Motorcycle fiberglass fairings have gained immense popularity among both manufacturers and enthusiasts due to their optimal blend of strength, lightweight construction, and versatility in design. This article delves into the composition and production methods of fiberglass fairings, their aerodynamic advantages, durability, cost-effectiveness when compared to alternative materials, and unparalleled customization opportunities. Understanding these facets not only highlights their significance in performance riding but also underscores their role in enhancing the aesthetics of motorcycles, making this essential knowledge for both current and aspiring business owners in the motorcycle industry.

null

null

Harnessing the Wind: Aerodynamics, Craft, and the Practical Edge of Fibreglass Motorcycle Fairings

Air is a constant, invisible partner when a motorcycle is in motion. It presses against the rider, the wheel rims, and every contour of the chassis, turning speed into drag, heat, and fatigue if the design is not conscious of this relentless force. Fibreglass fairings answer that challenge with a rare combination: a material profile that can be molded into complex, aero-aware shapes, yet remain light enough to preserve the bike’s agility. These fairings are fashioned from glass-reinforced polyester resin, a system that layers stiff, load-bearing fibers within a resin matrix. The result is a shell that feels almost sculptural in its ability to hold a shape while resisting deformation at speed. The inherent rigidity of fiberglass, paired with careful layup and curing, keeps fatigue at bay even as the rider leans into wind pressures at highway tempos or dives into a sweeping corner on a track. And because fiberglass is moldable, designers can translate the aerodynamic theories of racing into street-legal, resilient forms without the same cost overhead that comes with more exotic composites. In practical terms, this means riders can enjoy a streamlined silhouette that deflects air efficiently, reduces drag, and preserves the feel of a nimble chassis beneath the same workshop that brought a bike from concept to curb.

The aerodynamic advantages begin with the fairing’s ability to introduce smooth, continuous flow over the front fascia and along the sides of the bike. By guiding air around the rider and the engine bay rather than letting it crash into exposed surfaces, fiberglass fairings lower form drag—the resistance created by the shape of the bodywork. Lower drag translates directly into fewer watts burned overcoming wind and, consequently, better fuel economy at sustained speeds. But the benefits go beyond fuel savings. When the airflow is smoother, the front end stays more stable, a feature that matters as speeds climb and the rider’s attention is pressed toward control rather than compensation for buffeting or flutter. The rider’s helmet, shoulders, and torso become part of a streamlined line rather than new sources of turbulence, which helps reduce fatigue on long rides and preserves stamina for more precise handling when conditions become unsettled.

The choice between full and partial fairings is not merely about appearance; it is about tailoring the wind boundary around the bike to suit different riding intents. A full fiberglass fairing provides exceptional wind deflection, creating a continuous barrier that shields more of the rider and the engine from wind pressure. This is particularly valuable on long-distance cruises, where sustained air resistance would otherwise sap energy and concentrate fatigue in the upper back and neck. Partial fairings, while offering less wind deflection, can still deliver notable improvements by smoothing the airflow around key zones such as the cockpit and the leading edges of the radiator, where turbulence often forms. In both cases, the sculpted lines, once they are right for the model, shape the wake behind the bike. The reduced wake area not only improves top-end stability but also lowers the likelihood of buffeting when a gust enters the rider’s lane. The net effect is a chassis that feels more predictable at speed and more responsive when the throttle is nudged toward acceleration, even on days when the wind refuses to cooperate.

For riders seeking a more performance-oriented edge, race-inspired fairings push the conversation into higher gear. These designs embrace sharp contours, vented ducts, and even winglets that are meant to manage downforce and cooling in ways that the street-going version rarely requires. The vented ducts act as controlled channels for air to flow to radiators and brakes, drawing heat away from cooperative components while maintaining a pressure regime that prevents excessive drag. Winglets, in turn, can influence the airflow in front of the bike so that the front wheel remains planted as speeds climb and the front-end geometry experiences minute shifts in lift. All of these features, carefully integrated, can turn a fairing from a protective shell into an aerodynamic instrument that sharpens turn-in, steadies the front wheel, and clears the path of excess energy that would otherwise cause instability. It is not magic; it is a careful balance of pressure, flow separation, and structural support, all radiating from a fiberglass shell that can be designed to meet exacting race-inspired specifications without the cost of more exotic composites.

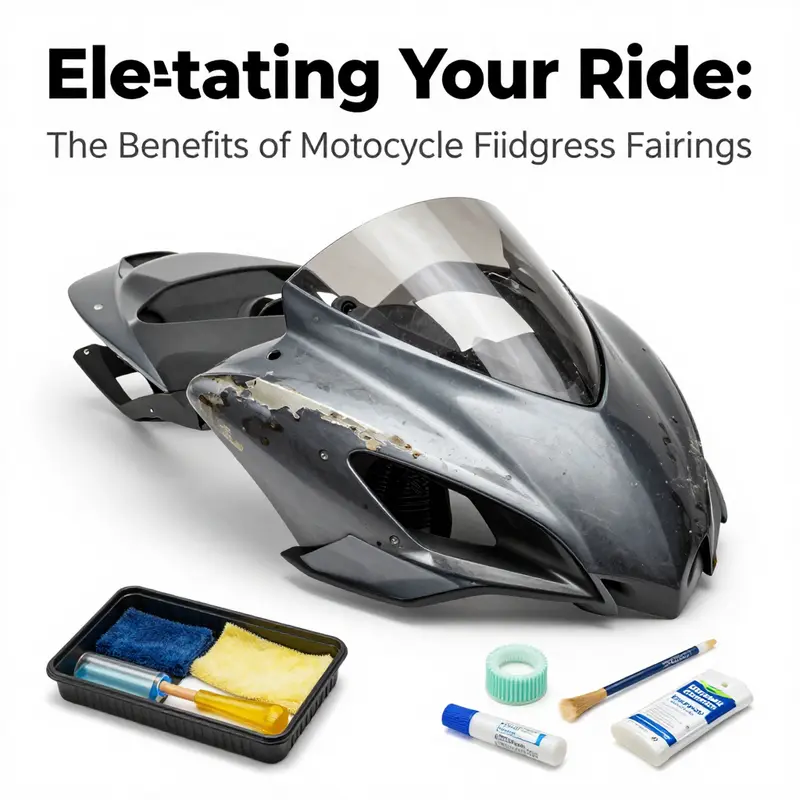

Yet fiberglass is not a perfect solution for all riders. It offers a compelling value proposition: durability relative to its cost, with the flexibility to tailor shapes to a wide range of motorcycles. Compared with some high-grade plastics used in OEM or aftermarket parts, fiberglass can be more affordable to manufacture and repair, which makes it especially appealing for restoration projects and budget-conscious upgrades. The caveat lies in impact resistance and UV exposure. While a well-made fiberglass fairing can absorb a fair amount of energy and recover well from minor impacts, it is generally not as inherently impact-resistant as certain plastics designed for higher energy absorption. It is also more susceptible to UV degradation if not properly finished or protected. Those considerations are not fatal to performance, but they do shape the maintenance plan. Regular inspection for microfractures, resealing of joints, and periodic refinishing to protect against sun exposure all contribute to longevity. The payoff is a shell that remains shaped to the aerodynamic target over years of use, not simply a one-off design that looks fast in a photo but loses its line under the rigors of road wear.

In practice, achieving the aerodynamic promise of fiberglass fairings begins with careful compatibility checks and professional application techniques. A fairing must align with the bike’s frame, mounting points, and weight distribution so that the added surface area does not shift the center of gravity in a way that undermines handling. The installation process benefits from experienced hands because even small misalignments can create unintended gaps, rough flow separation, or buffeting that undermines the predicted gains. Beyond mounting, suitable sealing around joints helps manage crosswinds and reduces the risk that loose seals become a source of squeaks or wind noise at high speed. Maintenance, then, becomes a stewardship act. Clean joint lines, inspection for delamination or cracking after a heavy impact, and timely repainting or varnish reapplication all protect the fiberglass and keep its aerodynamic surfaces true. In this sense, fiberglass fairings demand the same attentive mindset as any finely tuned performance component: a balance between form, function, and responsible upkeep.

This holistic view of aerodynamics—where material properties, manufacturing processes, design philosophy, and maintenance converge—frames fiberglass fairings as more than a protective shell. They are active contributors to velocity management. The material’s flexibility supports sculptural precision, enabling the execution of aerodynamic studies in the workshop room and translating them into real-world gains on the road or track. When a rider feels the stability that comes with clean air, the sense is not merely confidence but a tacit recognition that shape and structure are working together to free energy for forward motion rather than wasting it in turbulence. The aerodynamics are a dialogue between the rider and the machine, and fiberglass is uniquely suited to sustain that dialogue across a spectrum of riding environments.

For those who want to peek behind the curtain of what makes a fiberglass fairing so effective, consider the way the shell interacts with the rider’s posture and the bike’s overall geometry. A thoughtfully contoured fairing supports a rider’s posture by smoothing air across the helmet and shoulders, reducing the high-velocity pressure that would otherwise push a rider higher in the seat. This, in turn, helps the rider stay centered over the bike, improving balance during corner entry and exit. The improved stability encourages smoother throttle modulation and more precise steering input, which compounds the aerodynamic benefits with real-world handling improvements. And when the bike is ridden at speed on a windy day, the same contours that guide air around the rider also help slip the wind along the bike’s sides, minimizing crosswinds that might destabilize lateral movement. All of these attributes—shape, rigidity, and the possibility of race-inspired features—form a cohesive argument for fiberglass fairings as an aerodynamic tool, not just a cosmetic layer.

Interested readers may explore compatible options to see how these ideas translate across different models and years. For riders curious about compatible shapes, the Honda fairings collection offers a practical glimpse into how fiberglass can be shaped to balance protection and speed, including options that fit a wide range of models. Honda fairings collection.

External resources can further illuminate the selection and care required to maximize these advantages. For a concise guide on choosing and maintaining fiberglass fairings, see: How to Choose Motorcycle Fiberglass Fairings. This reference complements the practical guidance embedded in design discussions, offering a broader perspective on how material choices, finishing, and mounting practices come together to support performance and longevity across diverse riding contexts.

Fortitude in Fibreglass: Navigating Durability, Maintenance, and Performance in Motorcycle Fairings

Fibreglass fairings have earned a quiet reputation among riders and builders for a practical blend of strength, lightness, and adaptability. They sit between the raw rigidity of composites and the sometimes brittle resilience of higher-end plastics, offering a chemistry that can be molded into complex shapes while resisting the repetitive stresses of high-speed wind and pothole-sized reminders of the road. The backbone of these panels is a glass-reinforced polyester resin system that contributes both to rigidity and to a manageable weight that translates into better handling and improved fuel efficiency without surrendering protective capability. In performance-focused and custom builds, that balance matters as much as any aerodynamic tweak. Yet when we talk about durability, the story is not simply about a number on a spec sheet. It is about how a component that is both a protection layer and a stylistic statement behaves across miles of riding, how it ages, and how riders can care for it so that its performance remains dependable year after year.\n\nFrom a materials perspective, fibreglass fairings carry a tangible advantage in tensile strength relative to many alternatives commonly found on budget builds. The glass fibers embedded in a polyester matrix resist deformation under heat and load more consistently than thinner, more flexible plastics. This makes fibreglass fairings particularly well-suited to environments where heat from engine proximity, air friction, and sustained high speeds can tax lighter plastics. The practical upshot is a higher resistance to impact-induced damage and a more forgiving response when the bike encounters aggressive wind gusts or a rough patch on the road. The same reinforcement that contributes to stiffness also supports a reduction in weight. In typical configurations, fibreglass fairings offer a noticeable weight advantage—often around a 30% reduction compared with traditional plastic fairings. That reduction might seem modest in the abstract, but on a sportbike it translates to crisper steering, quicker throttle response, and lower unsprung mass that improves stability when entering a corner or tracking a straight line at speed.\n\nDurability, however, is not a single attribute measured in a single test. It unfolds in stages as the fairing ages and as mounting points are stressed over thousands of miles. Fibreglass panels can be remarkably resilient, yet they can develop stress points at mounting locations where the bracketry, fasteners, and shield lines pull against the resin and gel coat. The risk is not merely cracking; it is a slow accumulation of micro-cracks and gel coat chalking that can allow moisture ingress or degrade the finish if left unchecked. That is why proper installation matters as much as the material itself. A fairing designed with model-specific fit helps distribute load points evenly, reducing the likelihood of concentrated stress near bolts or along the lower edge where debris strikes are most common. In this sense, the durability of fibreglass is as much about engineering and fit as about raw material strength. A well-aligned fairing forms a single, cohesive shield around the bike, letting the resin and glass work together to absorb and dissipate energy rather than concentrate it at a few high-stress tabs.\n\nThe maintenance philosophy for fibreglass fairings aligns with their durability: proactive care that protects both the gel coat and the underlying composite. Regular cleaning is a simple but essential habit. Gentle soap and water do the job without inviting the micro-scratching that harsher cleaners or abrasive pads can cause. Direct contact with solvents or aggressive solvents should be avoided, as these can dull the gloss of the gel coat or degrade the resin interface over time. The gel coat serves as the first line of defense against UV radiation, road salt, and the daily barrage of environmental grime. Over months and years, UV exposure can lead to chalking or dulling of the surface. A light cycle of cleansing and a periodic wax or sealant designed for gel coats can help preserve the surface gloss and, crucially, maintain a barrier against moisture. This barrier is not only cosmetic; it helps limit the penetration of contaminants that could creep into micro-cracks and hasten their growth.\n\nWhen damage does occur, the response should be measured and professional. Minor scratches and chips deserve prompt attention to prevent moisture from seeping beneath the gel coat and initiating delamination between the gel layer and the fiberglass. In such cases, a repair typically involves matching resin, filler, and gel coat to the existing material to restore both aesthetics and structural integrity. A patch that is well integrated will reinforce the affected area and prevent a small blemish from becoming a larger maintenance concern. The key is to use compatible materials and a careful layering process that preserves the resin’s cohesive bond to the surrounding fiberglass. For riders engaged in restoration projects or upgrades on older builds, this emphasis on professional repair and correct resin compatibility becomes even more important because the joints and seams may have seen more cycles of heat and contraction, which can change how stress is distributed across the panel over time.\n\nAnother dimension of durability is how the fairing interacts with the rest of the bike during installation and operation. The mounting hardware, brackets, and alignments create an ecosystem in which fairings perform. If a fairing is not correctly aligned, or if mounting hardware is overtightened, the resulting stress can create micro-movements that eventually lead to hairline cracks or seam failures. The converse is also true: a precise fit minimizes vibration, reduces crack formation, and extends the life of the finish. Riders who opt for model-specific fairings—designed to line up with mounting points, fairing stay locations, and the intake geometry of the chassis—often experience smoother airflow, lower stray loads, and fewer stress-induced failures. In practice, this translates to fewer field repairs and longer intervals between maintenance sessions.\n\nSourcing high-quality fairings further influences durability. OEM-certified fibreglass variants—those built to exacting standards for a given model—tend to offer better compatibility with the bike’s frame architecture and a more reliable fit right out of the box. This reduces the likelihood of stress points that can arise from awkward gaps or misaligned edges. For riders who value both longevity and affordability, the balance lies in selecting components that deliver reliable performance without paying the premium associated with some alternatives. The right supplier can provide fibreglass panels that are engineered for consistent resin cure, uniform fiber distribution, and predictable finish quality, which all contribute to a longer service life under real-world riding conditions.\n\nCustomization holds a practical place in this durability calculus. Fibreglass is one of the few materials that responds well to alterations in shape and surface treatment without sacrificing integrity. The same ability that allows a panel to be sculpted into a sleek, aerodynamic contour also supports personalized decals and color schemes. A properly finished and sealed surface can resist chalking and micro-scratches even after repeated polishing and repainting, which means riders can refresh the look of their bike without compromising the core material. For those considering personalization, this aspect of fibreglass is not merely aesthetic; it is part of how the panel endures through time and use. The continuous cycle of cleaning, sealing, and occasional cosmetic refresh can help sustain the appearance as well as the performance of the fairing.\n\nWithin this broader narrative, an internal reference point can be helpful for riders seeking compatible options without wading through dozens of supplier listings. A well-curated collection such as the Honda fairings catalog offers a reliable starting point for assessing model-specific fit, revision histories, and compatibility with common mounting practices. See the Honda fairings collection for context on how fitment and finish are coordinated across a family of panels designed to work together on a given chassis, ensuring consistent load paths and predictable maintenance needs. Honda fairings collection.\n\nMaintenance and durability, then, are inseparable processes. The lifecycle of fibreglass fairings hinges on how riders care for the surface, how accurately the panels are aligned during installation, and how often damaged or aging elements are replaced or reinforced. The practical takeaway is simple: treat fibreglass fairings as a durable, shape-retentive skin that benefits from routine care, thoughtful installation, and disciplined maintenance. When these conditions are met, the panels maintain their protective role, preserve aerodynamic advantages, and continue to contribute to the bike’s visual language without becoming a source of ongoing concern. The combination of higher tensile strength, a notable weight advantage, and a repair-friendly interface with compatible resins and fillers makes fibreglass a compelling option for riders who value performance alongside affordability. It is not a one-size-fits-all solution, though. Its durability is best realized when paired with model-specific fitment, careful installation, and a maintenance routine that recognizes gel coat as the first line of defense—protecting the reinforcement beneath and keeping the overall geometry airtight and efficient.\n\nExternal resource for additional context on fiberglass repair and materials can be found in the following reference: https://www.alibaba.com/product-detail/2005-2006-CBR600RR-Fiberglass-Motorcycle-Fairings_1600579747757.html

null

null

Fibreglass Fairings: Speed, Style, and the DIY Edge

Fibreglass motorcycle fairings occupy a practical space where performance metrics meet hands-on customization. Lightweight and moldable, fibreglass lets riders tune aero profile, weight distribution, and aesthetics without the higher price tag of OEM plastics. This blend of engineering and craft invites a workflow where a stock shell becomes a personalized platform tailored to riding goals and visual taste.

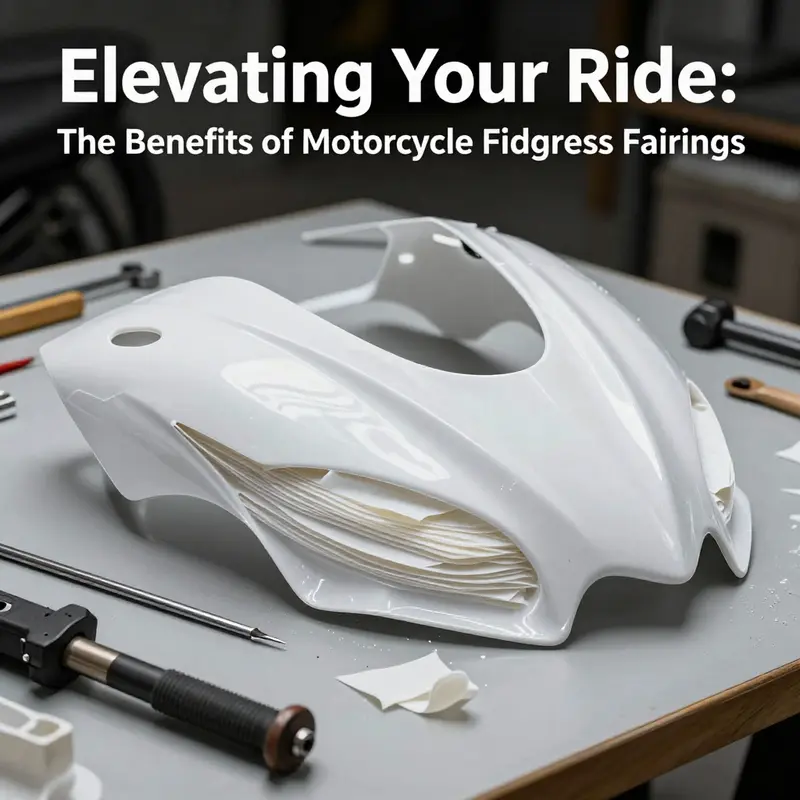

Under the hood, fibreglass is a glass-reinforced polyester system. The glass fibers reinforce the resin, producing panels that combine stiffness with impact resilience while keeping weight down. Because the layup can be adjusted, builders can push for track stiffness or street-sport balance, trading a bit of durability for effortless shaping or a more responsive ride. The material accepts complex contours, vents, and sculpted lines that mirror a rider’s function and style, often with fewer toolchain limitations than some rigid plastics.

Beyond performance, fibreglass offers a broad canvas for expression. Finish options range from traditional hand-painted schemes to decals, metallics, and transparent hues, allowing a bike to tell a personal story without sacrificing strength. Proper fit and alignment remain critical; compatible models and professional mounting help preserve panel gaps, routing, and aerodynamics at speed. For enthusiasts, the result is a lightweight, repairable shell that can be tuned over time as tastes evolve or goals shift.

In practice, a successful fibreglass project blends careful layups, quality resins, and meticulous finishing. The reward is a bespoke fairing that respects the machine’s original geometry while delivering measurable gains in handling, speed, and aesthetics. For riders chasing a balanced compromise between cost, customization, and reliability, fibreglass fairings offer a practical, creative path forward.

Final thoughts

Choosing the right motorcycle fairing material can significantly impact performance, aesthetics, and rider satisfaction. Fiberglass fairings not only provide a combination of strength, lightweight properties, and aerodynamic advantages but also present excellent opportunities for customization at an accessible cost. For business owners capitalizing on the motorcycle market, investing in fiberglass fairings can lead to enhanced product offerings and attract a diverse clientele. Offering these innovative solutions means aligning with rider aspirations for speed, style, and individuality.