Introduction

Motorcycle fairing heat shields play a vital role in enhancing rider safety and preserving vehicle integrity by managing the high temperatures generated by engines and exhaust systems. For business owners in the motorcycle industry, understanding the nuances of heat shield design, model-specific fitment, and aftermarket innovations can translate into better product offerings and satisfied customers. Delving into design and material considerations reveals how these components balance thermal protection with durability. Exploring model-specific integration highlights the importance of precise compatibility and efficient heat dissipation tailored to each bike’s structure. Lastly, a look at aftermarket developments uncovers new materials and styling options that expand business opportunities through customization and enhanced safety features.

Tables of Contents

Chapter 1: Design and Material Considerations of Motorcycle Fairing Heat Shields

- Optimizing Material Choices for Superior Thermal Resistance in Motorcycle Fairing Heat Shields

- Precision Manufacturing: Shaping Materials into Effective Motorcycle Fairing Heat Shields

- Optimizing Strength and Weight: Material Choices in Motorcycle Fairing Heat Shield Design

- Advanced Heat-Shield Materials and Aerodynamic Synergy for Optimized Motorcycle Fairing Performance

Chapter 2: Model-Specific Integration of Motorcycle Fairing Heat Shields

- Precision Engineering and Thermal Dynamics in Tailored Motorcycle Fairing Heat Shields

- Economic Impact and Market Dynamics of Model-Specific Heat Shield Integration

- Global Market Forces and Regulatory Complexities Shaping Model-Specific Heat Shield Solutions

- Enhancing Rider Comfort and Safety through Tailored Heat Shield Integration

Chapter 3: Aftermarket Innovations and Applications of Motorcycle Fairing Heat Shields

- Cutting-Edge Materials and Smart Thermal Solutions in Aftermarket Motorcycle Heat Shields

- Emerging Market Dynamics and Economic Influence of Aftermarket Motorcycle Fairing Heat Shields

- Navigating Geopolitical Currents: How Global Forces Shape Aftermarket Fairing Heat Shield Supply Chains

- Balancing Rider Safety, Environmental Impact, and Cultural Values in Aftermarket Heat Shield Advancements

Chapter 1: Design and Material Considerations of Motorcycle Fairing Heat Shields

1. Optimizing Material Choices for Superior Thermal Resistance in Motorcycle Fairing Heat Shields

Selecting the right materials for motorcycle fairing heat shields demands a delicate balance between thermal resistance, durability, and flexibility. High-quality ABS plastic remains the predominant choice due to its excellent heat tolerance, remarkable elasticity, and resistance to cracking under thermal stress. These features help the fairing shield endure repeated exposure to engine and exhaust heat while absorbing vibrations and impacts from road use without compromising structural integrity.

ABS plastic’s heat endurance suffices for moderate temperature zones near the engine and exhaust, where it maintains its form and protective qualities without deforming or brittle failure. To enhance thermal resistance further, manufacturers commonly apply specialized heat-shield coatings or incorporate multi-layered constructions that reflect and dissipate radiant heat away from both the rider and sensitive inner components. This layered approach not only improves insulation but also manages weight considerations, ensuring the shield does not add excessive bulk that could affect motorcycle handling or aesthetics.

For premium applications, carbon fiber enters the equation as a lightweight, high-strength alternative offering superior heat resistance and rigidity. Its integration often appears in custom or performance-oriented fairings, where advanced material properties contribute both functionally and visually. Carbon fiber shields adeptly deflect intense heat while reinforcing the fairing’s structural framework, though their higher cost and manufacturing complexity limit widespread usage compared to ABS.

Material thickness and layering become vital parameters, as too thin a shield may fail to protect sufficiently, whereas overly thick shields add unnecessary weight. Impact resistance and durability are also factored in to prevent damage from debris or minor collisions. Injection molding is favored for producing ABS shields, enabling precise OEM-level fitment and repeatability, which ensures seamless integration with the motorcycle’s original design.

Models like the Yamaha YZF600 R6 and Suzuki Hayabusa highlight the practical application of ABS fairings with integrated heat-shield technologies, emphasizing elasticity and thermal endurance for consistent performance. These examples underscore how strategic material selection and treatment directly influence rider safety and component longevity.

For further insight into affordable and quality motorcycle fairing options that align with these material considerations, explore Summit Fairings’ comprehensive resources on affordable motorcycle fairings.

More details on material use and protective designs can also be found in technical references covering the thermal properties of ABS and composite materials used in motorcycle applications [1][3][5].

2. Precision Manufacturing: Shaping Materials into Effective Motorcycle Fairing Heat Shields

The manufacturing process of motorcycle fairing heat shields plays a pivotal role in defining their performance and integration with the bike’s design. Selecting materials such as aluminum alloys—most commonly 6061 aluminum—and stainless steel sets the foundation, as these metals combine heat resistance, corrosion protection, and manageable weight. The real challenge lies in transforming these materials into precisely shaped shields that snugly fit around exhausts, brakes, and fairing contours while ensuring optimal thermal protection.

Manufacturing often begins with template creation and test fitting, a critical step that guarantees the heat shield matches the complex shapes of motorcycle components. This approach prevents gaps that could reduce protection and ensures the rider’s safety and comfort. Fabrication techniques include the use of CNC machining, laser cutting, or manual shaping to achieve exact cuts and forms. Once cut, the metals are bent and molded carefully to follow aerodynamic lines and component clearances without interfering with moving parts or other heat-sensitive areas.

Surface treatments enhance durability and functional performance. For aluminum, anodizing creates a corrosion-resistant layer, while reflective coatings can be applied to better deflect radiant heat. Stainless steel shields benefit from their inherent resistance but may also receive polishing or protective finishes for longevity and aesthetic appeal. Although carbon fiber composites offer lightweight thermal barriers, their adoption in motorcycle heat shields remains limited due to higher costs and complex curing processes that demand specialized facilities.

Designers must balance the thermal load expected from exhaust gases or braking systems against the shield’s thickness and material properties, impacting both weight and protection efficacy. Compatibility with adjacent components is also a concern, avoiding galvanic corrosion by selecting materials that do not react adversely when in contact.

Emerging composite technologies, inspired by aerospace manufacturing—such as advanced fiber layups and out-of-autoclave curing—show promise for future motorcycle applications, potentially enabling lighter, more effective heat shields with tailored thermal resistance.

Understanding these intricate manufacturing steps reveals why the combination of design foresight, material science, and precision fabrication is essential for producing motorcycle fairing heat shields that reliably protect riders, preserve components, and complement the bike’s form. For more insights on motorcycle fairing options and related components, explore the comprehensive Summit Fairings blog.

Detailed examples of aluminum heat shield manufacturing highlight the precision and care involved in crafting these essential parts: https://www.longezpush.com/chapter-9-main-gear-landing-brake/

3. Optimizing Strength and Weight: Material Choices in Motorcycle Fairing Heat Shield Design

Striking the right balance between durability and weight is essential when designing motorcycle fairing heat shields. These components must withstand the high temperatures generated by engines and exhausts while remaining light enough to preserve the motorcycle’s handling and performance. Material choice plays a pivotal role in achieving this balance. High-quality ABS plastic is widely favored due to its elasticity, resistance to cracking, and reliable heat tolerance. It provides robust protection against thermal and mechanical stress without burdening the motorcycle with excessive weight.

While carbon fiber composites offer superior strength-to-weight ratios and are prized for lightweight applications, their use in heat shields is less common. This is mainly due to their higher cost and specific heat resistance constraints. However, carbon fiber excels in other motorcycle components aiming for weight reduction and structural reinforcement.

Design innovations complement material selection by incorporating heat-resistant layers or coatings within plastic shields. These enhancements bolster thermal insulation without significantly increasing mass, helping fairings to endure engine heat while protecting riders and adjacent parts. Structural patterns, such as grid reinforcements or precise contours, further improve air circulation to dissipate heat effectively. This combination of design and material science ensures longevity and sustained performance.

Advanced manufacturing methods like injection molding optimize material distribution. By producing consistent thickness and reinforcing stress points, these processes minimize unnecessary bulk, preserving strength while reducing weight. Fairing kits for sport motorcycles commonly apply such approaches to prevent cracking and thermal degradation while keeping components light and aerodynamic.

Overall, integrating high-grade ABS plastics enhanced with heat-shield technology represents a practical and cost-effective solution. It achieves crucial resistance to heat and mechanical forces while maintaining manageable weight. By thoughtfully merging material properties with innovative design and precise manufacturing, modern motorcycle fairing heat shields deliver essential protection that complements both safety and rider experience.

For more insights into quality durable materials and designs, explore the affordable motorcycle fairings at Summit Fairings which emphasize these critical factors in their product lines.

4. Advanced Heat-Shield Materials and Aerodynamic Synergy for Optimized Motorcycle Fairing Performance

Motorcycle fairing heat shields serve a dual role: protecting riders from intense engine and exhaust heat, and enhancing the motorcycle’s aerodynamic efficiency. Achieving this balance requires careful integration of specialized heat-shield materials with aerodynamic design principles to optimize thermal management without compromising performance.

Among the commonly utilized materials, ABS plastic is favored for fairing and duct covers due to its elasticity, impact resistance, and moderate heat tolerance. This material allows for precision molding to conform tightly to motorcycle contours, as seen on models like the Suzuki GSX-R. The flexibility of ABS ensures durable heat resistance while maintaining structural integrity amid vibrations and mechanical stresses.

Aluminum stands out as a prime choice for exhaust pipe shielding because it dissipates heat quickly and remains lightweight, preventing excess mass that could hinder agility. Its high thermal conductivity disperses radiant heat from exhaust components, reducing rider burn risk and preserving adjacent fairing plastics. This material’s resilience in harsh thermal environments complements the ABS components used elsewhere on the bike.

Integrating aerodynamic considerations into heat shield design is equally critical. Smooth surfaces with carefully crafted shapes reduce drag and minimize turbulence, sustaining high-speed stability. Inclusion of strategically placed vents and airflow channels guides cool air over heated zones, assisting in heat dissipation and improving rider comfort by enhancing ventilation. These features often collaborate with existing motorcycle systems, such as intake ducts and helmet vents, for a cohesive airflow strategy.

Design and manufacturing practices emphasize the fusion of material properties and aerodynamic form. Injection molding techniques produce precise ABS components, while aluminum shields are engineered to balance robust heat protection with minimal weight impact. The resulting components not only guard against thermal damage but also contribute to ride quality by maintaining aerodynamic performance and reducing wind noise.

This integrated approach ensures that motorcycle fairing heat shields perform beyond basic protection, actively enhancing overall bike dynamics and rider experience. For deeper insights into fairing customization and options, exploring resources on motorcycle fairings offers valuable perspectives.

References: [1][2][3][5]

Chapter 2: Model-Specific Integration of Motorcycle Fairing Heat Shields

1. Precision Engineering and Thermal Dynamics in Tailored Motorcycle Fairing Heat Shields

Integrating heat shields into motorcycle fairings involves more than simple attachment; it demands precision engineering that aligns with each model’s unique design and thermal profile. To achieve optimal performance, heat shields must fit flawlessly with the contours and mounting points of the motorcycle’s fairing. This seamless fit prevents gaps that could undermine thermal protection or cause vibrations, which is especially critical for sportbikes with full fairings such as those produced through injection molding or crafted from carbon fiber composites. These materials not only meet precise dimensional requirements but also offer the combined advantages of lightweight strength and thermal resistance.

Material selection plays a pivotal role in balancing durability and heat management. Commonly, ABS plastics enhanced with heat-resistant coatings serve aftermarket solutions due to their resilience and cost-effectiveness. However, premium models often integrate carbon fiber or specialized composites delivering superior heat insulation and structural integrity without adding excessive weight. This advanced material science complements the sophisticated task of managing heat transfer from engine and exhaust components to protect both rider and fairing materials from damage.

Thermal management must harmonize with aerodynamic efficiency. Designs employing computational fluid dynamics (CFD) ensure that heat shields do not disturb the airflow channels or cooling ducts meticulously engineered into the fairing. For example, aerodynamic features found in touring motorcycle fairings are optimized to channel air around hot engine parts, minimizing heat felt by the rider while maintaining downforce and stability. Adding heat shields requires careful consideration so these airflow patterns remain uninterrupted, preserving rider comfort and bike performance.

Installation technology further demands attention to detail, incorporating manufacturer-specified fasteners and torque settings to maintain the structural integrity of the assembly. Model-specific mounting kits often facilitate correct alignment, especially when fairings include integrated electrical components like turn signals. Wiring must be carefully routed to prevent interference or heat damage, ensuring the shield complements rather than compromises the bike’s electrical and mechanical systems.

This holistic integration approach—uniting precise fitment, advanced materials, aerodynamic harmony, and meticulous installation—underscores how technological considerations shape heat shield design for individual motorcycle models, reinforcing safety and performance standards.

For readers interested in exploring comprehensive options for motorcycle fairings and compatible accessories, the explore the best motorcycle fairings at Summit Fairings provides valuable insights and selection guidance.

Source: https://www.hendersonhd.com/New-Inventory-2025-Harley-Davidson-Motorcycle-Scooter-FLHX-Street-Glide-Grand-American-Touring-hendersonhd-17655656

2. Economic Impact and Market Dynamics of Model-Specific Heat Shield Integration

Integrating model-specific heat shields into motorcycle fairings creates a dynamic balance of economic opportunities and manufacturing challenges that influence the entire value chain. One of the most notable impacts is the ability to leverage bundled pricing strategies. When manufacturers include a heat shield tailored to a particular motorcycle model alongside the fairing itself, they reduce the complexity and cost of separate component sourcing and installation. This not only streamlines the supply process but also enhances the perceived value for the consumer. Bundled products can command premium prices due to their convenience and assured compatibility, thereby boosting profitability without alienating price-sensitive segments.

Moreover, customization at the model level permits precision in thermal management that prevents damage to sensitive fairing components and protects riders from heat exposure. This translates economically into lowered warranty claim risks and reduced after-sales service expenses. Fewer repairs and replacements foster brand reliability and customer loyalty while easing operational costs. Such efficiency supports the argument for integrated heat shields as a long-term cost-saving investment rather than just an upfront expense.

However, initially, model-specific integration introduces manufacturing complexity. Specialized tools, custom materials, and exacting production parameters require greater technical expertise and may elevate production costs. Yet, with increased demand and volume, economies of scale emerge. Precision manufacturing evolves into a more predictable and cost-effective process, making these integrations more accessible across wider markets. This scaling effect helps maintain stable retail pricing amid enhanced product quality and functionality.

Additionally, the integration of advanced heat shields addresses regulatory challenges by aiding compliance with strict environmental and safety standards. Design innovations that improve airflow and reduce heat-related emissions open doors to markets enforcing stringent controls. This regulatory alignment expands sales potential and elevates the motorcycle’s market competitiveness without compromising design integrity.

Through these economic lenses, it becomes clear that model-specific heat shield integration is not only a technical necessity but a strategic commercial advantage. It encapsulates enhanced consumer appeal, responsible manufacturing, and adaptive market positioning. For riders and manufacturers alike, this integration underscores the value of seamless design meeting practical economics.

For further insights on motorcycle fairings and integrated components, visit Explore the Best Motorcycle Fairings at Summit Fairings.

Source: Accio Business Trending Report on 2025 GSXR750 Fairings featuring heat shields integration

3. Global Market Forces and Regulatory Complexities Shaping Model-Specific Heat Shield Solutions

Global market dynamics and regulatory frameworks profoundly shape the tailored integration of motorcycle fairing heat shields. Manufacturers and suppliers must navigate an intricate landscape influenced by evolving consumer demands, material innovations, and varying regional standards while ensuring precise fitment for specific motorcycle models.

Material advancements drive much of this innovation, as performance-oriented riders seek lightweight, durable heat shields crafted from carbon fiber composites or heat-resistant ABS plastics. Such materials not only contribute to superior thermal management but also maintain aerodynamic efficiency and UV resistance essential for protecting fairings over time. Adapting these materials to diverse models—ranging from high-performance sport bikes to cruisers—requires detailed engineering rooted in the model’s unique heat flow patterns and fairing geometry.

Beyond materials, international supply chain complexities significantly impact availability and cost. Tariffs, shipping duration, and sourcing hubs all influence how swiftly and affordably component manufacturers can deliver heat shields optimized for a particular bike. Providers who leverage bulk shipping strategies and maintain global distribution networks can better meet fluctuating demand and facilitate model-specific customization at scale.

Regulatory standards vary widely by region, further influencing design and integration. Compliance with certifications like TÜV, which governs safety and material quality, demands rigorous testing and adherence to specifications tailored to each model’s heat exposure and structure. These certifications not only assure rider safety but also affect market acceptance, forcing manufacturers to tailor products regionally or globally while maintaining consistent protection.

Simultaneously, the market increasingly favors bundled accessory packages that include fairing heat shields paired with compatible windscreens or tank covers. This strategy enhances installation ease and parts compatibility for model-specific setups, enriching rider safety and comfort. Customization options reflect the rider’s desire for both protection and personalized style, compelling manufacturers to offer a diverse range of finishes and material grades.

Ultimately, these intertwined global market forces, supply logistics, regulatory requisites, and consumer preferences form the foundation of how model-specific motorcycle fairing heat shields are designed, produced, and distributed. The resulting products embody a careful balance of performance, safety, regulatory compliance, and aesthetic appeal.

For deeper insight into fairing customization and accessories, see Explore the Best Motorcycle Fairings at Summit Fairings.

4. Enhancing Rider Comfort and Safety through Tailored Heat Shield Integration

Motorcycle fairing heat shields tailored to specific models significantly elevate rider comfort and safety by directly addressing the unique heat dissipation challenges posed by each bike’s design. These custom-fitted shields create a critical barrier between the rider and the intense engine or exhaust heat, reducing the risk of burns and discomfort during extended rides or in warm conditions. By managing heat flow precisely where it is most needed, model-specific integration not only shields vulnerable fairing plastics but also improves rider endurance, a crucial factor for both daily commutes and long-distance adventures.

Beyond thermal protection, heat shields intricately influence motorcycle ergonomics by shaping airflow around the rider’s position. For example, certain aerodynamic advancements incorporate heat shield elements that guide cooling air effectively while minimizing heat exposure. This integration preserves rider control and confidence by keeping peripheral temperatures manageable, especially under high-performance conditions. In some advanced motorcycles, innovative heat management systems adapt dynamically to riding conditions, balancing thermal retention for emission control with aerodynamic efficiency to enhance performance without sacrificing rider comfort.

On a broader scale, these tailored heat shields contribute to environmental considerations by optimizing exhaust heat retention, which supports catalytic converter efficiency and reduces harmful emissions. Such engineering highlights a growing commitment to sustainable motorcycling where performance and environmental impact are harmonized. Additionally, the longevity of the motorcycle itself benefits, as temperature-sensitive components are protected from heat-induced degradation, safeguarding both reliability and investment.

The cultural dimension of model-specific heat shields also reflects riders’ desires for customization and precision engineering. Solutions designed for a particular bike model foster a sense of ownership and pride by perfectly marrying function with the motorcycle’s styling cues. This bespoke approach enhances the overall riding experience, underscoring the importance of heat shields not simply as protective accessories but as integral elements of modern motorcycle design.

For riders seeking comprehensive advice on upgrading their fairings with proper heat management solutions, exploring a wide range of options at Summit Fairings offers valuable insights and choices tailored to individual needs. To understand how advanced aerodynamic and thermal designs influence modern motorcycles, Yamaha’s patented active aero system stands as a prime example of innovation harmonizing heat management and performance (source).

Chapter 3: Aftermarket Innovations and Applications of Motorcycle Fairing Heat Shields

1. Cutting-Edge Materials and Smart Thermal Solutions in Aftermarket Motorcycle Heat Shields

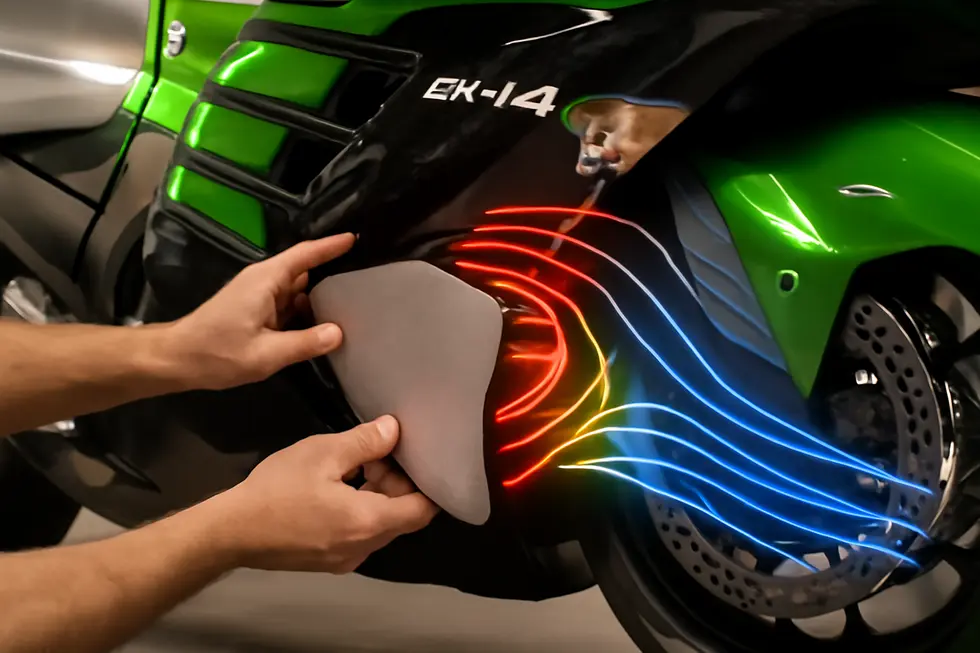

Advancements in aftermarket motorcycle fairing heat shields have ushered in a new era of performance, safety, and rider comfort through innovative materials and intelligent thermal design. Modern heat shields have evolved beyond basic protection to incorporate OEM-grade plastics enhanced with integrated thermal barriers. These materials, like high-quality ABS combined with embedded heat-resistant layers, strike a balance between durability, impact resistance, and superior heat insulation, outpacing older, less effective options.

Beyond materials, aerodynamic integration has become a core focus in aftermarket designs. Sophisticated systems employ dynamic venting mechanisms powered by compact stepper motors and controlled by onboard electronics. This technology allows the heat shield to actively regulate airflow, directing hot air away from sensitive components while optimizing aerodynamic drag. Such advancements help keep critical elements like catalytic converters within optimal temperature ranges, which benefits overall engine efficiency and longevity.

Additional aftermarket enhancements extend to airflow optimization accessories that work synergistically with heat shields. Devices such as tank lift kits and strategically placed cooling wings boost air circulation around heat-prone areas, notably improving engine and oil cooling under demanding riding conditions. Riders consistently report noticeable reductions in thermal discomfort and component temperatures, reflecting the practical benefits of these solutions.

Moreover, many aftermarket heat shield kits emphasize easy, bolt-on installation with precision fitment tailored to popular motorcycle models. This facilitates customization without sacrificing protective performance. Options for custom finishes and integrated design features enable riders to maintain a visually appealing profile alongside functional upgrades.

These advancements represent a convergence of material science, thermal dynamics, and adaptive engineering—all aimed at elevating the aftermarket fairing heat shield landscape. For those seeking reliable protection paired with innovative thermal management, exploring the array of modern options unlocks new levels of ride quality and protection.

Further insights into high-quality fairing materials and protective upgrades can be found in detail at the Explore the Best Motorcycle Fairings at Summit Fairings resource.

For more on intelligent thermal management technology in motorcycle applications, consult Yamaha’s patented solutions described here: Yamaha R1 active aero patent detailing dynamic vent-controlled thermal management.

2. Emerging Market Dynamics and Economic Influence of Aftermarket Motorcycle Fairing Heat Shields

The aftermarket sector for motorcycle fairing heat shields is witnessing significant transformation driven by innovation, material advancements, and evolving rider demands. This niche market thrives on enhancing thermal management, safety, and aesthetics, catering mainly to performance enthusiasts and customization aficionados. Demand is increasingly focused on advanced materials like carbon fiber, praised for its lightweight strength and UV resistance. For instance, aftermarket carbon fiber fairings tailored for sportbikes command premium prices yet attract consumers seeking improved heat dissipation and aerodynamic gains beyond standard OEM parts.

Heat shields have become essential accessories, often integrated within bundled fairing kits that deliver comprehensive upgrades combining protection, style, and ergonomics. The inclusion of thermal comfort features such as strategically placed air vents highlights the industry’s emphasis on rider safety and component longevity. This evolution reflects the rising expectation for multi-functional parts that not only shield against engine and exhaust heat but also augment resale value and visual appeal.

Economically, the aftermarket balances two dynamics: OEM accessories preserve brand consistency and assure fitment reliability but usually carry a higher price, while independent aftermarket brands provide varied, cost-effective alternatives catering to a broader budget range. Bundled kits have gained traction by offering convenience and perceived value, reinforcing consumer preference for one-stop upgrade solutions.

Despite a downturn in new motorcycle sales and tempered used-bike valuations during early 2025, the aftermarket sector remains resilient through its appeal to premium and performance segments. Enthusiasts invest in specialized components such as heat shields to optimize their rides, underpinning a steady demand momentum within this subset. Such market dynamics underscore how innovation centered on lightweight materials and integrated thermal management continues to fuel economic significance in aftermarket motorcycle accessories.

For those interested in deeper insights on high-performance materials and market opportunities in this space, exploring detailed case studies like the Ducati Panigale V2 2025 aftermarket fairing trends is highly informative. More about premium fairing options can be found at the Summit Fairings blog.

External resource reference: https://www.accio.com/business/trending-panigale-v2-2025-fairing-front

3. Navigating Geopolitical Currents: How Global Forces Shape Aftermarket Fairing Heat Shield Supply Chains

The supply chain dynamics of aftermarket motorcycle fairing heat shields are profoundly influenced by global geopolitical factors that govern the flow of raw materials, manufacturing hubs, and distribution channels. Materials such as ABS plastic and carbon fiber, essential for durability and thermal insulation, are often sourced from diverse regions worldwide. Political tensions, trade disputes, and tariff impositions in these key supplier countries can disrupt supply continuity and inflate costs, challenging manufacturers to adapt swiftly.

Asia stands out as a central manufacturing region, housing many production facilities crucial to the aftermarket heat shield market. Regional conflicts or shifting trade policies here not only affect manufacturing output but also complicate logistics networks. These disruptions reverberate throughout the supply chain, delaying parts availability and potentially impacting the rollout of innovative designs intended to enhance rider protection and aesthetic appeal.

In response, manufacturers and suppliers increasingly prioritize supply chain resilience by diversifying sources and incorporating advanced materials that balance heat resistance with lightweight properties. Innovations such as multi-layered coatings improve thermal protection while carbon fiber upgrades provide superior strength without added weight. These technical advancements dovetail with geopolitical realities, pushing the aftermarket sector to remain agile amid fluctuating global conditions.

The implications extend beyond production to the rider experience. Reliable supply chains ensure that aftermarket heat shields continue to safeguard fairings against engine heat effectively while maintaining precise OEM fitment standards—which is critical for both safety and style. Enhancing rider comfort by mitigating radiant heat exposure remains a priority, making uninterrupted access to quality materials and timely distribution essential.

For enthusiasts seeking to upgrade or maintain their motorcycles, understanding these geopolitical influences offers insight into price fluctuations and availability challenges. The interplay of global politics with materials sourcing and manufacturing underscores the complexity behind what might seem like simple protective accessories.

To explore how these multifaceted factors impact fairing options, consider the detailed insights available from Discover Affordable Motorcycle Fairings at Summit Fairings.

More in-depth perspectives on the effects of geopolitics can be found through aftermarket industry examples, such as specialized replacement heat shields that address both performance and styling needs under shifting global supply conditions. (https://www.revzilla.com/motorcycle/rush-replacement-heat-shields-for-harley)

4. Balancing Rider Safety, Environmental Impact, and Cultural Values in Aftermarket Heat Shield Advancements

The evolution of aftermarket motorcycle fairing heat shields extends beyond functionality, weaving together societal responsibilities and environmental mindfulness. At the heart of these innovations lies the fundamental goal of protecting riders from the intense engine and exhaust heat that can cause discomfort or burns. Aftermarket solutions address variable conditions riders face, often arising from modifications that alter heat distribution. By incorporating advanced materials and precision fitment, these heat shields significantly enhance rider comfort and safety, ensuring critical components remain undamaged during extended rides.

Yet, motorcycle customization carries aesthetic and cultural weight within communities. Modifications involving heat shields not only affect thermal management but also influence bike appearance and identity. Riders often seek a balance between improved performance and preserving their motorcycle’s style, reflecting personal and social expression. Thus, designers and manufacturers must innovate without compromising the visual harmony that riders cherish. This intersection of function and form fosters a culture of responsible customization, where safety and style coexist.

Environmental considerations increasingly shape aftermarket product development. The selection of materials like carbon fiber or composites is scrutinized for sustainability, given the energy-intensive manufacturing of some options. Emerging innovations emphasize recyclable, lightweight, and less environmentally taxing materials, reducing the ecological footprint from production to disposal. Moreover, effective heat shields contribute indirectly to fuel efficiency by maintaining optimal engine temperatures, which can lower emissions and benefit the environment.

Durability and reparability are also prioritized to minimize waste, encouraging longer product lifespans and reducing the frequency of replacements. Regulatory frameworks ensure aftermarket parts meet safety and environmental standards, promoting responsible production and usage.

Ultimately, advancements in aftermarket motorcycle fairing heat shields illustrate a conscientious approach that respects rider welfare, environmental sustainability, and the cultural significance of motorcycle modification. By harmonizing these aspects, the industry supports safer, greener, and more expressive motorcycling experiences. For riders seeking comprehensive fairing solutions that blend innovation with thoughtful design, exploring trusted sources can offer valuable insights and options.[1][2][3][5] For further exploration of diverse motorcycle fairings that complement heat shield innovations, visit Summit Fairings’ blog.

Final thoughts

Understanding the multifaceted role of motorcycle fairing heat shields is essential for business owners seeking to enhance product offerings in a competitive marketplace. By prioritizing advanced design and material selection, companies ensure heat shields deliver optimal protection and durability. Emphasizing model-specific integration further aligns product performance with rider safety and installation efficiency. Meanwhile, embracing aftermarket innovations not only broadens product lines but also meets the modern consumer’s demand for safety combined with style. Together, these elements underscore the value of fairing heat shields as indispensable components that safeguard riders and elevate motorcycles’ functionality and aesthetics.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined