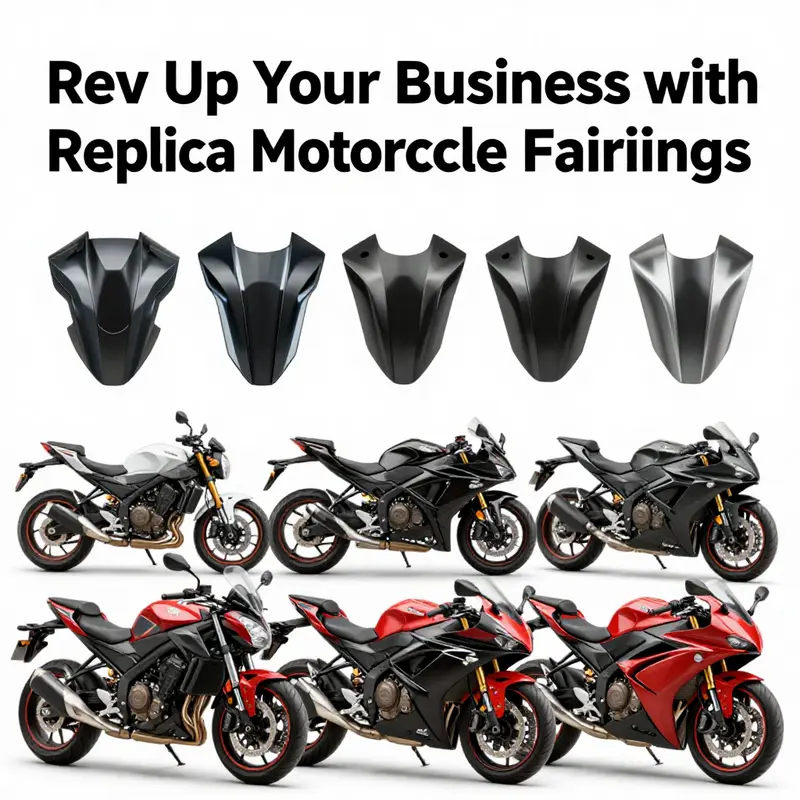

Replica motorcycle fairings are increasingly popular among enthusiasts and businesses alike, offering a blend of aesthetic appeal and functional advantage at a more accessible price than OEM parts. As the market continues to grow, understanding the types and designs of fairings available, the materials used in their production, and the trends shaping consumer preferences is crucial for business owners in the motorcycle industry. This article will explore these vital aspects, offering insights into how they can elevate your offerings and meet customer demands effectively.

null

null

Weave, Weight, and Wind: How Materials Shape the Performance and Aesthetics of Replica Motorcycle Fairings

Replica motorcycle fairings occupy a unique space in the riding world. They promise the look and feel of high-performance or iconic machines without the sticker shock of genuine OEM parts. Yet the material behind that skin—the stuff that most riders never see unless a clip-on dangles or a panel cracks—matters as much as the shape it covers. The material determines how the fairing behaves at speed, how it wears in the sun, how it ages under heat and rain, and how authentic the final presentation appears to the eye. In this chapter, we explore the material triad often used to craft replica fairings—ABS plastic, fiberglass, and carbon fiber—and how each option reframes the relationship between form and function. We’ll travel beyond surface appearance to consider how these choices influence rigidity, airflow, weight, repairability, and even the tactile sense a rider experiences when leaning into a corner or blasting along a straightaway. The discussion unfolds as a single thread rather than a collage of disparate points, because the truth about replica fairings is that the material and the design are inseparable partners in performance and aesthetics.

ABS plastic sits at the heart of mass-produced replica fairings. It is the most common entry point for riders who want a convincing look without a daunting price tag. The material’s uptake into the aftermarket scene is driven by a simple equation: low cost, versatile tooling, and a surface that can be finished to a very convincing OEM-like gloss. ABS blends well with conventional painting techniques, which means a seamless color match and a smooth, uninterrupted surface that slides through air with minimal drag. For most street and touring applications, ABS is more than adequate. It yields a fairing that keeps the wind off the rider, reduces turbulence around the chest and shoulders, and maintains a neat edge line where the wind meets the rider’s torso. The practical payoff is a calmer ride and improved comfort on longer jaunts, where the rider’s posture and breathing can be as important as engine output.

But any discussion of ABS must acknowledge its limits. The same cheap price that makes it attractive also hints at a trade-off. ABS tends to be more brittle than its fiberglass cousins when subjected to high impact or sudden temperature shifts. A parked motorcycle under a blazing sun can heat ABS to degrees that soften its resin, potentially leading to warping if the design does not factor in adequate cure and post-molding finishing. Even with UV stabilizers, prolonged exposure can lead to color fading and a slightly dull surface after years in the sun. The upshot is that ABS-based replicas are excellent for riders who prize appearance and light-to-moderate use, but they may require more attentive maintenance in extreme climates and more frequent touch-ups after minor scrapes. The surface, while capable of a laser-straight paint job, is also more dependent on the base primers and topcoats used in its finish, which means the final aesthetics hinge on careful preparation and quality coatings.

Fiberglass fairings ride a middle path between cost and performance. They are sturdier than ABS, with greater stiffness and resistance to deformation under load. This translates into more predictable aerodynamics, especially for riders who push toward higher speeds or navigate challenging road surfaces. Fiberglass has a natural advantage when it comes to shaping complex curves and achieving intricate details. In the hands of a skilled fabricator, it can be molded into shapes that closely imitate the precise lines of a premium fairing, preserving the bike’s heirloom silhouette. The surface of fiberglass also accepts finishing processes with a certain forgiving ease, allowing for a glassy paint finish that reflects light in a way very close to factory panels. The net effect is a fairing that feels robust, with a satisfying heft that communicates durability without being so heavy as to hamper acceleration or handling.

Weight is a central variable in how a fairing influences a motorcycle’s overall dynamics. Fiberglass sits between ABS and carbon fiber in this respect. It adds more mass than ABS, which can slightly affect acceleration and rotational inertia, particularly on smaller sportbikes with a delicate balance between exhaust gas flow and wing-like skin. On the flip side, the added stiffness reduces flex under hard braking or aggressive cornering, which helps preserve trim angles and the rider’s intended line through a bend. This stiffness also yields a more stable shape under high-speed pressure, which in turn benefits airflow management. A well-made fiberglass kit, finished with a meticulous paint job and a tight, uniform seam where panels meet, tends to deliver a tactile sense of solidity that is appealing to riders who value both aesthetic fidelity and reactive handling.

However, fiberglass demands careful finishing. The material’s porosity means it can accept filler and primer differently than ABS, requiring precise sanding and layering to achieve a perfectly smooth surface. Any inclusions or low spots become visible once the paint is laid on, which makes inspection and quality assurance crucial in the manufacturer’s workflow. The result, when done correctly, is a fairing that looks nearly OEM put together, with seams that disappear under gloss. The higher skill threshold for fiberglass is one reason why some builders charge a premium for fiberglass replicas, reflecting the labor intensity involved in achieving top-tier fit and finish. Yet for riders who want more performance-oriented panels without stepping up to carbon fiber, fiberglass offers a compelling blend of stiffness, detail fidelity, and cost efficiency.

Carbon fiber stands as the premium end of the spectrum. It is the archetypal choice for riders who chase the lightest weight and the sharpest performance. The engineering logic behind carbon fiber is straightforward: a high strength-to-weight ratio yields lower overall mass, reduced rotational inertia, and a potential uptick in acceleration responsiveness. When carbon fiber is used for fairings, the rider can feel the difference in agility as the bike responds to throttle and steering inputs with heightened immediacy. The aesthetic payoff is equally pronounced. The carbon weave—its checkerboard pattern peeking through a clear coat—offers a high-tech look that many riders associate with top-tier machinery and race-day credibility. The visual language of carbon fiber signals precision, zero-compromise design, and a commitment to performance that resonates with enthusiasts who measure value in lightness and stiffness as much as price.

Yet carbon fiber is not simply a magic wand. The cost of carbon fiber fairings remains significantly higher than ABS or fiberglass, reflecting raw material costs, specialized layup processes, and the investment required for high-quality finishing and quality control. Repairs are more intricate. A damaged carbon panel often requires patching or panel replacement rather than a straightforward crack repair, and the repair path can involve aesthetic matching through resin systems that preserve the weave’s appearance. The stiffness that carbon fiber provides, while beneficial for aerodynamics and high-speed stability, can also transfer more vibration or micro-movements to the rider through mounts if the mounting hardware is not properly tuned. In addition, carbon fiber’s thermal properties demand careful consideration of engine heat management and mounting locations to avoid micro-cracking or delamination at the edges where heat travels along the surface. For riders who push toward extreme performance or who crave the racing lineage carbon represents, the payoff in speed and presence is often worth the additional cost and maintenance considerations.

The evolution of materials has given rise to hybrid composites and advanced polymers, a nod to the ongoing pursuit of better stiffness-to-weight ratios, improved impact resistance, and more forgiving finishing processes. Hybrid composites may blend carbon fiber with glass fiber or other reinforcing fabrics to balance weight savings with damage tolerance. These materials can offer a practical compromise: significant weight reduction compared with all-glass fiber while maintaining more forgiving impact resistance than a full carbon laminate. Advanced polymers—engineered resins, UV-stable coatings, and toughened matrices—can improve environmental durability, resisting both sun fade and moisture-induced degradation. The result is a range of options that align with different riding scenarios. A rider who frequents sunny, coastal climates might prioritize UV stability and colorfast finishes, while a track-focused pilot might prioritize rigidity, precise tolerances, and weight considerations for cornering dynamics. The modern fairing landscape, then, presents a spectrum rather than a single path, inviting riders to weigh aesthetics and performance against budget and anticipated use.

Moreover, the way a material behaves under wind loads and engine heat informs design choices as much as the color and shine do. A well-chosen material helps maintain a smooth, continuous surface that promotes predictable airflow—an essential factor when riders lean into corners at speed or ride through gusty crosswinds. The surface finish is a critical, often overlooked, component of aerodynamics. A glossy, seamless surface will encourage laminar flow and reduce skin friction, while a rough or uneven surface can provoke premature boundary layer transition, increasing drag and potentially creating buffeting at certain yaw angles. For replica kits, achieving this level of finish is a multi-step process: selecting the appropriate base material, applying a compatible primer system, executing a precise body filler strategy when needed, laying on paint with a uniform thickness, and finally sealing with a topcoat that resists UV damage and weathering. Each stage must be tailored to the chosen material because bonding, flex characteristics, and surface energy all vary between ABS, fiberglass, and carbon fiber.

The practical implications for riders extend into maintenance and customization. ABS-based replicas are often easiest to repair at home after a minor crash or a road rash encounter. With proper technique, they can be sanded and repainted to preserve the look without needing specialized equipment. Fiberglass kits demand a bit more patience, but they reward the rider with a tougher shell that can endure occasional curb strikes and gravel contact with less permanent deformation. Carbon fiber repairs, while possible, tend to require professional hands. A patch or resin repair in carbon fiber has to preserve the weave’s integrity, ensure adhesive compatibility, and often demands a controlled curing environment to maintain the surface’s gloss and structural continuity. In all cases, the key to long-lasting aesthetics is proactive maintenance: cleaning, UV protection, and timely touch-ups to prevent minor vulnerabilities from becoming major repairs.

Fitment and compatibility form another essential thread in this material story. The best replica kits are those that honor the geometry of the bike they’re meant to adorn. A kit that fits poorly can cause more than cosmetic disappointment; it can introduce alignment gaps, rubbing at fairing edges, and mounting stress across fasteners and brackets. Material properties influence this fitment reality. A stiff, rigid carbon panel can sometimes demand more precise manufacturing tolerances to align correctly with the bike’s frame, while a slightly more forgiving fiberglass panel may accommodate a broader range of minor frame variations without sacrificing the overall line. The consequence is a nuanced conversation about where to invest in quality control and how a kit’s fit will influence ongoing maintenance. In practice, discerning riders look for clear fitment guides, robust alignment photographs, and credible installation instructions—evidence of a maker’s attention to the cumulative effect of a fairing’s material choices on the bike’s fidelity and around-town usability. When the right material meets the right process, the result is a seamless silhouette that respects the bike’s original aesthetics while offering the rider the freedom to personalize with color, texture, and detailing.

Aesthetics cannot be separated from performance in this discourse. The way a fairing looks—its weave visibility, its gloss depth, the evenness of the paint—has a direct impact on perceived quality and pride of ownership. Carbon fiber, with its distinctive weave, offers a prestige element that many riders equate with performance pedigree. Fiberglass, finished with high-quality primers and clear coats, can rival the luster of carbon when done with care, while ABS can achieve a showroom-like gloss that appeals to riders prioritizing a convincing OEM look at a more approachable price. The surface treatment—whether it is the depth of the color, the clarity of the clear coat, or the way light plays off the panel’s curvature—becomes the final arbiter of how authentic the replica feels under real-world riding conditions. It is not enough to replicate the shape; the material must also convey the sensation of owning a bike’s essence while perched on the seat and taking in the windshield’s reflections at highway speeds.

In some cases, the choice of material informs not just performance and appearance but the rider’s entire maintenance philosophy. Carbon fiber, for example, often triggers conversations about weight savings that are most noticeable in endurance rides or long track sessions. Riders who value every gram of weight reduction may opt for carbon fiber, knowing that the trade-off includes higher costs and more meticulous repair work if the panel experiences damage. Those who seek a balance between look and reliability may lean toward fiberglass as a pragmatic compromise that still yields noticeable stiffness without the higher price tag of carbon. Those who value accessibility and ease of repair may choose ABS when the priority is a convincing look with straightforward upkeep. The material conversation is thus a mirror of riding goals—are you chasing sprinting acceleration, or quiet reliability, or a blend of both?

This deliberate material triad also interacts with the broader ecosystem of after-market customization. A well-curated replica kit is more than just a shell; it is a conduit for a rider’s identity, a way to express a unique stance on the sport. A kit’s material choice can influence how readily a rider can personalize with decals, airbrush artwork, or textured finishes that replicate carbon’s three-dimensional depth. In practice, the finish layer becomes a canvas for a rider’s personal brand: a glossy black that absorbs light with a mirror-like gleam, a metallic hue that catches sun at just the right angle, or a clear-coated weave that reveals the carbon’s geometry without overwhelming the eye. The synergy between material, finish, and color is what elevates a replica from a simple visual copy to a convincing, integrated statement about rider philosophy and the machine it adorns.

Finally, the topic would be incomplete without acknowledging the procurement and acquisition context for replica fairings. The choices discussed here typically unfold within a market that values fit and finish alongside cost and availability. A well-informed buyer reads fitment guides, reviews installation notes, and assesses whether the kit aligns with their bike’s frame geometry, radiator routing, and mounting points. In this sense, the material choice becomes a practical factor in the purchasing decision: a rider who wants near-OEM aesthetics at a lower cost may choose ABS for ease and accessibility; a rider who values track-ready stiffness and a premium look may gravitate toward fiberglass or carbon fiber; and a rider who seeks the pinnacle of lightweight performance may opt for hybrid composites to balance durability and weight saving. The landscape is dynamic, shaped by evolving manufacturing processes, new resin systems, and an expanding palette of surface finishes that allow replicas to mimic not only the look but the feel of the original machines. As you consider a replica kit, remember that the material is not a mere backdrop; it is the engine of performance, the keeper of aesthetics, and the gatekeeper between thrill and caution. For readers exploring a broad range of authentic shapes and lines, a curated selection of fairings is accessible through dedicated collections that bring those details into reach, such as the Honda fairings collection. This internal path offers a practical starting point for comparing shapes, lines, and overall fitment as you weigh material choices against your riding goals.

For a deeper, more technical look at how these material choices translate into mechanical behavior and long-term durability, consider the broader literature on motorcycle fairing materials and their properties. As with any structural skin, the interaction of material stiffness, layup technique, environmental exposure, and mounting hardware determines the motorcyclist’s experience. In the end, the right replica fairing is the one that respects the bike’s heritage, acknowledges the rider’s ambitions, and performs consistently across miles of asphalt and weather. The interface between skin and rider is not merely cosmetic; it is a critical contributor to aerodynamics, cooling, vibration damping, and the tactile sense of control at speed. This is the essence of choosing between ABS, fiberglass, carbon fiber, or a hybrid: each material tells a different story about how a replica becomes part of the bike’s ongoing performance and its enduring visual appeal.

External resource for further reading: https://www.motorcyclecruiser.com/motorcycle-fairings-materials/

Riding the Replica Wave: Trends, Standards, and the Quiet Confidence of Aftermarket Fairings

The market for replica motorcycle fairings is more than a simple appetite for aesthetics. It is a reflection of riders seeking a balance between style, protection, and value in a world where customization has moved from afterthought to practice. When a rider chooses a replica kit, they are weighing a spectrum of considerations that begins with look and ends with the way a bike behaves on the road or the track. The latest market analysis shows a dynamic and expanding landscape. In 2024, the global motorcycle fairing market was valued at about USD 1.2 billion, and projections place the compound annual growth rate at 8.1 percent from 2026 to 2033, with a forecasted value near USD 2.3 billion by the end of the period. These figures illuminate more than profit; they reveal a shifting culture of customization where affordability, performance, and long-term ownership converge. The growth is not uniform in every region or every segment of riding, but the trajectory is clear: more riders are looking to change the shell of their machines to reflect personal taste and to improve wind management, protection, and comfort for longer rides. The implications ripple through design, manufacturing, distribution, and even the way riders evaluate risk and reward in the aftermarket space.

To understand why this market is expanding, one must begin with the fundamentals of what riders are seeking: an aerodynamic balance that respects the bike’s handling, a fairing that can withstand everyday exposure to sun, rain, and road debris, and a precise fit that minimizes installation time and maintenance headaches. The consumer’s eye is trained on a threefold equation. First is aerodynamic balance: the fairing should slice through air without introducing drag that saps performance or destabilizes the chassis at speed. Second is structural durability: the material must tolerate UV exposure, temperature swings, and the occasional off-track brush with curbs or gravel. Third is fitment accuracy: gaps must align with mounting points, contours must align with the frame and other components, and the overall assembly should preserve or improve the rider’s tactile sense of the machine’s handling. These criteria, while technical, translate into tangible benefits on the road— steadier airflow around the rider, reduced fatigue on long journeys, and a more unified silhouette that echoes the original design intent without the price tag of a genuine OEM shell.

Material choice sits at the heart of this balance. The common options—ABS plastic, fiberglass, and carbon fiber composites—each bring a different set of compromises. ABS plastic is a workhorse for most street and touring applications. It offers light weight, reasonable impact resistance, and cost efficiency, making it a sensible default for riders who value durability without breaking the bank. Fiberglass, while heavier than ABS, provides greater strength and resistance to heat, an advantage under aggressive riding or track use where higher temperatures and tougher loads test the shell’s limits. Carbon fiber, the premium tier, delivers extraordinary stiffness and a distinctly high-end aesthetic. It is prized for its exceptional strength-to-weight ratio and its aerodynamic advantages, yet its higher cost means it is often reserved for riders who prioritize performance and prestige in equal measure. The material choice, in other words, is not just about how the fairing looks, but how it behaves under real-world conditions and over time. It influences weight distribution, cooling airflow, and even the feedback a rider receives through the handlebars and footpegs during spirited riding.

Alongside materials, the design language of replica kits ranges from complete, full fairings that wrap around the bike’s front and sides to half fairings that emphasize a sportier, more exposed silhouette. Each configuration carries implications for airflow and protection. Full fairings maximize wind protection and can deliver cleaner rear-end aerodynamics, which some riders interpret as reducing fatigue on long haul rides. Yet if not engineered with careful attention to the rider’s position and the bike’s intake geometry, a full enclosure can impede airflow to critical components or add unwanted weight, subtly altering the machine’s balance at high speed. Conversely, half fairings or clip-on styles tend to favor weight savings and a more aggressive stance, sometimes at the expense of wind protection and weather sealing. The key is not a single “best” form, but a design that respects the original geometry and the rider’s intended use, while delivering predictable handling and reliable fitment.

These considerations underscore why fitment accuracy remains a non-negotiable feature for reputable manufacturers and informed buyers. A kit that promises a precise fit but arrives with misaligned mounting points or ill-fitting edges creates a cascade of issues—from cosmetic gaps to compromised steering geometry and rattle under vibration. The best-fit principles are supported by detailed fitment guides, compatibility charts, and, increasingly, transparent labeling of materials and processes. For consumers, this translates into a more confident purchasing decision, a smoother installation process, and a longer service life for the investment. For manufacturers, it translates into stronger brand trust and repeat business in a market where reviews, fitment documentation, and post-purchase support are critical differentiators.

Quality standards in the replica fairing sector matter more than ever as riders treat aftermarket shells as integral components of the bike’s performance envelope. International quality management systems, particularly ISO 9001, are increasingly referenced by reputable manufacturers as a baseline for process discipline and continuous improvement. In addition, specific testing criteria such as SAE J2527 address impact resistance, a critical factor when riders consider protection from road debris and minor collisions. The combination of ISO 9001 and SAE J2527 connotes a commitment to not only meeting but maintaining engineering benchmarks. Transparent documentation helps buyers understand what they are getting: the material composition, the manufacturing method, and the level of testing the kit has undergone. It also helps separate the credible players from those who rely on vague claims or inconsistent results. When a kit carries verifiable certifications and clear, label-backed information about UV resistance and structural integrity, it becomes a safer, more reliable option—particularly for riders who log long miles or ride at higher speeds where stability and durability are paramount.

The market’s maturation also shines a light on sustainability as a driver of consumer choice. As production methods evolve, there is growing demand for eco-friendly practices and recyclable materials. The shift toward more sustainable production is not merely a trend; it is a response to the broader expectations of riders who value environmental stewardship alongside performance and aesthetics. For many, choosing a kit with clear recyclability credentials or demonstrated efforts to minimize waste during manufacturing aligns with a broader commitment to responsible ownership. This is not a one-size-fits-all commitment, but a spectrum that includes using recyclable resins, optimizing cutting patterns to minimize waste, and adopting more energy-efficient curing and finishing processes. The result is a product category that does not just enhance the appearance or performance of a bike, but also embodies a broader ethos of responsible manufacturing that resonates with a generation of riders who are increasingly mindful of their environmental footprint.

From a consumer’s perspective, the decision to purchase a replica fairing kit involves a synthesis of practical and aspirational factors. The practical side includes fitment accuracy, durability, and the ability to maintain or improve the bike’s handling characteristics. The aspirational side centers on the ability to evoke a particular look—the streamlined lines, the color stories, the sense of belonging to a performance lineage—without paying OEM prices. The market data support this dual motivation. With strong growth forecasts, manufacturers recognize that the segment is not simply about low-cost imitation but about high-value customization that respects the balance between form and function. As the market expands, the best-performing kits tend to be those that present a credible, testable design story: a clear articulation of how the fairing deflects wind, how the mounting points preserve or improve alignment, and how the product family accommodates a range of rider preferences—from touring to track-day performance.

For buyers navigating the landscape, the buying journey is increasingly data-driven. Compatibility charts and installation instructions are not afterthoughts but foundational documents that guide the purchase. Reviews and community feedback provide a practical barometer of a kit’s real-world performance, including how well each piece tolerates heat, sun exposure, and road grime, or how easily a kit can be installed by a DIY enthusiast. In this context, the aftermarket ecosystem thrives on clear expectations and reliable after-sales support. The presence of robust installation guides and comprehensive product specifications reduces the potential for a misfit that could affect handling or safety. It also helps riders plan maintenance and anticipate any spares or repair parts that may be required over time, which is especially important when a kit uses complex clips, gaskets, or alignment features that interact with the bike’s frame and bodywork.

Within the broader market, a subtle but significant strand is the way retailers and online marketplaces shape consumer access to information and options. The availability of detailed specifications, high-quality imagery, and compatibility guidance empowers consumers to compare options without physically handling every kit. This is particularly valuable for riders who are upgrading an older machine or trying to reconcile a mid-life restoration with modern aerodynamic expectations. Online retailers can serve as curated hubs where shoppers assess fitment guides, review performance metrics, and cross-check with their own bike’s geometry before committing to a purchase. The role of trusted retailers is elevated when they publish test results or independent assessments that speak to both comfort and performance under real riding conditions. In other words, the buying experience becomes a more informed, lower-risk proposition as the market matures.

The market’s trajectory also prompts ongoing conversations about design integrity and safety. A well-engineered replica kit should improve the rider’s comfort by smoothing wind flow and reducing fatigue, while not compromising the bike’s balancing characteristics. Conversely, a poorly engineered kit can introduce instability at high speeds, impede airflow to critical components, or create maintenance headaches due to poor fitment. These outcomes are not merely theoretical; they translate into riders choosing more carefully, relying on reputable sources, and favoring products that come with solid engineering documentation and transparent manufacturing processes. The best factories embrace a holistic approach: it is not enough to replicate a look; the look must be integrated with a credible engineering rationale that aligns with the bike’s original design intent and with the rider’s performance goals.

In this evolving landscape, one can still find a spectrum of options, from kits that closely mimic OEM aesthetics to those that reinterpret a classic silhouette with modern materials and engineering sensibilities. The balance between look and function continues to be a central determinant of value. A well-made replica kit offers more than visual appeal; it can contribute to improved handling by reducing drag, protecting vulnerable components from weather exposure, and providing a more comfortable seating position during extended rides. The long game for riders is worth considering: a kit that preserves the bike’s core geometry, accepts the rider’s style, and endures the daily grind of weather, road debris, and seasonal changes. These are the hallmarks of a mature market that respects both the rider’s investment and the machine’s performance heritage.

For readers seeking concrete avenues into this world, one practical takeaway is the importance of engaging with suppliers who publish clear material disclosures and testing data. Ask for ISO 9001 certifications, request evidence of SAE J2527 testing, and seek documentation on UV resistance and impact performance. A seller that can present a transparent quality narrative is more likely to deliver a product that remains functional and visually satisfying after months of use. In parallel, keep an eye on sustainability claims, and probe what happens to offcuts and scrap during production. The consumer who integrates these questions into their decision process contributes to a cycle of responsible manufacturing that benefits the entire ecosystem—from raw material suppliers to final assembly and beyond.

As the industry continues to evolve, it is helpful to view the landscape through a lens that blends market data with practical riding realities. The figures are not mere numbers; they reflect an expanding community of riders who value customization as a form of personal expression and who demand that the changes they embrace do not compromise safety or reliability. The future of replica fairings is likely to be characterized by ongoing refinement in fitment, more nuanced material science, and an increasingly rigorous adherence to quality standards that reassure buyers. The interplay of economics, design, and engineering will continue to shape how riders choose, install, and maintain their kits. In that sense, the replica fairing market stands as a microcosm of modern manufacturing: a space where cost-conscious consumers demand high-performance outcomes, where materials and processes are pushed toward greater efficiency and performance, and where transparent communication between maker and rider becomes a core driver of trust and satisfaction.

For readers who want a tangible example of how these principles translate into a real-world option, consider exploring curated collections that offer carefully aligned fitment with a reputation for predictable results. You can investigate the Honda fairings collection to observe how a collector mindset for fitment guides both selection and installation practices, as well as the presentation of compatibility information that helps buyers plan their upgrades with confidence. This approach highlights how a well-documented, thoughtfully engineered kit can align with the broader market’s emphasis on quality, safety, and performance, reinforcing that replicas can be more than a visual upgrade—they can be a carefully engineered enhancement that respects the bike’s original behavior while offering a personalizing touch. This is not merely about copying an appearance; it is about integrating a credible alternative that complements the rider’s objectives, the machine’s dynamics, and the road’s demands.

In the end, the market’s growth, the insistence on robust quality standards, and the evolving consumer insights we see today signal a mature aftermarket culture. Riders are seeking more than just a quick cosmetic fix; they want a balanced, reliable, and informed upgrade that feels like a natural extension of the bike they ride. The industry’s capacity to deliver on that promise will be tested by continued improvements in materials, engineering, and documentation, as well as by a growing expectation that sustainability and ethics accompany every choice a rider makes. The chapter of replica fairings written by this era is still being authored, sentence by sentence, by engineers, designers, retailers, and the riders who trust them. It is a narrative about making a high-performance look accessible, without compromising the very qualities that make a motorcycle a reliable and exhilarating partner on the road.

External resource: MarketsandMarkets provides a comprehensive analysis of the size, share, trends, and forecast for the motorcycle fairing market, offering broader context for the chapters that follow. See https://www.marketsandmarkets.com/Market-Reports/motorcycle-fairing-market-1159.html for more details.

Internal reference for further exploration: readers seeking practical examples of compatible options and installation guidance can explore a curated Honda fairings collection here: Honda fairings collection.

Final thoughts

To effectively position your business in the niche market of replica motorcycle fairings, it is paramount to understand the various types available, the materials utilized in their construction, and the prevailing market trends. By aligning your offerings with consumer preferences and sustaining high-quality standards, you can carve a substantial niche that appeals to both casual and performance-oriented riders. This understanding not only increases customer satisfaction but also enhances your business’s bottom line.