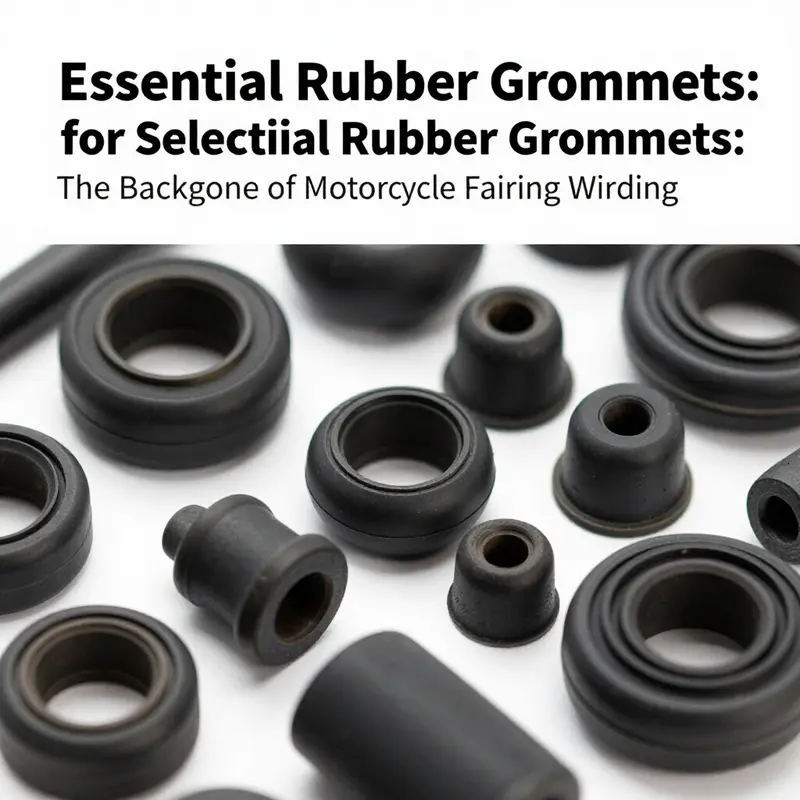

Rubber grommets for motorcycle fairings play a crucial role in ensuring the safety and reliability of a motorcycle’s electrical system. As motorcycles traverse diverse environments, the protection of wiring harnesses and cables becomes paramount. The relevance of selecting appropriate grommets goes well beyond a simple fit; it encompasses key aspects such as environmental resilience, vibration dampening, and organizational aesthetics. This article will explore three critical chapters that delve into the selection criteria for rubber grommets, the benefits they bring to wiring integrity, and the importance of durability and material specifications. Together, these elements form a comprehensive understanding of how rubber grommets significantly contribute to overall motorcycle performance and longevity.

Grommets at the Edge: Rubber Seals Protect Wiring on Motorcycles

Wiring harnesses routed through a motorcycle’s fairing live in a harsh environment of vibration, moisture, and debris. Rubber grommets at the entry points shield cables from sharp edges, seal out water and dust, and help dampen movement so connections stay reliable over time. A well-chosen grommet balances hole size, inner diameter, and durometer to fit the cable pack while absorbing vibration without crushing the wires.

Material choice matters: EPDM is common for exterior use due to weather and UV resistance, while NBR offers good oil resistance near engine areas. The key is a compound that resists cracking under temperature cycles and maintains a supple seal. Size and fit are equally important: the hole must accommodate the harness without pinching, and the grommet’s outer diameter should sit flush with the panel edge to avoid rubbing paint or insulation.

Installation and maintenance are practical considerations. Press-fit grommets install quickly and minimize edge damage; threaded designs offer secure retention in high-vibration setups. Regular checks — inspecting for cracks, hardening, or movement — extend service life and prevent intermittent electrical faults. For a shop or DIY rider, choosing a grommet kit with a consistent durometer and a range of hole sizes simplifies inventory and ensures consistent performance across model years.

Sealing the Ride: How Rubber Grommets Protect Wiring and Extend Reliability in Motorcycle Fairings

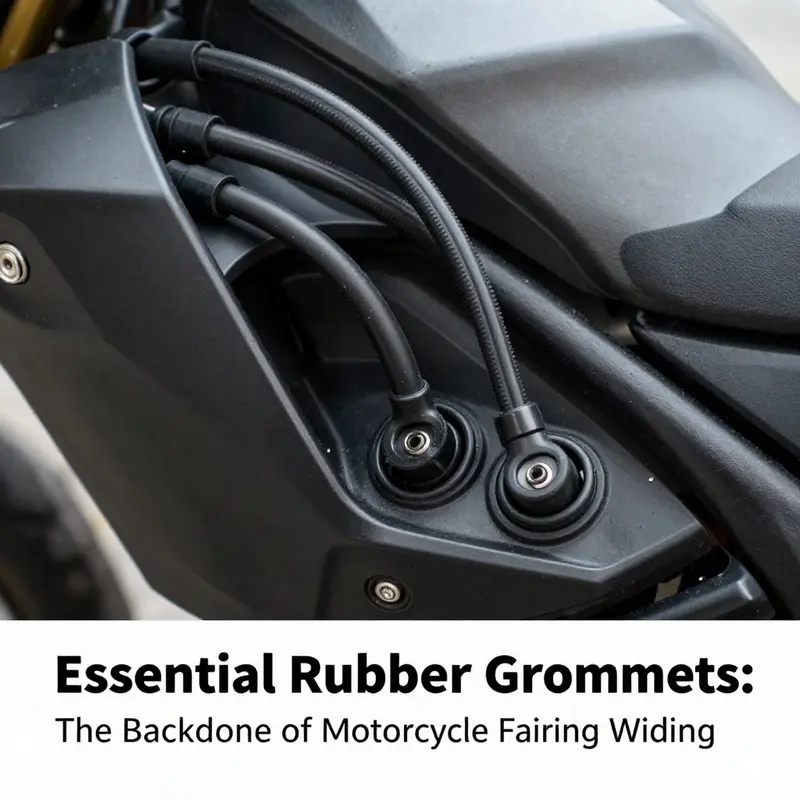

Every ride begins with a threshold that looks simple but performs a crucial job. Where a fairing panel meets a passage for cables, the gap is more than a hole. It is a potential stress point that translates every vibration, edge, and weather condition into wear on wire insulation and connectors. Rubber grommets turn that threshold into a forgiving path. They are small, but their impact on reliability is outsized. They do not merely hide a cut edge; they actively shape how electrical systems endure heat, moisture, and continuous motion. In the chorus of parts that keep a motorcycle alive, grommets are the quiet guardians. They keep harnesses organized, shield wires from sharp edges, and preserve the integrity of electrical connections that riders rely on in rain, heat, or the long miles of highway.

The core function of a grommet is straightforward: it cushions and guides. The bolster it provides against abrasion is the first line of defense. Where cables rub against metal or plastic edges, the insulation can wear thin. Once insulation is breached, moisture and debris can intrude, and fatigue sets in. A robust rubber grommet absorbs the friction and distributes the stress over a broader, softer surface. The result is less micro-cutting of the insulation and a longer life for the entire wiring harness. In practice, this means fewer brittle strands, less risk of short circuits, and more predictable electrical performance across miles of riding conditions.

These benefits extend beyond mere durability. A well-chosen grommet also contributes to a cleaner, more professional look inside the fairing. When cables are routed neatly through grommets, the harnesses sit away from rough edges and settle into organized channels. The fairing panels themselves become less likely to trap moisture against vulnerable connectors. The net effect is a system that looks intentional and performs reliably because it is protected at the most vulnerable touchpoints.

Material choice matters. For most motorcycle environments, the best grommets come from durable, weather-resistant rubbers such as EPDM or neoprene. EPDM shines under UV exposure and temperature swings, while neoprene offers strong resistance to oils and some solvents. Both materials handle the rapid heat cycles of a engine bay and the sudden cool of night rides, maintaining elasticity and seal integrity without cracking. In the best designs, the rubber remains flexible even after years of exposure, sealing out moisture and dust while accommodating the small movements that occur as the bike vibrates and as panels flex during cornering or braking. The choice is not merely about a rubber piece; it is about a predictable performance envelope that synchronizes with the fairing material and the cable sheathing it protects.

To get the most out of these little protectors, sizing is everything. Wires and harnesses vary in diameter, and fairing panels differ in thickness and hole geometry. A grommet that is too small will pinch, exceed its elastic range, or fail to seal properly. A grommet that is too large can allow movement and permit wear from shifting cables. The optimal fit involves a careful match of inner diameter to cable thickness and an outer profile that creates a snug seat within the hole. Those outer dimensions often include a flange that bites into the panel surface, a feature that keeps the grommet from migrating in response to vibration. When designers and technicians get this balance right, the harnesses stay organized, the edge protection remains intact, and the assembly presents a clean, professional appearance that reflects quality workmanship.

The sealing role of grommets is particularly meaningful in the fairing’s interaction with the elements. Weather exposure is not a single moment but a continuous cycle. Water may find tiny ingress paths around a poorly seated entry, and dust can accumulate where panels rub. A good rubber grommet forms a tight, resilient barrier around the passing cables, reducing the likelihood of water tracking along harnesses and condensing on connectors. This protective barrier helps prevent corrosion and electrical leakage. Even in dusty or sandy environments, the grommet’s soft, flexible material remains a barrier and a buffer, preserving electrical reliability when the bike is exposed to wind-driven grit or sudden rain.

Vibration is another dimension where grommets show their value. A motorcycle is a symphony of micro-motions, a constant exchange of forces between engine torque, road texture, and aero loads. Wires and connectors inside a fairing would otherwise act as a rattling chorus of buzz and whine. Rubber’s intrinsic damping properties absorb a portion of those forces, reducing the transmission of vibration into the harness. The result is fewer loose cables, less abrasion, and a quiet, more predictable electrical system. This damping effect also helps prevent micro-movements from becoming macro-failures. With less movement and less wear, there is reduced risk of fatigue in wire strands and terminations over the life of the motorcycle.

The practical benefits extend into maintenance and service. Rubber grommets are designed for ease of installation and minimal upkeep. They can be pressed into holes or secured with flanges and clips, depending on the design. A well-made grommet holds its position through the bike’s entire heat cycle, and it does not require frequent adjustments once installed. The duty cycle of a grommet aligns with the bike’s own maintenance rhythm; a quick inspection during routine service can verify that edges remain covered, seals stay intact, and no signs of cracking or compression are present. This simplicity is part of the reason grommets are so valued by riders who perform their own maintenance or work with trusted technicians.

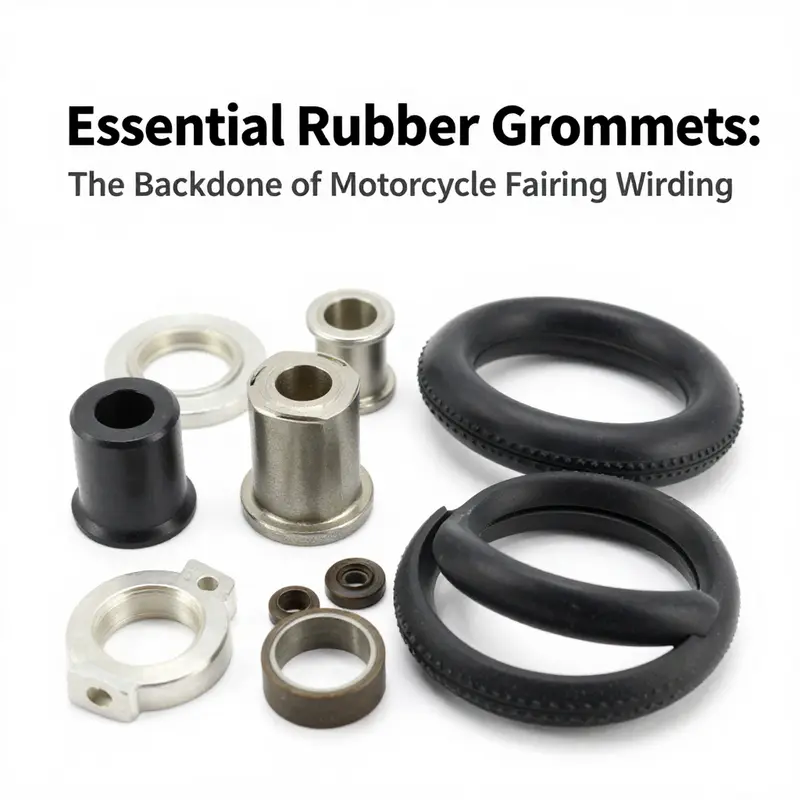

Choosing the right grommet, however, is a nuanced task. Compatibility goes beyond the internal diameter. It includes tolerance for the fairing material, the cable jacket, and the panel’s thickness. Some fairings are thinner, composite or plastic, while others are metallic and offer more bite for a gasket-like seal. In such cases, a grommet with a slightly stiffer profile or a heavier flange can preserve a reliable seal without excessive compression of the cable jacket. Conversely, a very soft grommet might be ideal for delicate wiring but may not hold up in areas of higher vibration or where the panel’s edge experiences more contact stress. The goal is a harmonized trio: the panel, the cable, and the grommet that sits between them, each reinforcing the others.

As the electrical system becomes more complex, with more circuits and tighter packaging in modern fairings, grommets take on a broader role. They facilitate routing through curved or contoured openings, allowing designers to create paths that minimize bending radii and preserve insulation integrity. A well-considered grommet entry can even extend the life of heat-shrink jackets and protective sleeves by distributing stress away from vulnerable junctions. In other words, the grommet is not just a passive cushion; it is an active part of the harness routing strategy that can influence how reliably power and signals reach their destinations under real-world riding conditions.

From the perspective of a rider who wants both performance and durability, the story of grommets also includes practical purchasing and replacement considerations. Material selection is the first practical decision. For a bike that spends time in sun and rain, EPDM or neoprene-based grommets deliver the best balance between elasticity and aging resistance. If a fairing area is exposed to fuel or oil splashes, neoprene’s resistance to oils becomes valuable. In protected interior spaces or on fairings made from tougher plastics, a mid-range EPDM grommet can suffice while maintaining a long service life. The sunlight exposure that comes with outdoor storage or bursts of sun during high-speed runs matters too; aging grommets can become hard and less compliant, increasing the risk of seal degradation. Regular inspection during routine maintenance, even for components that do not visibly fail, helps ensure that the harnesses remain shielded as the bike ages.

Additionally, installation practices influence long-term performance. A clean hole is essential; burrs or sharp edges should be deburred before grommet insertion. The edge should be smooth enough to avoid cutting the grommet’s outer shell or inner lip during assembly. If the fairing panel’s hole is undersized, a careful reaming or sizing step can prevent premature compression and the risk of tearing the grommet’s edge. When attaching a grommet, it is wise to verify that the harness sits comfortably within the bore, with a slight bend radius that avoids kinks. Avoid over-tightening any securing features that might pinch the grommet or squeeze the cable jacket. In practice, an effortless press-fit plus a light, even seating pressure gives the best combination of seal and flow for the harness.

For riders who enjoy customizing their fairings or migrating between different models, interchangeability becomes important. A standard grommet size can simplify upgrades and maintenance, allowing a rider to swap through different fairing configurations without redesigning the routing. The ability to standardize the path helps keep the electrical system consistent across model changes, reducing the risk of misrouting or mismatched edge geometry. This standardization is especially valuable for riders who customize their bikes with additional electronics like auxiliary lighting, performance sensors, or ride data systems; these additions expand the number of cables that require protected passages and reliable sealing.

The wider ecosystem of fairing components has also embraced grommets as a design consideration. The grommet’s presence can influence how a panel is serialized and how it interfaces with the rest of the harness. In a setting where fairings are designed with integrated ducts, vents, or channels, grommets can accommodate more complex cable shapes and provide a route that reduces surface contact with warm or humid air. In such designs, the grommet helps maintain the fairing’s aesthetic and aerodynamic goals, as cables lie neatly in place without protruding, which would otherwise encourage debris collection or air intrusion. The result is a smoother, more cohesive look and feel that complements the bike’s performance engineering.

In contemplating the lifecycle of a motorcycling electrical system, the grommet emerges as a deceptively simple yet robust element. It is easy to overlook in the short term, especially when the bike starts reliably and the wires do not spark. Yet the grommet quietly supports the system during the most demanding moments: a long-distance ride under variable weather, a track session with high vibration, or a routine service where a technician checks the wiring harness for signs of wear. When the grommet is well chosen, well seated, and well maintained, it becomes part of the backbone that keeps electrical behavior consistent. It contributes to a safer, more dependable riding experience, where the rider can rely on the dashboard not to blink or surprise them with a fault during important miles.

For those seeking to align function with form, the availability of fairing accessories and grommets in compatible sizes makes a practical difference. The landscape of options in the market—ranging from simple, undisguised o-ring style grommets to more elaborate grommet-and-flange assemblies—gives technicians the freedom to select a solution that complements the panel material and the cable jacket. The choice may hinge on whether the mechanic prioritizes a quick swap during a mid-ride repair, or a permanent, flush-sealed installation that resists moisture ingress for a decade. In either case, the grommet’s resilience and correct sizing stand between the harness and the elements, acting as a quiet shield that preserves electrical life while the rider focuses on the road ahead.

As a final reflection, consider the broader context of motorcycle design where even seemingly minor parts carry significant responsibility. Rubber grommets offer a balance of protection, sealing, and ease of maintenance that aligns with the ethos of practical engineering. They do not promise glamour; they deliver steadiness. They do not alter speed or horsepower; they increase reliability and user confidence. When you factor in the protective role they play for wires, connectors, and protective sleeves, grommets emerge as essential components that contribute to safer riding, fewer electrical problems, and longer-lasting electrical systems. This understated reliability is what sustains riders through rain, heat, and miles of winding road, turning a simple hole in a fairing into a dependable conduit for life-sustaining electrical signals.

For readers looking to explore compatible fairing assemblies and harness routing options, you can browse the Honda fairings collection to see how various panels are designed to accommodate standard grommet sizes and how cable passages are integrated within the fairing structure. Honda fairings collection.

External reference: https://www.sohu.com/a/607983235_121015

Durable Pathways: How Rubber Grommets Shield Wiring Through Motorcycle Fairings

A motorcycle is a collection of moving parts, and at the heart of reliable electrical life lies the rubber grommet that guides and guards wires as they pass through the fairing. When durability is on the line, the grommet’s job is quiet but essential: seal, cushion, and accommodate movement without letting moisture, dust, or abrasion reach the harness. In practice, material choice matters. EPDM and neoprene are common because they resist UV light, stay flexible over wide temperatures, and age well in outdoor environments. Too stiff a grommet can press on cables; too soft a one can deform and invite water or grit through the bore. The bore size and wall thickness must balance a snug fit with enough room for the harness to flex. The outer flange should seat flush against the panel, providing a seal without creating a hard edge that could abrade the wires.

Routing is another key: grommets should form a gentle bend and distribute pressure across the bundle to avoid insulation damage. In addition, consider the panel edge: deburr or chamfer holes to reduce wear. A grommet that survives sun and rain ages gracefully, while a neglected one can crack or lose elasticity and allow chafing or moisture ingress. Maintenance matters: inspect grommets during fairing service and replace when aging signs appear. This is a small habit with big payoff in reliability on long rides. When selecting grommets for multiple models, prioritize standard sizes that cover a range of bore and outer diameters, enabling cross model compatibility. Finally, remember that grommets are part of a larger routing system including clips, conduits, and channels; together they reduce movement and protect the cable harness. The right combination yields a tidy, durable, and dependable electrical path through the bike experience.

Final thoughts

Rubber grommets are indispensable components of motorcycle fairings that directly impact wiring safety and longevity. By understanding the selection criteria, along with the benefits and material specifications, business owners can make informed decisions that enhance their motorcycle products. High-quality rubber grommets not only ensure the integrity of electrical systems but also uphold the aesthetics and reliability of every bike. As these components protect against environmental factors and mechanical wear, investing in quality grommets becomes a pivotal step in maximizing the durability and performance of motorcycles. Embrace these insights to elevate your products and improve customer satisfaction in the competitive motorcycle market.