Introduction

Removing paint from motorcycle fairings is a crucial process for automotive repair and customization businesses seeking to maintain high-quality finishes while minimizing damage. Motorcycle fairings, typically made from ABS plastic or fiberglass, require specialized paint removal approaches that balance effectiveness with the preservation of material integrity. This guide outlines essential methods—starting with chemical paint strippers crafted specifically for plastics, progressing through precise sanding techniques, advancing to laser paint removal procedures—and concludes by emphasizing the importance of proper preparation and careful handling of fairings. Each chapter builds on foundational knowledge to equip business owners and technicians with practical insights, enabling them to optimize workflow, uphold professional standards, and enhance customer satisfaction.

Tables of Contents

Chapter 1: Ensuring Safety While Using Chemical Paint Strippers to Remove Paint from Motorcycle Fairings

- Crucial Safety Measures for Chemical Paint Stripper Use on Motorcycle Fairings

- Mastering the Art of Chemical Paint Stripper Application for Motorcycle Fairings

Chapter 2: Mastering Sanding Techniques for Flawless Paint Removal on Motorcycle Fairings

- Progressive Medium to Fine Grit Sanding for Smooth, Damage-Free Motorcycle Fairings

- Wet Sanding Essentials: Safeguarding Plastic Motorcycle Fairings During Paint Removal

Chapter 3: Advanced Laser Paint Removal Methods for How to Remove Paint from Motorcycle Fairings

- Cutting-Edge Laser Technologies Transforming Paint Removal on Motorcycle Fairings

- Weighing the Environmental and Economic Advantages of Laser Paint Removal on Motorcycle Fairings

Chapter 4: Preparing and Handling Fairings for Effective How to Remove Paint from Motorcycle Fairings

- Mastering Delicate Disassembly and Cleaning for Optimal Motorcycle Fairing Paint Removal

- Blending Mechanical and Chemical Techniques for Safe, Efficient Paint Removal on Motorcycle Fairings

Chapter 1: Ensuring Safety While Using Chemical Paint Strippers to Remove Paint from Motorcycle Fairings

1. Crucial Safety Measures for Chemical Paint Stripper Use on Motorcycle Fairings

Chemical paint strippers provide an effective solution for removing paint from motorcycle fairings, but their use demands careful attention to safety to protect both the user and the fairing material. These strippers often contain potent ingredients that can emit harmful fumes and cause skin or eye irritation on contact, making precautionary steps essential for a safe and successful paint removal process.

Firstly, always work in a well-ventilated environment—preferably outdoors or in a space equipped with exhaust fans—to minimize inhalation of fumes. Strong chemical vapors can pose respiratory risks, and good airflow helps reduce their concentration.

Wearing proper personal protective equipment is equally critical. This includes chemical-resistant gloves to prevent skin exposure, safety goggles to shield the eyes, and long sleeves or protective clothing to protect against splashes. Avoiding direct contact with the chemical safeguards skin from burns and irritation.

It is also vital to ensure the workspace is free from ignition sources. Many paint strippers are flammable, so keep away from open flames, heat sources, or sparks. A clean and organized area reduces the risk of accidental fires during application.

Before applying any stripper broadly, perform a test spot on an inconspicuous section of the fairing. This allows you to verify that the chemical does not cause discoloration, warping, or surface damage, especially important for plastics like ABS or fiberglass composites commonly used in motorcycle fairings.

Strictly adhere to the manufacturer’s instructions for application time and removal methods. Overexposure can damage the fairing surface, so timing must be followed closely. After the stripping process, thoroughly rinse or neutralize residual chemicals according to guidelines to prevent ongoing degradation or complications during repainting.

By integrating these safety protocols, you protect yourself and maintain the integrity of the motorcycle fairings throughout paint removal. For a deeper understanding of alternative removal options that emphasize safety and precision, consider exploring advanced techniques such as laser paint removal, which requires specialized safety procedures including protective eyewear and trained operation source.

For further insights on motorcycle fairing materials and their care during refurbishment, visit Explore the best motorcycle fairings at Summit Fairings, which offers valuable guidance on material types and maintenance.

2. Mastering the Art of Chemical Paint Stripper Application for Motorcycle Fairings

Successfully removing paint from motorcycle fairings with chemical strippers hinges on careful preparation and precise application. The first crucial step is selecting a paint remover that is specifically formulated for plastics like ABS or fiberglass, which are commonly used in fairings. Using harsh solvents risks melting or warping the material, so choosing a plastic-safe product protects the integrity of your motorcycle parts.

Preparation is equally important. Working in a well-ventilated environment reduces exposure to harmful fumes. Protective gear such as gloves, goggles, and a respirator mask safeguards your skin, eyes, and respiratory system from chemical irritation. Before applying any stripper, clean the fairing surfaces thoroughly using a mild detergent or degreaser safe for painted surfaces to remove dirt and oils. This ensures the stripper reacts evenly with the paint.

When applying the chemical stripper, use a brush or plastic applicator to create an even, thin coat. Avoid thick layers or pooling, which can lead to uneven results or damage spots on the plastic. Allow the paint stripper to dwell according to the manufacturer’s instructions, generally between 10 and 30 minutes. During this time, monitor the process closely to confirm the paint softens adequately while the fairing material remains unharmed.

Once the paint has softened, gently lift it with plastic scrapers or soft cloths. Metal tools should be avoided as they can scratch or gouge the fairing, causing irreversible damage. After removing the paint, rinse the surface thoroughly with water and mild soap to remove all chemical residues. Dry the parts promptly to prevent any moisture-related issues, especially on any metal components nearby.

A valuable precaution is to test the stripper on a small, inconspicuous area before proceeding with larger sections. Applying the product in shaded, cool areas rather than direct sunlight or hot surfaces enhances its effectiveness by slowing evaporation.

If you plan to repaint, use non-solvent degreasers afterward to prepare the surface for new paint adhesion. Mastering these application techniques ensures effective paint removal without compromising the fairing’s quality, providing a solid foundation for repainting or refurbishment.

For further detailed insights on motorcycle fairings, explore this resource.

Chapter 2: Mastering Sanding Techniques for Flawless Paint Removal on Motorcycle Fairings

1. Progressive Medium to Fine Grit Sanding for Smooth, Damage-Free Motorcycle Fairings

Achieving a perfectly smooth and paint-free motorcycle fairing surface hinges on mastering medium to fine grit sanding techniques. This process carefully balances effective paint stripping with preserving the structural integrity of fairings, which are commonly crafted from delicate ABS plastic or fiberglass composites. Starting with a medium grit, typically around 400, enables removal of most paint layers and surface blemishes without applying excessive pressure that could gouge the fairing. The key is to maintain light, even strokes and allow the abrasive paper to work rather than forcing it.

From there, transitioning gradually to finer grits in the range of 800 to 1000 (and higher when needed) smooths out the scratches left by coarser papers. This refinement is essential for preparing the surface for a flawless primer and paint finish. Fine grit sanding avoids rough texture and ensures paint can adhere evenly without imperfections. Utilizing wet sanding with soapy water or specialized lubricants during fine sanding diminishes dust and heat generation, both of which could compromise the fairing’s plastic properties.

To maintain uniformity and prevent unintended waviness, using a sanding block or pad is crucial. These tools distribute pressure evenly, allowing consistent abrasion that preserves the fairing’s contours. Sanding patterns should be deliberate—either smooth back-and-forth or circular overlapping motions—to cover the surface evenly and avoid uneven spots.

After sanding, thorough cleaning is indispensable. Residual dust or particles must be removed before applying primer or paint to ensure adhesion and durability. Throughout the sanding process, conservative technique is paramount; aggressive or deep sanding risks permanent damage to the fairing’s finish and structure.

This graduated approach to sanding is widely recognized in automotive refinishing practices, emphasizing gradual smoothing and wet sanding to perfect surfaces. It harmonizes effective paint removal with fairing preservation, making it the ideal method for enthusiasts performing restoration or customization projects. Those interested can explore more about choosing the right fairings and parts on Summit Fairings’ blog.

For additional detailed guidance on sanding and polishing steps in automotive finishing, Eastwood’s comprehensive paint guide offers valuable professional insights.

2. Wet Sanding Essentials: Safeguarding Plastic Motorcycle Fairings During Paint Removal

Wet sanding stands out as a vital technique when removing paint from motorcycle fairings, especially those crafted from delicate plastics like ABS or fiberglass. Unlike dry sanding, wet sanding uses ultra-fine sandpaper—commonly starting at 2000 grit—lubricated with water or soapy water. This lubrication plays a crucial role in minimizing friction and heat buildup, which, if left unchecked, can warp or damage the fairing’s surface. The water also helps carry away sanding residues, ensuring a smoother finish and reducing clogging of the sandpaper.

To protect the fairing’s integrity during this process, it’s essential to apply only gentle, consistent pressure. Letting the abrasives do the work prevents gouges and uneven patches that can compromise the plastic. Beginning on a discreet area helps identify how the material responds to sanding and ensures the paint layer or clear coat isn’t sanded through prematurely. Once the initial smoothing is complete, progressing to finer grits, such as 3000, refines the surface further. This gradual refinement prepares the fairing for subsequent polishing, restoring its gloss and smoothing out imperfections.

One of the key benefits of wet sanding is its ability to balance effective paint removal with preservation of the substrate. Ice-cold sanding water keeps the plastic thermally stable, which helps maintain the original contours and avoids deformation. This approach also reduces micro-scratches that can show up with more aggressive methods. Post-sanding, applying polishing compounds combined with protective clear coats reestablishes the fairing’s visual appeal while shielding it from future wear.

While wet sanding is accessible for many DIY enthusiasts, significant repainting projects or damage restoration may call for professional attention. Experts might use plastic welding, fillers, or color matching to fully rejuvenate fairings without replacement. Nevertheless, wet sanding remains a foundational skill that guarantees safe, controlled paint removal without risking the plastic’s strength and appearance.

For those looking to explore high-quality motorcycle fairing options or seeking further guidance on fairing maintenance, resources like the Explore the Best Motorcycle Fairings at Summit Fairings provide valuable insights.

For a deeper understanding of paint oxidation and restoration, which ties closely to why careful sanding is essential, consult this authoritative guide: Fresh Layer – Car Paint Oxidation Causes, Prevention, and Restoration.

Chapter 3: Advanced Laser Paint Removal Methods for How to Remove Paint from Motorcycle Fairings

1. Cutting-Edge Laser Technologies Transforming Paint Removal on Motorcycle Fairings

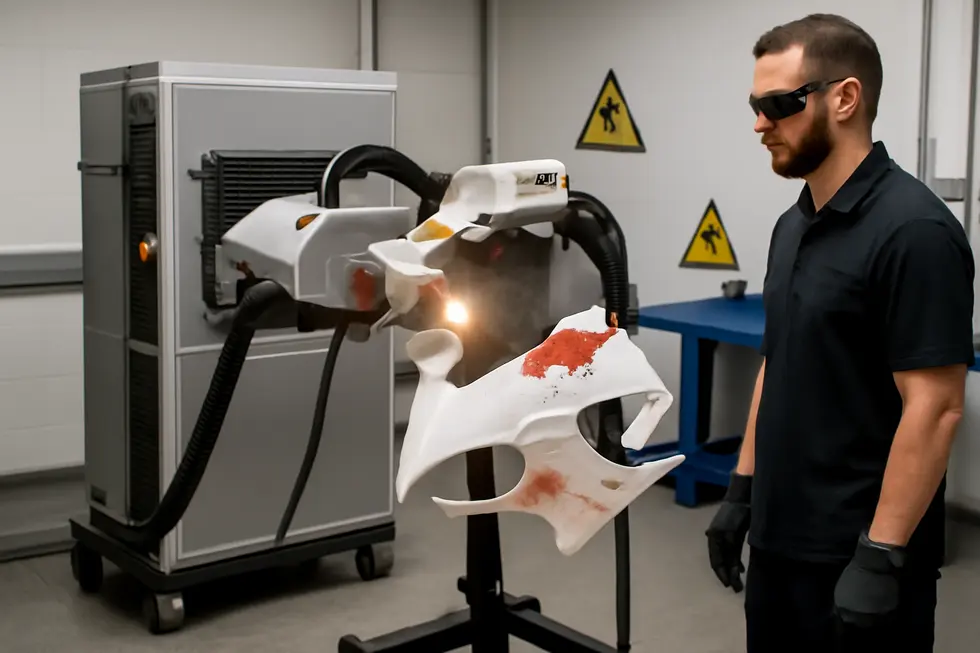

Advanced laser paint removal methods have revolutionized the way paint is stripped from motorcycle fairings, combining precision, efficiency, and environmental care in a single process. Central to this innovation is the use of pulsed fiber laser technology, which emits controlled high-intensity pulses tailored to vaporize paint layers while preserving the integrity of delicate substrates such as ABS plastic or fiberglass. These laser systems offer adjustable power settings and optical focus, allowing operators to precisely target paint without causing thermal damage or surface distortion. With lifecycles reaching up to 100,000 hours and minimal maintenance requirements, pulsed fiber lasers represent a cost-effective and durable solution for both professionals and advanced DIY enthusiasts.

Complementing this technology, laser ablation systems integrated with advanced sensors and optics further refine paint removal processes. These patented sensors guide laser beams with remarkable accuracy, optimizing energy consumption and reducing unnecessary material exposure. This sensor integration ensures environmentally friendly operation by eliminating hazardous chemical runoff and airborne particulates commonly associated with traditional stripping methods. Such eco-conscious advancements are especially pertinent in automotive refinishing, where minimizing waste and environmental impact is paramount.

While CO2 lasers are more traditionally applied to cutting or marking of plastics and wood, they occasionally serve in paint removal under careful modulation, especially on certain fairing materials. However, they generally lack the specialized precision and control offered by fiber-pulsed systems for this application.

Modern laser paint removal units also incorporate intuitive user interfaces with customizable power levels, pulse frequencies, and built-in safety features including mandatory protective eyewear and controlled operating environments. These controls safeguard both the operator and the fairings, preventing overheating or accidental surface damage. Depending on job size and complexity, handheld portable lasers or fully automated robotic systems can be employed, ensuring versatility across various scales of paint removal projects.

Motorcycle fairings benefit significantly from this non-contact, highly controlled technology. Laser cleaning processes preserve the structural and aesthetic quality of fairings, removing paint cleanly and efficiently without abrasion or chemical exposure. Conducting test patches prior to full-scale removal helps optimize laser parameters, balancing speed and power for best results. The precision and reduced environmental footprint of laser methods clearly position them as a forward-looking approach to fairing maintenance and restoration.

For those interested in exploring available equipment and specifications, suppliers offering a range of handheld and automated laser cleaning machines can be found on platforms like Alibaba Laser Cleaning Machines.

This integration of pulsed fiber lasers, sensor-guided ablation, and eco-friendly operation stands at the forefront of paint removal technology, delivering unmatched results for motorcycle fairings while addressing sustainability and operator safety with equal priority.

2. Weighing the Environmental and Economic Advantages of Laser Paint Removal on Motorcycle Fairings

Advanced laser paint removal methods represent a significant step forward in the quest to efficiently and safely strip paint from motorcycle fairings. Unlike traditional chemical or mechanical techniques, laser cleaning eliminates reliance on harsh solvents, which often contain volatile organic compounds (VOCs) that threaten both air quality and water systems. By avoiding these chemicals, this method substantially reduces hazardous waste generation and the risk of environmental contamination, aligning the paint removal process with more eco-conscious practices.

The precision offered by laser technology also means the underlying fairing materials—commonly ABS plastic or fiberglass—remain intact and undamaged. This level of accuracy leads to fewer scraps and less material waste during repainting or restoration phases. While lasers do consume electrical energy, particularly fiber lasers operating between 1000W and 2000W, their overall environmental footprint may still be lower than that associated with the production, transport, and disposal of conventional chemical strippers.

From an economic perspective, laser paint removal can deliver faster results compared to manual sanding or chemical methods, enhancing workflow efficiency in repair shops or manufacturing environments. The reduction in labor intensity—due to automation potentials and the elimination of handling toxic substances—not only improves safety conditions but also brings tangible cost savings. Although the initial investment in laser systems is substantial, often running into thousands of dollars, the long-term savings on consumables like solvents and waste disposal fees help balance these upfront costs.

Maintenance of laser equipment, such as periodic lens cleaning and system upkeep, is critical to preserving operational efficiency but generally involves predictable expenses. Over time, the combination of speed, precision, and lowered labor demands positions laser paint removal as a financially viable solution, especially for businesses prioritizing high throughput and consistent quality.

This balance of environmental stewardship and economic practicality makes advanced laser methods increasingly attractive for motorcycle fairing paint removal—particularly when maintaining surface integrity and sustainability are priorities. Those interested in in-depth information about motorbike fairings and their maintenance might find valuable insights with a trusted source specializing in motorcycle components.

For more detailed perspectives on sustainable and cost-effective maintenance practices, see resources on motorcycle fairings and related care.

External insights into laser cleaning technology and its efficiency can be found at: https://www.sciencedirect.com/science/article/pii/S0045653519335491

Chapter 4: Preparing and Handling Fairings for Effective How to Remove Paint from Motorcycle Fairings

1. Mastering Delicate Disassembly and Cleaning for Optimal Motorcycle Fairing Paint Removal

Mastering Delicate Disassembly and Cleaning for Optimal Motorcycle Fairing Paint Removal

Successfully removing paint from motorcycle fairings begins with careful disassembly and meticulous cleaning, ensuring the panels remain intact and ready for refinishing. The process demands patience, precision, and respect for the fairing’s vulnerability, especially since most are crafted from ABS plastic or fiberglass. Selecting the proper tools, such as Phillips and flat-head screwdrivers alongside Allen wrenches, helps prevent stripping fasteners or cracking panels. Disassembly should follow a logical sequence—generally starting with upper fairings, then midsections, and finally lower panels—to minimize structural stress. Disconnecting electrical connectors gently while safeguarding wiring is crucial to avoid costly damage. It’s also wise to park the motorcycle on a stable, level surface and disconnect the battery or negative terminal, eliminating risk of electrical shorts during handling. Documenting each step with photographs provides a reliable roadmap for reassembly and prevents forcing clips or fasteners, which could crack or deform parts.

After removal, fairings must be thoroughly cleaned. Dirt, grease, and grime not only impair paint stripper effectiveness but can also lead to uneven removal or surface scratches. Using mild soap solutions applied with soft cloths preserves the plastic’s finish. Harsh chemicals or abrasive cleaners are unsuitable because they risk degrading the plastic or negatively interacting with paint layers underneath. A clean surface ensures better adhesion and control when applying paint-removal treatments, whether chemical or mechanical.

Once cleaned, the fairings are primed for paint removal methods tailored to the material. Chemicals designed specifically for plastics offer effective softening while maintaining fairing integrity. However, it’s essential to test these products on a small hidden spot first to detect any adverse reaction. Safety precautions, such as wearing gloves and ensuring proper ventilation, protect both surface and user. Similarly, gentle sanding with fine-grit paper may serve if paint persists, but must be done delicately to avoid warping or thinning the panels.

Following paint removal, another cleaning phase removes residual chemicals or dust. This prepares the surface for possible polishing, decontamination, or repainting steps. Applying protective coatings like wax or ceramic finishes after repainting bolsters durability and maintains a vivid look over time.

By mastering careful disassembly combined with expert cleaning, you set a solid foundation for effective, damage-free paint removal that extends the life and aesthetics of your motorcycle fairings. For a clear example of proper disassembly techniques protecting wiring and panel integrity, consult the Yamaha YZF-R6 fairing removal tutorial here.

For additional guidance on sourcing quality replacement parts or fairings for repair or customization, visit Explore the best motorcycle fairings at Summit Fairings.

2. Blending Mechanical and Chemical Techniques for Safe, Efficient Paint Removal on Motorcycle Fairings

Removing paint from motorcycle fairings demands a balanced approach that combines mechanical and chemical methods, tailored to protect ABS plastic or fiberglass surfaces. Mechanical techniques focus on physically lifting and stripping paint without harming the substrate, while chemical methods soften paint layers to ease removal. Together, they create a comprehensive strategy for thorough and safe paint elimination.

Mechanical removal primarily encompasses gentle sanding, media blasting, and careful scraping. Sanding utilizes fine to medium grit sandpapers (usually between 400 and 600 grit) to gradually wear down paint layers. This process requires a delicate touch because excessive pressure or too coarse grit risks scratching or thinning the fairing’s surface. Media blasting employs softer blasting media like soda or plastic beads, which remove paint evenly with minimal warping risk; however, this requires specialized equipment often found in professional settings. Scraping paint flakes manually can assist in removing loosened paint post-chemical treatment but must be done cautiously to prevent gouges.

Chemical paint removal relies on strippers designed specifically for plastics or fiberglass, ensuring the fairings’ structural integrity remains intact. These formulations—often free of harsh solvents like methylene chloride or based on citrus extracts—penetrate and soften paint, making it easier to lift away with plastic scrapers or cloths. Proper ventilation is vital, along with protective gloves and eyewear, to safeguard the user from potentially harmful fumes and skin contact. Pretesting a small, inconspicuous area of the fairing confirms compatibility and prevents unexpected damage.

Before applying any removal methods, thorough cleaning and degreasing of the fairings are essential to remove dirt, oils, and wax that could interfere with the strippers or abrasives. Removing the fairings entirely from the motorcycle offers full access and prevents harm to attached components like wiring and fasteners—tools like screwdrivers and Allen wrenches are usually required, while photographic documentation aids later reassembly.

Typically, starting with chemical softening makes subsequent mechanical removal less strenuous and more precise. After paint elimination, it is crucial to wash the fairings thoroughly to neutralize chemical residues and allow proper drying. Storing the fairings in a clean, shaded area helps preserve their condition until repainting or replacement.

This combined process ensures efficient paint removal while safeguarding the fairing’s material and finish, providing a solid foundation for restoring or customizing your motorcycle. For specific guidance on fairing removal applicable to popular models, refer to detailed tutorials such as the Yamaha YZF-R6 fairing removal guide. For further insights into motorcycle body part care, consult comprehensive resources like Summit Fairings’ blog.

Final thoughts

Effectively removing paint from motorcycle fairings requires a careful balance between thorough paint stripping and protection of the fairing materials. Chemical paint strippers, when selected specifically for plastic safety, offer an accessible and efficient starting point for business owners tackling paint removal projects. Where paint resists chemical methods, refined sanding techniques with fine grit paper provide a controlled alternative, though caution must be taken to avoid damage. For those seeking the highest precision and efficiency, laser paint removal presents an advanced solution, ideal for professional shops equipped with specialized machinery. Underpinning all these methods is the vital step of proper preparation—meticulous removal and handling of fairings not only prevents damage but streamlines the entire process. By integrating these approaches, business owners can enhance operational quality, reduce customer wait times, and preserve the value of motorcycle fairings, ultimately driving better service outcomes and business growth.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined