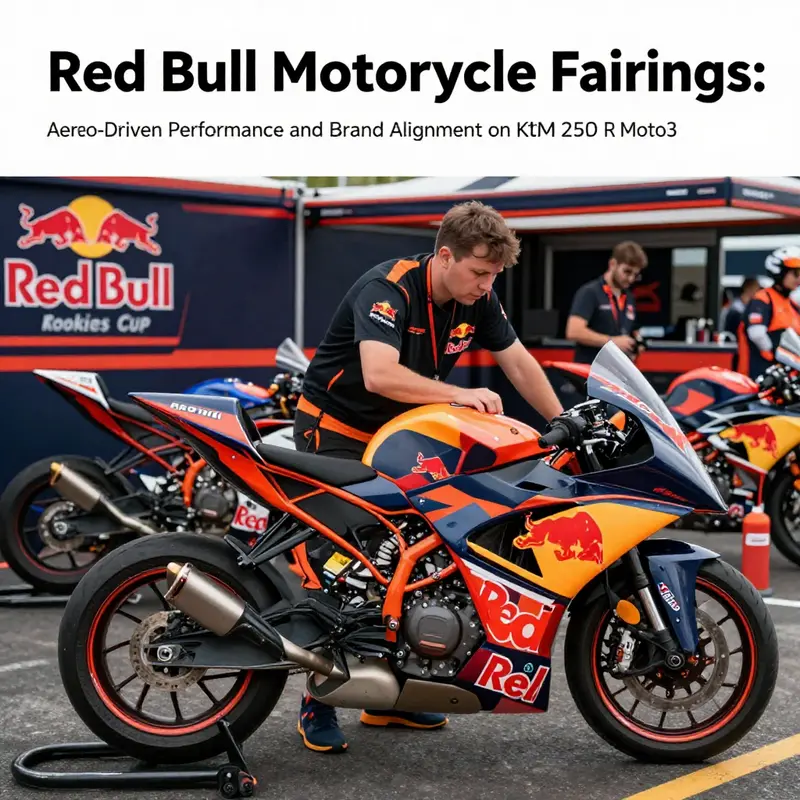

Red Bull motorcycle fairings sit at the convergence of engineering performance and sponsor-driven branding within KTM’s Moto3-based racing ecosystem. These race-oriented front-body panels are not consumer-grade aesthetic pieces; they are a calibrated set of components designed to optimize airflow, reduce drag, and stabilize the bike at racing speeds, while ensuring sponsor visibility across every frame of media and every moment in the paddock. For business owners—whether you’re manufacturing race parts, managing licensing and sponsorships, or evaluating distribution across motorsport channels—understanding the scope, constraints, and opportunities of these fairings helps inform product strategy, supply-chain decisions, and market positioning. The Red Bull MotoGP Rookies Cup, in particular, centers its competition on KTM RC 250 R motorcycles configured to Moto3 specifications. Official listings reference a standardized Red Bull Rookies Cup main fairing for KTM RC125/RC3 variants, signaling a formalized, sponsor-aligned bodywork suite that must fit the chassis with repeatable, predictable performance and rapid changeover during events. While detailed public specifications are sparse, the underlying design philosophy is clear: prioritize aero efficiency over rider wind protection, ensure tight tolerances for quick replacement, and preserve the synergy between sponsor branding and race capability. This article unpacks three core areas that matter to business leaders: (1) aerodynamic design and race-performance integration with the KTM RC 250 R/Moto3; (2) materials, construction, and compatibility with the RC3-10-0065 main fairing; and (3) how official race-partner branding and the Red Bull Rookies Cup influence performance outcomes and commercial value. Each section connects back to the central premise: Red Bull motorcycle fairings are strategic assets that couple technical performance with sponsor-led market presence, shaping both on-track outcomes and off-track business opportunities.

Red Bull-branded Fairings: Aerodynamics, Integration, and Sponsor Identity on a Moto3-inspired Platform

In high-performance motorcycle design, the bodywork is more than protection; it is a carefully engineered tool for airflow and sponsor storytelling. The Red Bull-branded fairings on a Moto3-inspired platform embody the idea that form must follow function. They shape the air around the rider and frame while projecting sponsor identity with clarity on every lap, tilt of the bike, and broadcast angle. This chapter explores how the livery integrates with aerodynamics, cooling, and rider dynamics to deliver consistent performance across sessions.

A primary objective of the fairing is aerodynamic efficiency: minimizing frontal area, managing wake, and preserving stable downforce as speeds rise. The panels are sculpted with smooth edges and gentle tapers to reduce pressure recovery losses and keep the boundary layer energized around critical components such as the radiator and exhaust. The sponsor graphics are embedded in a way that respects the airflow, avoiding harsh edges or discontinuities that could trigger local turbulence or measurement errors in wind tunnel tests.

Integration with the chassis is a design constraint as much as an opportunity. The fairings attach to a purpose-built structure that prioritizes repeatable mounting, accessible maintenance, and precise geometry. Contours are matched to engine envelope, cooling paths, and exhaust routing so the aerodynamic envelope remains intact under race-day stresses. The result is a second skin that complements the bike’s mechanical backbone rather than compromising it, providing predictable behavior when a rider presses toward the edge of grip.

Material choice underpins both performance and durability. Lightweight composites with high stiffness-to-weight ratios are common, balanced with surface finishes that allow accurate painting, decal placement, and long-term resistance to heat and debris. The fabrics and laminates must tolerate heat, vibration, and truth-to-geometry manufacturing tolerances without warping or introducing unwanted texture. The end product is a smooth, uniform surface that supports wind-tunnel fidelity and on-track legibility of sponsor marks.

From concept to race-day reality, development relies on a blend of simulation and empirical testing. Computational fluid dynamics hints at ideal shapes, while wind tunnel work validates boundary layer behavior, wake capture, and overall lift distribution. On-track testing confirms that the packaging remains stable in varied riding styles and track geometries. Throughout this process, the livery remains legible at high speeds and across lighting conditions, a testament to careful color blocking and decal placement that harmonizes with the aero profile.

Branding and engineering are inseparable in race bodywork. The sponsor identity is not a surface add-on but a cross-cutting element of the design that must coexist with aero performance. When executed well, sponsor logos feel like a natural extension of the bike’s engineering story rather than a static overlay. This integration supports a coherent narrative of professional preparation, precision, and performance that fans and partners recognize across media and venues.

In the broader market, the balance between official race-bodywork and aftermarket options emphasizes compatibility, repeatability, and branding coherence. Readers can see parallels in collections that address fitment and finish across platforms, with racing-specific requirements driving prioritization toward aerodynamics, quick-change capability, and sponsor fidelity. The practical takeaway is that these panels are not merely decorative; they are tuned components that contribute to the bike’s speed, stability, and story.

Red Bull Racing Skins: Materials, Fit, and the RC3-10-0065 Main Fairing Within KTM Moto3’s Aero Ecosystem

The skin of a race bike tells a story before the engine even burbles to life. It speaks in lines and planes, in the way the fairing sweeps from the radiator to the tail, and in how sponsor colors ride the bike’s silhouette at speed. When the Red Bull branding is applied to a KTM Moto3–class machine, the fairing becomes both a performance surface and a moving billboard. The dual purpose is not a compromise but a carefully engineered convergence: the surface must slice through air with minimal disturbance while delivering maximum sponsor visibility across every frame of the race, every broadcast, and every still photo that fans study long after the checkered flag. In this chapter we trace how Red Bull’s race-grade fairings come to life, how they are constructed, and how the RC3-10-0065 main fairing fits into the broader aero and logistics ecosystem surrounding the KTM RC125/RC3 platforms and the Moto3-spec RC250 R machines that have defined the Cup since 2013. The narrative is not limited to a single model year or a single factory catalog. It is a thread that runs through the way modern sponsorship, lightweight composites, and standardized mounting points shape the on-track reality of a production-based race class.

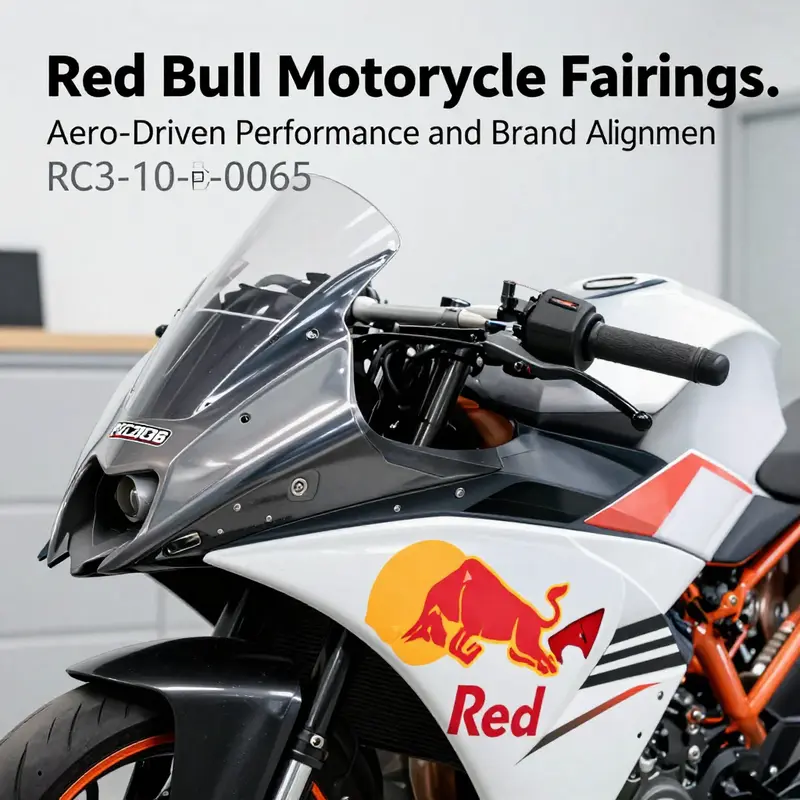

From the outset, the design emphasis in Red Bull–themed race fairings is aerodynamic coverage over rider wind protection. The rider’s comfort is still a consideration, but the championship goal is high-speed stability, repeatability, and predictable airflow patterns around hot components such as the engine envelope, radiators, coolant lines, exhaust outlets, and the fuel system. When a team bolts on a Red Bull–liveried main fairing, it does so with the expectation that the panel will not only maintain symmetry with the livery across sessions but also align with a tightly engineered aerodynamic envelope. This is where the RC3-10-0065 designation emerges as more than a catalog number. In practice it signals a sanctioned interface point for the RC3/RC125 family that has to marry the aerodynamic skin with the chassis geometry of a Moto3-oriented race bike. The intersection of branding and engineering is where the story of these fairings becomes most vivid: a surface shaped to minimize drag and lift, while also presenting sponsor identity on a stage that prizes visibility as much as velocity.

The materials conversation deepens this tale. Publicly available technical papers on Red Bull–themed fairings are sparse by design, reflecting the secretive terrain of factory race parts. Yet the broader experience of top-tier race fairings offers a reliable baseline. The materials are chosen for lightness, impact resistance, and stiffness, essential traits when a panel must survive the occasional contact with a metal frame, a curb during a pit stop, or a stray stone kicked up from the apron of a turn. In many cases, high-performance race fairings adopt a composite approach—multiple layers of glass or carbon fiber-reinforced polymer around a core substrate—or, in some configurations, a robust, high-impact ABS plastic. Injection-molded ABS has become a common baseline due to its precise tolerances, clean surface finish, and cost efficiencies at scale. When Red Bull branding is the visible surface, the underlayers must be engineered to deliver a clean, paint-ready finish that can withstand the consequences of a race weekend: the heat from nearby exhausts, the glare of track lighting, and the occasional micro-meteoritic impact of track debris.

In the context of the RC3-10-0065 main fairing, the approach to material selection aligns with the demands of repeatable, race-ready fitments. The RC3-10-0065 designation, while often linked in vendor catalogs to RC3/RC125 configurations, is part of a larger ecosystem where each part is designed to align with official mounting points on a KTM-based platform that participates in Moto3-spec competition. While the public documentation for RC3-10-0065 does not disclose every minute specification, the available evidence points to a production method that favors measured tolerances and robust fit. The resulting product is one that can be pre-drilled, pre-fitted, and installed with minimal modification during event weekends. This is not merely convenience; it is a race-weekend imperative. In the high-stakes tempo of a Grand Prix weekend, the time spent mounting or adjusting bodywork is time not spent on track prep, engine tuning, or rider briefing. Therefore, precise pre-drilling of mounting tabs and holes is an essential feature. It ensures that a replacement panel can be swapped rapidly between sessions or even mid-race if allowed by the rules, maintaining aero continuity and livery integrity while minimizing downtime.

If we widen the lens to consider other Red Bull–braided race fairings, a useful comparative reference emerges. Even though the RC3-10-0065 discussion centers on KTM and Moto3, the broader practice of sport-livery fairings has been observed in other high-profile Red Bull editions. In a widely cited example from the road-racing world, a 2012–2016 Red Bull–themed edition for the Honda CBR1000RR leaned on a triple-layer ABS construction created via injection molding. The result was a fairing with a near OEM fit, designed to slide into place with pre-drilled mounting points, and finished to a standard that supported aggressive race use while preserving the brand’s iconic look on every surface. Such cross-pollination in the marketplace—that brand identity and manufacturing discipline echoing across brands—offers a practical frame for understanding how Red Bull fairings achieve their dual aims: aero performance and sponsor visibility.

Within this comparative frame, the Honda example serves as a reference point for expectations around fitment and finish. A reliable supplier or OEM-aligned reproduction kit for the Red Bull Honda CBR1000RR, for instance, would emphasize resin types, mold cycle times, and post-cure finishing protocols that respect the integrity of the injected ABS or composite structure. The same logic applies to KTM’s RC-based competition fairings: the mounting interface must be precise enough to maintain consistent aerodynamics while providing the repeatability demanded by race weekends. This is why a part like RC3-10-0065 is described in vendor listings as a sanctioned component for Red Bull–associated racing programs, and why teams seek to source this component from official spare parts catalogs or factory documentation. The consequence of this sourcing discipline is not simply a sturdy panel; it is also a standardized standard of fit that reduces downtime and ensures that sponsor identity remains aligned with the machine’s geometry as it evolves across seasons.

The knowledge gaps are real here. Public, comprehensive technical datasheets for RC3-10-0065 are not widely published, and the details a team might want—such as exact material thicknesses, resin systems, or mold cycle parameters—often live behind the official KTM Spare Parts portals or direct factory documentation. Nevertheless, the narrative that emerges from vendor catalogs and racing-part references is clear: Red Bull fairings are built to a specification that ensures precision in mounting and surface finish, with a focus on aero accuracy and repeatable replacement during events. In practice, this means that a team can trust the RC3-10-0065 main fairing to align with the declared chassis mounting geometry for RC125/RC3 models and to participate in a consistent aerodynamic envelope across seasons. The reliability of that alignment matters because the race track is unforgiving to even small misalignments. The stakes are mechanical and aerodynamic: misalignment can create drag, lift imbalances, or local flow separation that erodes corner speed and stability. The skate-precision with which pre-drilled mounting tabs are positioned, therefore, is a quiet but critical aspect of why these panels are valued by teams that compete at the limit.

Material integrity and the manufacturing ethos behind Red Bull race fairings are as much about survivability as about appearance. The triple-layer ABS concept, where present, is chosen for structural resilience in addition to surface fidelity. In high-speed race environments, the outer skin must resist impact while maintaining paint integrity under UV exposure and heat. The internal layers contribute to this resilience, preserving the panel’s geometry and its aerodynamic performance year after year. The goal is not simply a one-season replacement; it is a dependable piece of the bike that can endure the rigors of a race program and still present a clean, sponsor-oriented silhouette. The result is a mounting system that is robust, a surface that remains smooth under track debris, and a finish that can withstand repeated pre-race taping and panel alignment checks without losing its visual punch.

From a branding and logistics perspective, the RC3-10-0065 main fairing is part of a formalized supply chain. Official parts catalogs, spare parts references, and factory-level documentation are the backbone of the operation. Teams rely on this infrastructure to source standardized, sponsor-aligned bodywork that matches the livery and aerodynamic profiles required by the Red Bull–sponsored series. In the Red Bull MotoGP Rookies Cup framework and related KTM racing platforms, that standardization matters for more than uniformity. It minimizes variation from bike to bike, reduces the risk of incompatibility during a race weekend, and supports a predictable replacement workflow when panels are damaged or worn. The economics here are meaningful: while race-specific fairings command higher prices than street-focused or one-off items, the costs are offset by reduced downtime and by the trust that the surface will meet both the performance and branding expectations in the harsh daylight of a Grand Prix event.

The editorial arc of these observations circles back to the importance of design intent. The fairing is not a mere shell; it is an aerodynamic instrument, a branding canvas, and a mechanical interface all at once. For the RC3-10-0065 main fairing, the design intent is to preserve a precise chassis envelope around the KTM RC125/RC3 family that the Moto3 platform depends on for predictable performance. The integration with Red Bull’s sponsor identity means that the fairing must also deliver a visually consistent, high-contrast presentation across tires, brake disks, and radiators that fans and cameras can read quickly. The result, when executed well, looks effortless and behaves decisively on the track. Riders feel the consistency in the air as much as the stability in the steering; technicians appreciate the repeatable mounting process; and branding teams savor the moment when the livery lines up perfectly with the bike’s geometry in every frame of the race. In this light, the RC3-10-0065 main fairing is more than a component. It is a carefully engineered link between performance and sponsorship, between aerodynamics and aesthetics, and between a rider’s world on the track and the sponsor’s visible world in the stands and on television.

For readers who want to explore a concrete example of how OEM-aligned fairings are presented and documented in a brand-safe environment, an industry-reference page detailing Honda’s Red Bull edition offerings provides a useful comparative case. See Honda’s official resources for context on how branded composites are documented and validated for track use. This reference is useful for understanding the level of expression that a high-performance, sponsor-branded panel aims to achieve in terms of fitment precision and surface detailing. External resource: https://www.hondamotorcycles.com/ . And for those curious about the kind of catalog pages that describe compatible Honda CBR fairings with Red Bull branding, an internal showcase of the Honda CBR1000RR fairings (2012-2016) collection offers a practical sense of how such components are structured and marketed within a human-made ecosystem of fit, finish, and function. Internal link example: Honda CBR1000RR fairings (2012-2016) collection.

In closing, the Red Bull fairings that clothe KTM-based race machines in the Moto3 ecosystem embody a synthesis of material science, manufacturing discipline, and brand storytelling. The RC3-10-0065 main fairing stands as a representative node in this network—a node defined by precise fit, repeatable mounting, and a surface that carries the energy and recognition of a sponsor who has become a symbol of speed, risk, and innovation. While the public technical datasheets may remain sparse, the practical implications are unmistakable: a well-engineered fairing is a crucial enabler of performance, reliability, and sponsor visibility on every lap, under every light, and in every frame that a global audience watches.

Wings on the Wind: Red Bull–KTM Fairings and the Rookies Cup Pipeline

Race fairings are more than shells; they’re aerodynamic canvases and engine-cooling channels fused into a single part. In Red Bull–KTM racing, the official RC-series fairings serve both performance and branding goals. They are designed to fit the RC125/RC3 family with consistent mounting points, enabling quick changes during a race weekend. Materials prioritize light weight and impact resistance, typically composites with smooth surfaces to minimize drag and control flow. The livery travels with the fairing, turning the wind tunnel into a moving billboard while the engineering team pursues marginal gains in aero efficiency. Across the Red Bull Rookies Cup, standardized bodywork helps young riders focus on data and feedback rather than parts compatibility, while the sponsor’s presence reinforces branding as a performance culture. Looking ahead, further material innovations and tighter integration with electronics could push aerodynamics and rider development in tandem, keeping the Red Bull–KTM pipeline as a model of sponsor-aligned engineering in motorsport.

Final thoughts

Red Bull motorcycle fairings exemplify a strategic blend of high-performance engineering and sponsor-driven branding within KTM’s Moto3 framework. For business leaders, the key takeaways are clear: these fairings are purpose-built, materials-driven components that enable repeatable aero performance while delivering sponsor value across media and events. Understanding the RC3-10-0065 main fairing’s role in compatibility with RC125/RC3 platforms helps organizations evaluate supply-chain alignment, licensing requirements, and aftermarket opportunities. The branding framework around the Red Bull Rookies Cup demonstrates how sponsor identity can influence product development cycles, inventory planning, and partner programs. By aligning product strategy with the needs of official race teams and their events, businesses can optimize uptime, reduce downtime for parts replacement, and maximize the return on sponsorship investments through consistent visibility and reliable performance on track.