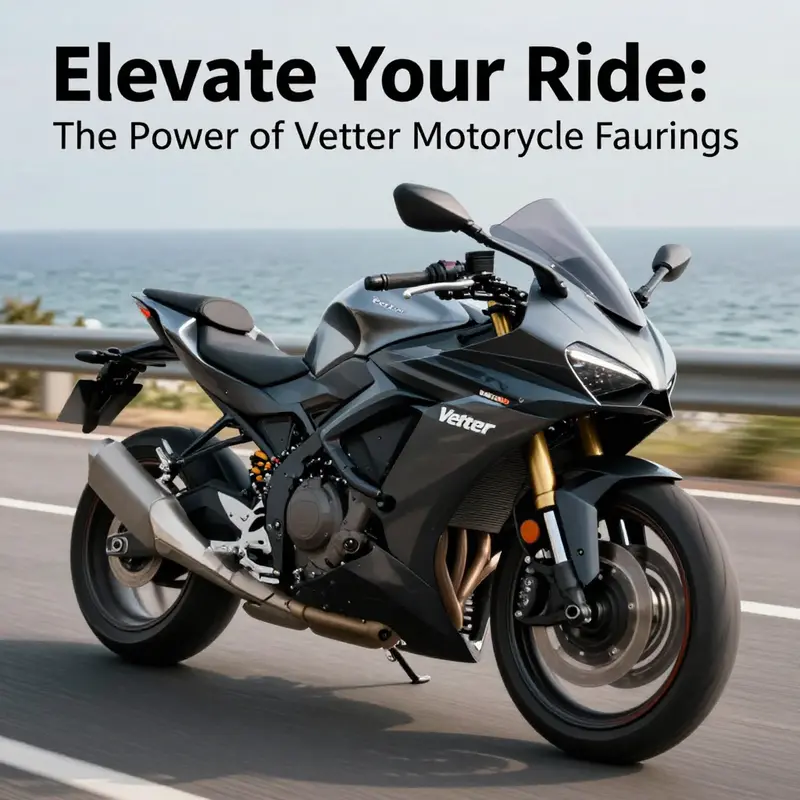

Vetter motorcycle fairings represent a leap forward in motorcycle customization, offering unmatched performance enhancements and aesthetic appeal. As businesses tap into the lucrative aftermarket motorcycle parts industry, understanding the advantages of Vetter fairings becomes paramount. From improved aerodynamics to superior material innovations, the following chapters will explore the performance benefits, groundbreaking design features, compatibility for various models, and trending consumer preferences that make Vetter a leading choice among motorcycle enthusiasts. Each chapter plays an integral role in illustrating how Vetter fairings can drive sales and satisfaction in your motorcycle offerings.

Performance as a Second Skin: The Aerodynamic Precision and Endurance of Vetter Motorcycle Fairings

Riding at highway speeds is a conversation with wind. On a naked bike, the air becomes an adversary that you learn to manage with posture and endurance. On a bike equipped with Vetter motorcycle fairings, the conversation shifts. The wind is still there, but the fairings shape it into a cooperative current, threading air so smoothly that the ride feels less like a battle and more like a measured glide. This is not merely about looking sleek; it is about translating engineering into real world advantages. The story of Vetter fairings is a story of precision in form meeting precision in function. By systematically reducing drag, guiding airflow, and shielding the rider, these fairings turn high speed from a test of strength into a measured performance envelope. And that envelope expands when we consider the full spectrum of riding—from long distance touring to spirited weekend sessions on winding roads, from weather protection to mechanical efficiency. The result is a blend of speed, stability, and comfort that is rarely captured by simple aesthetics alone.

The essence of aerodynamic improvement begins with a simple truth: air does not want to go around a motorcycle; it wants to fill the space around it. A fairing acts like a carefully shaped inlet for air, a sculpted barrier that smooths the velocity field so that pressure differences remain controlled and predictable. When the shapes are optimized for laminar flow, turbulence is tamed, and the bike can slice through atmosphere with less energy wasted in eddies and vortices. For the rider, this translates into reduced wind pressure on the upper body, a calmer helmet area, and less fatigue after hours in the saddle. The impact is not only on speed but on the rider’s ability to maintain form—shoulders relaxed, wrists comfortable, torso upright or tucked as the ride demands—without the instinct to brace against gusts or buffeting. The science behind this is practical and accessible: by shaping the fairing to manage boundary layers and to encourage smooth transitions at the interfaces where airflow meets the bike, a manufacturer can cut drag while preserving stability. It is a careful balance between function and aesthetics, because a flaw in the visual language of a fairing often signals an aerodynamic drawback as well. In design centers and workshop bays, the best shapes are born from a dialogue between computational insight, wind tunnel intuition, and real road testing. The closer the collaboration among these elements, the more reliably a fairing can deliver both speed and confidence when the lock is clicked on at highway velocities.

Beyond the pure science of drag reduction, the practical advantages of Vetter fairings extend into rider comfort and endurance. Windblast—the pressure and shear forces that strike the rider from the forward-facing wind—is not merely a nuisance; it is a source of fatigue that compounds over miles and hours. A well-tuned fairing serves as a shield that reduces this windblast on the torso, neck, and head. The ergonomic outcome is a more natural seating posture during long hauls, a more acclimated breathing rhythm, and a lower tendency to tense the shoulders or crane the neck to peek over a rising wind. In long-distance contexts, that translates into the ability to ride further with less effort, maintaining clarity of vision, steady throttle control, and a more predictable line through corners. If you ride for work, sport, or exploration, the ergonomic benefits become as tangible as the speed gains—your body accepts the miles with less protest and more efficiency.

Protection is another pillar of performance. Fairings cover more than just the rider; they guard sensitive components and the bike’s vital systems from debris, weather, and incidental contact. Small rocks, rain, and road spray find a less inviting path when a fairing intercepts their trajectory. Engine casings, radiators, wiring harnesses, and electronics sit behind a buffer that dampens impact energy and reduces potential damage. This protective layer can contribute to lower maintenance costs over time and less downtime between rides. In a sport or touring context where the bike is a tool rather than a display, maintenance intervals and reliability become a direct contributor to real-world performance. The peace of mind that comes from dependable protection means a rider can maintain pace and confidence across a season without being diverted by rough weather or rough roads.

Thermal management is a subtler but crucial facet of performance. Airflow around the engine and cooling system creates an external environment that influences internal temperatures. A thoughtfully designed fairing channels air to manage hot zones, guiding heat away from sensitive components and helping maintain an optimal operating window even during sustained high-speed runs or steep climbs. In track days and intense highway stretches, temperature spikes can degrade power delivery, reduce efficiency, and shorten component life. When aerodynamics and cooling converge in concert, a motorcycle not only runs cooler but runs with a more consistent power curve. The material choices reinforce this balance: fiberglass and high-strength composites provide rigidity while keeping weight down, reducing the inertial penalties that high-speed air demands. These materials also resist environmental wear and UV exposure, preserving both form and function through the sun and rain that travel companions typically bring to the ride.

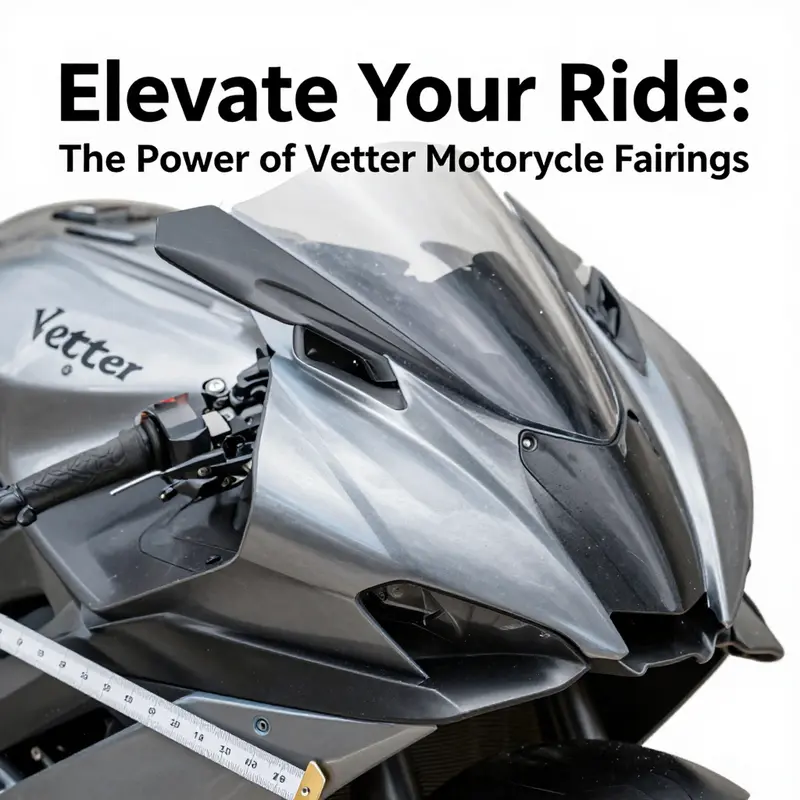

Vetter’s engineering philosophy emphasizes precision in fit and finish. The classic promise of an aftermarket fairing is not just that it looks the part, but that it integrates with the motorcycle’s geometry with minimal fuss. Precision fitment reduces the risk of gaps that could disrupt airflow or introduce rattle under vibration. It also minimizes the labor and frustration typically associated with installation, especially on older or uncommon platforms where factory tolerances can diverge from modern expectations. A well-fitted fairing is a quiet one, not only aesthetically pleasing but acoustically neutral, as gaps and misalignments can create unwanted wind noise, buffeting, and micro-motions at speed. The fitment quality bears a direct link to performance: when a shell sits true, the sculpted air pathways remain intact across riding conditions, and the rider benefits from a predictable, stable ride rather than a compromise between fashion and function.

Material choice underlines the practical balance of strength and lightness. ABS plastic and fiberglass composites bring different advantages to the table. ABS offers impact resistance and fine-grained detailing that can capture aggressive lines, while fiberglass provides stiffness and a robust feel with lower thermal sensitivity in some designs. Both materials offer resilience against UV exposure and weathering, ensuring the fairing holds its shape and color over time. The blend of materials is often tuned to the model’s intended use, the rider’s preferences, and the expected range of operating temperatures. The overarching objective is to maintain shape fidelity while keeping weight manageable. A lighter shell reduces the momentum of air that must be redirected, which in turn helps with acceleration and quickness of steering response. Yet the shell must retain enough mass to withstand road hazards and the occasional impact without compromising safety or requiring frequent replacement.

The aesthetic aspect of performance should not be discounted. A fairing that looks streamlined tends to convey a sense of precision and purpose that mirrors the rider’s intention. The visual language of Vetter fairings—the clean lines, the uninterrupted sweep of the shoulder through the lower body, and the careful alignment with the bike’s natural silhouette—speaks to a broader design ethos. It is not merely about fashion; it is about telling the rider that every curve has a reason, that every contour is a calculated choice to improve efficiency and control. A visually coherent shell supports confidence in control and enhances the rider’s focus on the road ahead, not on the clocking in of minute performance gains. The result is a riding experience that feels like a single, well-tuned instrument rather than a collection of add-ons. For riders who value both form and function, the best fairings meet at this intersection: they perform as they look, and they look as they perform.

In practice, the breadth of Vetter fairing options speaks to the varied needs of riders. Full fairings envelop the bike, crafting a continuous aerodynamic envelope that optimizes high-speed stability and weather protection. Half fairings offer a balance of wind protection with greater access to the rider and maintenance points, suitable for those who crave some exposure while preserving essential performance benefits. Universal headlight fairings provide flexibility for custom builds, where fitment precision might require more bespoke tailoring. The design language behind these choices centers on compatibility with diverse riding styles—from sport and track-inspired setups to touring configurations and cafe racer aesthetics. A rider who values long-range comfort can still enjoy an aggressive stance, while someone chasing top-end speed can exploit the same shell to preserve stability at warp speed. The key is that each option adheres to the core principles of aerodynamics, protection, and durability, while offering the flexibility that the aftermarket landscape demands. To illustrate a practical bridge between the catalog and the road, consider the entry points a rider encounters when exploring a catalog such as the Honda fairings collection, which exemplifies how many design directions can be harmonized with a common aerodynamic core. Honda fairings collection provides a window into how different shapes and mounting philosophies translate into riding behavior across a range of machines.

This blend of engineering rigor, material science, and user-centric design positions Vetter fairings as a premium upgrade for riders seeking measurable performance benefits. The conversation between wind and machine is ongoing, and each ride offers a new data point. When the fairing aligns with a rider’s preferences—whether that means a tightened wind envelope for a race-day sprint or a broad, forgiving shield for a cross-country voyage—the performance return becomes personal. The rider discovers a more composed experience at speed, reduced fatigue on long hauls, and fewer maintenance surprises along the way. In that sense, performance is not a single statistic such as drag coefficient or top speed; it is a composite of stability, comfort, protection, and reliability. It is the difference between a ride that feels like a constant adjustment and a ride that feels like a well-calibrated instrument clicking into place with every turn of the throttle.

To those who measure a motorcycle by how it performs in the real world, the value of a well-designed fairing becomes clear. It is not a cosmetic add-on but an integrated system that extends the bike’s capability, enabling riders to push farther, smile longer, and return home without the fatigue that often accompanies long journeys. It is the sense that the machine and rider are in harmony, moving as a single organism through air and weather. As performance gains become part of the daily riding experience, the decision to invest in a high-quality fairing becomes less about chasing the latest trend and more about embracing a durable, practical upgrade that pays dividends in speed, efficiency, comfort, and peace of mind. For readers who want to explore options and understand how aerodynamic design translates into tangible road benefits, the conversation is anchored in the fundamentals described here and reinforced by real world testing and feedback from the rider community. External resources from industry leaders provide additional context on how aerodynamic engineering translates into performance benefits, complementing the practical knowledge outlined here. See the official overview of performance benefits for a broader perspective on how deliberate shaping and material choices influence ride dynamics. https://www.vetterfairings.com/performance-benefits

Aeroform Heritage: Design and Material Innovations Shaping Vetter Motorcycle Fairings

From the moment a rider slips behind the dash of a motorcycle, the bodywork surrounding the bike becomes more than a cosmetic shell. It is a carefully engineered interface between machine and weather, weight and wind, fatigue and focus. In the long arc of motorcycle history, Vetter Fairing Company carved out a distinct path by treating fairings not merely as covers, but as integral components of performance, comfort, and style. The chapter that follows traces a lineage—how design goals and material choices evolved in tandem to redefine what a fairing could do on a motorcycle. It is a story of curves and composites, wind tunnels and hands-on craftsmanship, and of a philosophy that the rider’s experience should be enhanced without compromising the machine’s essence. The arc begins with a vision of aerodynamics steadily advancing from mere shield to essential performance feature, and it ends with a transformed aftermarket landscape where modularity, durability, and aesthetics converge.

In the mid-1970s, the industry witnessed a milestone that would echo through decades of design discourse. A Vetter fairing introduced a wind-deflection approach that prioritized rider stability and fatigue reduction at speed, while still honoring the machine’s silhouette. The emphasis was not only on cutting through air but on shaping it in a way that allowed the rider to maintain control, visibility, and comfort across longer journeys. This was more than a surface solution; it was a philosophy of motion. The idea then, as it remains now, is to design a form that reads the wind as an ally rather than as an adversary. As with any engineering advance, the mathematical elegance of the form must be matched by practical resilience. The fairing had to withstand exposure to sun, rain, grit, and the occasional souvenir from a blustery ride, all while retaining a precise fit to a diverse range of chassis. In that sense, the design objective extended beyond aerodynamics to encompass durability and long-term reliability in the real world of ownership and use.

The design innovations that defined this era were anchored in a simple truth: performance and protection should harmonize with the rider’s experience. Aerodynamics emerged as a central discipline, not an afterthought. The shaping of the fairing—its silhouette, its leading edges, the sweep of its curves—was crafted to reduce drag and manage buffeting. A well-proportioned fairing can create a coherent airflow around a rider’s torso, guiding pressure away from the helmet and shoulders and contributing to smoother steering at high speed. The engineers recognized that rider comfort translates into endurance. When wind pressure is balanced across the torso, the rider maintains better posture, breath control, and alertness. The result was not a single, blunt blade of plastic but a curated family of shapes designed to complement the bike’s chassis geometry, seat height, and riding posture.

Yet even the most refined aerodynamic philosophy needs a practical, adaptable framework. Here, modularity became a defining feature. The ability to mix and match components—wind-deflecting segments, screen heights, and mounting brackets—allowed riders to tailor the fairing to their personal style and riding discipline. A sport rider could opt for more aggressive contouring to minimize drag at higher speeds, while a touring rider could select a profile that optimizes wind protection without sacrificing maneuverability. The modular approach also facilitated maintenance and customization over time. If a rider wanted to switch from a race-inspired look to a more understated finish for a season of endurance events, the system supported that evolution without requiring a complete overhaul. Aesthetics followed function here, with surface detailing and color integration treated as an extension of aerodynamic intent rather than as an afterthought.

Aesthetics themselves evolved from the need to integrate performance with a coherent visual language. The fairings of this era were not only about reducing drag; they became a vehicle’s visual identity. The lines were kept clean and purposeful, with a sense of continuity that extended from the headlight nacelles to the tail. The design language sought balance—between sharp, confident angles and softer, more organic transitions—so the motorcycle could project speed and poise even when it was standing still. This attention to appearance mattered because motorcycles with a strong visual presence tend to be more appealing for customization. A fairing is the canvas on which a rider’s personality can express itself through paint, trim, and mounting accessories. The modern aftermarket ecosystem owes a debt to this early commitment to aesthetic coherence, a recognition that form and function are not rivals but partners in the riding experience.

Material innovation runs in close concert with form. The earliest fairings that bore the Vetter label leaned on fiberglass for its advantageous blend of stiffness, lightness, and workability. Fiberglass offered a practical starting point: it could be molded into complex shapes, yet remained feasible for production and repair. The fiberglass composites also tolerated the environmental realities of motorcycle life. They resisted impact to a reasonable degree, handled thermal cycling without cracking, and stood up to UV exposure with proper formulation of resins and surface finishes. But as performance expectations rose and the demand for longer life under all-weather exposure grew, the material baseline would shift. The industry’s evolution toward reinforced plastics—engineered blends that pair resin matrices with reinforcing fibers—brought an increase in rigidity, impact resistance, and overall durability, all while keeping weight in check. The incremental move from a pure fiberglass approach to reinforced polymers signaled a wider trend in aftermarket components: craft materials that offer predictable behavior under real-world stresses and time.

Alongside these material milestones, environmental durability became a practical design constraint. Fairings need to hold their shape and finish after years of sun exposure, temperature swings, and the abrasive realities of road debris. UV resistance isn’t a flashy virtue; it is the reason color remains stable, edges stay sharp, and gloss persists after many sunlit miles. In parallel, chemical resistance matters—the way plastics resist oils, fuel vapors, and cleaning agents. These concerns are not merely about aesthetics; they influence how a fairing ages, how it can be repaired, and how it participates in the broader lifecycle of the motorcycle. The material strategy thus becomes a balancing act: lightness for performance, strength for durability, and stability for long-term maintenance. The shift toward reinforced plastics, then to sophisticated composites, reflects a growing maturity in how aftermarket components are engineered to deliver consistent ride quality over time.

Modern applications of these historical design and material decisions extend beyond shaping and strength. Contemporary fairings—whether used to optimize wind management, to host protective enclosures for components, or to mount a spectrum of accessories—now emphasize how the rider perceives the journey. Windshields are not simply obstacles to be navigated; they are instruments that adjust the rider’s encounter with air, noise, and visibility. Well-calibrated shields can reduce buffeting without compromising airflow to the engine compartment or the rider’s lateral field of vision. Trim kits, mounting rails, and accessory docks reflect the modular ethos by enabling personal touches that do not derail the core aerodynamic compromise. In this sense, the evolution of the fairing is inseparable from the rider’s day-to-day experience. A thoughtful exterior shell translates into tangible benefits: less fatigue, steadier hands, clearer perception of the road ahead, and more time to enjoy the ride instead of fighting the wind.

Design and material innovations also foster a broader cultural dimension. The fairing becomes part of the collectible fabric of motorcycling, a reminder of an era when engineers and designers sought to harmonize human comfort with mechanical performance. The modular approach that once allowed riders to tweak fitments and appearances now also makes restoration and customization more accessible. A fairing from a bygone decade can still be restored and modernized without sacrificing its original character, because the design language and material choices were made with a respect for both form and function. The legacy of this approach has reinforced an enduring principle: durability and adaptability should be built into design at the outset, not tacked on as afterthought attributes. In practice, this means that the modern aftermarket scene continues to value a blend of robust fiberglass and reinforced plastics, supplemented by protective finishes that guard against sun and weather while enabling technicians to repair and refine over time.

To connect these threads to the present, consider how the historical emphasis on wind management informs today’s offer of modular systems. A fairing is no longer a single rigid piece; it is a capable assembly that can accommodate wind deflection, decorative accents, and functional elements such as vents and mounting points. The interplay between design and material science informs the product development cycle: engineers prototype new curves, test them for drag coefficients and stability, then select resins and reinforcements that preserve those shapes under real-world use. The result is a family of components whose performance characteristics are predictable and whose maintenance profile is practical for riders who demand reliability across seasons and miles. In this way, Vetter’s early emphasis on aerodynamic efficiency and material resilience remains a living principle. Even as the aftermarket landscape expands with new technologies and manufacturing methods, the core objective persists: to deliver protection, comfort, and control without reducing the soul of the machine.

For riders who want a direct link to contemporary practice while honoring the historical lineage, a broader catalog of fairings offers a way to explore the continuum from era-spanning design to current engineering refinements. This chapter’s focus on design and material innovations serves as a bridge between the original intent of early fairings and the new generation that continues to push the envelope. The idea is not to worship a particular era but to recognize the throughline: form follows function, but the function itself is enriched by craft, material science, and a deep understanding of rider psychology. The fairing of a motorcycle is where engineering and artistry converge into a single experience—the way it looks, the way it moves, and the way it makes the rider feel when the road opens up ahead.

As you reflect on this heritage, you can see how the principles persist in today’s aftermarket ecosystems. The best designs remain those that respect both the science of air and the art of human control. They acknowledge that riders are not just operators of machines; they are partners in a shared journey where temperature, wind, light, noise, and posture all interact to shape perception and performance. In that sense, the Vetter lineage embodies a philosophy of design that prioritizes rider comfort without compromising the machine’s identity. It is a careful balance between wrapping the rider in a shield and deploying a careful sculpture of air around the bike. This balance continues to guide contemporary fairing development, encouraging innovations that are both technically sound and visually coherent. It is this synthesis—the aerodynamic rationality, the resilient material choices, and the aesthetic coordination—that constitutes the enduring craft of Vetter-influenced fairings.

If you wish to explore related collections that echo this heritage while remaining mindful of the practicalities of compatibility and fit, you can look into the broader catalog of fairings. For a direct route to a representative fairings collection, follow this link to a category that organizes options by chassis and application: Kawasaki fairings collection. This resource provides a sense of how today’s aftermarket offerings maintain the balance between performance goals and consumer needs, reflecting the same design discipline that guided earlier generations. The path from past to present is continuous, not interrupted by trends, and it is this continuity that makes the study of Vetter’s design and material choices especially instructive for enthusiasts who care about the long arc of motorcycle aesthetics and function.

In sum, the story of Vetter’s fairings is a story of disciplined design meeting practical material science. Aerodynamics was not an abstract ideal but a tool to make riding safer and more enjoyable. Modularity turned a single design into a toolkit adaptable to different riders and disciplines. The materials—fiberglass evolving into reinforced plastics—delivered durability without sacrificing lightness. The visual language grew into a recognizable aesthetic that could complement a wide range of bikes while allowing riders to imprint their own personality on the machine. The modern fairing, in its various permutations, embodies those same commitments: to protect, to perform, and to please the eye. As the conversation about motorcycle aerodynamics and protective bodywork evolves, the lessons from this era remain relevant—engineered intuition that puts rider experience at the center and treats the fairing as a functional sculpture designed for the road ahead.

For enthusiasts who want to navigate the current marketplace with awareness of this heritage, the fairings catalog remains a useful compass. You can discover a curated selection of components that align with the principles described above by visiting the Kawasaki fairings collection. This link anchors a practical pathway into modern options that still respect the medium- and long-term considerations of fit, durability, and performance. The continuity from earlier design ambition to today’s production realities is what makes studying this chapter worthwhile for riders seeking consistency across generations of engineering and craft.

External reference: For a historical reference on the specific mid-1970s wind-deflection approach and material choices that shaped early Vetter fairings, see the official archive that documents these innovations and the philosophy behind them.

External resource: https://www.vetterfairings.com/products/windjammer-iii-motorcycle-fairing-1975-print

Harmonizing Fit and Flourish: Compatibility and Personalization with Vetter Motorcycle Fairings

To illustrate how this narrative translates into action, consider a rider who wants a complete, aesthetically cohesive front-end transformation without altering the bike’s essential geometry. The rider starts by selecting a full fairing with an integrated approach to wind deflection, including a thoughtfully designed windscreen. They then decide on a chassis-friendly finish that requires only a straightforward paint-and-clear coat process, preserving the integrity of the original panels and their attachment points. In parallel, they might explore optional LED accents that can be integrated into the fairing’s contour to increase daytime visibility, while remaining inconspicuous when not illuminated. The fairing’s side panels can be paired with a separate upper piece to achieve a balanced, cohesive silhouette that maintains the machine’s character while delivering enhanced protection on long highway sections. A modular mindset makes a big difference here: the rider can start with a complete kit and then, over time, swap or refine individual components as preferences evolve. What matters is that each step maintains compatibility with the bike’s architecture and remains adjacent to the fairing’s core mounting system rather than forcing structural compromises. This philosophy aligns with best practices in aftermarket customization: build around the system, not around a single component that may require disproportionate changes elsewhere. In terms of aesthetics, a well-matched color and finish can accentuate the bike’s lines, lending a refined, unified appearance that looks as if the entire front of the machine was redesigned from the factory line. Yet the real payoff is tactile: a rider who sits behind a well-integrated windscreen experiences reduced buffeting, a calmer cockpit, and less fatigue after hours in the saddle. The rider’s posture remains comfortable, and the headwind is managed in a way that does not demand constant micro-corrections on the bars. In this light, compatibility and customization are not competing goals but complementary forces that, when aligned, deliver a more confident and enjoyable riding experience. The careful orchestration of fit, finish, and functional upgrades makes the fairing a characterful extension of the rider’s own intentions—a practical yet expressive upgrade that respects the original machine while inviting new capabilities for protection, weather resilience, and personal style. The result is a narrative told through the bike’s lines and the rider’s choices, a story that continues to unfold with every mile and every dusk ride. To readers seeking a direct path to practical options, a curated selection on a trusted retailer’s Honda-fairings collection may serve as a useful starting point, providing clear guidance on compatible model ranges and available finishes. This approach anchors the storytelling in a concrete path forward, while the broader customization ethos remains a source of ongoing inspiration for riders who want to shape their bikes into a more personalized, better-performing version of themselves. For further technical details on fitment and the nuanced considerations behind compatibility, consult the official resources that outline how fairings are designed to align with specific mounting points and airflow characteristics. Honda fairings collection offers a practical glimpse into how a curated range can support both compatibility and customization goals without compromising structural integrity, while preserving the bike’s original DNA. External readers may also find value in consulting the manufacturer’s fitment guide for additional specifications and cautions that accompany aftermarket upgrades.

Heritage Shapes, Modern Demands: The Market Pulse Behind Vetter Motorcycle Fairings

The market for aftermarket motorcycle fairings sits at a crossroads where respect for historical silhouettes meets a demand for contemporary performance. In this space, a brand with roots in precision craft and bespoke bodywork occupies a distinct niche. Riders who care about aerodynamics, weather protection, and the visual language of their machines often pursue pieces that merge classic mood with practical engineering. The narrative of today’s fairing market, including the Vetter legacy, is less a tale of mass numbers and more a study in how a lineage of craft can remain relevant as riding styles diversify and technological possibilities expand. What emerges is a pattern of consumer behavior that rewards parts engineered to deliver both form and function, while also honoring a sense of heritage that cannot be manufactured away by mere colorways or bold graphics.

At the core of current consumer preferences lies a revival of classic aesthetics. Enthusiasts are drawn to shapes that echo the bikes that first planted the idea of aerodynamic sport touring in riders’ imaginations. These shapes evoke an era when builders experimented with bold profiles and generous wind protection, not as a nod to retro cosplay but as a serious attempt to improve comfort and control on longer journeys. What makes the revival sustainable is the intersection with modern materials and manufacturing methods. Advanced plastics, improved resin systems, and reinforced composites now offer UV resistance, impact tolerance, and long-term durability that were not as readily available decades ago. In practical terms, this means riders can opt for fairings that visually celebrate the past while delivering today’s expectations for longevity and lower maintenance. The market responds when a design language is perceived as authentic rather than merely nostalgic, and that perception is strengthened when the unit can withstand the time and weather a long ride can throw at it. In this sense, the appeal of heritage-inspired fairings rests on a balance: the silhouette must feel earned, not manufactured to fit a fleeting trend.

This is not a nostalgia play alone. The modern consumer looks for personalization that goes beyond color and decals. The most sought-after fairings are those that offer refined finishing options, customizable paintwork, and materials with consistent, repeatable quality from batch to batch. The higher end of the market has long understood that a well-made shell does more than protect the bike; it signals the rider’s taste and commitment to the build as a whole. Limited editions and handcrafted or semi-handcrafted finishes have become a focal point for enthusiasts who want something unique without sacrificing reliability. In practice, this translates into a marketplace where small, controlled runs of fairings—crafted to a standard that can be trusted on a thousand-mile journey—carry a premium. The consumer is willing to pay for ownership of a piece that feels special, that has a story, and that continues to perform when the road turns rough or the weather turns uncertain.

The functional expectation attached to these aesthetic choices has evolved as well. Buyers now expect fairings to do more than simply shield a rider from wind. They want integrated wind management that reduces fatigue on long rides, that channels air efficiently around the rider’s torso, and that minimizes turbulence in a way that translates into steadier handling at speed. As the riding experience itself grows more diverse—sport riders chasing agility, touring riders chasing comfort, and cafe racers blending lean lines with daily practicality—the fairing must flex with the rider’s goals. This requirement has driven a movement toward modularity and adaptability. It is not about a single rigid shell but about a system that can be tuned with different panels, vents, and mounting options. A well-engineered fairing now considers ease of installation as a core feature, because a product that is difficult to fit will either fail to reach its audience or will be replaced by a competing solution that promises a simpler, more predictable fit. The practical benefit is clear: riders can preserve or rebuild the look they want without sacrificing the bike’s geometry or requiring extensive modification to the chassis.

In parallel with these design priorities, the market shows an expanding appetite for reliability and longevity. Materials science has become a decisive factor. ABS and fiberglass composites still dominate the field for their impact resistance and moldability, but the way these materials are used has matured. The emphasis is on consistent wall thickness, robust edge detailing, and paint-friendly surfaces that resist micro-scratches and UV degradation. This is not simply about resisting weather; it is about sustaining a glossy, finished appearance after years of exposure to sun, rain, grit, and road salts. The result is part engineering, part craft, and part risk management. A rider investing in a high-quality fairing expects to navigate a landscape of potholes and debris with minimal maintenance, and the product’s life cycle becomes a judge of value in a world where the resale some buyers rely on is increasingly important.

The breadth of the market is another key dimension. If the early era of fairings favored a few widely popular shapes, today’s market embraces a spectrum that includes full fairings, half fairings, and even more modular, universal configurations that can be adapted to a range of frame geometries. This flexibility is particularly welcome for restorations and custom builds, where the goal is to blend new performance benefits with an appearance that honors a bike’s original character. In practical conversations among builders and riders, this translates into a preference for systems that can be matched not only to a bike’s age but to its intended use. A sport-oriented machine may benefit from a lower profile and more aggressive aero, while a classic touring machine benefits from panels that provide wind protection with a refined silhouette. The best products manage both ends of the spectrum and allow the rider to tune the balance over the life of the bike.

A vibrant online and community-driven ecosystem also informs modern buying decisions. The second-hand market for vintage parts remains robust when the condition, authenticity, and fitment history are clear. Collectors and restorers are willing to pay premiums for pieces that have been preserved in a way that respects the original construction, while builders who prize originality may seek out unaltered parts that still carry their vintage patina. The digital conversation around these pieces—whether through forums, build threads, or auction or marketplace activity—feeds a broader understanding of value. It becomes less about chasing a particular model as a symbol of status and more about owning a piece with a narrative: a fairing associated with a notable build, or one that has been restored to factory spec with careful attention to period-correct finishes and hardware. In this environment, the “story” behind a fairing becomes part of its value proposition, alongside the skill of fitment and the quality of the finish.

From a business perspective, the trend toward customization is reshaping how manufacturers and aftermarket houses approach the product development cycle. The consumer now expects more from a single purchase: a visually striking shell, a system that can be tuned to wind conditions, and a package that makes the installation straightforward for a hobbyist or a professional shop. This is a call to manufacturers to provide better documentation, clearer mounting guidelines, and more dependable hardware. It is a call to retailers and builders to offer color-matching services, protective coatings, and post-purchase support that reduces the friction of installation and maintenance. The ecosystem thus rewards companies that invest in process quality as much as in design language. When a company communicates clearly about fitment across generations and outlines compatible mounting points, it reassures the customer that the investment will be reusable across a range of projects. This is especially important for enthusiasts who undertake restorations or ongoing customization across multiple bikes.

The consumer segment is both broad and nuanced. Dedicated vintage enthusiasts who collect and restore bikes cherish authenticity and optical fidelity; their demand often leans toward fairings that have a documented history or provenance. At the same time, a growing cohort of riders views fairings as a platform for personal expression, with choices that reflect not just performance metrics but the rider’s identity and the bike’s story within their life. In the best cases, a single purchase can speak to both sides of the spectrum: a fairing that looks period-correct, performs reliably in modern conditions, and fits a range of frame geometries without invasive modifications. This dual appeal helps explain why certain shapes endure in the market and how brands can maintain relevance while expanding their technical offerings.

The strategic implication for the market, including brands with a heritage emphasis, centers on a few clear priorities. First, consistent quality control matters more than ever. A single imperfect panel can undermine a customer’s trust and disrupt the reputation that comes from decades of craft. Second, clarity in fitment and compatibility is essential. Riders want to know that a fairing will align with mounting points and not require extensive reengineering. Third, design language must be expressive yet practical. The most successful pieces capture the essence of a period look without sacrificing the ease of maintenance and the possibility of upgrades or replacements as needs evolve. Finally, a robust narrative around durability, color stability, and ease of service becomes a differentiator in a crowded aftermarket space. A company that can articulate these values while delivering tangible performance gains will likely build lasting relationships with a diverse, global audience.

To illustrate how this dynamic translates into consumer behavior, consider how riders approach a recent cycle of restorations and modern builds. Many enthusiasts begin with a fairing as a starting point to reframe a bike’s silhouette. They then select finishes and hardware that align with their broader goals for the project—whether that means a subtle nod to the machine’s heritage or a bold, contemporary interpretation of a vintage form. The process is iterative: the rider evaluates fitment, checks for interference with brakes and tires, considers radiator and headset clearances, and assesses how easily the panel can be removed for maintenance. It is this practical loop—design, test, adjust, and repeat—that defines how consumers engage with a historically informed market today. The result is not merely a purchase; it is a statement about the rider’s approach to building and maintaining a machine that remains a source of personal enjoyment and public admiration.

Within this broader landscape, one can see how a brand with a long-standing reputation for precision and fitment becomes a touchstone for quality. Even as the market expands to include new materials and more modular approaches, the fundamental expectations recognized by riders—durability, a believable retro silhouette, and reliable performance—remain constant. Brands that cultivate trust in those dimensions can maintain relevance while also appealing to new riders who may not have owned the era that inspired the look. In other words, heritage-inspired fairings are not merely decorative; they anchor the rider’s confidence in the product’s capacity to perform under real-world conditions. The result is a market where performance and aesthetics reinforce each other, and where the consumer’s willingness to invest in a well-made piece is driven by a clear sense of value that aligns with long-term riding goals, not just short-term fashion.

For readers seeking tangible examples of how this market reality translates into shopping options, one can observe the broader ecosystem that supports these decisions. On one hand, there are established retailers and builders offering a range of shells designed for compatibility with a spectrum of classic and modern machines. On the other hand, a surge in community-driven customization projects underscores how riders view fairings as a canvas for personal expression, not as a single-purpose accessory. The convergence of these currents—heritage-inspired design, customizable finishes, and modular engineering—forms the heartbeat of today’s market. It signals that the next era of Vetter-type fairings will likely lean into more streamlined installation processes, better interoperability with modern components, and an even more nuanced approach to color and texture that can withstand the test of time while still feeling evocative of the past.

As the dialogue between past and present continues, the market’s trajectory appears less about chasing another trend and more about sustaining a philosophy: fairings that honor the rider’s story while delivering comfort, control, and confidence on the road. This philosophy serves as a practical guide for builders, retailers, and riders who want to invest in pieces that will perform across a spectrum of riding contexts. It also provides a roadmap for future product development, where the best innovations will be those that respect tradition while embracing the evolving realities of riding—wind tunnel data interpreted through the lens of a rider’s experience, materials that stand up to years of exposure, and interfaces that encourage care and customization rather than quick, disposable replacements.

For readers who want to explore related options and understand how these trends manifest across different makes and eras, a look at one prominent online hub for compatible fairing options can be instructive. Honda fairings illustrate how a broad catalog can support both restoration projects and modern builds, offering a sense of how aftermarket lines can speak to a range of riders while maintaining a clear standard of fitment and finish. While the specific models or curves are not named here, the underlying principle is universal: the best aftermarket shapes honor tradition without compromising on today’s performance expectations.

The story of Vetter and its peers, viewed through this lens, is a case study in how a brand can endure by listening to riders’ evolving needs and by translating a heritage language into practical, reliable, and inspiring products. The market’s pulse—its appetite for authentic silhouettes, its demand for personalized detailing, and its insistence on durability—points toward a future where every fairing is not just a protective shell but a narrative on wheels. In this context, the Vetter name stands as a reminder that craftsmanship, foretold in decades past, can still drive demand when paired with quality control, thoughtful design, and an understanding that the rider’s journey is the true measure of value.

External reference: https://www.ebay.com/itm/1979-vetter-windjammer-motorcycle-fairings-print-ad/255846314518

Final thoughts

In conclusion, Vetter motorcycle fairings are not merely a functional upgrade but a strategic investment in aesthetics and performance that can significantly enhance your motorcycle offerings. By understanding the numerous advantages—from performance gains and material innovations to broad compatibility and emerging market trends—you can better position your business to meet consumer demands and capitalize on the growing customization market. Offering Vetter fairings allows you to cater to passionate riders seeking both style and function, thereby enhancing customer satisfaction and loyalty.