heat reflection but also reduce overall weight—an essential consideration in motorcycle performance. As the market evolves, there is a growing trend among manufacturers to implement these advanced thermal management systems, raising the bar for both safety and performance in modern motorcycles.

Furthermore, as riders begin to understand the vital role of heat management, the demand for high-quality aluminum-backed solutions continues to grow. Retailers and distributors now offer a wide range of options tailored for specific motorcycle makes and models, making it easier for riders to select a product that meets their unique thermal protection needs. For instance, platforms like eBay provide extensive listings of aftermarket heat shields and fairings, where enthusiasts can find high-quality aluminum-backed products designed for various models, ensuring that they obtain the right fit for their particular motorcycle type.

In summary, aluminum-backed thermal solutions represent an essential evolution in motorcycle heat protection technology. They enhance performance by dissipating heat effectively, ensuring safety, and prolonging the lifespan of fairings while remaining user-friendly through straightforward installation processes. For riders committed to optimizing their motorcycle’s performance, incorporating these innovations into their fairing solutions is a critical step toward achieving an optimal ride experience.

Chapter 2: The Role of Motorcycle Fairing Heat Protection in Performance and Safety

1. Maximizing Performance and Comfort: The Essential Role of Heat Shields in Motorcycle Fairings

Heat management is a critical concern for motorcycle enthusiasts, especially those operating high-performance or touring bikes. As engines rev up and power demands increase, the heat generated by the engine and exhaust systems becomes significant. In this context, motorcycle fairing heat protection serves a dual purpose: enhancing safety while simultaneously contributing to performance optimization. By implementing effective heat shielding within fairings, manufacturers ensure that riders not only endure less thermal stress but also experience improved ride quality and fuel efficiency.

The design of motorcycle fairings is oriented towards protecting the rider and vital components of the bike but also aims to improve aerodynamics. Poor aerodynamics can lead to increased air resistance, which consequently affects fuel efficiency and overall performance. Heat shields, through their function of isolating hot parts from the fairing, further complement these aerodynamic objectives. Utilizing materials like foil-coated fiberglass or aluminized thermal insulation, riders benefit from enhanced thermal protection that prevents the structural malformations of bodywork—preserving the aesthetic appeal and functionality of their motorcycles while maintaining optimal engine performance.

One of the less discussed but crucial aspects of heat shields is their ability to maintain an ideal operating temperature within the engine compartment. A cooler engine operates efficiently and yields better fuel economy. Heat shields act as barriers to mitigate the transfer of heat from engine components to the outer bodywork. This not only allows the engine to function within its optimal temperature range but also minimizes the risk of overheating, which is a considerable concern during long excursions or high-speed rides. By promoting a stable thermal environment, riders experience improved throttle response and efficient fuel combustion, translating directly into sharper performance and responsiveness on the road.

The psychological requirements for motorcycling comfort cannot be overlooked either. Riders facing undue heat buildup often suffer from fatigue more quickly, which can compromise safety as concentration wanes during extended rides. By employing heat shielding technology, motorcycle manufacturers and riders can ensure a more comfortable and pleasant riding experience. With effective thermal barriers in place, the risk of discomfort or heat-related distractions diminishes, allowing riders to focus on the thrilling experience of motorcycling rather than physical irritations caused by excessive heat.

Moreover, the enhanced aesthetics afforded by maintained fairing integrity cannot be overstated. Riders invest a great deal of time and monetary resources into customizing and maintaining their machines. Heat damage, such as warping or discoloration of fairings, could detract from a motorcycle’s appearance and overall value. Heat shields protect against such deterioration, ensuring the fairing maintains its visual appeal and enduring performance.

For those considering upgrades or replacements, a wide range of motorcycle fairing heat shields is accessible from various suppliers, providing an opportunity for riders to enhance both performance and safety. It’s essential, however, for riders to select heat shielding products that align with their specific motorcycle model and riding styles. Effective heat protection is not purely an aftermarket accessory; it is an integral part of motorcycle performance, ensuring that each ride is not only enjoyable but also safe.

In summary, the incorporation of heat shields within motorcycle fairings is not merely for protection against heat; it serves as a significant contributor to performance, efficiency, and rider comfort. As such, seeking quality motorcycle fairing heat protection is a crucial step for anyone aspiring to optimize their ride, contributing to a safer and more exhilarating experience on two wheels.

2. Preserving Rider Comfort: The Impact of Fairing Heat Protection on Safety and Performance

Motorcycle riding is often perceived as a thrilling escape, where the rush of wind and the sound of engines fuse into a symphony of freedom. However, this exhilaration is significantly influenced by the engineering that protects both the bike and the rider. One of the fundamental aspects of motorcycle design is the fairing, specifically how its heat protection properties play a vital role in ensuring safety and enhancing performance. As engines and exhaust systems generate substantial heat, motorcycle fairing heat protection becomes essential to prevent thermal damage that affects both the bike’s integrity and the rider’s comfort.

Fairings serve not only to enhance aerodynamics but also to shield riders from excessive heat. High-performance and touring motorcycles, in particular, generate considerable amounts of heat that can transfer to the fairing material. Without adequate thermal protection, riders could experience discomfort or, worse, heat stress, especially on long journeys where exposure to high temperatures accumulates. Prolonged contact with hot fairings can lead to fatigue, reduced concentration, and ultimately, compromised safety during high-speed maneuvers where focus is paramount.

The core function of a heat shield in motorcycle fairings is to act as a barrier against extreme temperatures. Using specialized materials, manufacturers implement effective heat shielding systems designed to withstand intense heat from engine components like exhaust manifolds and header pipes. A commonly employed solution is foil-coated fiberglass, with an adhesive backing that can endure temperatures up to 850°F (approximately 454°C). This material is easily installed on the inner surfaces of the fairing, creating an effective thermal barrier that prevents heat from permeating through.

Moreover, the integration of aluminized thermal insulation further enhances heat management. Often sold as adhesive-backed heat blankets, these materials are designed to reflect radiant heat, maintaining a cooler environment for both the bike’s components and the rider. The versatility of these solutions also sees them utilized in other applications, such as automotive or industrial setups, demonstrating their effectiveness across a spectrum of high-temperature scenarios.

For riders who prioritize performance alongside comfort, investing in quality heat protection is not merely a luxury; it is a necessity. Inadequate heat management can lead not only to thermal damage of the fairing but can also increase the risk of accidents prompted by rider discomfort or distraction. Through careful selection of materials and installation practices, riders can experience optimally operating motorcycles that keep heat at bay while enhancing safety through consistent rider focus.

The variety of aftermarket solutions available allows riders to customize heat protection that aligns with their specific motorcycle models and riding styles. Platforms that specialize in motorcycle fairings, such as e-commerce sites, offer extensive selections tailored to various brands and models, ensuring that every rider can find a product that suits their needs. Choosing appropriate heat shields such as those compatible with models like the Honda CBR1000RR or the Yamaha YZF-R1 is crucial.

In conclusion, motorcycle fairing heat protection goes beyond just safeguarding the motorcycle itself; it plays a pivotal role in promoting rider safety and performance. By mitigating the risks associated with heat stress and ensuring the integrity of fairing materials, effective thermal management systems create a harmonious balance between comfort and performance on every ride.

3. Optimizing Thermal Comfort: The Integration of Heat Protection for Endurance Riding

The quest for comfort in motorcycling is intrinsically linked to thermal regulation, an aspect that is gaining traction in the design and functionality of motorcycle fairings. A pivotal yet often overlooked consideration is how fairing heat protection contributes to a stable and enjoyable riding environment, particularly during long journeys. As motorcycle enthusiasts know, the balance between performance and comfort can dramatically affect the quality of an experience on two wheels.

Motorcycle fairings primarily serve to enhance aerodynamics and provide wind protection, yet their potential for managing heat demonstrates their multifaceted role. High-performance models and touring motorcycles, which often house powerful engines and advanced exhaust systems, generate significant heat. The heat emanating from these components can infiltrate the cockpit, leading to discomfort and fatigue for the rider. This is where thermal management strategies become critical.

Among modern advancements, fairings constructed from high-end composite materials are particularly effective in minimizing heat exposure. Many of these materials, designed not only for durability but also for thermal efficiency, can include built-in insulation or reflective properties that effectively reduce the heat transfer into the rider’s zone. Such integration of materials allows for a more controlled environment within the fairing, significantly enhancing comfort levels for the rider, especially during extended trips. Riders may experience a decreased thermal load, allowing for better focus and endurance on long hauls.

Passive cooling mechanisms are pivotal in modern fairing designs. Reflective coatings and insulating layers offer protection against external temperatures, while vented fairings actively channel airflow around critical hot spots. This not only cools the engine compartment but also helps maintain an optimal temperature within the rider’s cabin. Such innovations exemplify the movement towards a holistic approach in motorcycle engineering, whereby comfort, safety, and performance coalesce.

A comprehensive study published in the Journal of Thermal Science and Engineering Applications (2024) reveals an astonishing correlation between effective fairing heat protection and rider performance. It suggests that with appropriate heat shielding, the perceived ambient temperature around the rider can be reduced by as much as 5°C in high-temperature conditions. This reduction plays a direct and substantial role in maintaining mental acuity, essential for riding safety and performance. Consequently, riders equipped with motorcycles featuring such thermal regulation mechanisms are likely to experience reduced fatigue, thereby decreasing the likelihood of decision-making errors on the road.

Moreover, the role of heat management in rider fatigue cannot be overstated. Prolonged exposure to excessive heat can lead to dehydration and increased heart rates, factors that impair focus and reaction times. Therefore, integrating effective heat protection into the fairing design emerges as not just a luxury, but a necessity for those longer journeys where safety is paramount.

For riders looking to enhance their motorcycle fairings, a diverse array of heat shields is available in the market, with many options compatible with various models. Notably, platforms such as Summit Fairings offer a vast selection of heat-resistant materials tailored to different motorcycle brands. It’s imperative to choose the right product that aligns with one’s specific thermal challenges and riding conditions. By prioritizing thermal comfort and adopting cutting-edge fairing technologies, riders are not just investing in their bike’s performance but also in their own safety and enjoyment on the road.

Chapter 3: Evaluating Financial Implications of Motorcycle Fairing Heat Protection

1. Balancing Initial Investments with Long-Term Value in Motorcycle Fairing Heat Shields

Investing in motorcycle fairing heat protection solutions entails a multifaceted analysis of initial costs versus long-term benefits. At first glance, the price of high-quality heat shields, such as the widely used pre-cut foil-coated fiberglass models with adhesive backing averaging around $9.95 each, may seem minimal compared to the potential costs associated with damage to fairings from heat exposure. However, a deeper evaluation reveals that the economic advantages extend far beyond the initial purchase price, making these products a financially prudent choice for motorcycle enthusiasts and regular riders alike.

The core function of these heat shields is to protect the motorcycle fairings from thermal damage inflicted by hot engine components. Given that high-performance and touring motorcycles generate substantial heat during operation, ensuring the integrity of the bodywork is crucial. Prolonged exposure to extreme temperatures can warp, discolor, or fracture the fairing material—damage that may necessitate costly repairs or complete replacements. The relatively low initial investment in heat shielding materials serves as a critical safety measure and proactive maintenance strategy.

These heat shields are engineered to endure temperatures up to 850°F (approximately 454°C), which means they effectively minimize thermal degradation. Beyond physical protection, using heat barriers allows for better temperature regulation within the motorcycle’s body and engine compartments. This can lead to reduced rider fatigue on long rides, as it helps maintain a more comfortable and safer riding experience. The importance of comfort cannot be overlooked since it can influence riding duration and enhance overall enjoyment, further underscoring the value of investing in effective heat protection.

From an economic perspective, the long-term savings associated with heat shields are substantial. By preventing damage resulting from high temperatures, riders can significantly lower maintenance costs over the lifespan of their motorcycle. The durability of these protective films directly correlates to the extended lifespan of the motorcycle’s fairings, which translates into fewer repairs and replacements. For budget-conscious riders, this represents a worthwhile investment.

Moreover, choosing a heat shield that fits the specific thermal dynamics of various motorcycle models ensures optimized performance. Riders often find that platforms such as eBay offer various options tailored to their motorcycle’s make and model, presenting an opportunity to secure a product that meets their thermal management needs without compromising on price or effectiveness. When searching for heat shielding options, it’s essential to consider the product specifications to ensure compatibility with your motorcycle’s requirements.

In essence, while the upfront costs of motorcycle fairing heat protection solutions may appear modest, the broader financial implications are compelling. The decision to install heat shields is not merely an expense but rather an investment in longevity and reliability. By safeguarding vital components from the ravages of heat, riders can enhance the performance and aesthetic appeal of their motorcycles, paving the way for enjoyable rides that stand the test of time. This consideration makes it clear that prioritizing heat protection is not just about immediate costs; it’s about securing significant long-term value.

For more information on specific motorcycle models and heat protection options, check out the extensive selection available at Summit Fairings, offering tailored solutions for various motorcycle makes and models.

2. The Cost-Effectiveness of High-Performance Materials in Motorcycle Fairing Heat Protection Solutions

In the realm of motorcycle fairing heat protection, the quality of materials used plays a pivotal role not just in thermal performance but also in the overall economic viability of long-term maintenance and ownership costs. For riders, especially those who rely on high-performance or touring motorcycles, the battle against engine-generated heat is one that can significantly impact finances over time. The choice between premium heat protection solutions, such as fiberglass or aluminum-backed materials, versus lower-grade options presents crucial financial implications.

High-quality materials like foil-coated fiberglass and aluminized thermal insulation are designed to withstand extreme temperatures, often upwards of 850°F (454°C). These superior materials are not just about withstanding heat but are also engineered to enhance the lifespan of motorcycle fairings. When properly installed, these materials function as effective thermal barriers, preventing harmful heat transfer to the fairing bodywork. Consequently, this reduces the risk of warping, discoloration, and potential structural degradation that low-grade options may yield under continuous exposure to high temperatures.

The financial ramifications are evident when we consider the lifecycle of motorcycle fairing heat protection. A high-performance heat shield may demand a higher initial investment; however, riders often find that the durability of these materials justifies the cost. Regular replacement of lower-quality heat shields can rapidly escalate maintenance expenses, creating a cycle of ongoing spending that nickel-and-dimes the motorcycle owner. For touring riders, whose machines are subjected to prolonged heat from engine and exhaust systems, investing in robust heat shields not only avoids frequent repairs but also enhances comfort during long journeys by minimizing excessive cabin heat.

Consider the case of a touring motorcycle owner who opts for a quality protective foil designed to insulate plastic fairings and luggage. Initially priced higher, this product can save the owner from costly repairs due to heat-induced failures that low-quality shields simply could not endure. Anecdotal evidence suggests that popular premium heat protection products can sell over 100 units per month, illustrating a market trend where riders value the investment in quality. This willingness highlights an understanding that, in many cases, durability translates to a better economic decision over time.

The economic analysis of motorcycle fairing heat protection solutions extends beyond mere upfront costs. It encompasses considerations of frequency of replacements, reductions in repair costs, and the overall longevity of motorcycle components. Premium materials contribute not only to enhanced thermal resistance but to favorable maintenance cycles that keep motorcycle ownership more sustainable.

Additionally, as motorcycle technology evolves, so does the need for effective heat management strategies. Riders are increasingly aware that the integration of quality heat shields can maintain optimal operating temperatures within engine compartments. Without adequate shielding, overheating can lead to not just deterioration in aesthetic appeal but structural weaknesses that compromise safety. Thus, choosing the right materials for heat protection should be viewed not solely through the lens of initial expenditure but rather as a cornerstone of responsible motorcycle maintenance.

In conclusion, while the allure of lower-cost heat protection solutions is apparent, the initial savings may be misleading when considering the total economic impact over time. Prioritizing quality in heat shielding for motorcycle fairings is not just an investment; it is a crucial component of preserving the integrity of a motorcycle’s performance and value. For those looking to enhance their fairing longevity, exploring options such as motorcycle fairings from trusted sources can reinforce this economic strategy with invaluable benefits.

3. Emerging Trends in Materials and Market Demand for Motorcycle Fairing Heat Shields

The rapid evolution of the motorcycle fairing heat protection market is a fascinating testament to changing rider expectations and technological advancements in materials science. One of the most prominent trends emerging in this sector is the increased demand for advanced heat shield materials that offer both efficiency and sustainability. Riders across the globe are increasingly looking for solutions that enhance comfort and protect their motorcycles from thermal damage, particularly with the rise of high-performance and touring motorcycles where heat management is paramount.

Manufacturers are responding to this demand by integrating innovative materials, such as ceramic coatings and advanced composite polymers, into their heat shield designs. These materials are not only lightweight but also exhibit superior thermal resistance and heat dissipation capabilities. For instance, ceramic coatings can provide a robust barrier against extreme heat, helping to maintain optimal engine temperatures while ensuring the integrity of sensitive electronic components. Additionally, the use of composite polymers is gaining traction due to their durability and resistance to thermal degradation, thereby enhancing the longevity of motorcycle fairings.

Furthermore, recent market analysis indicates that the global motorcycle pipes heat shield sector is on a trajectory of substantial growth. Innovations in modular designs are particularly noteworthy, as they allow for easier installation and maintenance, addressing a long-standing challenge for both manufacturers and consumers. By simplifying the installation process, these modular heat shields help reduce long-term operational costs and improve product reliability. Imbued with user-friendliness, they not only encourage consumers to invest in high-quality products but also enhance the aftermarket repair and upgrade market, particularly for models like the Honda CBR1000RR and Yamaha YZF-R1.

From an economic perspective, these advancements stimulate competitive dynamics within the industry. As riders prioritize safety and comfort, manufacturers are ramping up investments in research and development, directly influencing the pricing of premium heat protection solutions. The race for higher-value products enables manufacturers to create jobs in engineering and materials science, while simultaneously boosting the growth of ancillary industries such as automotive electronics and protective gear.

Additionally, the increasing emphasis on sustainable practices is prompting the adoption of eco-friendly and recyclable materials in heat shields. This aligns with broader global sustainability goals and positions manufacturers to potentially benefit from government incentives or tax benefits. As environmental consciousness continues to rise, products that embrace sustainability will likely gain a competitive edge in terms of market appeal and consumer preference.

The evolving landscape of motorcycle fairing heat protection illustrates a clear link between technology, consumer demands, and economic implications. As manufacturers continue to innovate, the market is expected to witness a shift towards higher-quality, more effective heat management solutions that contribute overall to both performance and rider satisfaction. For riders eager to explore upgrades for their current setups, various platforms showcase a range of motorcycle fairing heat shields from top brands, ensuring a wealth of options tailored to specific needs and riding conditions.

In conclusion, the momentum generated by emerging materials and the shifting demands of the riding community reflects a dynamic interplay of technology and economy. For those interested in staying ahead in understanding the market intricacies, a detailed report offers insights into current trends and future projections, paving the way for informed decision-making in motorcycle fairing heat protection solutions.

Chapter 4: Harnessing Heat Resistance: A Deep Dive into ABS Plastic Heat Insulation Solutions for Motorcycle Fairings

1. Optimizing Motorcycle Fairings with Self-Adhesive ABS Plastic Insulation Pads for Heat Protection

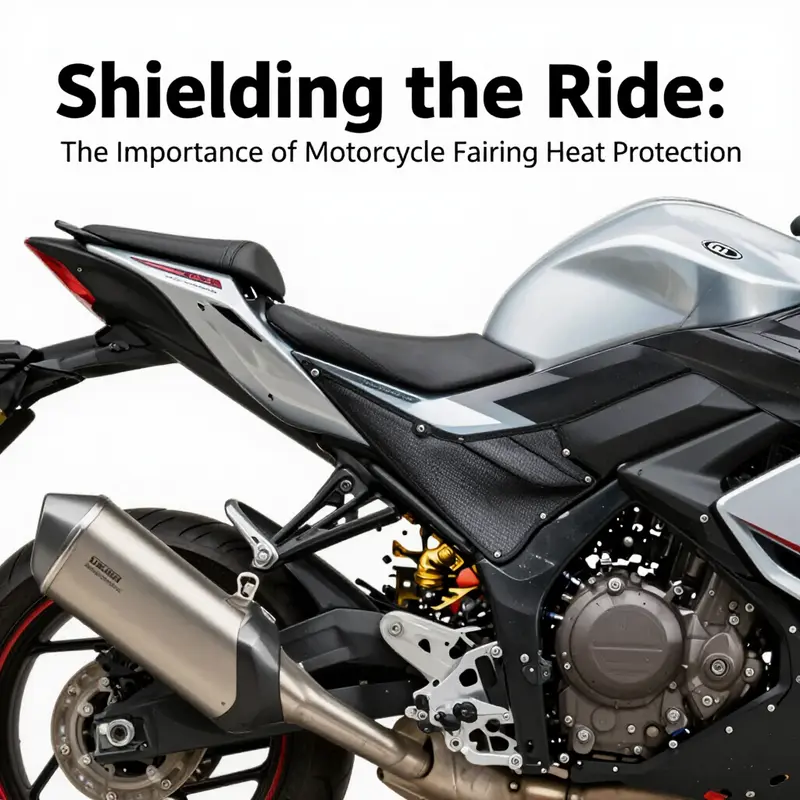

Motorcycles, particularly high-performance and touring models, generate substantial amounts of heat during operation, primarily from the engine and exhaust systems. This heat can have detrimental effects on motorcycle fairings, especially those made from ABS plastic or composite materials. As riders seek solutions to shield their fairings from thermal damage, self-adhesive ABS plastic insulation pads have emerged as a reliable choice. These pads are designed to withstand the intense temperatures caused by close proximity to hot engine components like exhaust manifolds and header pipes, protecting the bodywork from melting, warping, or discoloration.

What sets these insulation pads apart is their professional-grade, 5mm thick ABS plastic composition, known for exceptional thermal resistance and durability. This thickness serves a critical role in effective heat dissipation, functioning as a robust thermal barrier. For example, the pre-cut designs available for popular motorcycle models such as the Suzuki Hayabusa (1999–2020), Honda CBR1000RR (2004–2005), and Kawasaki Ninja ZX6R (2000) ensure that users can enjoy not only ease of installation but also a tailored fit tailored specifically to their motorcycles’ geometries. By minimizing installation time and reducing the likelihood of improper placement, these pre-cut designs enhance the overall efficacy of the protection being employed.

The major advantage of self-adhesive ABS insulation pads is their tool-free installation. Designed with a self-adhesive backing, they can be applied directly to the fairing surface, making them highly accessible for both do-it-yourself enthusiasts and professional mechanics alike. This ease of use allows riders to invest more time in enjoying their motorcycles rather than worrying about complex installation processes. Moreover, brands promoting these pads emphasize their dual functionality—not only do they provide thermal insulation, but they also act as acoustic barriers. By minimizing engine noise transmission into the cockpit, these pads can significantly enhance the riding experience, particularly for long-distance travelers who depend on comfort during extended rides.

Consumer feedback consistently highlights the superior protection offered by these insulation pads against thermal degradation. Riders report successful experiences in preventing distortion and melting of their fairings, as well as shielding paint finishes from the intense heat produced during operation. This additional layer of protection not only safeguards the aesthetics of the motorcycle but also contributes to deeper financial savings by preventing costly repairs or replacements down the line.

Market confidence in self-adhesive ABS plastic insulation pads is further reflected in the terms offered by suppliers, such as free shipping and flexible return policies. These assurances enhance customer trust, confirming the reliability and performance of the products being sold. As motorcycle fairing protection becomes increasingly necessary, the role of these pads in preserving both aesthetics and structural integrity has been firmly established.

In conclusion, self-adhesive ABS plastic insulation pads represent an efficient and effective way for motorcycle enthusiasts to safeguard their fairings from thermal damage. With their robust material, precise fit, and ease of application, they are an ideal choice for riders looking to maintain their motorcycles in optimal condition. For a closer look at a comprehensive collection of motorcycle fairings, including those compatible with popular models, you can explore options available here.

2. Reflective Aluminum Heat Shields: Revolutionizing Motorcycle Fairing Protection

Reflective aluminum heat shields have become a cornerstone of motorcycle fairing protection, particularly in high-performance models where the engine and exhaust systems generate substantial heat. These innovative shields utilize the unique properties of aluminum—its high reflectivity and impressive thermal conductivity—to efficiently deflect radiant heat away from the fairing, ensuring that the motorcycle’s bodywork remains intact and visually appealing. By preventing heat accumulation on sensitive plastics and composites, these shields address a critical concern for riders who want to preserve both the aesthetic and structural integrity of their motorcycles.

Unlike traditional insulating materials that function by absorbing heat, reflective aluminum shields operate through thermal reflection. This method allows them to keep surface temperatures lower, which is vital in high-stakes riding environments. For example, motorcycles like the Suzuki Hayabusa or GSX1300R, known for their robust power and propensity to produce considerable heat, greatly benefit from this technology. The reflective action of the aluminum creates a barrier that minimizes heat transfer, thus prolonging the life of the fairing material and preventing issues like warping or discoloration that can arise from excessive heat exposure.

A commonly favored product in this category is the Aluminum Reflective Heat Shield Sheet, which stands out for its customizable nature. Riders appreciate its lightweight composition, durability, and ease of installation; it can be tailored to fit specific motorbike shapes and mounting needs. The application process is straightforward, as the shield can be affixed via adhesive backing or mechanical fasteners, offering flexibility to both original equipment and aftermarket installations. For those looking for enhanced longevity without sacrificing performance, these shields serve as both a reliable protection method and a cost-effective upgrade.

Moreover, for riders interested in a more integrated solution, several manufacturers provide pre-cut professional-grade heat shield pads made from self-adhesive ABS plastic. While these pads are tailored for specific models like the Suzuki Hayabusa (1999–2007), they typically offer less efficacy at managing extreme radiant heat compared to their aluminum counterparts. This distinction is crucial because, in environments with consistent high heat—such as during extended highway rides or under aggressive acceleration—reflective aluminum shines in its performance. Riders must consider the thermal environment and specific requirements of their motorcycles when evaluating heat protection options, balancing the benefits of warmth mitigation and fairing longevity.

In essence, reflective aluminum heat shields are an excellent choice for anyone seeking effective heat protection for motorcycle fairings. They prove particularly valuable for touring bikes, high-performance cruisers, and long-distance travel enthusiasts who find themselves often exposed to high temperatures. By strategically mitigating thermal stress, these shields uphold not only the visual allure of the motorcycle’s bodywork but also its functional resilience over time. As motorcycle enthusiasts continue to seek out ways to enhance their riding experience, integrating such advanced heat protection methods remains an essential consideration that informs both safety and performance.

For those exploring options for enhancing their motorcycle fairing heat protection, resources are readily available, making it easy to track down the products that fit their needs best. One excellent platform to discover a variety of fairing components is Honda Fairings Catalog, which provides access to an extensive selection of compatible motorcycle fairings and heat shields.

3. Harnessing Heat: An In-Depth Look at Consumer Preferences and Trends in Motorcycle Fairing Heat Protection Products

The landscape of motorcycle fairing heat protection products has rapidly evolved, reflecting not just the technical advancements in material science but also the shifting preferences of consumers towards more reliable and efficient solutions. As the comfort and performance demands of riders intensify, these protective innovations have become imperative, particularly in the niche market of high-performance and touring motorcycles. This demand is underscored by the notable rise observed in the motorcycle heat protection accessories market, projected to experience a remarkable growth rate of about 12% year-on-year through 2026. This surge arises from rider demands, especially from enthusiasts using models known for generating high heat levels, such as the Kawasaki Ninja and Suzuki Hayabusa, which are designed with sophisticated fairing systems that are susceptible to thermal extremes.

Recent industry reports highlight a clear trajectory in consumer preferences that emphasizes high-strength materials and factory-specific designs. Consumers increasingly prioritize products crafted from advanced materials such as high-strength ABS plastic or flame-resistant composites, which not only exhibit superior heat resistance—capable of withstanding temperatures above 200°C—but also provide significant impact resistance. Approximately 78% of motorcycle riders favor these materials over traditional rubber or foam, which are often viewed as inadequate due to their reduced durability and ability to degrade with time. This shift underscores a fundamental change in consumer priorities, where functionality and longevity take precedence over merely aesthetic considerations.

Moreover, the demand for custom-fit solutions is prevalent among riders. Products designed for specific motorcycle models are more appealing since they eliminate the guesswork involved in fitting generic products, allowing for a seamless installation. Evidence shows that the repurchase rate for model-specific heat insulation kits is nearly 40% higher than for universal options, reflecting the growing expectation for convenience and reliability. The industry is responding to this trend with products tailored for specific models, like those for the Yamaha YBR125 or Harley-Davidson Electric Glide series, ensuring that riders receive optimal fitment without additional alterations.

Another rising trend is the integration of multifunctional features into heat protection products. Today’s consumers are not just seeking heat shields; they desire comprehensive solutions that also dampen vibrations and resist abrasions. Innovations, including heat insulation pads equipped with abrasion-resistant sliders and vibration-dampening layers, are gaining traction as they fulfill multiple roles while protecting vital areas of the motorcycle’s fairing. Remarkably, about 65% of newly released high-end products feature these integrated designs, signaling a broader industry trend towards comprehensive protective solutions.

The importance of brand reputation and safety certification in consumer decision-making cannot be overstated. Products endorsed by trusted organizations, such as the American Motorcycle Association or those that comply with international safety standards like ISO 9001, significantly influence purchase behaviors. Certified products boast conversion rates over three times higher on e-commerce platforms than their uncertified counterparts, demonstrating that consumers are willing to invest in quality backed by reliable assurances.

This evolving market, driven by increasing demands for precision, performance, and multifunctionality, will inevitably continue to influence the nature of motorcycle fairing heat protection products. As the industry embraces innovations such as smart materials and modular designs, riders can look forward to solutions that offer not just protection, but also value-added benefits that enhance their overall riding experience. For those exploring options, platforms such as Summit Fairings remain valuable resources, featuring a range of products that underscore these evolving consumer trends.

Chapter 5: Innovations in Motorcycle Fairing Heat Protection Engineering

1. Harnessing Adaptive Technologies for Next-Gen Heat Management in Motorcycle Fairings

The evolution of heat protection in motorcycle fairings is on the brink of a technological renaissance, driven by the integration of adaptive technologies that promise to revolutionize thermal management practices. Traditional heat shields have relied on static materials, unable to adapt to real-time changes in temperature or riding conditions. However, with the advent of smart materials and responsive systems, the future landscape hints at an enhanced level of heat control that not only protects the fairing but also enriches the overall riding experience.

Emerging Adaptive Solutions

Among the most fascinating innovations shaping this future are Phase-Change Materials (PCMs). These advanced substances are capable of absorbing excess heat during high-speed rides—when temperatures can spike significantly—and releasing it gradually as the motorcycle slows down. This mechanism ensures that the fairing maintains an optimal temperature, reducing the risk of warping or thermal degradation that can occur due to inconsistent heat exposure.

Similarly, Shape-Memory Alloys are gaining attention in the realm of motorcycle fairing heat management. These materials react to temperature fluctuations by undergoing reversible changes in shape, allowing for adaptive heat regulation. Such adaptability not only ensures better heat dissipation but also extends the durability of components integrated within the fairings.

Smart Thermal Management Systems

Another key component in this adaptive framework is the integration of sensor networks that can monitor temperatures around the engine components in real-time. These systems are equipped to detect temperature spikes and can trigger cooling mechanisms—such as micro-fans or fluid circulation systems—precisely when their activation is necessary. This energy-efficient approach minimizes unnecessary power usage and contributes to the motorcycle’s overall performance. By constantly adapting to external conditions, these intelligent systems contribute not only to rider comfort but also to the longevity of sensitive electronic components installed within the fairing.

Digital Design Innovations

Underlying these developments is a significant trend toward the use of advanced digital design tools, such as Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE) software. These tools facilitate the simulation of thermal flows and structural stresses, enabling engineers to craft fairings with embedded heat-dissipating channels and strategically placed thermal barriers. This innovative approach is crucial for modern electric motorcycles, which experience considerable heat generation due to densely packed battery packs and power electronics. Lightweight composite materials, like carbon fiber-reinforced polymers with enhanced thermal conductivity, can be utilized to create efficient fairings that do not compromise on aerodynamics or weight.

The Road Ahead

As the motorcycle industry continues to evolve, the importance of effective heat protection engineering cannot be overstated. The trajectory towards adaptive technologies signifies a bright future in motorcycle design, wherein thermal management is not a mere afterthought but a highly prioritized aspect of engineering. The successful implementation of these technologies promises not only to improve rider comfort during lengthy rides but also to ensure that motorcycles remain reliable and safe. For those interested in upgrading their fairings or finding compatible heat shields, platforms like eBay offer an expansive range of options tailored specifically for various motorcycle models, bridging the gap between innovative technology and rider needs effectively.

The exploration of heat protection methods will play a pivotal role in shaping the motorcycles of tomorrow, particularly as more designs integrate electric powertrains. These advancements resonate with a broader goal: to provide riders with machines that guarantee peak performance while ensuring safety and comfort on every ride. The integration of these adaptive technologies will redefine what we expect from motorcycle fairing heat protection, paving the way for an exciting chapter in the realm of motorcycling.

2. Revolutionary Materials: The Future of Heat Protection Engineering in Motorcycle Fairings

The landscape of motorcycle fairing heat protection is undergoing a substantial transformation, driven by groundbreaking advancements in material science. As manufacturers and riders alike seek solutions that optimize thermal management while minimizing weight and environmental impact, several innovative materials are emerging at the forefront of motorcycle engineering. Understanding these developments is critical for both performance enthusiasts and daily riders who depend on the durability and safety of their machines.

One of the most significant innovations dominating the heat protection sector is the utilization of advanced composite materials. The introduction of Ceramic Matrix Composites (CMCs) exemplifies this shift. CMCs boast exceptional heat resistance and offer superior durability compared to conventional metals such as aluminum or steel. These advanced composites can withstand the extreme temperatures generated by motorcycle exhaust systems without compromising structural integrity, thus protecting sensitive components from thermal damage. This level of resilience not only ensures longer-lasting fairings but also significantly enhances rider comfort by maintaining an optimal thermal environment around the engine compartment.

Moreover, high-performance polymer-based coatings are gaining traction within the industry. These innovative coatings not only provide a robust heat shield but also contribute to lightweighting efforts—an essential criterion in modern motorcycle design. As enthusiasts seek performance advantages, these polymers help to improve fuel efficiency across both internal combustion engines and the rapidly growing segment of electric motorcycles.

In parallel, the introduction of nano-insulating materials has revolutionized heat management. Innovations such as aerogels and graphene-enhanced polymers exhibit remarkable thermal insulation properties while being lightweight. Their increasing adoption in the motorcycle industry aligns with the broader trend of minimizing weight to maximize efficiency. This is particularly crucial in electric motorcycles, where effective heat management of the battery packs becomes paramount in ensuring optimal performance and safety. Thus, the lightweight nature of these materials not only caters to performance standards but also serves as a strategic advantage in extending the range of electric bikes.

Perhaps one of the most exciting developments is in smart heat-shielding technologies. Utilizing Phase-Change Materials (PCMs) and thermally responsive coatings represents a significant leap forward. PCMs have the capability to absorb excess heat during operation and gradually release it when temperatures cool, creating a stable thermal environment. This adaptability is vital in maintaining engine performance and preventing overheating in critical components. Likewise, thermochromic or adaptive coatings that change their reflectivity based on temperature create a dynamic insulating barrier. Such intelligent materials are set to enhance safety levels significantly while prolonging the life of fairing components that might otherwise suffer from thermal stress.

The emphasis on sustainability is another critical aspect of these material advancements. With growing environmental awareness, the motorcycle industry is exploring bio-based resins and recycled composites as viable alternatives to conventional materials. This focus not only addresses environmental concerns but also supports a transformative approach to manufacturing that aligns with future regulatory standards and consumer preferences.

These innovations are paving the way for a more sustainable and high-performing motorcycle fairing industry. As the global motorcycle market evolves, particularly with the rise of electric two-wheelers, the integration of these advanced materials is not just beneficial but essential. Enhanced thermal management will be key to ensuring the reliability and safety of next-generation motorcycles, making it imperative for riders to stay informed about these material developments.

For those considering upgrades or replacements for motorcycle fairings, numerous options are available. From the advanced ceramic applications to cutting-edge lightweight polymers, selecting the right materials is critical. Explore options suited to various models, such as Honda fairings, where the latest innovations in heat protection can be readily found.

3. Harnessing Smart Materials and Connectivity for Enhanced Heat Protection in Motorcycle Fairings

The motorcycle industry stands on the brink of a technological revolution, particularly in the area of heat protection engineering for fairings. As motorcycle designs evolve towards high-performance and electric models, the challenge of effective thermal management becomes increasingly critical. The old methods of passive heat shielding are swiftly being overshadowed by innovative intelligent systems that not only combat heat but also enhance overall riding experience.

At the core of these advancements is the integration of smart materials and connectivity. Innovations such as thermally responsive polymers and phase-change materials (PCMs) are being embedded within the fairing structures themselves. These materials are capable of absorbing excess heat during strenuous riding conditions and gradually releasing it when the bike is idle. This self-regulating mechanism prevents the localized overheating that could lead to warping or structural damage, ensuring the longevity of both the fairings and the underlying components.

Moreover, the shift toward real-time thermal management brings the concept of IoT-enabled sensors to the forefront. Equipped with the ability to monitor temperature fluctuations, these sensors provide data critical for predictive maintenance. If a thermal anomaly is detected, the system can trigger immediate adaptive responses, such as activating cooling mechanisms or adjusting operational parameters to preserve performance integrity. This not only augments rider safety but also extends the life cycle of motorcycle components, reducing the likelihood of costly repairs or replacements.

The fusion of digital intelligence with advanced material science opens avenues for novel applications in motorcycle fairings. For instance, manufacturers are now exploring carbon fiber composites that incorporate integrated heating elements and cooling channels. This combination not only optimizes thermal efficiency but aligns with the increasingly stringent energy requirements of electric motorcycles, where battery performance is paramount. By employing algorithms that analyze data from onboard sensors—capturing factors like ambient temperature, engine load, and rider velocity—these advanced systems can precisely control heat dissipation, ensuring that the heat produced by high-performance engines or batteries is effectively managed.

Another exciting concept emerging in this domain is the potential for intelligent transport systems (ITS). Future motorcycle fairings might be embedded with communication devices that share thermal and operational data with other vehicles and infrastructure. This networked approach can foster coordinated thermal management strategies that respond not only to the bike’s immediate thermal condition but also to broader environmental factors, enhancing both safety and energy efficiency across the board.

In summary, the future of heat protection for motorcycle fairings is set to become more agile and responsive than ever before. As the industry continues to embrace smart technologies, riders can look forward to enhanced safety, improved component durability, and a dramatically more efficient riding experience. For those interested in upgrading to the latest fairing technology designed to handle these modern demands, resources are readily available, making customization more accessible than ever. Check out the variety of selections for brands like Honda and Yamaha, ensuring that your motorcycle not only performs well but stays protected against the rigors of thermal stress. Products such as foil-coated fiberglass and aluminized thermal insulation materials can be found to suit any specific model, meeting the evolving needs of today’s riders.

Final thoughts

Investment in motorcycle fairing heat protection is not merely an enhancement of safety and performance; it is an essential consideration for manufacturers and riders alike. By embracing advanced materials and tailor-made solutions, businesses can not only protect their products but also improve rider satisfaction and safety. As the landscape of heat protection technologies evolves, staying informed can ensure that businesses remain competitive in the motorcycle industry, helping them to meet the demands of modern riders looking for both safety and performance.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

We are one of the leading motorcycle fairing export sites, with over 3,000 styles across almost all motorcycle models. Buy from summitfairings.com, and pay 10-40% less than the prices on other sites. If you have any questions, we promise we will have your answer within six hours.