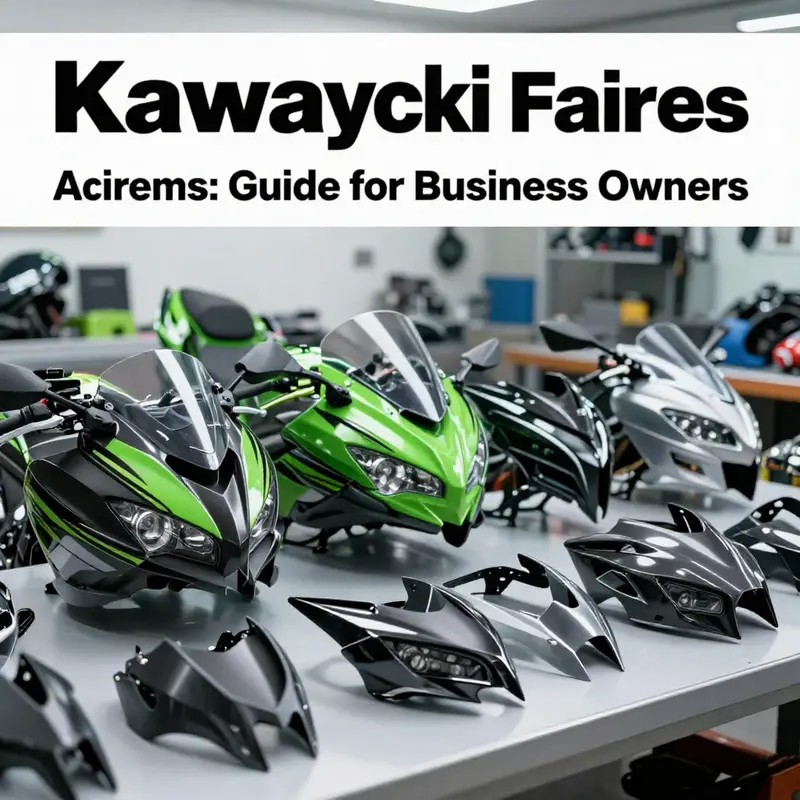

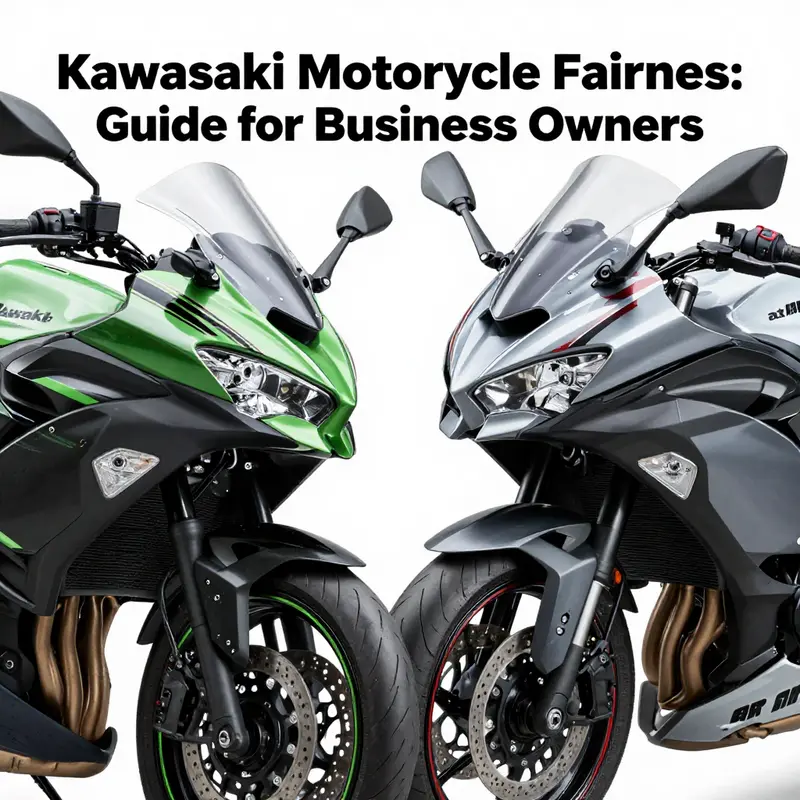

Motorcycle fairings play a crucial role in both the aesthetics and performance of Kawasaki bikes, which is essential knowledge for business owners in the motorcycle industry. Understanding fairings is vital in catering to customer needs, enhancing bike performance, and ensuring safety. This comprehensive guide covers the types of Kawasaki motorcycle fairings, popular materials used in their construction, and the differences between OEM and aftermarket options. Each chapter delves deeper into these elements to equip you with the necessary insights to better serve your clientele and optimize your business offerings.

Wings of Design: How Kawasaki Fairings Shape Speed and Style

Fairings do more than clothe a motorcycle in sleek lines. They are the aerodynamic skin that shapes how air moves around the rider and the chassis. On a Kawasaki, fairings influence not only top speeds and fuel economy but also ride feel, maintenance access, and personal expression. The choice between full, half, and quarter fairings is a balance of wind protection, weight, and serviceability. Full fairings deliver maximum wind shielding and a clean silhouette for high-speed riding, but they add weight and can complicate maintenance access. Half fairings offer a middle path, providing substantial protection while keeping the engine and frame easier to reach. Quarter fairings emphasize lightness and style, with less wind protection but easier customization and quicker maintenance. Materials matter: ABS plastic offers durability and paintability, while composites such as fiberglass or carbon fiber provide weight savings and stiffness at a premium. OEM kits promise factory fit and finish; replica or aftermarket kits widen aesthetic options and can reduce cost. The modular approach common on modern Kawasaki platforms lets riders swap panels in stages, tuning aero performance without replacing the entire assembly. Ultimately, the best choice aligns wind management, weight, and access with the rider’s goals whether track-ready performance, everyday comfort, or a unique cafe-racer stance. The fairing is more than a cover; it is a tool that translates the rider’s intentions into real-world behavior—stability, speed, and a voice that says, this bike is mine.

Weight, Strength, and Style: The Materials Behind Kawasaki Fairings and Your Ride

Materials have always been more than a surface on Kawasaki fairings. They are the quiet engines of performance, shaping aerodynamics, weight, durability, and even the emotional pull of a rider’s connections with their machine. When you stand back from a Kawasaki with its contours catching the light, you are looking at the visible face of a decision that began long before the first bolt was tightened: which material will carry the bike’s speed, protect the rider from the elements, and still respond to the subtle demands of daily use or aggressive track workloads? The answer lies in a thoughtful spectrum of options, from the ubiquitous ABS plastics that power mass production to the high-tech fibers that lattice the line between compromise and peak performance. Each material speaks to a different riding philosophy, a different budget, and a different moment in the life of the bike.

At the heart of the material conversation is ABS plastic, the workhorse of OEM fairings across Kawasaki’s lineup. ABS, or acrylonitrile butadiene styrene, is prized for its balance: it is tough enough to shrug off the everyday abuse of stones, grit, and road salt, yet pliable enough to be molded into the sweeping shapes that define modern sport and nakeds alike. Its impact resistance makes it forgiving in the moment of impact and its moldability lends itself to the highly engineered curves that improve airflow without sacrificing fit. For manufacturers, ABS is a happy medium between cost efficiency and functional resilience. For riders, it translates into fairings that can be produced with consistent color matching, predictable repair costs, and a resilience that keeps riding days going rather than sending a bike into the shop after a tip-in or a driveway misjudgment. The result is a broad reliability that works across multiple models and riding styles, making ABS the backbone of many Kawasaki OEM kits. Yet the same characteristics that make ABS so practical can also limit performance in environments that demand the lightest possible setup or the utmost stiffness under track-true loads. ABS components tend to carry more mass than composites, and while they offer respectable rigidity, their stiffness-to-weight ratio cannot compete with advanced fibers when a rider is chasing lap times or long-range efficiency on the highway.

If ABS is the everyday hero, fiberglass and carbon fiber sit on the more specialized shelf, where riders seek higher performance at the expense of cost and complexity. Fiberglass strikes a balance that appeals to serious track riders and dedicated enthusiasts who want a noticeable upgrade in durability and a more refined feel without stepping into the premium price range of carbon. It is denser than carbon fiber, but still a significant improvement in strength-to-weight over ABS. Fiberglass fairings tend to absorb and distribute impact differently; they can be more forgiving in a crash scenario and often resist fatigue better than thin ABS panels under high-speed vibrations. The manufacturing processes for fiberglass allow for broad customization and easier repairability compared with carbon fiber, which translates into aftermarket options that can be tailored to a rider’s evolving needs. For track day veterans who want stronger panels that resist deformation during hard cornering or aggressive braking, fiberglass provides a practical upgrade path without the full premium of carbon. The cost advantage alone makes fiberglass a popular choice for mid-tier kits and for riders who push their bikes to limits but stay mindful of the bill at the end of the season.

Carbon fiber embodies the peak of performance-focused materials. It is not merely about a whisper-light presence on the bike; it is about a fundamental redefinition of how the fairing behaves in the wind. Carbon fiber’s intrinsic stiffness and extremely favorable strength-to-weight ratio translate into a fairing that resists flexing under motor torque, wind pressure, and the chatter of high-speed riding. The aerodynamic shapes that a rider can push into become more effective when the surrounding structure can hold its form with minimal sag or distortion. The down side is, of course, cost and manufacturing complexity. Carbon fiber requires specialized layups, precise resin systems, and careful curing processes; imperfections in any step can undermine strength or performance. The result is a premium kit that carries a price premium, but for riders who chase speed, precision, and feedback, carbon fiber fairings can be a decisive upgrade. They are most at home on race-bred builds or sport motorcycles that spend a lot of time on the track or at highway speeds where every gram saved contributes to stability and reduced rider fatigue. In the context of Kawasaki bikes, carbon fiber becomes a language of performance — a visual and tactile cue that says the rider has chosen the lightest option compatible with their goals, with the understanding that maintenance of these panels demands care, attention to mounting tolerances, and often higher repair costs if damage occurs.

In recent years, a growing segment has introduced twin-part composite kits that blend lightweight fibers with modular design strategies. These kits—often seen on performance-oriented builds and some modern aftermarket offerings—take advantage of hybrid construction to reduce weight while preserving—or even enhancing—damage tolerance and practical serviceability. Fiberglass and carbon fiber can be partitioned into zones, allowing a rider to tune where weight is saved and where rigidity matters most, such as around the front fairing, radiator shrouds, and upper panels that encounter the greatest wind loads. The modular approach also helps with repair and customization. Instead of replacing a full kit after a gnarly crash, an owner can swap smaller sections or upgrade specific components to recalibrate aerodynamics and aesthetics without a total fairing overhaul. The resulting freedom is particularly meaningful for riders who participate in track days or who like to evolve their machine as skills and ambitions grow.

The material choice does not exist in a vacuum. It reverberates through performance, maintenance, and even the sensory experience of riding. For instance, carbon fiber’s rigidity and lightness can improve high-speed stability, allowing the rider to feel a more immediate response in steering input and a steadier wind buffet at speed. Carbon’s stiffness also interacts with the motorcycle’s overall chassis dynamics, where the fairing’s interaction with the air can alter the downforce and the fore-aft balance at elevated speeds. At the same time, the tactile feedback from the fairing and its surface can be markedly different depending on the chosen material. ABS panels tend to feel slightly more forgiving under a rider’s gloved touch, offering a predictable, slightly flexy response that many riders associate with confidence in unpredictable weather or rough pavement. Fiberglass and carbon, by contrast, provide crisper feedback, a more solid sense of contact with the wind, and, in carbon’s case, a whisper-quiet sense of weight shedding that a rider may perceive as a direct link to speed itself.

These material decisions also ripple into the practical realities of ownership. OEM fairings, typically built around ABS, are designed for large-scale production, consistent fitment, and predictable repair ecosystems. They are often optimized for color retention, UV resistance, and overall longevity under daily riding conditions, with mass-market supply chains that help keep prices accessible for a broad range of riders. Aftermarket options, including those based on fiberglass or carbon fiber, bring a more specialized set of advantages: enhanced stiffness, thinner walls for aerodynamic efficiency, and the opportunity to tailor the look to a rider’s personal aesthetic and performance goals. They also offer modular designs and colorways that can reflect individual tastes, from stealth black to vibrant two-tone schemes. The trade-offs, however, are clear: price, repairability, and sometimes fitment strictness. A high-performance carbon kit may demand precise mounting tolerances and careful alignment, while a fiberglass option might be more forgiving during installation yet require maintenance to preserve its structural integrity over time.

Model-specific considerations largely drive the material strategy a rider selects. For example, in sport-oriented or supersport contexts, a rider might lean toward carbon or a carbon-fiber–hybrid kit to shave weight and sharpen handling, accepting the higher cost and the nuance of care that carbon demands. On a daily commuter or a bike used for weekend canyon runs, ABS remains a formidable option, delivering broad compatibility, ease of repair, and durable wear life against road debris. For riders who want a blend of performance and practicality, a fiberglass upgrade can deliver meaningful gains in stiffness and resistance to deformation under load without dipping into the most extreme price tier. Modern aftermarket ecosystems increasingly offer modularity and compatibility with factory lines, enabling a broader spectrum of riders to realize their goals without sacrificing the comfort of a familiar repair network. In the end, the choice of material is a negotiation among weight, rigidity, cost, and the rider’s unique relationship with their bike.

Another layer to this discussion is the sourcing and availability of parts. OEM fairings built from ABS are widely documented across Kawasaki’s historical and contemporary ranges, which makes sourcing parts easier, especially for classic or aging models where authenticity and color matching matter. For those who pursue performance or aesthetic customization, the aftermarket market opens up opportunities for tailored silhouettes, such as race-replica front ends or minimalist cafe-racer-inspired panels. In this space, composite fairings are often framed as upgrade paths that can deliver the ride feel many riders chase, with airfoil-inspired shapes that are designed to optimize the flow of air across the bike at speed and reduce drag. In parallel, the emergence of hybrid kits on platforms like Alibaba has broadened the range of options, enabling riders to pick weight-saving and form-fitting components that align with their ambitions. Such options illustrate a broader trend: fairing design is increasingly about choice and precision rather than a single default solution. The capability to swap or upgrade panels in a modular fashion grows the community’s ability to tailor bikes to track goals, daily usage, or a balance between the two.

The practical takeaway for a rider standing at the crossroads of material choice is straightforward, albeit nuanced. If the goal is to maximize track performance and optimize handling at high speed, carbon fiber or high-grade composites offer the best payback in weight and stiffness, with the caveat of higher cost and the need for careful maintenance and professional repair when damage occurs. If daily reliability and ease of maintenance trump every other consideration, ABS remains an excellent default that delivers durability, color stability, and consistent fitment across a broad spectrum of Kawasaki models and years. If the rider seeks a middle path—enhanced performance without crossing into carbon’s premium territory—fiberglass composites present a compelling compromise. They offer meaningful improvements in rigidity and damage resistance, with more approachable pricing and repairability than carbon. Importantly, many riders will find a combination of materials within a single bike’s fairing strategy to be the optimal arrangement: ABS where impact resistance matters most against road debris, fiberglass in zones demanding additional stiffness, and carbon where every gram saved translates into a measurable gain in performance.

The inner logic of material choice also extends to how a fairing integrates with other performance systems on the motorcycle. Aerodynamic efficiency hinges on the fairing’s ability to hold its shape under wind pressure and to interact predictably with the bike’s frame, steering geometry, and suspension under load. This interdependence means that even small shifts in panel stiffness can influence handling, steering response, and stability. A light carbon front end can reduce inertia and alter how air streams around the wheel arch, affecting grip and ride feel at the apex of a turn. A robust ABS midsection may offer better impact absorption and longevity in daily riding, preserving the rider’s confidence when navigating rough pavement. The more modular and tunable the kit, the more riders can dial in these interactions. The objective remains consistent: balance, not maximization. Balance between lightness and durability, between speed-focused design and the practical realities of road wear, between the magic of aero performance and the cadence of everyday riding.

For riders who want to dive deeper into the spectrum of Kawasaki fairing options, there is a broad ecosystem of products and discussions that can guide a thoughtful choice. The community conversation often centers on fitment compatibility, the ease of install, and the potential for color and finish matching to a bike’s existing palette. If you are exploring the possibilities, you may want to peruse a dedicated Kawasaki fairings collection to see the range of shapes, finishes, and materials commonly offered. These resources provide a sense of what is feasible within a given budget and riding style while preserving the tone of the bike’s original design language. As you weigh your options, it helps to keep the perspective that fairings are both performance tools and aesthetic canvases; the material you select will sculpt not only how the bike cuts through air but how it communicates with the rider and the world that watches from the shoulder of a winding road. For a closer look at the broader Kawasaki aftermarket landscape, you can explore the Kawasaki fairings offering and community options, which often highlight the integration of form and function in a way that speaks to riders who measure progress in tenths of seconds and miles per hour as much as in paint and texture.

In sum, the materials chosen for Kawasaki fairings carry weight far beyond their physical mass. ABS provides reliable, cost-effective service for everyday riding; fiberglass offers a practical bridge to enhanced performance and durability; carbon fiber delivers the lightest, stiffest option for those chasing peak handling and speed. Hybrid and modular composites open doors to customization, enabling riders to shape aerodynamics and weight in concert with their own goals. The conversation surrounding fairing materials is, at heart, a conversation about balance—between speed and stability, between cost and capability, and between the rider’s vision and the road that carries them forward. As you plan your next upgrade or restoration, ask not only what you want to look like, but what you want your bike to do when it meets the road at speed, under load, and in the changing light of a ride well earned. The material choice you make will be the quiet partner in that journey, shaping both your bike’s performance and the story you tell on every twist of the handlebar.

Internal link for further exploration: For a broader look at Kawasaki fairings collections, visit the Kawasaki fairings collection. Kawasaki fairings collection

External resource: https://www.alibaba.com/product-detail/KAWASAKI-NINJA650-2020-2023-Motorcycle1601094898479.html?spm=a2700.galleryofferlist.po22&src=gallery&clickTrackInfo=eyJwbGFjZSI6Imdvb2dsZV9nZW5lcmF0ZWQiLCJjbGlwX2NvZGUiOiJrYXdhc2thcF9uaW5qYTY1MCIsImNvbGxlY3Rpb24iOiJnaW5qYSIsInBhZ2UiOiJncmFwaGljcyIsIm5hbWUiOiJrYXdhc2thcF9uaW5qYTY1MCIsImRlc2NyaXB0aW9uIjoiS0FXT1NLSV9OSU5KQTY1MF8yMDIwLTIwMjMgTW90b3JjaXZlbCBGYWlyZW5zIFN0b3JlIEJ1aWxkIFBvc3QiLCJpZCI6IjE2MDAwOTQ4OTg0NzkiLCJzaG93X2lkIjoiMTYwMDA5NDg5ODQ3OSIsImRhdGUiOiIyMDI2LTAyLTA1IiwicmVzcG9uc2UiOiIxNjAwMDk0ODk4NDc5IiwiZGVsZXRlIjoiMSIsImRldmljZSI6ImJyb3duIiwiY29tcGFueSI6IkFsaWJhcmRvIiwiY3VycmVuY3kiOiJDTUIiLCJpc2FjdGlvbiI6ImZhbHNlIiwiaWRfcHJvdmlkZWRfZnJvbSI6IjE2MDAwOTQ4OTg0NzkiLCJmdWxsX3VybCI6Imh0dHBzOi8vYXJ0aWNpdGVzLmFsaWJhcmRvLmNvbS9wcm9kdWN0LWRldGFpbC9LQVdBU1tLSV9OSU5KQTY1MF8yMDIwLTIwMjMtbW90b3JjaXZlbC1mYWlyZW5zLWJ1aWxkLXByb2R1Y3QtaWQvMTYwMDA5NDg5ODQ3OSIsImFkbWluIjoiMSIsInVzZXJfbmFtZSI6ImFsaWJhcmRvIiwiY2hhbm5lbCI6ImFsbG93IiwiY29tcGFueSI6ImFsaWJhcmRvIiwiY29udGVudCI6ImFsbG93IiwiY29tcGFueSI6ImFsaWJhcmRvIiwiY29uc3RydWNoaW5nIjoiYmxvdyIsImV4cGlyZSI6IjIwMjYuMDIuMDUiLCJwcm9kdWN0X2lkIjoiMTYwMDA5NDg5ODQ3OSIsInJlc3BvbnNlX2lkIjoiMTYwMDA5NDg5ODQ3OSIsImRlY2lzaW9uIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsimFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsimFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsimFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsimFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsImFkbWluIjoiMSIsIn0=

null

null

Final thoughts

In conclusion, understanding Kawasaki motorcycle fairings is imperative for business owners looking to enhance their offerings and meet customer demands. By being knowledgeable about the types of fairings, the materials used, and the distinct advantages of both OEM and aftermarket options, you can provide better recommendations and services to your customers. This knowledge will not only assist in driving sales but will also contribute to delivering a superior riding experience that can set your business apart in the competitive motorcycle market.