Replacement motorcycle fairings are pivotal for enhancing both the performance and appearance of motorcycles. As business owners in the motorcycle industry, understanding the intricacies of fairings—from the types available to material considerations, fitment accuracy, and supplier evaluations—will equip you to better serve your customers. This article elucidates the various fairing types such as full, half, quarter, and semi-fairings, delves into the significance of selecting the right materials, underscores the necessity of ensuring fitment compatibility, and discusses evaluates suppliers effectively. By the end of this guide, you will be poised to make informed decisions that help manage inventory, maintain quality, and provide excellent service.

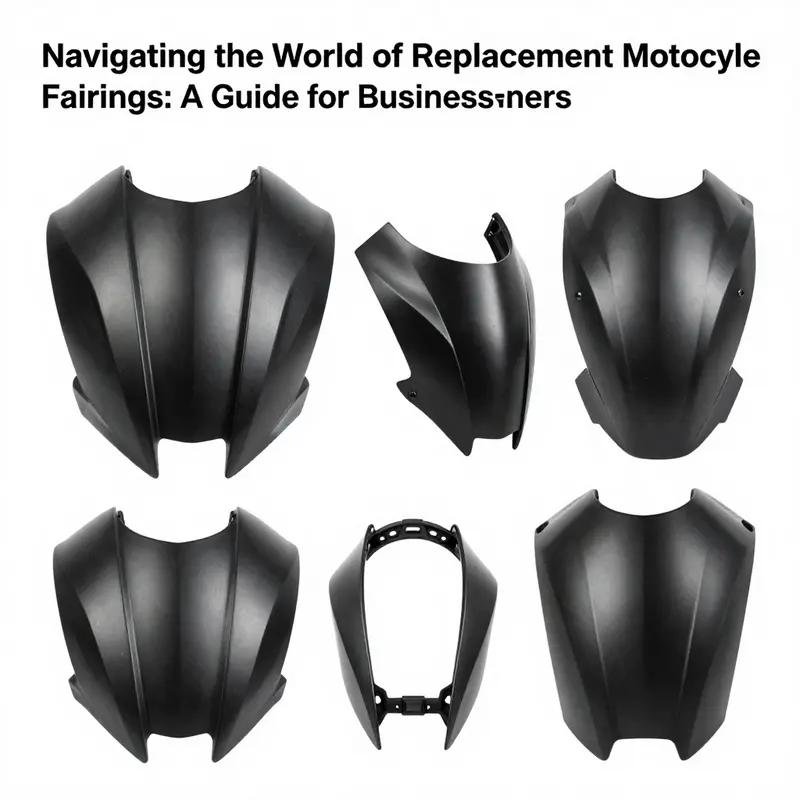

Full, Half, Quarter, and Semi-Fairings: How Selection Impacts Performance, Protection, and Practicality

Replacement motorcycle fairings are more than cosmetic updates; they shape aerodynamics, rider comfort, engine accessibility, and long-term maintenance. When choosing aftermarket panels, riders weigh wind management, protection, weight, and serviceability rather than color or fit alone. The four configurations—full, half, quarter, and semi-fairings—offer a spectrum that can be tuned to track performance or daily commuting.

Full fairings deliver wind protection and aerodynamic efficiency. They enclose the engine and components, reduce drag, and can improve stability at speed. They shield from rain and road debris, help preserve paint and wiring, and can contribute to chassis stiffness. Trade-offs include added weight, higher cost, and more complex installation and repair if damage occurs.

Half fairings provide a middle ground that reduces wind around the cockpit while leaving the lower portions exposed. They lower weight, improve access for maintenance, and preserve a sporty riding posture. Drawbacks include less overall protection and slightly more wind around the torso at high speeds.

Quarter fairings are minimalist, mainly for styling. They offer limited wind protection but keep front-end access straightforward and simplify paint work.

Semi-fairings sit between half and full, delivering more protection than half but easier service than a full shell. They suit sport-touring riders who want a balance of enclosure and maintenance access.

Materials and production quality matter. ABS remains common, but composites and other plastics are used to tailor weight, rigidity, and finish. The key is how well the part accepts paint, resists UV, and holds its shape under heat and vibration. Choose suppliers with in-house tooling and clearly documented finish standards, and verify fit with model-specific compatibility checks.

Compatibility matters. Replacement panels should align with frame geometry, mounting points, and routing. Request sample panels to evaluate surface finish, paint adhesion, and UV resistance before committing to production quantities. A robust evaluation framework helps avoid misfits and delays.

Durability and long-term reliability come from consistent quality control, proper installation, and good supplier support. A well-chosen fairing stays aligned, protects critical components, and remains serviceable over miles of riding.

Practical approach. Define riding climate, conditions, and willingness to invest in fitment tests and paint work. Catalogs grouped by model families help narrow options and visualize how a given set of panels will sit on a bike. For example, collections/honda-fairings can guide model-specific selection.

For deeper technical grounding, consult official product guides and engineering data. They clarify aero role, radiator interaction, mounting geometry, and maintenance expectations. Always verify certification, surface finish, and UV resistance to ensure safety and longevity.

In short, the best replacement fairing balances fit, durability, and safety over the long ride.

Material and Fit: Choosing the Right Replacement Fairings

Selecting replacement motorcycle fairings blends engineering, aesthetics, and practicality. The material you choose influences not just appearance but how a panel performs in use. Weight, rigidity, impact resistance, and paint durability all trace back to the base material. In a crowded market, understanding these fundamentals helps riders pick replacements that maintain safety, performance, and the bike’s character. This chapter treats material choice as the starting point for a broader evaluation that also includes fitment, manufacturing quality, and after-sales support. When a fairing aligns with the bike’s geometry and the rider’s expectations, riding becomes more predictable, comfortable, and enjoyable.

Common materials used in replacements fall into a familiar trio: ABS, polycarbonate, and fiberglass. Each offers a different balance of advantages and trade-offs. ABS is economical, lightweight, mold-friendly, and paint-ready, making it a popular baseline choice. It tolerates cosmetic customization well but can degrade under strong UV exposure without protection and may lack the stiffness of fiberglass under certain loads. Polycarbonate offers exceptional toughness and clarity, with strong impact resistance and better UV resistance in treated variants, though it is typically pricier and can scratch more easily without a protective coating. Fiberglass provides stiffness and a potentially lighter, rigid panel ideal for performance-oriented builds, but it requires more specialized finishing and repair work and can incur higher initial and maintenance costs.

Wall thickness matters: typical fairing panels run around 2–3 millimeters. A thicker panel can feel more durable but adds weight and may affect heat dissipation and fit; thinner panels save weight but may be less resistant to repeated debris impact. Whenever possible, check for uniform wall thickness and request samples to assess consistency. Surface finish, paint adhesion, and UV resistance are influenced by base material, processing, and post-production treatments, not just color and gloss alone.

Beyond materials, fitment is critical. Poor molding tolerances, misaligned mounting points, or mismatched ducts can undermine even the best material. Reputable suppliers with in-house tooling often offer tighter tolerances and easier customization, which can matter for performance builds where airflow, venting, or winglets are involved. When evaluating suppliers, look for demonstrated production quality, transparent testing, and a track record of meeting safety and finish standards. A reliable supplier should provide clear information about wall thickness, UV treatment, and finish specification, plus reasonable warranty terms.

In practice, a balanced recommendation follows the rider’s use case: if budget and easy customization are priorities, a high-quality ABS with UV protection is a solid baseline. For riders needing maximum impact resistance and a premium look, polycarbonate can deliver, provided you accept higher cost and the need to protect the surface from scratches. For track-focused or highly customized aesthetics, fiberglass remains a compelling option, with the caveat of more involved manufacturing and repair. The key is to verify material specification and ensure the panel’s wall thickness and surface finish meet defined standards.

When choosing a source, consider a collection aligned to a specific make or model to improve fit and color matching. For example, a Honda fairings collection can help ensure alignment with mounting points and contours, while a trusted supplier will back up fitment with repeatable production quality and documented testing. The goal is a predictable purchase that minimizes the need for custom fabrication and the risks that come with poor fit.

Ultimately, material choice is not a single feature but a system. It should harmonize material behavior under load, environmental durability, manufacturability, and fitment with the bike. A reliable selection process combines robust material fundamentals with supplier credibility to deliver replacements that preserve the bike’s character, performance, and the rider’s confidence across miles and seasons.

A Precision Fit: Navigating Compatibility and Safe Installation of Replacement Motorcycle Fairings

The shell that wraps a motorcycle does more than frame a rider in a stylish silhouette. It channels air, shields vulnerable components, and helps stabilize handling at speed. When that shell becomes damaged or worn, a replacement fairing is an appealing fix. Yet the value of a replacement kit hinges on fitment as much as on color, texture, or price. A properly fitted set preserves the bike’s intended geometry, keeps airflow where it belongs, and avoids introducing new points of stress into the frame or mounting hardware. In practical terms of everyday riding, a seamless shell is a safer shell. The promise of a sleek, like-new appearance only holds if the parts actually align with the bike’s anatomy and its engineering expectations. This chapter traces the throughline from model-specific compatibility to the realities of installation, with an eye toward durability, safety, and long-term reliability. It is a narrative of precision and prudence, where every mount, every fastener, and every contour matters as much as the finish itself.

At the heart of replacement fairings is model-specific compatibility. Every motorcycle balances a unique set of geometry, mounting points, and rider interface components—points of interface that are easy to overlook in a catalog photo but essential to a secure, safe fit. The primary rule is unambiguous: fairings must be engineered for the exact make, model, and year of the bike. Even small distinctions in frame geometry, the location of fastener bosses, or the shape of the handlebar collar can create misalignment that shows up as gaps along the joint lines, unsightly misfits at the headstock, or, worse, shifted lines that alter the way air flows around the radiator and beneath the rider. When a listing explicitly calls out compatibility with a particular model-year pair, it is signaling that those critical interfaces have been accounted for. Buyers should cross-check this with the official product data and, if in doubt, contact the seller for confirmation. A missed compatibility cue can cascade into poor airflow, rattling at speed, or even interference with steering under extreme conditions.

Material choice and how it interfaces with fitment add a second layer of complexity. OEM fairings typically rely on robust ABS plastic known for impact resistance, dimensional stability, and UV resistance. But aftermarket options span a spectrum—from reinforced ABS blends to fiberglass, to carbon fiber composites, and even hybrid laminates that mix stiffness with lightness. Each material presents its own tolerances and interface behaviors. A part manufactured to a slightly different thickness or rigidity, even within a single kit, can subtly alter how it sits against the frame, how mounting points align, or how the panels compress under bolt torque. Lightweight composites can improve weight distribution and performance aesthetics, yet they demand tighter manufacturing tolerances to retain OEM-like fit. Conversely, heavier or less precisely formed panels may look right in a photo but exhibit gaps or binding with wind-taring components at speed. This is not just a cosmetics issue; it can shift vibration characteristics and stress concentrations at mounting points, which over time may invite cracks or joint separation. The takeaway is clear: compatibility and material fidelity go hand in hand. Buyers should not assume that a lower price equates to a simpler, sturdier installation. It is equally important to verify whether the supplier provides detailed tolerances, mounting hardware, and any necessary interface modifications.

The practical challenges of installation reinforce the necessity of precise fit. Even kits that appear to align visually can conceal issues that only show up when the fasteners are tightened and the fairings are pressed into their real operating environment. Missing hardware is a common pitfall; some aftermarket kits include all required bolts, spacers, and plugs, while others assume the buyer will source components locally. In some cases, the kit may require minor modifications to the frame, the subframe, or the electrical system—particularly for integrated turn signals or LED lighting modules. If harnesses or connector plugs do not align with the bike’s loom, electrical functionality can be compromised or, in the worst-case scenario, a short circuit or blown fuse could occur. For this reason, many riders find value in either a professional fitting or a qualified shop with experience in bike bodywork. A technician can map each mounting point, confirm panel-to-panel alignment under load, and ensure that headlights, gauges, and indicators sit within their intended apertures without obstruction.

A nuanced step in the evaluation of any replacement fairing is the validation of the product’s compatibility data through multiple channels. The reality in the market is that sellers may advertise model-specific compatibility while the practical reality can vary by sub-model or regional specification. This is where in-depth data and third-party feedback become crucial. Prospective buyers should look for listings that provide explicit model-year compatibility, exact mounting point references, and, ideally, a means to verify surface finish, paint adhesion, and UV resistance on a sample panel or a test fit piece. In some markets, suppliers advertise perfect fit or model-specific compatibility, while the user experience shared by others reveals real-world installation nuances. Reading reviews that describe fitment outcomes—whether the panel lines align with factory gaps, whether the fairings maintain their shape after the first ride, or whether paint match remains consistent after exposure to sunlight—offers a practical lens that goes beyond spec sheets.

The conversation around fitment is inseparable from the broader discipline of supplier evaluation. A robust framework for choosing a replacement fairing should weigh technical capability, operational stability, and transactional reliability. Technical capability means more than a glossy finish; it includes precision mold-making, proper interface geometry, painstaking tolerances, and the ability to provide custom modifications when necessary. Operational stability encompasses the supplier’s infrastructure, lead times, quality control, and the consistency of product batches. Transactional reliability covers order accuracy, communications clarity, return policies, and the ability to resolve issues quickly. A sole focus on price, without vetting these dimensions, often leads to later misalignment, inconsistent finishes, or shipment delays that disrupt a rider’s schedule and confidence.

With those principles in mind, practical consideration of the purchasing path becomes meaningful rather than merely procedural. Buyers should start by identifying the bike’s exact make, model, and year, then compare those specifics against the listing’s compatibility notes. If the listing claims compatibility for a range of years, verify whether the claim includes sub-models or regional variants that could affect installation. Where in-house tooling and mold design capabilities exist, it is reasonable to anticipate better fitment outcomes and easier customization—such as revised intake ducts, venting for cooling, or winglets for performance-oriented builds. For riders leaning toward customization or performance augmentation, modular designs that permit individual part replacement—without forcing a full fairing kit retreat—can be a practical advantage. Yet modularity must be matched by precise interfaces between modules, so each piece can interface with the bike and with neighboring panels without gaps that invite wind flutter or moisture intrusion.

As part of the due diligence, a conservative buyer’s approach can include requesting sample panels or a small set of panels to test surface finish and adhesion before committing to a full kit. A test fit in a controlled workshop environment, before paint and final assembly, can reveal misalignments that photos or product descriptions obscure. In markets where sun exposure is intense, UV resistance becomes a practical concern; a panel that looks fine in a showroom can fade or craze after a season if the resin system or pigment chemistry is not up to standard. These checks are not merely cosmetic; they protect investment, ensure a consistent color match with existing components, and preserve the integrity of mounting hardware by preventing accelerated wear at contact points. For buyers who want to see tangible evidence of a proper fit, forums and user reviews often provide the most insightful, unfiltered accounts of fitment in real-world riding conditions. The objective is a uniform, tight sequence of joints along each seam, with panels that sit flush against the bike’s contours, maintain clearance around the handlebars and instruments, and avoid interference with cooling vents, radiator outlets, or wheel paths during suspension travel.

Another practical pathway through the landscape of replacement fairings is to consider brand-agnostic catalogs or category pages that group fairings by vehicle family rather than by exact model. Such catalogs often offer broad templates and show which mounting philosophies tend to align with certain frame shapes. If you are browsing a dealer’s general catalog, look for notes about how the kit interfaces with the bike’s subframe, the radiator guard, or the steering head. Do not overlook the importance of the hardware kit that accompanies the panels. A well-made fairing kit should include not only the panels but the appropriate fasteners, spacers, and plugs to ensure proper alignment and tension across fastener points. Mismatched hardware can create uneven pressure distribution along a joint, which in turn can produce paint cracking, panel delamination, or warping under heat. The net effect of a meticulously assembled kit is a ride with predictable handling, where the fairings do not introduce flutter or vibrations at highway speeds.

For readers and riders who want to explore options with confidence, a practical tip is to access a dedicated parts collection that specifically emphasizes compatibility and coverage. In the realm of replacement fairings, a pragmatic route is to consult a category or collection page that consolidates model-compatible options, often with filters for make and model and year. A direct reference point to consider is the Kawasaki fairings collection, which curates the available panels and suggests suitable fitment with many sport and sport-touring configurations. This approach helps ensure you’re viewing components that are designed to interface with common mounting points and standard electrical harness layouts, reducing the guesswork that can accompany generic aftermarket offerings. See the Kawasaki fairings collection for a practical overview of compatible options.

The process of selecting and fitting replacement fairings, then, is not a single decision but a sequence of checks and confirmations. It begins with a clear understanding of the bike’s exact specification and a realistic assessment of how the chosen fairing material will interact with that specification. It continues with a careful review of the supplier’s data—tolerances, installation notes, and hardware inclusions—and culminates in a measured installation that respects the bike’s structural integrity, electrical system, and aerodynamic design. The aim is not merely to replace a shell but to restore, or even improve, the bike’s original performance envelope. It is a discipline of precision, not perception, where every measurement, every seam, and every alignment point contributes to a ride that is safe, reliable, and true to the rider’s expectations.

In short, when you plan a replacement fairing project, the path to success is paved with three questions. First, is the kit truly compatible for your exact bike, year, and sub-model? Second, does the material and the thickness align with OEM tolerances and the bike’s structural requirements? And third, does the supplier offer transparent data, robust customer support, and a realistic path to fitment without compromising safety? Answering these questions with diligence yields not only a polished exterior but a fairing system that behaves predictably under wind and weather, preserves rider visibility and control, and resists the fatigue that comes from misalignment. If you approach replacement fairings with this mindset, you reduce the risk of future misfits and you elevate the probability of a finish that stands up to daily riding and the occasional track-day alike. External resources and supplier reviews can support your due diligence, but the most decisive indicators are the tangible fit and the quiet confidence that comes with a shell that remains true to the bike’s original geometry and purpose. External reference: https://www.alibaba.com/product-detail/KAWASAKI-NINJA650-2020-2023-Motorcycle_1600849328384.html

For readers seeking a broader, practical view of compatible options and cataloged ranges, the Kawasaki fairings collection provides a focused lens on what is typically available for sport and sport-touring applications. It offers a structured overview of mounting philosophy and interface conventions across a family of models, which can help buyers quickly gauge whether a given kit aligns with their bike’s fundamental geometry and mounting strategy. This broader context can support a more informed comparison when evaluating a specific listing, reducing the guesswork that can otherwise slow progress toward a proper fit. See the collection here: Kawasaki fairings collection

Choosing the Right Skin: How to Evaluate Suppliers for Replacement Motorcycle Fairings with Confidence

Riders chasing replacement motorcycle fairings pursue more than a fresh look. They seek a balance of compatibility, durability, and performance that preserves safety and ride feel. In practice, that balance rests on choosing the right supplier as much as on selecting the right material. A robust supplier evaluation becomes the frame through which cost, quality, and risk are weighed. Without it, the bargain price can yield a misfit, inconsistent finishes, or delays that ripple through a season of riding. With it, a replacement fairing becomes a reliable component, one that preserves aerodynamics, withstands harsh sun, resists impact, and remains stable through the miles that matter most to a rider’s confidence. The chapter that follows treats supplier evaluation as a disciplined approach rather than a reflexive bargain hunt. It is a path that begins with a clear specification of needs and ends with a supplier relationship built on predictability and shared standards. In between, technical capability, operational stability, and transactional reliability form the three pillars that support long-term value, especially when the market for replacement fairings is shaped by the realities of global manufacturing and complex logistics.

At its core, material specification is the first hinge on which quality swings. The standard for most replacement applications is automotive-grade ABS plastic, known for impact resistance, dimensional stability, and cost efficiency. ABS offers a robust combination of rigidity and toughness that can handle road vibrations and the occasional curb encounter without excessive weight. But buyers who race or demand higher performance may encounter fiberglass-reinforced or carbon fiber options. These materials carry higher labor costs and a degree of variability tied to hand-layup processes. The nuance here is not merely a preference for a lighter or stiffer shell; it is a question of whether the supplier can consistently reproduce the necessary surface finish, paint adhesion, and UV resistance across batches. In markets with intense sunlight, UV stability is not optional; it is essential for color retention and structural integrity over time. Consequently, the evaluation framework calls for concrete demonstrations: sample panels that can be subjected to surface-finishing tests, paint adhesion tests, and accelerated aging trials. Third-party test reports, when available, offer independent validation that helps translate lab results into road-ready performance.

Beyond the material itself, the question of fitment anchors the entire evaluation in reality. A high-quality fairing can be useless if it does not align with a specific model’s geometry and mounting points. The supplier should be prepared to provide technical verifications that go beyond marketing promises. That often means a capability to produce sample panels to assess surface finish, to verify paint adhesion under heat cycling, and to confirm UV resistance across the anticipated exposure profile. In markets where sun and heat are relentless, a few samples can save weeks of back-and-forth rework. If a supplier has in-house tooling and mold design capabilities, it becomes possible to tailor the parts to the rider’s needs—modifications such as intake ducts, venting, or even aerodynamic features like winglets, when they serve a performance-oriented goal. These capabilities, while not always necessary for every buyer, become decisive when the objective is frequent replacements, specialized race setups, or long-term touring configurations that demand precision and repeatability.

Perhaps the most telling evidence of a supplier’s reliability lies in the supply chain’s consistency, not just in the quality of the parts. Manufacturing hubs matter because they influence both cost and speed to market. China remains a dominant source for many components in this sector, with Guangdong Province and its cluster of manufacturing cities offering mature chains for ABS, fiberglass, and UV coatings. Proximity to major ports helps accelerate shipping and reduce the logistical friction that can lengthen lead times. Zhejiang’s Ruian region is renowned for precision mold-making, an asset when exact tolerances and complex geometry are required. Fujian suppliers emphasize export logistics, turning around packaging, compliance labeling, and freight coordination into a turnkey service that can shave days off a project timeline. Anhui’s emergence as a hub for automated mass production highlights the potential for consistent quality at scale, driven by robotics and lean manufacturing. Each region brings a distinct strength, and the astute buyer recognizes that a supplier’s location is not merely a location but a capability set that interacts with lead times, capacity, and risk management.

Lead times, too, reveal the texture of a supplier’s operation. ABS injection-molded kits typically carry shorter cycles, while full carbon-fiber builds demand longer durations due to curing and finishing stages. Understanding these timelines matters because the decision to place a large order hinges on planned maintenance windows, seasonal demand, and the rider’s broader project timeline. High-volume facilities can produce thousands of sets monthly, which makes them well-suited for bulk orders that justify containerized shipping and favorable freight terms. Such economics underscore why the buyer’s assessment cannot stop at the price quote. It must extend into capacity planning, scheduling reliability, and the supplier’s demonstrated ability to scale without compromising fit and finish.

A supplier’s performance is only as strong as the data that describes it. The evaluation framework becomes most effective when it treats performance as a living metric rather than a one-off audit. The three pillars—technical capability, operational stability, and transactional reliability—offer a practical, data-driven lens. Technical capability is the measure of what a supplier can produce and how consistently they can replicate it. Operational stability captures the predictability of their operations—their lead times, quality control routines, and their ability to manage variability in demand. Transactional reliability looks at communication, responsiveness, on-time delivery, and the ability to honor commitments under pressure. Even in markets without formal certifications like ISO 9001, these performance indicators are meaningful proxies for process maturity. A supplier who can demonstrate high on-time delivery rates, rapid response times, and a track record of returning inquiries with clear, actionable information earns trust that matters when a niche requirement or a strict deadline surfaces.

The practical steps of evaluating a supplier reflect the realities of a global, demand-driven market. Begin with a clear specification of needs, including material choice, thickness tolerances, color-matching standards, and resistance to the environment in which the parts will operate. For many buyers, a well-drafted requirements document also includes expectations for surface finish quality, paint adherence, and UV durability across a defined number of cycles. The next phase is live testing: request sample panels and evaluate them against the criteria. A responsible supplier will accommodate this testing step without resistance, recognizing that the test acts as a shared risk reducer. When the supplier can provide in-house tooling and mold design, inquire about their capacity to support modifications beyond basic geometry. There may be legitimate constraints, but some suppliers will offer design-for-manufacturability insights that help optimize performance, from improved airflow to reduced weight without sacrificing strength.

Another practical aspect of supplier evaluation concerns bulk orders and logistics. Large orders, such as those that exceed hundreds of sets, can be shipped more cost-effectively when sourced near established manufacturing hubs. Containerized shipping becomes an operational advantage in these scenarios, but only if the supplier can deliver consistently on schedule and within agreed packaging standards. Here, a set of quantitative expectations—on-time delivery rate, measured in percentage terms, and the supplier’s response speed to inquiries—serves as a performance bar. A high on-time rate, say near or above 97 percent, signals a mature operation with disciplined forecasting and reliable production planning. A quick response time reflects a customer-focused culture that reduces friction during a project and helps align expectations across multiple stakeholders, including distributors and workshop partners. Customer retention, a downstream indicator, often reveals stability in supplier relationships and the ability to manage post-sale issues with minimal disruption to downstream assembly lines.

The decision to look beyond price is more acute in the context of fitment risk. It is not enough to compare quotes on a single line item; it requires evaluating whether the supplier’s process reduces the likelihood of misalignment with a model’s mounting points, fairing contours, and fitting hardware. Measurement, tolerance management, and a culture of continuous improvement matter here. The buyer can mitigate risk by insisting on technical verification steps that quantify how close the final product aligns with the original geometry. In practice, that means validating the surface finish, the paint adhesion, and the UV resistance of a sample panel, then corroborating those results with a second panel from a different batch to ensure repeatability. If a supplier can present evidence of in-house tooling and mold design, the buyer gains a degree of confidence that minor modifications—such as venting improvements or intake ducting—can be introduced without sacrificing symmetry or alignment. In such cases, the partnership moves from a simple transactional relationship to a collaborative development effort that yields long-term benefits for both sides.

Within this dialogue, the role of regional specialties becomes clearer. Buyers can leverage the strengths of different hubs to optimize overall supply chain resilience. For instance, a supplier in a mold-focused region can deliver parts with tight tolerances required for complex aerodynamic shapes. A partner in an automation-driven region may offer consistency in mass production, lowering unit costs and reducing variability. A logistics-centric region can manage packaging, labeling, and freight coordination that smooths entry into overseas markets. The strategic takeaway is not to stereotype suppliers by geography but to map capabilities to project needs and to build a network of partners that can collectively meet demand while preserving quality. The ability to adapt to supply fluctuations—whether caused by global events, raw-material price shifts, or shifts in demand—depends on having multiple credible sources and clear criteria for evaluating each one.

In practice, a buyer also benefits from a transparent, data-driven evaluation process that translates the three pillars into a scorecard. The scorecard should capture material specifications, testing results, lead-time reliability, and responsiveness, with notes on any deviations or corrective actions. Even without formal certifications, a well-maintained scorecard provides a narrative of process maturity and risk posture. The ultimate aim is to create a decision framework that can be revisited as project requirements evolve—whether the rider shifts from daily commuting to a touring-oriented setup or moves into a sprint-race environment requiring more aggressive intake and venting configurations. With such a framework, the purchase decision becomes a disciplined choice rather than a gamble. The rider or distributor benefits not only from a better-fitting part but from a reliable partner who communicates clearly, delivers on time, and maintains consistent quality across batches.

For readers seeking a practical starting point that aligns with the real-world options and model compatibility, exploring a manufacturer’s broader fairings collection can be helpful. A curated gateway like the Honda fairings collection offers a reference map for the typical geometry, mounting points, and painted surfaces that buyers encounter when they start comparing options. This does not imply endorsement of any single supplier; rather, it provides a yardstick for evaluating fitment and aesthetic alignment against a familiar baseline. By comparing the target project against such reference points, buyers can better interpret the quality signals embedded in product samples and the supplier’s documentation. Accessing a centralized catalog of model-specific fairings also helps illuminate the nuances that often determine compatibility, such as panel count, joint design, and hardware interfaces. The use of an internal reference can accelerate the alignment process between what the rider envisions and what the supplier can deliver, reducing the risk of later rework and dissatisfied outcomes. In this way, the supplier evaluation process intersects with practical modeling and project planning, reinforcing that successful replacement fairings arise from a deliberate, collaborative approach rather than a solitary purchase.

The evaluation framework described here does not merely protect dollars; it protects the rider’s confidence on the road. A part that fits well, finishes consistently, and lasts through the seasons provides peace of mind, minimizes downtime, and sustains the integrity of the bike’s aero profile. The discipline of supplier evaluation—rooted in material specifications, testing, regional capabilities, and performance metrics—transforms a potentially volatile procurement into a predictable, value-driven process. It also helps distributors and workshops build reputations for reliability, turning replacements from a one-time transaction into a trusted service that riders can count on, year after year. The ultimate payoff is simple in principle yet profound in practice: when a replacement fairing is selected through a robust evaluation, the rider gains not only a better-looking bike but a safer, more predictable riding experience with fewer surprises along the way.

External resource for deeper insight into supplier evaluation frameworks can be found here: Supplier Evaluation Framework for Motorcycle Fairings. For readers seeking direct access to model-specific catalog references and potential collaboration channels, you may explore a curated catalog of model-specific fairings as a practical reference point and starting ground for fitment comparisons: Honda fairings collection.

Final thoughts

In conclusion, navigating the complexities of replacement motorcycle fairings is essential for any business owner in the motorcycle industry. By understanding the different types of fairings available and their material nuances, ensuring proper fitment, and choosing suppliers wisely, business owners can enhance customer satisfaction and operational efficiency. Implementing these insights will not only streamline your inventory management but also fortify your reputation as a reliable source for quality motorcycle parts. A balanced approach to cost and quality can elevate your business to new heights, ensuring that you remain competitive in a dynamic market.