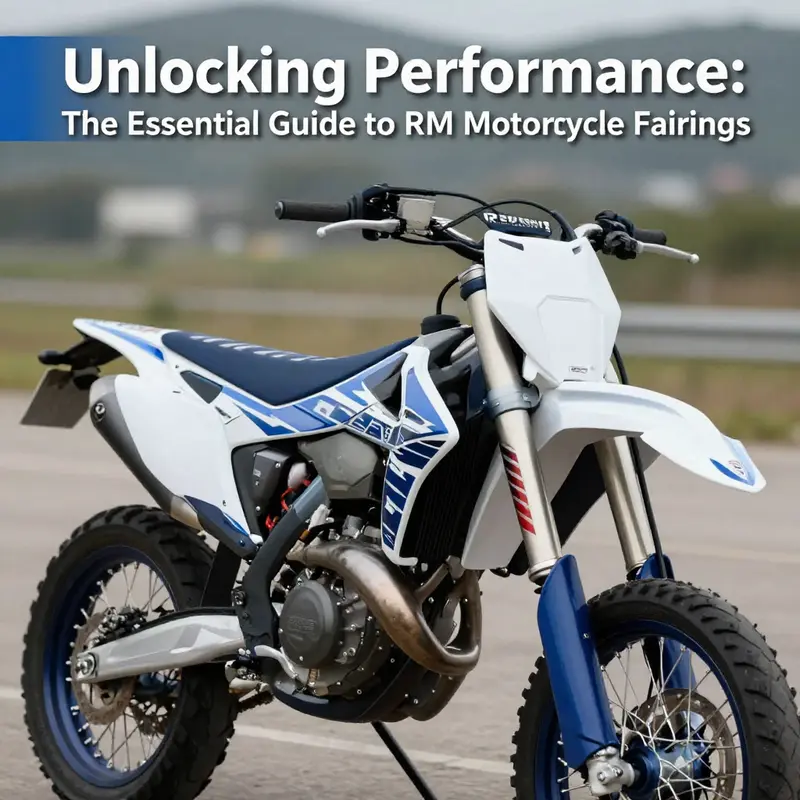

RM motorcycle fairings play a crucial role in enhancing both the performance and aesthetics of motorcycles, specifically those in the RM series like the Suzuki RM85, RM125, and RM250. These components are not just about looks; they significantly improve aerodynamic efficiency, protect vital parts, and provide opportunities for customization that appeals to both riders and competitors alike. In the following chapters, we will explore the aerodynamic benefits of these fairings, detailed material options, current market trends, available customization opportunities, and best practices for installation and maintenance. Each chapter contributes to a holistic understanding of RM motorcycle fairings, arming business owners with the knowledge to make informed decisions in this niche market.

Windswept Precision: Unpacking the Aerodynamic Edge of RM Motorcycle Fairings

The RM-series motorcycle fairings sit at the crossroads of function and form, where every contour is calculated to tame air and direct strength toward the rider and drivetrain. These fairings are not mere coverings; they are a carefully engineered response to the physics of motion. In the world of high-performance two-wheeled machines, the shape of the bodywork determines how the machine interacts with air at speed, how stable the chassis feels in gusts, and how fatigue travels up the rider’s shoulders over long or demanding stretches of track. When a rider leans into a sweeping bend or powers out of a straight, the fairings act as a strategic partner, smoothing the pressurized air that would otherwise buffet the rider and create drag that devours momentum. Even at modest speeds, a well-designed fairing system begins to reduce wind flutter and turbulence, making every kilometer feel more controlled and every corner more predictable. In the RM lineage, where riders push into corners with precision and chase every last fraction of a second, the aerodynamic intent behind the fairings becomes evident in the ride itself—an almost tangible sense that the machine has been sculpted to meet the wind rather than merely endure it.

Drag reduction sits at the core of these designs. The shapes are tuned to minimize pressure drag and form drag as air streams over, around, and past the bike. The leading edges, the gradual tapers, and the tucked-in profiles are all part of a continuous conversation between the bike and the air it moves through. The result is a bike that slices a cleaner path through the atmosphere, allowing the engine to operate with less resistance and the rider to maintain higher speeds with less muscular input. This is particularly valuable during high-speed riding when the difference between a marginal gain and none at all can be the difference between a podium and a near-miss. The effect is not just about speed; it translates into a more confident ride. When the air flows smoothly over the fairing, the rear wheel spins with a steadier wake behind it, reducing sudden shifts in behavior that can unsettle a rider in mid-canter absent a firm, predictable airflow. The perception of stability becomes part of how a rider chooses lines and chooses to lean, and that intangible steadiness is a direct byproduct of aerodynamic precision.

Beyond the absolute top-end benefits, the fairings contribute to fuel efficiency by dialing down wind resistance across a range of speeds and riding conditions. A more efficient airflow path means the engine does not have to work as hard to maintain speed, especially on longer rides or runs that test one’s endurance. It is a practical advantage for riders who use their RM-series machines not only on the track, but also on longer, mixed routes where fuel economy and endurance matter. The synergy between wind resistance and fuel usage demonstrates a broader design philosophy: every major performance enhancement on these machines is interdependent. A reduction in drag is not isolated to speed alone; it is linked to steering feel, throttle response, and even the rider’s comfort over time. In practice, this translates into a motorcycle that feels more composed at speed and more forgiving when negotiating crosswinds and deceptive gusts that can arise on open straights or exposed mountain roads.

The fairings also play a role in improving stability through airflow management around the chassis. As air is steered along the surface and around the bike, turbulence is smoothed out, and the wake behind the machine becomes more compact. This reduces the likelihood that the rider will encounter abrupt aerodynamic surprises during sudden throttle jumps or aggressive braking into a corner. The smoothing of the air stream around the bike contributes to steadier steering inputs and a more predictable front-end feel. In this sense, the fairing system acts like an invisible chassis component, influencing how the frame and suspension respond to rapid transitions and loading. The net effect is not a single dramatic improvement but a cascade of small, cumulative gains: higher confidence through stable handling, more efficient power delivery, quieter and more focused rider inputs, and a ride that keeps the rider connected to the road surface rather than fighting opposing air forces.

Material choice and construction methods underpin these aerodynamic benefits as well. Fairings built from fiberglass or high-impact plastics offer different balances of stiffness, weight, and impact resistance. Fiberglass provides a robust, easily repairable option with tailor-made shapes for track use, while high-impact plastics deliver lighter weight and better resistance to daily wear without sacrificing rigidity. The selection between these materials is a practical decision rooted in the intended use—whether the bike spends more time on the race course, the street, or an occasional gymkhana session. The manufacturing reality behind these shapes also matters. Many riders and teams source race-ready fairing kits that arrive as complete front or full-body sets, complete with mold-ready shapes and ready-to-fit profiles. This accelerates the path from concept to track-day setup, enabling riders to pursue performance-oriented builds without lengthy fabrication cycles.

The aftermarket ecosystem surrounding RM-series fairings reflects a marketplace that values precise fit and customization as much as raw aerodynamic efficiency. Aftermarket options emphasize compatibility across RM-series models, offering unbranded or generic options that claim a precise fit. This market dynamic speaks to a broader truth in modern motorcycle culture: riders desire the ability to tailor their machines to a unique look and feel while preserving or enhancing performance characteristics. The availability of new, ready-to-install fiberglass race fairings illustrates how performance and personalization can align. For riders seeking a personalized touch, customization options—such as logos or color schemes—are a natural extension of the aerodynamic conversations that these covers initiate. The aesthetic aspect, while secondary to performance, reinforces the idea that fairings are a complete system: they influence the wind, and they reflect the rider’s identity in the same breath.

The practical realities of sourcing and fitting RM-series fairings also shape their influence on performance. Ready-to-ship kits, often described as 100% new, reduce the friction between concept and track day, ensuring that the aerodynamic geometry remains true to the intended design. The ability to select a piece or a full set based on immediate stock availability makes fairings a more accessible upgrade for riders who value both performance and immediacy. The market’s emphasis on accurate fitment—sometimes described as precisely matching RM-series dimensions—reduces the risk of gaps, misalignment, or airflow disruption that can occur with ill-fitting parts. When the fairings align exactly with the bike’s lines, the aerodynamic benefits become more pronounced, and installation tends to be straightforward, preserving the intended airflow behaviors without compromising other components.

To deepen the connection between the rider, the bike, and the air, consider how the fairings sit within a broader engineering ecosystem. Aerodynamics can influence suspension tuning, brake cooling, radiator airflow, and even engine cooling flows. When the air is managed effectively by the fairings, the engine and brakes often operate within more stable thermal envelopes, enabling consistent performance through a race stint or a long ride. The environmental and riding conditions are layered into this equation as well: wind direction, rider stance, and body position interact with the fairing geometry to either amplify or soften aerodynamic gains. In this integrated view, fairings emerge not as isolated add-ons but as a core component of the bike’s dynamic system—one that fetches measurable benefits in speed, stability, and comfort while also shaping the sensory experience of riding. As riders push toward the edge of grip and power, the wind becomes an ally rather than a constant adversary.

For readers seeking further context on how aerodynamic design threads into broader motorcycle engineering, a comprehensive overview of engineering considerations in pricing, properties, and applications offers a useful reference point that complements this topic. See the external resource linked at the chapter’s end for additional perspectives on how engineering decisions translate into real-world performance metrics across different markets and machine configurations. In parallel, a practical entry point for visualizing and exploring compatible fare options is to explore the Suzuki fairings category, which showcases how the broader family of fairings is organized and presented to riders looking for both performance gains and personal style statements. The intersection of fit, finish, and function is where the RM-series fairings reveal their full potential—not just as protective shells, but as integral components of how speed, stability, and rider confidence are achieved on the road and on the racetrack.

In sum, the aerodynamic benefits of RM motorcycle fairings are substantial and multi-faceted. They reduce drag, improve fuel efficiency, enhance stability, and boost rider comfort, all while supporting precise fitment and customization. This combination makes the RM fairing a keystone of performance-oriented builds, where the air that surrounds the bike is treated as a design variable with measurable impacts on every ride. As one moves deeper into the chapter, it becomes clear that these shapes are not mere cosmetic accents but essential tools in the rider’s pursuit of speed, control, and endurance on diverse riding landscapes. For those who wish to explore related options and align with the broader ecosystem of fairings, consider the Suzuki fairings collection as a practical resource for understanding how these components relate to a wide range of machines and rider preferences.

Internal link note: Explore the broader range of options in the Suzuki fairings collection: Suzuki fairings.

External reference: For a broader, external perspective on engineering design decisions that influence performance and pricing in motorcycle engineering, see https://www.motorcycle.com.my/understanding-motorbike-price-in-malaysia-grades-properties-and-engineering-applications

Engineering a Second Skin: Material Realities and Aerodynamic Truths of RM Series Fairings

The skin of a modern motocross or off road racer serves as more than a decorative shell. It is an interface between rider, machine, and environment, shaping airflow, protecting components, and signaling intent on the track. In the RM series, the fairings are seen as performance parts rather than afterthoughts. They must balance stiffness, impact resistance, weight, and affordability. To understand how teams approach RM fairings, think of them as a system: a molded contour that holds together under high speed gusts, spray from the track, and repeated mounting cycles, while presenting a surface for paint and logos. In this sense, material choices behind these skins become a conversation about value, speed, and durability.

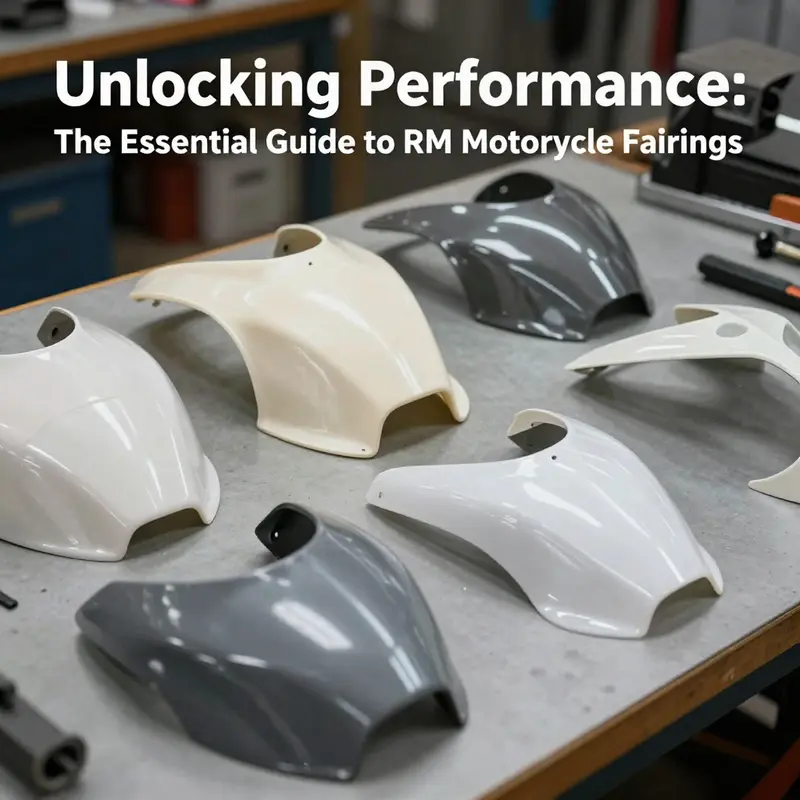

Among commonly used materials, ABS stands out for its mix of mechanical vigor and manufacturability. It offers good impact resistance, forgiving moldability for complex curves, and cost effectiveness. ABS-based fairings are favored in OEM and aftermarket since they provide a reliable base that can be repaired and replaced quickly.

Carbon fiber sits at the high end with unmatched strength to weight, but it remains more expensive and less common among midrange RM kits. It is chosen by teams chasing marginal gains under demanding race conditions.

Polypropylene appears in some sections as a cost controlled alternative, but it is not the dominant material in RM125 or RM series fairings. The key story is balance: price, impact resistance, and finish that teams want for judges, fans, and sponsors.

Manufacturing paths for ABS-based fairings rely on thermoplastic processes that support rapid production and consistent wall thickness. Finished parts are mounted to the bike with a mix of fasteners and gaskets, sometimes with a light gel coat to seal surfaces and improve paint adhesion. The surface finish influences airflow by smoothing roughness and providing a uniform boundary layer. Teams typically use a two step approach: a robust base shell plus a paint and clear coat system that resists UV and heat.

Aesthetics matter, but fit and function drive the decision matrix. Market options range from ready-to-ship unbranded kits to race focused fairings built from composites or reworked molds. The RM platform prizes repeatability, so a fairing that does not align with frame mount points can negate gains. ABS panels often enable smoother installations with fewer headaches across seasons.

Customization becomes a practical path to identity and performance. The base material should accept standard finishing techniques such as sandable surfaces, reliable primer adhesion, and durable paint systems. With ABS, decals, color, and coatings can be added without compromising the base structure.

For those seeking a broader ecosystem, the RM fairing landscape remains navigable. Complete front specific kits, side panels, and tail sections let riders assemble a package that suits their mechanical choices and riding style. The value proposition remains a balance of durability, repair ease, and affordable refresh.

To connect theory with practice, consider how a rider moves from stock to aftermarket skin without losing line integrity. A capable fairing kit is a re skinning of the whole profile, preserving lines while enabling color and texture changes. ABS as the backbone supports repairs and touch ups after heat cycles from track days.

In summary, the material choice for RM-series fairings centers on reliability, predictable aerodynamics, and a cost profile that supports replacement as wear accumulates. The broader ecosystem for RM fairings—availability of complete kits, compatibility considerations, and maintenance realities—helps riders align their mechanical choices with their riding goals.

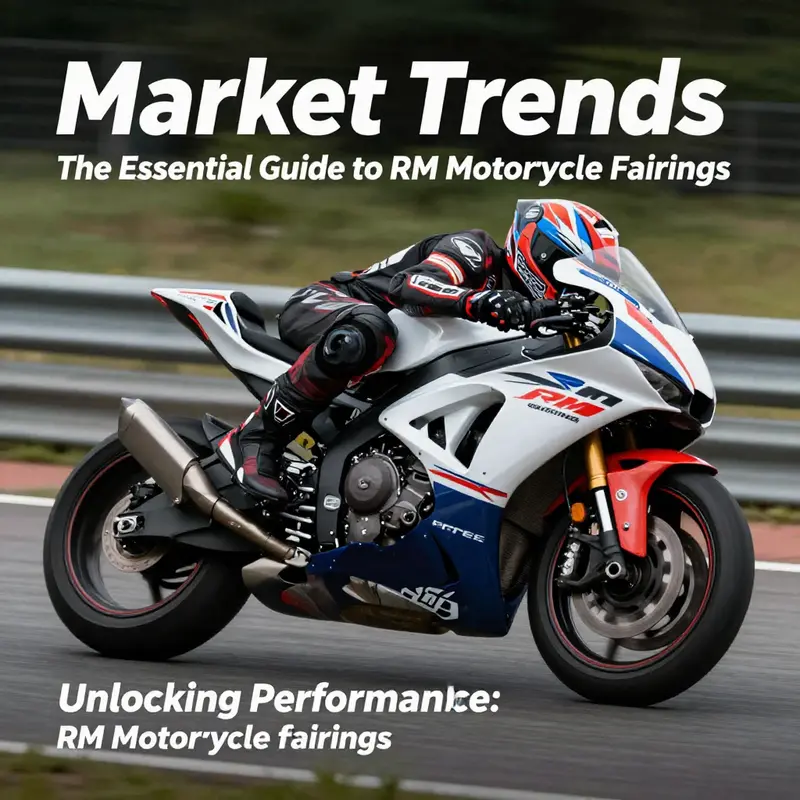

Riding the Wind: The Market Evolution of RM Motorcycle Fairings

The RM-series motorcycle fairings sit at the intersection of airflow science, craft, and brand storytelling. They are not merely shells that keep mud and wind off the rider; they are aerodynamic instruments, finishing touches, and a canvas on which riders and teams project performance, identity, and aspiration. In recent years, the market for motorcycle fairings has shifted from a niche supply chain focused on race teams and repair shops to a broader ecosystem that accommodates street and sport riders, custom builders, and regional distributors alike. That evolution mirrors a larger shift in how riders think about protection, efficiency, and aesthetics, and it matters for anyone who builds, sells, or rides RM-series bikes in any context. The conversation around RM fairings now blends engineering, manufacturing, distribution, and user experience into a single narrative about how modern motorcycles meet the dual demands of speed and style while enabling a more connected riding experience.

Aerodynamics remains a driving force. Riders crave smoother lines that cut through air with less turbulence, reducing fatigue on long sessions and maintaining stability at higher speeds. This is especially meaningful for RM-series bikes, where cornering precision and mid-range punch are prized in both racing and enthusiast settings. The modern fairing design embraces wind-tunnel-informed profiles that minimize drag while preserving access to critical radiators, air intakes, and steering geometry. Engineers no longer view fairings as static armor; they are dynamic components that interact with tire grip, suspension movement, and rider posture. The result is a part that helps the bike breathe, respond, and feel more planted during aggressive transitions or extended laps beneath harsh weather. In parallel, lighter materials and smarter manufacturing processes have allowed for more complex shapes without sacrificing durability, enabling more aggressive lines that still survive the demands of real-world riding.

The materials story is equally telling. Traditional fiberglass and high-impact plastics continue to serve as the backbone for RM fairings, prized for their balance of stiffness, impact resistance, and ease of repair. Yet the industry increasingly experiments with composites that offer better fatigue resistance and lighter weight. Additive manufacturing and rapid prototyping have moved from novelty to necessity for teams chasing perfect fitment and bespoke geometry. The ability to dial in details—how a panel meets the cockpit, where a contour blends with the tank, how integrated vents align with radiators—has a direct impact on performance and confidence. While durability remains essential, the emphasis now extends to finish quality, color stability, and the ability to withstand race-day conditions without sacrificing the sleek satin or high-gloss aesthetics riders expect.

Fitment is another dimension of the market that has widened significantly. RM fairings used to be treated as almost commodity items with a universal rough fit; today, buyers demand precision. The aftermarket and OEM ecosystems now thrive on tighter tolerances, data-driven fitment references, and customizable components that allow riders to tailor components to their specific bikes and riding styles. This is why suppliers increasingly offer modular kits, compatible mounting hardware, and compatibility guides that reduce install time and the risk of misfit. The consequence is a more approachable path for owners who want to swap between streetable aesthetics and race-ready configurations without the fear of misalignment or rattling under load.

From a business perspective, the market is expanding beyond the traditional channels of OEM supply and repair parts into a hybrid model that blends direct-to-consumer and small-batch production. Where once a rider would replace a fairing only after a crash or a major crash, today there is a spectrum of options: replacement shells, full kits, or even customized panels that carry a personal logo or team branding. The customization angle has grown from a novelty to a pragmatic feature that can influence a rider’s sense of ownership and pride. Small shops and independent builders can now offer tailored options with shorter lead times, while larger distributors can provide a predictable catalog of shapes, finishes, and dimensions that fit multiple RM-series iterations with minimal rework. In this sense, RM fairings are becoming a platform for expression as much as they are a protective shell.

Aesthetics, of course, still matter deeply. The visual language of a fairing communicates performance before a rider even twists the throttle. The patterns, colorways, and finish quality signal a bike’s pedigree and the rider’s intent—whether that intent is to chase lap times on a closed course or to project presence on a city street. The market responds to this with design that emphasizes high-contrast lines, bold palettes, and refined detailing that catches light in a way that feels fast even when the bike is standing still. This emphasis on appearance is not superficial; it reinforces branding, sponsorship visibility, and the rider’s own story. The fairing becomes not just a shell but a storytelling device that reveals a rider’s dedication to craft and speed.

Geography plays a meaningful role in shaping access to RM fairings. Demand is rising in regions where disposable income supports premium riding experiences and where owners value the interplay of performance and aesthetics. Markets in the Middle East and Africa, for example, show growing interest in higher-end, precision-fit components as riders pursue elevated experiences and more capable equipment. This regional tilt accelerates the normalization of aftermarket ecosystems that can deliver fast, reliable customization to a wider audience. For riders in these regions, a well-made fairing is not simply a cosmetic upgrade; it is a pathway to improved comfort, better aerodynamics, and a stronger sense of personal and vehicle identity as they navigate varied climates and road conditions.

The role of fairings is also expanding in the digital space. The latest design philosophies recognize that a fairing can host more than hardware; it can hold information and interfaces. Large-screen displays, integrated control interfaces, and even telemetry-friendly panels are gradually becoming features of modern fairings. For serious racers, this translates into more accessible data streams and easier integration with measurements that inform setup and strategy. For casual riders, it translates into a smoother, more connected ride where the fairing remains the primary interface with the bike’s performance and settings. The convergence of mechanical function with data connectivity marks a turning point in how manufacturers and aftermarket suppliers think about RM fairings.

A further driver of growth lies in the aftermarket ecosystem, where the balance of availability and affordability continues to shift. Online marketplaces and direct-to-consumer channels simplify sourcing and allow for rapid iteration. Even as the market broadens, the importance of precise fitment, robust finishes, and reliable service remains constant. The opportunity for customization—logos, colorways, and subtle shaping tweaks—has moved from a luxury to a standard consideration for many riders who want their RM bike to reflect their unique story. This has implications for how suppliers design their catalogs and how retailers train their staff to help customers select the right kit, understand compatibility, and manage expectations about weight, stiffness, and airflow.

In this evolving landscape, the RM fairing is no longer simply a component but a strategic element of performance and branding. It is a bridge between the rider’s ambitions and the bike’s capabilities, a canvas for innovation, and a conduit for a more personalized riding experience. The shifts toward advanced materials, precise manufacturing, and connected features all echo a broader industry move: fairings are becoming integral to the bike’s value proposition, shaping how riders feel, perform, and connect with their machines on every outing, whether on a race track, a testing road, or a daily commute. The market recognizes this reality, and as a result, the RM fairing space is likely to see continued experimentation, tighter integration with other components, and an expanding array of customization options that empower riders to craft not just the look of their bike but its behavior under wind and weight.

For readers seeking a practical glimpse into how this market conversation translates into choice and guidance, consider exploring the broader availability of compatible fairing options for RM-series bikes through the Suzuki fairings collection. This collection offers a window into how fit, finish, and style can align with performance goals and rider preferences, providing a reference point for what modern RM fairings can deliver. Suzuki fairings collection.

As the market continues to mature, stakeholders—from fabricators to riders—will increasingly rely on data-driven design, modular production, and sustainable practices to encode efficiency into every fairing. The interplay between aerodynamics, weight, durability, and aesthetics will define which designs endure and which fade away as new shapes and finishes emerge. The RM fairing is poised not just to resist the wind but to lead the wind in style, safety, and substance, weaving together technology, artistry, and performance into a single, coherent narrative that invites riders to push further, ride longer, and tell bolder stories with their bikes.

External resource: for a broader, market-wide context on how fairings are evolving across the motorcycle sector, see the Global Motorcycle Fairing Market Size, Share & Trends Analysis Report (2026–2033) at https://www.grandviewresearch.com/industry-analysis/motorcycle-fairing-market

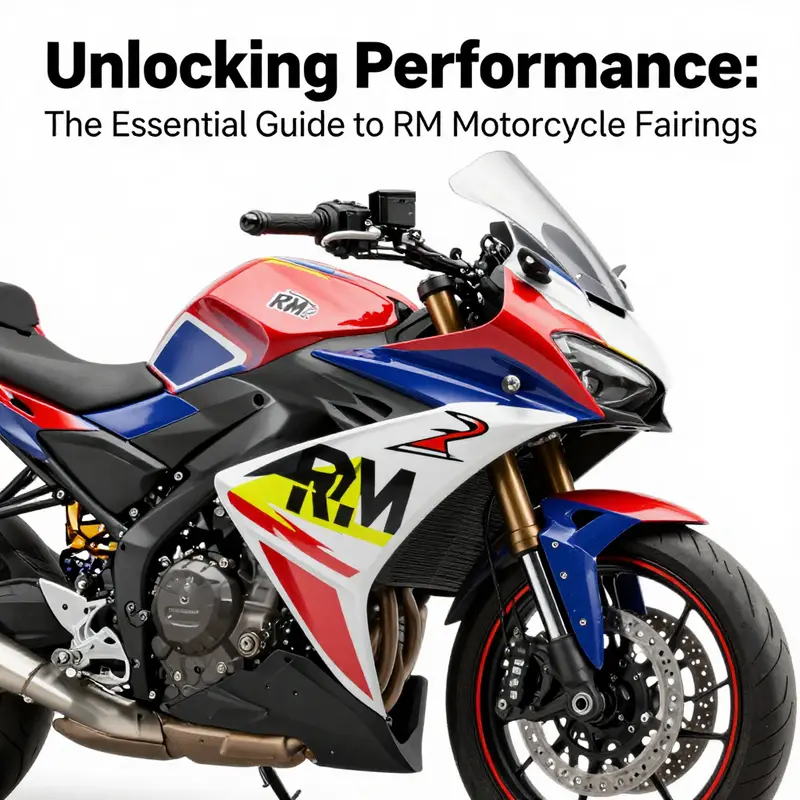

Beyond OEM: Crafting Customization with Aftermarket RM Motorcycle Fairings

Customization can feel like a personal manifesto written in fiberglass and plastic. For RM-series motorcycles, which have long attracted riders who blend speed with a hunger for individual expression, aftermarket fairings offer a way to rewrite the bike’s silhouette while preserving or even enhancing its core strengths. These body panels are more than decorative skins; they are carefully engineered to influence air flow, protect critical components, and accommodate a rider’s shifting needs. The materials used—ranging from ABS plastic to fiberglass and advanced composites—form a spectrum of trade-offs between stiffness, weight, and resilience. ABS, with its ductility and impact tolerance, remains a popular choice for riders who want quick-to-install panels that can survive the rigors of gate-to-gate track sessions or rough backroads. Fiberglass adds a lighter edge and strength that’s appreciated when a rider pushes for performance and aggressive aesthetics. Composite polymers push the envelope further, offering high stiffness-to-weight ratios and tailored aero characteristics, which can translate into tangible gains on the track or during a long, wind-influenced highway ride. The practical upshot is a toolkit that lets riders decide how far to go with their visual and aerodynamic goals without paying the premium associated with factory-sourced, model-specific parts.

The appeal of aftermarket RM fairings lies in the flexibility they offer. Customization spaces are intentionally modular, enabling riders to swap panels to achieve different color schemes, graphics, or aerodynamic profiles without committing to a full rework. This modular approach is especially valuable for those who race a preparation bike one weekend and want a more touring-friendly setup the next. The process is not simply about changing a color; it’s about shaping how air interacts with the bike at speed, how the rider sits within that airflow, and how the bike manages debris, weather, and the inevitable wear that comes with regular use. In this context, the fairing is a small ecosystem—its fitment points, mounting hardware, and alignment tolerances all influence how well it integrates with the bike’s frame geometry and components. A well-fitting set of panels preserves or even improves engine cooling airflow, allows for unimpeded access to serviceable parts, and minimizes rattles or flutter that can emerge at higher speeds or over rough pavement.

To appreciate the design philosophy behind aftermarket RM fairings, one can think in terms of three intertwined priorities: fit, protection, and personality. Fit means more than simply snapping pieces onto the frame. It requires precise contouring to the bike’s neck, belly, and tail sections, plus careful attention to mounting points that evolve with model years and subtle frame revisions. Protection involves more than shielding the engine; it includes protecting the headlights, instruments, and wiring harnesses from road debris, moisture, and temperature swings. Personalization, of course, is about communicating who the rider is as they ride—color, logo placement, and decals all contribute to a vehicle’s story. The modern aftermarket ecosystem acknowledges these priorities by offering panels that are not only aesthetically adaptable but engineered to withstand the stresses of aggressive riding and frequent maintenance checks.

Riders often begin with material choices that balance cost, ease of installation, and longevity. ABS panels, in particular, are widely favored for their forgiving nature and color-retention characteristics. They respond well to heat from sun exposure and resist impact in everyday mishaps. Fiberglass remains a go-to when weight reduction is a priority and when a rider seeks a refined, sport-oriented look. For enthusiasts who chase the ultimate in rigidity and aerodynamic control, composite options open up a design space where engineers can fine-tune stiffness, air intake, and under-panel shaping to shave seconds off a lap time or to dial in a smoother, more stable high-speed ride. The range of possibilities reflects a larger trend in the riding community: the move toward performance-oriented aesthetics that do not compromise on durability, safety, or serviceability.

As with any significant modification, the decision to adopt aftermarket fairings invites a spectrum of considerations. One decisive factor is how the panels align with the bike’s existing geometry and the rider’s preferred riding position. A panel line that creates a clean interface with the fuel tank, the seat cowl, and the frame backbone can influence how comfortable a rider feels in the tuck and how well the bodywork channels air around the engine, radiators, and exhaust routes. A well-conceived set of fairings can reduce wind pressure on the rider, mitigating fatigue over long stints and aiding stability in crosswinds. Conversely, poorly aligned panels can introduce turbulences that offset any aerodynamic gains and, in extreme cases, hinder turning response by altering mass distribution and center of pressure. This is why many riders emphasize measured, repeatable installation processes and, when possible, professional alignment checks after mounting new panels.

The breadth of available options also mirrors the diversity of riding styles in the RM community. For sport-oriented riders, split or dual fairings that leave room for a compact tail segment may offer a favorable balance of airflow, engine access, and rider protection. For long-distance enthusiasts, full fairings provide maximized coverage, shielding the rider and components from wind and weather while still accommodating essential maintenance access through removable panels. The aftermarket ecosystem also displays a surprising degree of customization potential: panels can be swapped, logos can be added, and color schemes can be tailored to a rider’s palette or to a particular race livery. When a rider weighs these choices, the conversation often turns to compatibility and the practical realities of fitment, rather than only their aesthetic appeal. In the end, the best aftermarket setup integrates seamlessly with the bike’s electrical routing, accessory mounts, and the rider’s ergonomic preferences.

Global supply networks have accelerated access to a wide range of aftermarket RM fairings, making the barrier to entry lower for individual riders and teams alike. A number of suppliers offer stock-ready panels that ship quickly, while others provide customization services that allow a rider to specify color, graphics, and even a personal emblem for a unique finish. The ability to source from multiple vendors also underpins price competition, which benefits the rider when choosing between a full set or selective replacements after a mishap. Importantly, this accessibility does not equate to a compromise in quality. Reputable providers emphasize safety certifications, impact resistance, and UV stability, ensuring that the panels will endure sun exposure and maintain their color and structural integrity over time. The result is a marketplace that supports both casual “retrofit” projects and serious race-prep builds, where the objective is to optimize the bike’s external envelope for performance without eroding reliability.

For riders who want to explore the spectrum of options without leaving the platform they trust, one practical starting point is to browse the Suzuki fairings collection, which aggregates compatible designs and colorways across a broad range of RM-adjacent models and eras. This yields a useful sense of how panel shapes have evolved, what mounting conventions are standard, and how color and texture strategies influence both visibility and presence on the road or track. The value of such exploration is not merely in selecting a single design but in understanding how modular components can be recombined as needs shift—whether the goal is a fresh look, improved aerodynamics, or a combination of both. A well-considered selection process also prepares a rider for future upgrades, since panel sets can be upgraded piece by piece as funds or priorities change, rather than confronting a full, heavy, and expensive replacement all at once.

In this evolving ecosystem, the customer experience has grown more nuanced. Some buyers welcome the option to customize with personalized logos or decals, while others seek precision-fit panels that align with exact mounting points and maintain the cleanliness of their electrical shrouds. This latter emphasis often nudges riders toward manufacturers or vendors with proven engineering data, including alignment templates and fitment notes that map out the installation sequence. For those who prefer the satisfaction of a DIY approach, a modular system can still deliver the same outcomes—just with more attention paid to fixture hardware, gasket seals, and paint protection. The long view favors fairings that stand up to road debris and weather, maintain their luster under UV exposure, and remain serviceable after a minor crash or impact. While not every rider opts for a full customization trajectory, the appeal remains potent: aftermarket RM fairings offer a pragmatic route to individual identity, performance tuning, and practical protection, all in a package that respects the bike’s original engineering while inviting personal expression.

As the riding community continues to evolve, so too does the culture surrounding aftermarket fairings. The conversations that emerge around fit, finish, and function reflect a broader shift toward rider empowerment: the sense that a motorcycle is not a fixed product but a flexible platform for experimentation and refinement. In this light, customization becomes less about chasing trends and more about refining experiences—tuning the bike’s appearance and aerodynamics to harmonize with a rider’s goals, climate, and terrain. The RM platform, with its combination of lightweight handling and high-reward performance principles, remains an especially fertile ground for such experimentation. And as always, responsible upgrading—careful measurement, test fitting, and proper protection—ensures that the heady pursuit of a more personalized machine remains safe, reliable, and enjoyable on every ride.

External resource: https://www.alibaba.com/product-detail/GOOD-NMAX-155-Fairings-New-ABS-Plastic_1601234567890.html

From Fit to Finish: Installing and Maintaining RM Motorcycle Fairings for Performance and Longevity

Fairings on RM motorcycles are more than skins that make a bike look lean and race-ready. In the RM family—whether you’re riding the smaller RM85, the RM125, or the bigger RM250—the bodywork is a carefully engineered first line of defense against wind, debris, and heat, while also shaping the motorcycle’s aerodynamics. The right fairings reduce drag, manage air through the radiator, and preserve the rider’s control by keeping the profile of the bike stable at speed. Alongside aesthetic appeal, they carry the practical weight of protecting critical components, the wiring harness, and the fragile fasteners that hold everything together. When a rider contemplates upgrading or replacing RM fairings, the decision often sits at the crossroads of performance, cost, and fit. In the broader market, aftermarket options span a spectrum—from unbranded pieces designed to approximate factory contours to more precise, purpose-built kits that promise race-ready fitment and a finish close to professional standards. The practical path, however, remains anchored in how the fairings are installed and how they are cared for afterward. The install, while technically straightforward in theory, is a step-by-step exercise in precision. Preparation begins with removing the stock panels and cleaning the mounting surfaces. The next phase is alignment. The RM’s frames and mounting points aren’t always perfectly matched to every aftermarket mold, so a patient rider will position the upper or half-fairings first, checking contours against the frame, tank, and handlebars. A 2017 installation guide described the process of mounting even just the upper fairing as potentially taking a half-day, largely because hole sizes must be resized and precise alignment achieved. In practice, this means carefully re-drilling or elongating mounting holes, then testing fitment before tightening anything to torque specs. This is not merely a matter of aesthetics; improper alignment can lead to gaps, rubs against the radiator shroud, or even interference with mirrors, turn signals, or the throttle linkage. The goal is a level surface that sits flush with the bike’s lines, with seams that are tight and even. The hardware used—bolts, washers, spacers, and grommets—needs to be appropriate for the material and design of the fairing. Some kits rely on thicker, reinforced mounting points, others on lighter ABS plastics that need bushing or reinforcement to remain rigid at high speeds. The careful torque specification for each fastener is not just a factory directive; it is a safety margin. Over-torquing can crack plastic or strip mounting points, while under-torquing invites vibration and eventual detachments on the road or track. Once the fairings are in place, the final checks focus on control clearance and visibility: do the lower panels clear the steering lock and brake lines? Do the seams line up with adjacent panels? Are the headlamp, turn signals, and mirrors unobstructed? The assessment is both visual and tactile; riders test gentle taps for any looseness, listen for rattling at idle, and feel for any unusual contacts when the suspension compresses over rough pavement. Maintenance of RM fairings is as important as installation. Regular cleaning with mild soap and water removes the salt, grime, and road-film that can degrade plastic over time. Harsh chemicals are to be avoided, as are high-pressure washers that can push water into seams or strip wax from painted surfaces. Inspection routines should be regular—look for cracks, chips, or signs of warping, especially after hard impacts or exposure to extreme temperature swings. Small cracks can often be repaired with plastic repair kits or by careful touch-up with color-matched paint and sealant; larger damage or structural failure generally requires professional repair or replacement, which can be costly. UV exposure is another factor; applying a protective wax or sealant helps preserve color and gloss and reduces micro-scratches that accumulate over a season of racing or riding on abrasive or dirty roads. The material choice also informs maintenance strategy. Fiberglass fairings, common in racing kits, are relatively easy to mend and repair if damaged, but they can be heavier and more brittle than modern ABS plastics. ABS is lighter and typically easier to repair through heat and adhesive methods, while carbon fiber variants offer stiffness and lightness for high-end builds but demand careful handling and professional repair if damaged. Each RM model benefits from a tailored approach because a kit’s fitment and the mounting approach can vary with the bike’s generation, the contour of the fuel tank, and the shape of the radiator shrouds. The owner must always reference the specific manufacturer’s manual for the fairing model in use, since procedures and material care can vary significantly between brands and between ABS, fiberglass, and carbon—even within the RM spectrum. A well-kept set of RM fairings can outlast multiple seasons of riding and racing, while also maintaining resale value for the bike and preserving the bike’s aggressive stance across years of riding. Beyond the mechanics of fit and finish, the decision to source RM-compatible fairings often circles back to the market landscape. The RM’s appeal in the aftermarket world is echoed by a broad array of options that promise precise fitment for RM85, RM125, and RM250 platforms, with some kits designed to work across multiple RM variants. These options frequently come as complete front fairing molds or full kit assemblies that include the top, side panels, and sometimes the lower cowl. The realistic market narrative includes both fully new fiberglass race kits and unbranded alternatives designed for compatibility rather than brand fidelity. The availability of direct supplier channels, including marketplaces that connect riders to manufacturers, enables a smoother path from purchase to ride. Such platforms emphasize not only price but also customization. A new kit might offer a 100% new mold, with tiered pricing that rewards larger orders, and even options for personalization such as a custom logo. The practical reality, however, is that price, fit, and finish should be evaluated together. A kit can look the part in a showroom photograph, yet misalignment, thin mounting points, or a brittle mounting hardware set can quickly undermine confidence on the track. This is why a careful install plan paired with a robust maintenance routine becomes the true foundation of an RM fairing upgrade. Riders may seek curated resources that help them compare fitment, weight, and durability in real-world conditions. The RM’s appeal in the aftermarket world is echoed by a broad array of options that promise precise fitment for RM85, RM125, and RM250 platforms, with some kits designed to work across multiple RM variants. These options frequently come as complete front fairing molds or full kit assemblies that include the top, side panels, and sometimes the lower cowl. The realistic market narrative includes both fully new fiberglass race kits and unbranded alternatives designed for compatibility rather than brand fidelity. The availability of direct supplier channels, including marketplaces that connect riders to manufacturers, enables a smoother path from purchase to ride. Such platforms emphasize not only price but also customization. A new kit might offer a 100% new mold, with tiered pricing that rewards larger orders, and even options for personalization such as a custom logo. The practical reality, however, is that price, fit, and finish should be evaluated together. A kit can look the part in a showroom photograph, yet misalignment, thin mounting points, or a brittle mounting hardware set can quickly undermine confidence on the track. This is why a careful install plan paired with a robust maintenance routine becomes the true foundation of an RM fairing upgrade. For riders who want to explore aftermarket options without committing to a full race-kit, many RM owners approach fairing upgrades as a staged process. They test partial fairing sets, assess fit with their specific RM model year, and observe how the panels respond to heat and vibration during a short ride. In some cases, this phased approach helps prevent damage that could occur from forcing a kit onto a bike that isn’t an exact match. The sourcing narrative often includes direct access to suppliers who can tailor solutions to a rider’s needs, whether that means adding a personalized decal or requesting a slightly different mounting hole pattern to accommodate aftermarket hardware. The process underscores a broader truth: fairings are as much about the relationship between rider, bike, and the shop as they are about the panels themselves. They represent a convergence of engineering pragmatism and visual identity, where the ultimate objective is to retain the RM’s performance envelope while expressing the rider’s personality. In the spirit of informed purchasing and careful upkeep, riders may seek curated resources that help them compare fitment, weight, and durability in real-world conditions. The RM’s appeal in the aftermarket world is echoed by a broad array of options that promise precise fitment for RM85, RM125, and RM250 platforms, with some kits designed to work across multiple RM variants. These options frequently come as complete front fairing molds or full kit assemblies that include the top, side panels, and sometimes the lower cowl. The realistic market narrative includes both fully new fiberglass race kits and unbranded alternatives designed for compatibility rather than brand fidelity. The availability of direct supplier channels, including marketplaces that connect riders to manufacturers, enables a smoother path from purchase to ride. Such platforms emphasize not only price but also customization. A new kit might offer a 100% new mold, with tiered pricing that rewards larger orders, and even options for personalization such as a custom logo. The practical reality, however, is that price, fit, and finish should be evaluated together. A kit can look the part in a showroom photograph, yet misalignment, thin mounting points, or a brittle mounting hardware set can quickly undermine confidence on the track. This is why a careful install plan paired with a robust maintenance routine becomes the true foundation of an RM fairing upgrade. For riders who want to explore aftermarket options without committing to a full race-kit, many RM owners approach fairing upgrades as a staged process. They test partial fairing sets, assess fit with their specific RM model year, and observe how the panels respond to heat and vibration during a short ride. In some cases, this phased approach helps prevent damage that could occur from forcing a kit onto a bike that isn’t an exact match. The sourcing narrative often includes direct access to suppliers who can tailor solutions to a rider’s needs, whether that means adding a personalized decal or requesting a slightly different mounting hole pattern to accommodate aftermarket hardware. The process underscores a broader truth: fairings are as much about the relationship between rider, bike, and the shop as they are about the panels themselves. They represent a convergence of engineering pragmatism and visual identity, where the ultimate objective is to retain the RM’s performance envelope while expressing the rider’s personality. In the spirit of informed purchasing and careful upkeep, riders may seek curated resources that help them compare fitment, weight, and durability in real-world conditions. For more context on the sourcing landscape and a sense of global availability, you can explore industry marketplaces and supplier directories. External Resource: https://www.alibaba.com. See also the Suzuki fairings collection for a practical reference on fitment and finish across different RM-generation bodies. Suzuki fairings collection.

Final thoughts

Understanding and utilizing RM motorcycle fairings can provide considerable benefits for both performance and style. From aerodynamic enhancements that improve speed and handling to a range of materials that cater to durability and aesthetics, business owners in the motorcycle industry can tap into a lucrative market. Staying updated on market trends and embracing customization options will enhance product offerings, satisfying increasingly discerning riders. Furthermore, being knowledgeable about proper installation and maintenance is essential for ensuring customer satisfaction and incentivizing repeat business. Ultimately, RM motorcycle fairings are a gateway to unlocking better performance and aesthetic appeal for motorcycles that riders cherish.