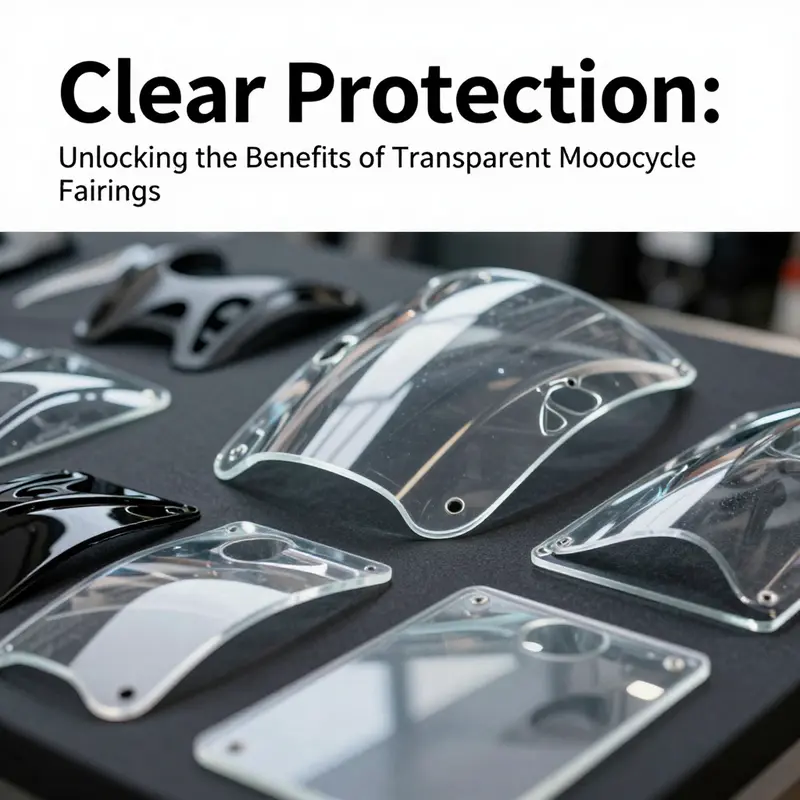

Transparent motorcycle fairings are more than just aesthetic enhancements; they represent a blend of form and function that optimizes rider experience. Designed to shield motorcycle riders from wind, debris, and environmental elements, these specialized fairings often utilize high-impact resistant materials for optimal clarity and durability. As we delve deeper into the world of transparent fairings, we will examine their critical applications in enhancing rider safety and comfort, innovative design advancements in materials used, their significant influence on aerodynamics and performance, and the evolving market trends and consumer preferences. Each chapter will provide insights that underscore the importance of transparent motorcycle fairings in modern riding.

Seeing Through Safety: How Transparent Fairings Shape Rider Comfort, Performance, and Protection

Transparent motorcycle fairings have quietly redefined what it means to ride for two hours or two days straight. They are not merely windows through which the road is viewed; they are engineered interfaces between rider, machine, and environment. In modern touring, sport-touring, and commuter motorcycles, transparent fairings stand at the intersection of visibility, protection, and efficiency. They shield the rider from wind, rain, dust, and debris while preserving a field of view that is crucial for quick assessment of traffic, road surface, and weather change. This combination—clarity plus barrier—forms a design philosophy that prioritizes rider safety and comfort without sacrificing the performance logic that governs aero efficiency. The materials behind these panels are carefully chosen for their balance of strength, lightness, and optical integrity. Typically, high-impact resistant polycarbonate or acrylic resins are employed, and they are manufactured to meet stringent safety standards that govern windshields and optical components in the automotive and two-wheeled sectors. These standards, drawn from international safety regulations, ensure that the material retains both its shape under pressure and its clarity when subjected to temperature swings and long-term UV exposure.

The tangible benefits of transparency begin with environmental protection. A transparent fairing acts as a technological wind shield that makes long rides more humane by reducing the direct wind strike on the rider’s visor, face, and chest. When the bike picks up speed, the rider is subjected to air pressure and turbulence that can cause fatigue, headaches, and a sense of vulnerability in exposed areas. A well-designed transparent panel smooths the air, curating a gentler flow that rides above the rider’s helmet and shoulders rather than slamming into them. The result is a perceptible shift in perceived wind resistance. In studies of aerodynamic performance, even modest improvements in airflow management around the upper body can yield meaningful gains in endurance and perceived comfort, especially on day-long journeys that would otherwise become tests of attention and tolerance. The visual clarity remains a constant, not an afterthought; it is the design constraint that ensures the rider never has to trade safety for comfort.

Equally important is the capacity of transparent fairings to tamper with wind noise and buffeting. Wind noise is not merely a nuisance; it is a contributor to fatigue, reducing vigilance and increasing the likelihood of error over time. The curved, bubble-like profiles that some transparently shielded configurations incorporate are not cosmetic flourishes. They are deliberate aerodynamic features that guide airflow smoothly over the rider’s shoulders and around the helmet. This deflection creates more consistent wind pressure across the torso, which translates into a calmer riding experience. In practice, riders report that even at freeway speeds the sense of wind fatigue diminishes as the air is guided along an optimized path rather than forced against the rider directly. The effect is particularly noticeable on longer routes, where the cumulative impact of turbulence would otherwise accumulate into tiredness that can impair reaction time.

From a safety perspective, transparent fairings contribute to more reliable machinery protection as well. They shield components located on the front end of the bike from rain, dust, and spray, reducing the likelihood that moisture will reach vital electronics or exhaust heat-sensitive areas. While a transparent fairing does not substitute for a full-body shield in a collision, it serves as a protective layer that preserves mechanical integrity under common road hazards. Debris strikes, small stones kicked up by other vehicles, and spray during wet weather are all challenges these panels are designed to withstand. The upshot is a lower probability of road moisture intrusion and debris ingress that could otherwise impair performance or lead to maintenance downtime. This protective role aligns with the broader objective of ride comfort: fewer interruptions, more consistent performance, and a rider who can maintain focus on the road rather than on weather quirks.

The choice of material is not a cosmetic preference but a fundamental determinant of how the system behaves under stress. Polycarbonate offers impact resistance that is well known to riders who have tested it against the realities of road life. Acrylic, while perhaps offering clearer optical properties in some formulations, tends to be stiffer and can be more brittle under certain impact scenarios. The industry commonly selects a polycarbonate or acrylic blend that has been treated with anti-scratch coatings and UV stabilizers. Anti-glare finishes further reduce eye strain when sunlight refracts through a transparent panel at oblique angles, a common condition in late afternoon riding or urban commutes that demand consistent visibility in mixed lighting. The combination of material choice and surface treatment determines not only how long the panel will endure but how clearly it will maintain the rider’s line of sight through a broad range of weather and light conditions.

What makes a transparent fairing a practical choice extends beyond the material and its coatings. The fairing system is usually integrated as either a half-fairing or a full fairing configuration, depending on the level of protection and wind reduction sought by the rider. In half-fairing designs, the transparent section is positioned to cover the upper portion of the bike—typically the headlight area, instrument cluster, and upper fuel-taring region—while leaving the lower engine and frame exposed. This arrangement provides a favorable balance of protection, weight, and maintenance access. It also respects the rider’s need for inspection and service of electronics and intake components beneath the panel. The full fairing, by contrast, can craft a more enveloping wind barrier that reduces wind fatigue to an even greater degree, particularly in high-speed contexts or in adverse weather. The transparent segment, always designed with care for optical clarity, becomes a critical element of the overall aerodynamic package rather than a decorative feature. The rider experiences fewer gusts, less helmet buffeting, and a more stable ride, especially when paired with a well-mannered frame and seat geometry.

Riders who seek to optimize wind protection without adding excessive bulk often turn to transparent windshields and wind deflectors, sometimes mounted as standalone shields or as complements to existing fairing structures. The attractiveness of these configurations lies in their adaptability: a transparent shield can be swapped or upgraded to fit different models and riding preferences, enabling riders to tailor the wind experience to their most common routes and climates. In practical terms, this means riders can gain warmth and comfort in cold, drizzly conditions without surrendering the visibility that is essential to safe riding. The ability to maintain warmth and reduce eye strain in damp weather is especially valuable for commuters who must ride through regular rain or salt spray. By filtering the weather while preserving a clear field of view, the transparent approach enhances safety and daily usability for riders who spend a lot of time on the road.

This approach to design also has implications for the bike’s operating performance. Aerodynamic efficiency is a central objective of modern fairing development, and transparent panels contribute to that objective by enabling smoother airflow around the rider without introducing heavy, opaque components that would add weight or disturb cooling or intake paths. When the panel is designed with aero contours that align with the bike’s bodywork, it works in concert with the rest of the fairing to reduce turbulence and drag around the upper body. In measured terms, well-executed transparent fairings can contribute to a meaningful reduction in rider wind resistance, with studies showing notable decreases in drag forces during sustained high-speed riding. The practical consequence is not just better fuel economy on longer trips but also greater stability in crosswinds, which translates into improved steering feel and rider confidence.

Safety standards play a pivotal role in ensuring that these components live up to their promises. A transparent fairing must pass tests that verify wind resistance, impact resistance, and optical performance under diverse conditions. Standards for windshields in automotive contexts and optical clarity in protective equipment guide manufacturers in selecting materials, thicknesses, and surface treatments that strike the right balance between protection and visibility. These standards are designed to ensure the panel can withstand dynamic wind loads at high speeds, resist impact from road debris, and maintain clear visibility through the life of the component. The discipline of compliance is essential because riders rely on these characteristics every time they press the throttle and glance through the panel at the road ahead. The durability demanded by these standards reduces the risk of panel cracking, hazing, or yellowing, which could otherwise compromise safety and performance over time.

Among the practical considerations for riders and technicians alike is maintenance. Transparent fairings require routine cleaning with non-abrasive cleaners that do not scratch the surface or degrade coatings. UV exposure can gradually dull clarity if the coating is not robust, so riders benefit from protecting the panel with UV-stable finishes and, where appropriate, hydrophobic treatments to shed rainwater so visibility remains high even in inclement weather. Care routines extend to checking mounting points for tightness, ensuring the panel remains firmly aligned with the bodywork to avoid flutter or vibration that could generate noise or accelerate wear. For commuters who tolerate daily exposure to city grime, this attention to care is essential to preserve the panel’s optical performance and protective function over time.

The broad applicability of transparent fairings makes them a strong fit for a spectrum of riding contexts. For riders who prize daily usability and predictable performance, the transparency provides consistent visibility while delivering wind protection. For weekend explorers and long-haul enthusiasts alike, the combination of comfort, reduced fatigue, and protective advantage supports a more enjoyable riding experience. In high-performance scenarios where rider focus and dynamic response are paramount, a transparent half-fairing or a form-fitting windscreen can reduce buffeting and contribute to a smoother interface between rider and motorcycle, preserving reaction time in demanding conditions. In all cases, the fundamental aim remains the same: to create a protective, clear, and durable shield that preserves the rider’s perception of the road while shielding sensitive components from adverse weather and road debris. This holistic approach to design—balancing protection, visibility, weight, and aerodynamic efficiency—underpins the rationale for transparent fairings as a standard feature in modern, rider-focused motorcycles.

Riders benefit from thoughtful integration with the rest of the bike’s systems. Instrument clusters, headlights, and electronic devices housed behind transparent panels require careful consideration of sealing, anti-fog properties, and electrical isolation. The reliability of these systems matters as much as the rider’s perception of the road. When a panel is designed to minimize fogging and maintain optical clarity across temperature swings, the rider’s situational awareness remains intact in rain, fog, or humidity. The synergy between panel design and system integration reinforces the message that transparent fairings are part of a larger strategy to improve rideability. This is not merely about looking through a window; it is about how the window participates in the hands, eyes, and mind of the rider as they negotiate corners, traffic, and weather.

From a broader design and manufacturing perspective, the rise of transparent fairings reflects a shift toward materials and processes that value optical performance as much as structural integrity. For manufacturers, this means investing in surface engineering, coating technologies, and precision molding that yield consistent transparency, scratch resistance, and impact resistance across a range of temperatures. It also means embracing international safety standards that govern the behavior of protective panels in dynamic riding conditions. The result is a family of components that behaves predictably, maintains clarity under stress, and contributes to an overall sense of rider confidence.

For riders looking to explore the possibilities, there is value in understanding the trade-offs between half-fairing and full-fairing configurations and how a transparent panel can be integrated with other protective features. A well-chosen design can deliver wind comfort and weather protection without imposing a burdensome weight penalty or complicating maintenance. In practice, this means considering factors such as typical riding speeds, climate, daily commuting needs, and the rider’s tolerance for wind exposure. It also means recognizing that the panel is only part of a larger aero equation, one that includes the bike’s frame geometry, seat position, and the rider’s posture. When all these elements align, the experience is not just safer; it is more relaxed, more precise, and more enjoyable. The rider can remain focused on the ride rather than compensating for wind or glare, and that is a meaningful advantage for anyone who spends long hours on the road.

As the landscape of motorcycle design continues to evolve, transparent fairings will likely become even more integral to the idea of a rider-centric bike. Advances in material science, coating technology, and computational aerodynamics promise to refine how these panels perform. In the end, the value proposition remains consistent: transparency that enhances clarity, protection, and comfort, with no compromise on safety or performance. This is the essence of transparent fairings—their ability to merge the rider’s need for visibility with the machine’s need for protection and efficiency, enabling a riding experience that is more perceptive, more controlled, and more confident across a broad spectrum of roads and weather. For readers who want to see this evolution in context, a closer look at the evolving ecosystem of fairing options demonstrates how these principles translate into real-world riding benefits, from urban commutes to cross-country treks.

External resource for further reading: Motorcycle Ride Magazine discusses the safety and comfort implications of transparent motorcycle fairings, offering a grounded look at how these components support rider well-being on long journeys. https://www.motorcycleridemagazine.com/transparent-motorcycle-fairings-safety-comfort-2025.

Internal reference for practical exploration: riders and builders can explore compatible fairing configurations and historical catalog options in various collections that showcase how transparent panels integrate with different chassis and cockpit layouts. For those curious about model-agnostic design simulations and frame-level integration approaches, one relevant collection to peruse is the Yamaha fairings collection, which presents a spectrum of fairing shapes and mounting philosophies that illustrate how transparent panels can be harmonized with racing- or touring-oriented aerodynamics. See: Yamah a fairings collection. Yamaha fairings collection.

Seeing Through Speed: Design Innovations in Transparent Motorcycle Fairings and the Materials That Make Them Possible

Transparent motorcycle fairings have emerged as a compelling fusion of aesthetics and engineering, a deliberate turn toward what some riders describe as an exposed heart of the machine. They invite the observer to see the engine and chassis not as hidden mechanics but as active participants in the motorcycle’s performance narrative. This design choice challenges conventional boundaries between form and function. It asks a simple yet powerful question: can protection, visibility, and style coexist in a single composite that remains reliable in rain, heat, grit, and high-speed air? The answer, increasingly, is yes. The core is material science, but the answer gains texture through manufacturing, testing, and the subtle art of integration. A well-executed transparent fairing does more than shield a rider from wind and debris. It communicates a philosophy of engineering confidence, a confidence that the machine’s core components can be safely displayed while still benefiting from streamlined, aerodynamic shielding. The result is not merely a different look but a nuanced performance proposition that appeals to riders who value clarity, lightness, and the tactile sensation of the bike’s mechanical heartbeat. In practical terms, transparent fairings are most often constructed from high-impact resistant polycarbonate or acrylic blends. These materials combine clarity with resilience, offering optical transparency that remains legible under rain and sun, while resisting the micro-abrasions and yellowing that can degrade visibility over time. The transparency is not a cosmetic afterthought but a core requirement: a surface that can tolerate stone strikes, bug splatter, and the occasional grit while preserving the rider’s field of view and the instrument panel’s legibility. The materials chosen for these applications also influence weight, stiffness, and even heat management. Modern transparent plastics can be significantly lighter than metal equivalents, which translates into measurable gains in handling and efficiency. In practice, a typical transparent fairing system uses multi-layered constructions, where an interior protective layer shields the core transparent shell from scuffs, followed by an outer coat that resists UV exposure and weathering. The material selection thus becomes a balancing act: the outer layer must resist ultraviolet degradation and environmental attack, while the inner layers preserve clarity and structural integrity under dynamic loads. This balance is crucial because riders rely on a clear field of view not only for navigation and safety but also for the quick read of the headlight and instrument cluster. A well-engineered transparent fairing preserves instrument visibility even in bright sunlight and against glare, a feature that underscores the practical value of transparency. Material science has advanced enough to offer a choice of formulations that address different climates and riding styles. In bright sunny regions, UV-stable and anti-yellowing formulations are prioritized to maintain consistent clarity for years. In high-rain or dusty environments, surface coatings that shed water and resist grime help sustain visibility and reduce cleaning frequency. At the manufacturing level, the process of turning a clear polymer sheet into a curved, aerodynamically optimized shell relies on thermoforming, precision cutting, and careful bonding to the underlying frame. The shaping phase must ensure that optical clarity is not compromised by surface irregularities. The bonding phase uses structural adhesives and, in some cases, laminated layers to ensure the clear shell remains firmly attached at high speeds and through temperature fluctuations. The result is a smooth, continuous surface that minimizes air disruption while maintaining rider protection. The structural design also considers edge geometry, mounting points, and integration with headlights. An exposed-heart aesthetic is achieved through a deliberate stance: the lower engine and frame are visible, while the upper volumes house the instrumentation and primary airflow. This approach emphasizes the machine’s mechanical “skeleton” without sacrificing shelter against wind fatigue or weather. From a performance standpoint, transparent fairings contribute to aerodynamic efficiency by directing airflow in a predictable manner. While the difference in drag can be modest, it can be meaningful over long distances or in racing contexts where every percentage point of wind resistance matters. Even modest improvements in wind flow can reduce rider fatigue, making long rides more comfortable and reducing the energy cost of maintaining high speeds. In practical terms, design teams measure these effects with wind tunnel tests and computational fluid dynamics simulations, then validate them with real-world testing. The transparency itself does not preclude clever contouring; rather, it invites a more deliberate orchestration of front-end geometry, headlight treatment, and upper fairing arcs to achieve a cohesive silhouette. Customization options further expand the appeal of transparent fairings. The translucent, see-through character invites color-tinted or textured options that can echo or contrast with the motorcycle’s base color. Vendors often offer multiple tint densities or surface textures that change the way light plays across the fairing, giving riders a chance to personalize the look while preserving visibility. The ability to apply tinted panels or subtly frosted finishes can transform the qualitative feel of a bike without compromising safety or instrument readability. In this respect, transparency becomes a canvas for expression rather than a limitation. Even the hardware for securing a transparent shell matters. Fasteners, seals, and mounting geometry are selected not only for strength and weather sealing but also for smooth aerodynamics and low-profile integration. The aim is to keep the edges clean and the surface uninterrupted, a requirement that reinforces the perception of speed and precision. As materials science evolves, engineers increasingly explore advanced composites and blends that can maintain optical clarity under stress, while delivering the needed stiffness and impact resistance. Some of these innovations push beyond simple clear polymers toward multi-functional layers that incorporate anti-scratch, anti-fog, and hydrophobic properties. Such surface engineering reduces maintenance needs and keeps the rider’s line of sight unobstructed after a rainy commute or a dusty climb. The safety and compliance dimension remains central. Transparent fairings must meet the same safety standards that protect riders using more traditional, opaque fairings. This includes durability under impact, resistance to crack propagation, and reliable performance across a range of temperatures. International safety standards guide testing protocols, ensuring that clear materials won’t fail catastrophically at high speeds or in adverse weather. The regulatory framework reinforces confidence in transparent designs and supports broader adoption across different markets and motorcycle categories. The design space for transparent fairings is not limited to street-oriented machines. Racing and performance-oriented builds benefit from transparency by showcasing the engine architecture and the meticulous craftsmanship of the bike’s drive line. In a racing context, even small weights and stiffness improvements can translate into measurable performance advantages. Although race teams increasingly use advanced composites that may not be fully transparent, the underlying principles—clarity, impact resistance, and effective protection of critical components—remain central. Transparent fairings also carry practical benefits for maintenance and diagnostics. A clear shell makes it easier to eyeball quick-service points, identify oil leaks, wiring harness conditions, and heat-related stress. For riders who value transparency in design as a philosophy—where form and function are openly reconciled—the combination of visibility and protection becomes a compelling argument for adoption across a broad spectrum of motorcycles, from daily commuters to premium sport bikes. The communication aspect matters to riders who want their bike to tell a story about engineering rigor. The visual access to the engine and related systems communicates confidence in the mechanical design, signaling that the bike’s performance is in plain sight and not hidden behind opaque panels. This visibility can also influence aftermarket culture, inviting enthusiasts to experiment with different looks through tinted or textured finishes that still maintain readability and safety. To see current transparent configurations in a real-world lineup, explore the Yamaha fairings collection, which offers a range of options illustrating how transparency can harmonize with brand aesthetics and performance aims. Yamaha fairings collection. For broader context on material choices and market offerings, researchers and designers frequently consult supplier databases and materials catalogs that discuss polycarbonate and acrylic blends, UV stabilization, and coating technologies. These references help teams choose the right balance of clarity, strength, and weather resistance for a given climate and riding style. As the field progresses, new coatings and surface treatments promise to extend the life of transparent shells under extended sun exposure and repeated wipe-downs, while nano-engineered surfaces may further reduce grime buildup and maintain optical clarity with minimal maintenance. In this sense, transparent fairings are not simply cosmetic; they are a platform for ongoing material innovation, a test bed for new coatings, and a lens through which riders experience the interplay of speed, protection, and perception. The trajectory points toward deeper integration of smart materials, where adaptable tinting, electrochromic features, or self-healing surfaces could offer dynamic control of visibility, glare management, and surface longevity. These developments would enable transparent fairings to respond to changing light conditions, weather, or riding mode, turning a static shell into an active component of the motorcycle’s performance envelope. Yet even as the technology becomes more sophisticated, the core advantages remain clear: protection without obscurity, clarity that endures across environments, and a design language that embraces performance by revealing it. The story of transparent fairings is a story about choosing materials and processes that permit a perceptible engine presence while delivering reliable protection, maintainable visibility, and aesthetic confidence. It is a narrative that ties together lightweight engineering, surface science, and a rider’s desire to see the machine as it truly is—an integrated system where every layer speaks to the same objective: to move with speed, with control, and with a sense of unflinching clarity. External resources can provide additional technical depth about material options and market availability. For a detailed supplier perspective on transparent polycarbonate and acrylic options used in fairings, see this resource: https://www.alibaba.com/product-detail/Motorcycle-Fairing-for-YBR125-Plastic_1601827977311.html?spm=a2700.1.wissu.1

Transparency in Motion: The Science and Practice of Transparent Motorcycle Fairings

Transparent motorcycle fairings occupy a niche in protective bodywork. They combine wind protection with an unobstructed view, enhancing rider connection to the road. The materials most commonly used are polycarbonate and acrylic, chosen for clarity, impact resistance, and durability. This balance matters for the rider’s visibility and comfort as well as the machine’s efficiency. A transparent fairing should not compromise aerodynamics or structural integrity. The goal is to maintain a clean path for air while preserving the rider’s perception of the bike’s lines, instruments, and the road ahead.\n\nThe aerodynamic story begins with shape and surface. Aerodynamics cares about contour, surface finish, and seamless transitions, not color. A transparent fairing that mirrors the sleek lines of a conventional shell can deliver similar drag reduction when the nose, wind-facing surfaces, and junctions are carefully shaped. In practice, this means a contoured nose, venting slots, and internal channels that guide air with minimal friction. When well conceived, the drag profile aligns with the bike’s riding envelope.\n\nWeight and handling are influenced by the choice of transparent plastics. Polycarbonate offers a compelling mix of lightness and toughness. A lighter upper shell reduces unsprung mass, contributing to more responsive steering. The practical upshot is a subtle improvement in maneuverability, especially at lower speeds where the fairing interacts with the rider’s inputs. The objective is to balance weight savings with impact resistance in an integrated performance strategy.\n\nTransparency introduces thermal management considerations. More light reaching the cockpit can raise heat, so ventilation channels and UV protective coatings help. Coatings that reduce glare, anti fog properties, and scratch resistance matter for long term visibility. Regular cleaning with non abrasive methods helps preserve optical clarity.\n\nSafety and standards anchor transparent fairings to expectations in motorcycling engineering. High quality transparent components must meet the same safety criteria as opaque parts. Impact resistance, UV stability, and environmental durability are essential. Manufacturers document compliance with recognized standards and perform testing to prove durability under riding conditions.\n\nFrom half fairings to full fairings, transparent panels have different roles. In half fairings the transparent portion covers the headlight area and instrument cluster, balancing protection with access. Full fairings rely on a continuous transparent surface integrated with the sides and bottom to channel air smoothly. For some riders, transparency enhances policy of rider electronics visibility, while still preserving elegant bike lines.\n\nIn racing contexts the material science remains the same, but the engineering aims to maximize stiffness, surface perfection, and resilience under wind pressure. The bottom line is that transparency can coexist with strength and aero efficiency when design and materials are chosen with care. The final value is a clear view with robust protection, not a delicate novelty.\n\nExternal reference: the Honda fairings collection offers transparent design language that harmonizes with a bike’s silhouette and instrument visibility.

Clarity Under Pressure: Navigating Trends, Tech, and Tastes in Transparent Motorcycle Fairings

Transparency in motorcycle fairings sits at an intriguing crossroads of function and form. On one side, riders demand wind protection, weather resilience, and protection from debris. On the other, they expect visibility, clarity, and a clean, lightweight silhouette that preserves handling characteristics. Transparent fairings attempt to satisfy both pressures at once. They shield the rider while keeping instrument clusters legible, headlights aligned, and the windscreen effect uninterrupted. Yet the market for these components remains less charted than that of helmets or other protective gear. The chapter that follows explores why that is, what drivers would shape future demand, and how manufacturers may translate safety, comfort, and aesthetics into actionable product decisions. The aim is less to forecast a fixed trajectory and more to illuminate the levers that will matter as riders, shops, and brands navigate this niche within a broader motorcycle ecosystem.

The absence of robust market data in the current research landscape is not a failure of curiosity but a signal about how specialized this domain remains. Transparent fairings occupy a space that blends safety engineering with design storytelling. They must perform under high wind loads, resist impact from insects and debris, and maintain optical clarity for both the rider and the bike’s electronic systems. These are not purely cosmetic decisions; they are technical commitments. When a material is chosen for a transparent fairing, it must endure abrasion, resist yellowing under UV exposure, and maintain a distortion-free window over thousands of miles of riding. Manufacturers must also consider the fatigue life of the attachment points, the sealing against moisture, and the interplay with lighting and instrumentation. In sum, the specifications behind a transparent wind deflector or a half fairing hinge on a synthesis of safety standards, material science, and user experience.

The consumer side of the equation is equally nuanced. Riders do not decide in a vacuum. Preferences shift with climate, riding style, and maintenance habits. A commuter who rides daily through winter rain might prioritize maximum wind protection and dry electronics, even if that comes with a slightly bulkier look. A weekend canyon carver may prize light weight and crisp aerodynamics, accepting that transparency adds risk of fogging or micro-scratches if used aggressively. A track day enthusiast may be most concerned with distortion-free optics and consistent glare control, because any optical anomaly at high speed can hamper reaction time. These divergent needs exist within a single market segment and complicate the task of predicting demand without targeted data. As a result, product development often relies on a blend of field testing, rider interviews, and iterative design, rather than a single set of market indicators.

One practical implication of this data gap is that transparency is often evaluated not in isolation but in the context of broader fairing ecosystems. A transparent section is typically part of a half fairing or a full fairing system. The decision to employ a transparent element interacts with other design choices, including where the rider sits in relation to the air stream, how much wind tunnel protection is required, and what level of maintenance the rider is willing to perform. In half fairing configurations, the transparent area usually covers the upper portion of the bike—near the headlight, instrument cluster, and upper fuel tank—while leaving the lower engine and frame exposed. This arrangement reduces wind fatigue without the weight and bulk of a full fairing. For riders who want even more wind protection without encasing the entire bike, transparent wind deflectors or standalone shields are used in conjunction with traditional fairing components. These configurations illustrate a central theme: transparency is as much about strategic placement as it is about material quality. That strategy, in turn, shapes consumer appeal.

Material choice stands at the core of how consumers perceive value in transparent fairings. Polycarbonate and acrylic are the go-to options because they offer a compelling mix of clarity and impact resistance. Polycarbonate, with its superior toughness, better tolerates impacts at speed and resists cracking under small objects striking the surface. Acrylic, while perhaps more prone to scratching than polycarbonate, often provides excellent optical clarity and can offer clearer, crisper transparency when well maintained. Each material demands particular care and protective coatings. Anti-scratch layers extend the life of a clear surface, while UV inhibitors slow the yellowing that naturally occurs with sun exposure. Anti-fog features and hydrophobic coatings can help maintain clarity in wet conditions, where rain, spray, and varying humidity threaten continuous visibility. When riders replace or upgrade a fairing, these attributes become a part of how they justify cost and maintenance commitments to themselves and to their machines.

From a manufacturing perspective, the pursuit of optical clarity and durability shapes the production process. The most common routes involve thermoforming or injection molding for polycarbonate, or thermoforming for acrylic sheets. Each method imposes tolerances that determine how distortion-free the final surface remains across temperature swings and weather exposure. The edges must be sealed to prevent moisture ingress that could cloud the surface or compromise electronics nearby. In high-performance contexts, the weight of the fairing is also a concern. Even small gains in weight can affect handling in quick transitions or on windy roads. For racing applications, where every ounce counts, the push toward lighter composites continues to influence the design of transparent elements. Carbon fiber and advanced resins are sometimes considered in high-end builds where a controlled trellis of transparency is achieved through clever layering and selective opacity. Ultimately, materials science integrates with aesthetics: riders want a surface that looks pristine, remains clear over time, and survives the rigors of aggressive riding.

The aesthetic dimension is not a luxury; it is a driver of perceived value and market acceptance. Transparent fairings contribute to a bike’s visual language by showcasing the geometry of the frame and the calm, uninterrupted line where visibility and style meet. This can be particularly appealing on sport and naked bikes where the rider becomes part of the machine’s story. Yet aesthetics must not compromise function. A surface that looks good but muddy or scratch-marked after a few rides can erode trust and willingness to invest. This tension explains why coatings, clean maintenance routines, and replacement cycles become talking points among enthusiasts and retailers alike. The design conversation thus extends beyond raw performance and into the realm of user experience, where the ease of cleaning, the ease of inspection for cracks or chips, and the ability to restore clarity after a road trip matter as much as the initial impression of a glassy shield.

Another layer of complexity emerges when considering safety and regulatory expectations. Transparent components must satisfy not only impact resistance tests but also alignment with visibility standards. Distortion in a shield can interfere with headlight performance or instrument readability, both of which have direct implications for rider safety. The surfaces should not introduce glare that could blind the rider or other motorists in bright sun or artificial lighting. As such, the development of a transparent fairing often involves collaboration across teams: mechanical engineers ensure structural integrity, optical engineers optimize clarity and glare control, and human factors specialists study how riders interpret information from the instrument panel through a curved, transparent window. Compliance with international specifications helps ensure that a given design is not just a niche curiosity but a viable option for a broad range of riders and markets.

Within the marketplace, consumer preferences for transparent fairings are likely to be shaped by climate-driven needs as well as lifestyle patterns. In rainy climates, riders may favor visibility and clean lines that minimize wind intrusion while preserving the protection from wet air and spray. In hot or arid environments, the priority might shift toward heat management and glare reduction, with coatings that curb surface fogging and keep the rider cooler through better optical performance. Enthusiasts who participate in track days might emphasize consistent performance under high-speed airflow and careful integration with other components such as mirrors, wind deflectors, or fairing vents. The aftermarket ecosystem responds to these distinctions by offering variations in thickness, coating, and mounting hardware. The result is a spectrum rather than a single standard: a hardware kit with transparent segments engineered to fit a range of models and riding contexts.

In practice, consumer acceptance of transparent fairings hinges on perceived value and reliability. A rider is more likely to invest if the product promises not only performance gains but also maintenance simplicity and long-term durability. This means packaging that includes clear maintenance instructions, compatible cleaning agents that do not cloud or scratch the surface, and predictable replacement cycles for coatings. It also means a robust support network of technicians who can assess and repair micro-scratches, verify mounting integrity, and reseal seams after exposure to rain and road grime. The aftermarket channel plays a critical role here, translating design intent into practical, user-friendly options. For readers seeking real-world examples of how fairing ecosystems organize around different brands and model families, the Honda fairings collection offers a compact window into the breadth of options that exist in the market. Exploring a curated range in this category can reveal how manufacturers balance optics, protection, and fit across bike generations and riding styles. Honda fairings collection provides a sense of how a broad catalog handles fitment, component integration, and visual language across models.

The consumer narrative also intersects with economics. Transparent fairings sit at a price point influenced not only by material costs but by precision manufacturing, coatings, and complex fitment. Buyers must weigh the incremental benefit of improved visibility and UV protection against the added cost and potential maintenance demands. This calculus varies with income, riding frequency, and the perceived return on investment in comfort and safety. In markets where riders face frequent rain or cold, the value proposition may tilt toward reliability and day-long comfort, making transparency an appealing feature that supports visibility and warmth. In markets with long dry seasons, the emphasis may lean toward weight and aerodynamic integration, rendering the decision more nuanced. As with many niche segments, part of the challenge is communicating measurable benefits when data are scarce. This is where case studies, performance tests, and rider testimonials become essential tools for manufacturers and retailers.

For researchers and marketers, the current data gap creates an opportunity to tailor inquiries that would illuminate how transparent fairings perform in real-world conditions and how consumers respond to these performance signals. A structured approach would track adoption rates among riders who upgrade to fairings, correlate maintenance costs with perceived clarity, and analyze the role of color and texture in consumer preference. It would also examine compatibility with different model lines and the ease with which local technicians can service or repair a transparent component. Such research would help distinguish between temporary novelty and durable value, guiding product roadmaps and communications strategies. It would also provide a more solid basis for predicting future demand, allowing manufacturers to align capacity, material sourcing, and after-sales support with a clearer understanding of user priorities.

The roadmap for transparent fairings, then, rests on bridging technical capability with consumer insight. On the technical side, ongoing advances in materials science and coatings will extend the life of transparent surfaces under demanding conditions. On the consumer side, a more granular picture of what riders want—whether it is fewer cleaning steps, better glare management, or improved integration with dashboards—will sharpen how products are designed and marketed. In the meantime, retailers and builders can demonstrate value by highlighting practical benefits: ease of inspection for electronics, the preservation of instrument readability, and the contribution to a rider’s sense of control on wet roads. These are not abstract advantages; they translate directly into daily riding quality and long-term ownership satisfaction.

Looking forward, the industry should keep sight of an essential premise: transparency is a feature that interacts with every other component of the bike. The wire harness behind a headlight, the way the gauge cluster is framed, and the position of the rider relative to the wind all influence how a transparent fairing is perceived and assessed. The best designs anticipate potential problem areas and address them with thoughtful engineering—such as edge protection for the clear surface, seals that keep moisture from creeping into critical joints, and mounting options that reduce vibration-induced micro-movements that might blur the rider’s view. When these issues are addressed, transparency becomes not just a shield for the rider but a design language that communicates clarity, confidence, and a willingness to engage with the road in a direct, unmediated way.

In closing, the market for transparent motorcycle fairings remains a sophisticated field where safety, engineering, aesthetics, and rider psychology converge. The knowledge base is still maturing, but the questions are clear: What do riders truly value when they choose a transparent solution? How can manufacturers deliver clear optics and durable protection at a reasonable price? How will regulatory and standards frameworks shape what is feasible in different regions? The answers will emerge from careful listening to riders, rigorous testing, and a willingness to translate insights into designs that perform as confidently as they look. For readers interested in seeing how a broad catalog categories its fairings in practice, a practical reference is available in the Honda fairings collection, which showcases a spectrum of fitments and design approaches used across generations. This chapter therefore leaves readers with a grounded sense of where transparency sits today and how it might evolve as riders and machines grow more connected and more demanding.

Final thoughts

The journey through the world of transparent motorcycle fairings emphasizes their pivotal role in enhancing rider safety, comfort, performance, and appealing design. As advancements in materials and designs continue to evolve, businesses must stay attuned to emerging consumer preferences and trends. By understanding the multifaceted applications and benefits of transparent fairings, business owners can better cater to the needs of the motorcycle community and leverage opportunities for growth in this niche market.