Victory Motorcycle Fairing stands at the intersection of durability and aesthetics, providing motorcycle enthusiasts with both protection and style. With features like a robust diecast aluminum housing and an IP67 waterproof design, these fairings cater to varied riding conditions while ensuring that visual appeal does not take a backseat. This article delves deeply into the various facets of Victory Motorcycle Fairing, serving as a crucial guide for business owners in the motorcycle accessories sector. By exploring its design and functionality, market dynamics, durability standards, economic impact, and user feedback, we’ll paint a comprehensive picture of the value that Victory Motorcycle Fairing brings to both consumers and businesses alike.

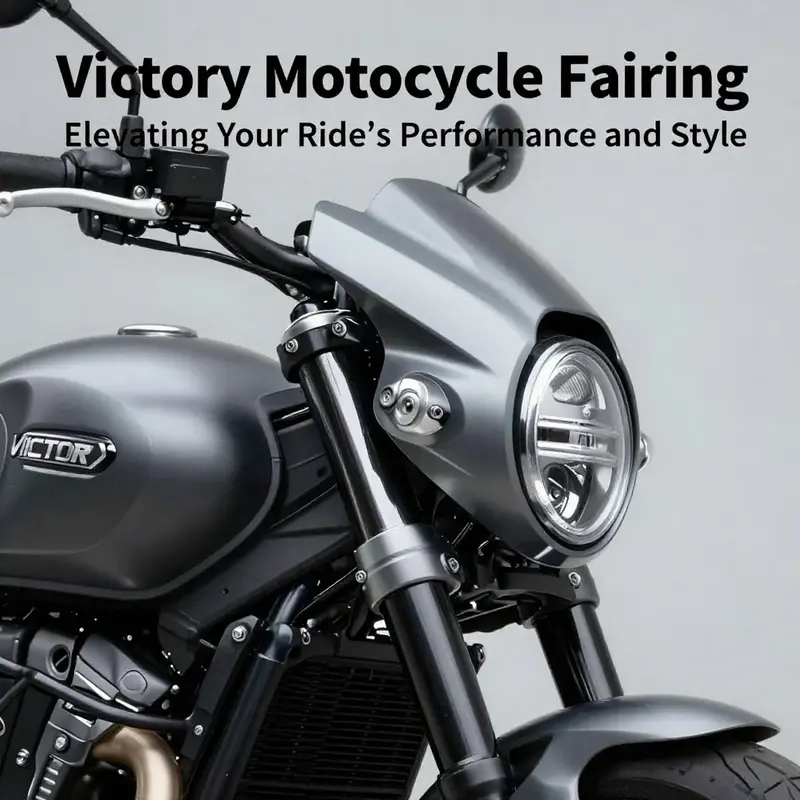

Batwing in Motion: Designing a Fairing that Merges Aerodynamics, Durability, and Rider Confidence

In the world of sport touring and aggressive cruising, the fairing is more than a decorative shell. It is a carefully crafted interface between a rider, the bike, and the elements. A well-designed fairing shapes the air that meets the machine, reduces fatigue on long rides, and preserves the machine’s personality in a symphony of curves and lines. The batwing-style fairing, as examined in the research materials, embodies this philosophy. It is a containment of aerodynamic intent and structural reliability, a component that must endure high-speed slipstreams, gusts, and shifting weather, all while keeping the rider shielded and comfortable. When we look at its architecture, several threads stand out: a diecast aluminum housing that promises rigidity and durability, an IP67 waterproof design that guards critical electrics, and a modular, rider-customizable approach that makes the fairing adaptable to different journeys and climates. These elements do not exist in isolation; they interact to shape performance, usability, and perceived value in a market where riders are increasingly discerning about both form and function.

From a design standpoint, the primary objective of a fairing is to streamline the airflow around the bike. The batwing-style form achieves this by extending the wind-facing surface outward while guiding the flow around the rider and the chassis in a way that minimizes turbulence. The distinctive silhouette serves a dual purpose. On one hand, it creates a cleaner aerodynamic profile that can contribute to marginal gains in speed, stability, and fuel efficiency over long distances. On the other hand, its shape communicates a stance that is both assertive and refined, aligning with riders who want a bold aesthetic without sacrificing ride quality. The aerodynamic logic behind this architecture rests on guiding the air in gentle contours rather than inviting abrupt separations at high speeds. In practice, this translates to smoother pressure distribution over the rider’s torso and shoulders, which translates into less fatigue and more control when cornering or braking in crosswinds.

The aesthetic language of the fairing is inseparable from its functional goals. The streamlined curvature and the volume of the housing are designed to look integrated with a motorcycle’s lines, not tacked on as a separate accessory. This harmony matters because the visual coherence of a bike often amplifies rider confidence. When a fairing looks like it belongs, a rider perceives it as a system that can be trusted under duress—whether slicing through a gust on an exposed highway or tucking behind the fairing to reduce wind pressure in a tunnel or canyon. The diecast aluminum housing underpins this perception of solidity. Aluminum, with its favorable strength-to-weight ratio and resistance to fatigue, provides a robust internal backbone that helps prevent flex and resonance that could otherwise disrupt rider comfort and instrument visibility at speed. It is not merely about weight; it is about predictable behavior when the bike is leaned into a turn, or when the wind imposes a side load that could excite unwanted vibration in a thinner, less rigid shell.

Beyond the raw materials, the weather-ready design of the fairing emerges as a critical feature. The IP67 waterproof standard cited in the research results is a reminder that contemporary riders traverse a spectrum of conditions. Electronics tucked within the fairing—such as dash illumination, wiring harnesses, and control modules—need protection from moisture, dust, and temperature swings. An enclosure built to IP67 specifications can withstand immersion in water up to a meter for a short duration and remains sealed against dust ingress. In practical terms, this means fewer maintenance surprises on a ride through rain, mud, or sudden splashes along a coastline road. Riders who value reliability can reasonably expect that the fairing will shield sensitive components during seasonal transitions when weather is unpredictable and road spray is common. The protective envelope contributes to a longer service life and reduces the chances of electrical faults that could otherwise complicate a ride or force a stop for troubleshooting.

A particularly thoughtful element in the design is the modular approach that enables customization without compromising the bike’s overall look or integrity. The wind deflectors, for instance, are not a purely optional add-on; they are integrated into a system with pre-drilled mounting holes located in the lower sections of the fairing. This arrangement allows riders to upgrade their experience by installing deflectors if they want more deflection in certain conditions, or leave them out when the weather is mild and a cleaner silhouette is preferred. The fact that these holes are pre-drilled and accessible via small push-out plugs reflects a design intention to simplify personalization. The rider can tailor the balance between wind protection and cockpit openness with minimal tools and effort, preserving the sleek appearance while expanding the range of riding scenarios that the fairing can support. This is not an ad hoc modification; it is an engineered pathway to adaptability, enabling a broader audience to justify the investment by aligning the fairing with their specific climate, riding style, and comfort thresholds.

This modular philosophy extends to the overall assembly as well. A key feature of the fairing is its ability to remain visually aggressive while remaining functionally versatile. The mounting system is designed to be compatible with a wide range of windshields and hardware, allowing riders to adjust rake, height, and even the angle to optimize line-of-sight and wind management. In practice, this means a rider who moves from a dry climate to a rainy season can recalibrate the setup to preserve maximum visibility and minimize wind pressure across the chest. For long-distance riders, the capacity to fine-tune the fairing’s interaction with the windshield translates into tangible benefits: reduced fatigue, steadier steering input, and a calmer cockpit at highway speeds.

An often underappreciated dimension of fairing design is how it contributes to or detracts from the bike’s overall ergonomics. The batwing-style arrangement does more than corral air; it sets a spatial relationship between rider, handlebars, and instrument cluster. A fairing that is too aggressive in its forward projection can trap heat or encroach on leg or arm movement, while one that tugs air too far away from the rider may fail to deliver meaningful comfort benefits. The design under discussion appears to strike a careful balance: it expands the rider’s protected envelope without creating a sense of imprisonment within the cockpit. This balance is partly achieved through the curvature that respects typical rider postures and partly through the controlled deflection that allows a precise amount of air to flow toward the chest and helmet region. Such design choices make the fairing a persuasive reason for riders to choose a particular look and feel, tying aesthetics to performance once again.

Market dynamics surrounding fairings reveal another layer of complexity. The research notes a competitive price range, with wholesale options available, indicating a broad appeal among riders and dealers who are seeking value without compromising performance. When a component can be procured at a price point that aligns with other essential riding gear, it becomes a more attractive investment. This price positioning also invites a range of purchase scenarios—from single-craft customization for enthusiasts to wholesale programs that encourage retailers to offer a full set of aerodynamic upgrades as part of a bike package. The fairing’s durable construction and weatherproof design further reinforce its value proposition: a rider can expect longer life and fewer service interruptions, which, in turn, improves total cost of ownership over time.

The design and functionality narrative extends into the broader ecosystem of motorcycle customization. Riders who appreciate modularity often seek components that can be adjusted to different bikes and styles without sacrificing the clean, aggressive lines of the original design. In this sense, the fairing acts as a bridge between form and function, a canvas upon which riders can project their preferences and riding philosophies. This is not merely about appearance; it is about shaping a durable, efficient, and adaptable cockpit. The fairing’s engineering choices—diecast aluminum housing, IP67 protection, pre-drilled wind-deflector holes, and a modular construction—converge to support a rider’s confidence, whether they are navigating a cloudburst or carving a mountain pass. The result is a product that reads not just as a single component but as a carefully crafted system that sustains performance through the seasons and across varied climates.

For readers seeking a broader sense of how fairings across brands approach similar challenges, a cross-reference to a broader catalog can illuminate common design language while highlighting unique nuances. A dedicated collection of fairings in the industry demonstrates how different manufacturers balance aerodynamics and aesthetics, and how consumers respond to those choices. This comparative lens helps explain why a rider might gravitate toward a certain form factor or materials set when upgrading a bike. In parallel, it underscores the importance of looking beyond a single feature—like a wind deflector—and recognizing how the synergy of materials, sealing, mounting systems, and visual language shapes overall rider experience.

The integrated design approach also anticipates future developments in fairing technology. As electronics become more centralized and integrated with riding aids, the need for reliable, sealed housings grows more acute. Advances in composite materials, smarter wind management, and adaptive deflection mechanisms may push fairings toward even more refined performance envelopes, while keeping the rider protected and comfortable. The current design, with its rugged aluminum housing and modular deflector system, lays a foundation that can absorb such innovations without a complete redesign. By prioritizing a respectful marriage of strength, weather resilience, and customization, the fairing speaks to riders who want a single, coherent platform that supports both high-speed performance and everyday practicality.

In summary, the batwing-style fairing embodies a philosophy of design where aerodynamics, durability, and rider comfort are not competing priorities but interlocking goals. The diecast aluminum housing provides structural integrity, the IP67 rating ensures resilience against the elements, and the modular wind-deflector system offers a path to personalized comfort across diverse weather patterns. The result is a product that does not merely adorn a bike; it actively contributes to the riding experience by shaping how a rider interacts with wind, weather, and the road ahead. As the market continues to demand higher performance with broader adaptability, this approach to fairing design serves as a compelling model—an example of how thoughtful engineering, when married to practical rider needs, can elevate the everyday act of riding into a more confident, controlled, and satisfying venture. For readers who want to explore related capabilities and design philosophies across the broader fairing landscape, the Yamaha fairings collection offers a glimpse into how different lineages interpret the same aerodynamic and ergonomic challenges, illustrating both shared principles and brand-specific nuances. (Internal reference: Yamaha fairings collection).

For those seeking a direct look at the external resource that showcases the exact fairing concept discussed here, an external product page provides a concrete example of the design, materials, and protection standards involved. External resource: https://www.victorymotorcycles.com/en-us/products/fairings/batwing-fairing-windshield-and-mount-kit.html.

Aftermarket Currents and the Silent Power of a Defunct Icon: The Market Dynamics of a Legacy Motorcycle Fairing

A fairing can do more than shield a rider from wind. It shapes stability, noise, heat management, and even the sense of control felt at speed. In the broader arc of motorcycle design, a legacy fairing from a once-dominant American cruiser brand still echoes through workshops and secondhand markets, long after its production line has gone quiet. The brand ceased production in 2017, leaving behind a complex afterlife that reveals how market dynamics evolve when a flagship component no longer rolls off a factory floor. What remains is not a simple remnant of a bygone era but a living substring of the industry’s ongoing dialogue between engineering heritage, supply chains, and rider demand. The current dynamics are less about new product launches and more about the aftercare of parts, the value of original design cues, and the evolving expectations of performance and reliability in an increasingly crowded aftermarket ecosystem. In examining these dynamics, the story unfolds as a continuity rather than a conclusion, where the very characteristics that once defined a model—durability, aerodynamics, and modular compatibility—continue to influence choices made by owners, garages, and suppliers today.

Historically, the fairing in question stood out for its engineering ambition. It adopted a diecast aluminum housing, a choice that carried durability without imposing excessive weight. This material selection reinforced the fairing’s structural integrity under high-speed loads and varied weather conditions. In a market that often balanced lightness against rigidity, the diecast approach provided a predictable, resilient platform for mounting and for protecting sensitive systems housed behind the panel. The integrity of the housing mattered not only for the rider’s immediate experience but also for long-term ownership. When a motorcycle ages, the fairing is among the components that see the most wear, exposure, and stress from vibrations and temperature cycles. A robust housing, therefore, translates into better protection for the underlying components, simpler maintenance, and a greater likelihood of preserving the original rider experience over time. Even as production dwindled, the technical memory embedded in that construction remained a reference point for aftermarket designers who sought to emulate or improve upon the established standard.

The fairing’s early acclaim also rested on its aerodynamic philosophy. The lineage includes a milestone from the early 2000s that set a high bar for drag reduction on heavy cruisers. The 2003 Vision model, in particular, introduced a fully enclosed fairing that achieved a drag coefficient as low as 0.36 Cd for its time. That figure did more than reduce wind resistance; it translated into measurable gains in high-speed stability and rider comfort. The closed contour managed air flow in a way that minimized buffeting and shifted the gust response away from the rider’s shoulders and chest. Such aerodynamic efficiency mattered not only for performance metrics but for the daily ride: a smoother ride at highway speeds, quieter airflow at cruising speeds, and less fatigue over long distances. Designers and riders alike recognize that a fairing is a controlled interface between machine and atmosphere. When it embodies efficiency, it becomes part of the rider’s sense of command. Although subsequent product lines moved beyond that exact design, the principle endured: aerodynamic refinement can redefine comfort, and comfort, in turn, sustains broader market appeal.

With the brand’s formal cessation, the fairing’s fate shifted from being a current production item to becoming a critical component in a broader aftermarket and preservation economy. Official production stopped, but the market did not vanish. Authorized channels retained parts support, including the fairing itself and related hardware. This continuity matters because it anchors the post-2017 ecosystem in reliability and compatibility. For owners seeking replacement or restoration, having access to original parts through authorized routes constrains the risk of mismatch, misfit, or material fatigue after years of exposure to sun, rain, and road salts. Yet the post-production market quickly tilted toward the secondhand and specialized modification space. The scarcity dynamics that unfold in such spaces—where original stock is finite and demand fluctuates with aging fleets, condition of surviving machines, and the ardor of enthusiasts—shape prices, availability, and the speed at which owners can realize a restoration or a personal customization project. In that sense, the market dynamics move from supply of new items to supply of pieces that can keep legacy machines aligned with current road realities. Owners often balance the desire to maintain authentic lines with the practicalities of compatibility with aftermarket offerings that promise improved fit, color, or airflow characteristics.

In analyzing the broader market context, one observes that the fairing landscape is undergoing a transformation that extends well beyond a single brand’s history. A recent, influential market study on motorcycle fairings highlights a global shift toward personalization, higher performance, and lightweight construction. Even as a once-strong production line has ceased, these industry currents shape the aftermarket and salvage economies surrounding legacy designs. Collectors and riders who want to preserve the authentic silhouette of a classic model find value not just in the piece itself but in the story, fitment, and condition of the surrounding hardware. The narrative of this fairing is thus inseparable from the broader arc of customization trends, where riders increasingly seek aerodynamic enhancements that marry historical design cues with modern materials and manufacturing tolerances. While mass production has moved on, the appetite for tailored, efficient, and weather-ready components remains sharp. The market’s health, in this lens, is not measured by new units sold but by the vitality of parts availability, archival support, and the capacity of the ecosystem to absorb, adapt, and reimagine legacy designs.

The IP67 waterproofing feature mentioned in contemporary discussions about robust, weatherproof components adds another layer to this dynamic. Weatherproofing matters for riders who navigate variable climates, commute in the rain, or tour across diverse landscapes. A fairing built to resist immersion and water ingress contributes to the reliability of electrical elements and mounting hardware. In practice, this translates to fewer service interruptions after exposure to moisture and a greater probability that a rider can complete a journey without the worry of moisture-related failure creeping into the electrical or control subsystems housed behind the panel. These attributes—durability, weather resilience, and compatibility with existing electrical infrastructure—become critical selling points in the aftermarket and can influence the decision calculus of buyers weighing legacy parts against newer, more widely available options. The market’s attention to such reliability signals a maturity in the consumer base; buyers are more likely to invest in a piece that promises long-term operability, even when the piece is no longer produced in a factory setting.

From a pricing perspective, the aftermarket and legacy-support markets demonstrate a practical sensitivity to production history and component scarcity. The historical price range for the fairing and associated parts, typically influenced by order quantity and wholesale arrangements, underscores the economy of scale that underpins the aftermarket. The range of prices, often cataloged in bulk or through authorized distributors, reflects a balance between the premium placed on original equipment quality and the flexibility afforded by shared engineering standards across different makes and models. This balance is particularly relevant when evaluating compatibility and fitment with a spectrum of contemporary aftermarket products that strive to emulate or complement the original geometry. In such a milieu, the decision to procure a part becomes a function of long-term ownership goals, the availability of aftermarket alternatives, and the perceived value placed on authenticity versus optimization.

To connect these threads to practical steps within the aftermarket ecosystem, consider the kinds of opportunities that exist for current owners and prospective buyers. A rider seeking restoration or upgrade might consult the broader ecosystem for compatible components that preserve the look while modernizing performance characteristics, such as improved seals, upgraded mounting hardware, or revised airflow elements designed to reduce drag without altering the character of the ride. The interplay between historical design intent and present-day engineering makes the process both technical and creative, inviting custodianship of a legacy while inviting innovation that respects form as well as function. In this light, the market dynamics of a legacy fairing are less about nostalgia alone and more about stewardship: keeping a line of design alive through careful maintenance, selective upgrading, and respectful adaptation to contemporary riding needs.

Within this ongoing conversation, a simple, practical touchstone emerges that can guide riders and shops alike. It is the recognition that the fairing’s enduring value rests on three pillars: the integrity of the original design intent, the resilience of its fabrication, and the availability of reliable parts and support for maintenance. When these pillars align, the legacy becomes more than a historical footnote; it becomes a living template for how to balance preservation with progress. As the market continues to evolve, the insights distilled from this story offer a framework for evaluating other legacy components in a world where aftermarket ecosystems increasingly define the riding experience as much as the factory lines once did. For those who want to explore the real-world landscape of aftermarket components touching two-wheeled performance, the broader ecosystem offers a spectrum of options inspired by the same aerodynamic principles and durable construction that once defined the legacy fairing.

In closing, the market dynamics surrounding a defunct icon’s fairing reveal a nuanced, forward-looking reality. The production halt did not erase the design’s influence or the rider’s appreciation for its balance of form and function. Instead, it redirected energy into preservation and customization, turning scarcity into opportunity and engineering heritage into ongoing inspiration. The story continues in workshops, scrapyards, and showrooms where enthusiasts weigh authentic parts against modern reinterpretations, guided by a shared understanding that air, water, and road all demand respect—and that the best solutions honor the past while meeting the present rider’s needs. For readers who want to see how legacy parts are integrated into today’s market, the landscape offers a cross-section of approaches, with frameworks that acknowledge both the value of preserved originality and the practicality of thoughtful modernization. If you want to explore how similar fairings from other makes are positioned in today’s aftermarket space, a curated source of contemporary Honda fairings collections provides insight into how modern suppliers structure fit, finish, and compatibility across a wide range of models. Honda fairings collection. It’s a reminder that while a single brand’s production may end, the broader design language and the demand for aerodynamic efficiency persist across the industry. For further reading on the global market environment and the drivers shaping the motorcycle fairing sector in the coming years, see the external resource cited below. External link: https://www.marketsandmarkets.com/Market-Reports/motorcycle-fairing-market-258945854.html

Durability-Driven Design for Victory Motorcycle Fairings

Durability on two wheels is more than a feature; it is a design mandate. In Victory Motorcycle fairings, the goal is to keep lines true, protect critical components, and age with the bike without visible compromise. The core approach pairs a rigid aluminum framework with carefully engineered polymer skins. Die-cast aluminum delivers stiffness and predictable fatigue performance, keeping the shell aligned under road shocks. ABS plastics add impact resistance and UV stability, absorbing energy from debris without cracking and fading over time. Integrated windshields are designed to work with the fairing to smooth airflow, reduce fastener stress, and preserve the visual profile. Waterproof sealing and weatherproofing guard electrical harnesses and sensors against rain, spray, and salt. Durability is validated through rigorous testing that simulates years of use, including temperature cycling, vibration, exposure to sunlight, and debris impacts. The result is a fairing that maintains its silhouette, protects vital systems, and preserves rider confidence mile after mile. Market positioning reinforces durability as a long-term value: fewer replacements, simpler maintenance, and compatibility across model years. For riders who want exact specifications, official product documentation provides precise material tolerances, seal configurations, and tests. In short, durability underpins aerodynamics, protection, and aesthetics, delivering reliability that lets the rider focus on the road.

Riding the Market: How High-Performance Fairings Reshape the Motorcycle Economy

The arc of a motorcycle’s performance and its market destiny often turns on a single, seemingly modest component: the fairing. Far from a purely aesthetic shell, a well-conceived fairing reframes aerodynamics, rider comfort, and the very economics of aftermarket parts. In a market that continually prizes efficiency, reliability, and customization, the fairing acts as both a technology carrier and a brand amplifier. The economic ripple started by a high-quality fairing extends far beyond its own price tag. It nudges consumer willingness to pay for the whole bike, influences service and maintenance patterns, reshapes aftersales revenue streams, and can even tilt the balance of competitive differentiation for manufacturers and retailers alike. As the global motorcycle market accelerates, the fairing emerges not only as a practical accessory but as a strategic lever in the broader machinery of the industry’s growth and resilience.

A critical driver of this dynamic is the fairing’s material and manufacturing profile. Diecast aluminum housings, in particular, offer a combination of robustness, precision, and heat management that few plastics or composites can match. When you consider the stresses a rider encounters—wind shear at highway speeds, debris impact on the open road, and the need for dependable electrical interfaces in all weather—the fairing becomes a first line of defense for the investment retailers and riders have already made in their bikes. The IP67 waterproof design, highlighted in the research, is more than a feature; it is a statement about reliability. For riders who ride in rain, humidity, or dusty conditions, the protection of electrical components translates directly into fewer service interruptions, higher uptime, and a more seamless riding experience. That reliability feeds into a willingness to invest in higher-end configurations, and in turn, sustains higher average order values across the accessory ecosystem. In markets where weather variability is the norm, this kind of protection is not merely desirable; it is a competitive necessity that reduces downstream warranty costs and preserves brand equity over the life of the motorcycle.

From a purely economic lens, the price profile of these fairings—ranging from roughly forty to eighty dollars in wholesale terms, depending on order quantity—underscores their role as cost-effective value adders rather than luxury afterthoughts. The margin calculus for wholesalers and retailers hinges on scale and customization. A higher-volume intake reduces per-unit production costs, allowing the same durable, weatherproof housing to support a broader margin structure or to seed promotional pricing that drives wider vehicle sales. This is particularly relevant as the market looks toward the growth horizon of the mid-to-late 2020s. Industry forecasts project a compound annual growth rate of about 11.7 percent for motorcycle fairings between 2025 and 2030. That trajectory signals more than rising demand for spare parts; it points to expanding opportunities for collaboration across the supply chain, including design teams, raw-material suppliers, manufacturing partners, and aftermarket distributors. In such an environment, small but scalable fairing lines can become central to a brand’s profit engine, turning a component into a measurable contributor to revenue and to the downstream ecosystem of helmets, apparel, and performance add-ons.

Aesthetics and branding are not superficial here. The design language of a fairing—line, curvature, texture, color coordination—contributes to the perceived value of the entire machine. When a fairing complements the motorcycle’s silhouette, it lifts the consumer’s impression of the bike’s overall quality, which, in turn, can elevate perceived resale value. In markets where customization is a major buying criterion, the fairing becomes a canvas for personal expression, and the business model shifts toward higher-value, bespoke configurations. The economic effect is twofold: first, the appeal of a distinctive look can justify premium price points; second, it broadens the addressable market by drawing in riders who are motivated less by raw performance and more by identity and statement. In this sense, the fairing becomes a vehicle not only for aerodynamics but for consumer storytelling and brand loyalty, both of which have clear, measurable implications for sales velocity and long-term brand equity.

The market dynamics around customization and personalization are particularly instructive. The data indicate growing demand for high-end, customized, and personalized fairings. This trend aligns with broader consumer preferences for differentiation in a crowded marketplace. When a rider selects a fairing that speaks to their identity—perhaps through colorways, textures, or sculptural details—the value proposition expands beyond function to include status, community belonging, and self-expression. For manufacturers, this translates into higher average order values and more predictable aftermarket revenue streams, as owners pursue complementary pieces such as belly pans, vents, and decorative accents. Retail partners benefit as well, because customization elevates the shopper’s lifetime value and increases foot traffic for related product lines. The economic impact, then, is not merely incremental; it is multiplicative, as the personalization trend amplifies demand across parallel segments of the motorcycle ecosystem.

The ecosystem’s health also depends on how well brands leverage industry events to showcase innovations. Large gatherings, such as the Blue Sky Heaven event scheduled for May 10–11, 2025, function as accelerators for brand visibility and product adoption. These events create opportunities for live demonstrations of aerodynamic performance, weather resilience, and modularity—key selling points for modern fairings. For attendees, immersive experiences translate into rapid comprehension of a fairing’s value proposition and a higher likelihood of immediate or near-term conversions. In aggregate, such events stimulate demand across the value chain: manufacturers gain valuable feedback to refine future designs, suppliers receive clearer forecasts for capacity planning, and retailers benefit from concentrated bursts of demand that can be translated into favorable purchase terms and promotional planning. The economic upshot is a more dynamic, feedback-driven market, where innovation cycles accelerate, and the market’s absorptive capacity expands in synchrony with rider expectations.

The geographies most likely to experience amplified effects from these trends are those with mature aftermarket ecosystems and strong riding cultures, balanced by developing markets where price sensitivity is tempered by growing mobility needs. The fairing’s value proposition—durability, weather protection, and aesthetic impact—speaks to riders who demand longevity and performance from both their bike and its accessories. In regions with pronounced seasonal riding patterns, the IP67 protection and the rugged construction of the housing reduce downtime, ensuring riders can continue to enjoy their bikes without interruption. This reliability translates into steadier aftermarket sales, more predictable wholesale demand, and less volatility in pricing. Over time, as more models converge on similar design language and performance targets, fairings can also become a standard upgrade path, nudging new-bike sales higher as riders perceive a more complete, supported ecosystem around the motorcycle platform they own. All of these factors contribute to a more resilient economic fabric for the entire category, cushioning it against macroeconomic fluctuations and enhancing its long-run growth potential.

In discussing the economic landscape, it is important to acknowledge the role of the aftermarket in sustaining value across the bike’s life cycle. The fairing acts as a bridge between original equipment and aftercare, shaping the flow of parts, service, and styling opportunities that riders pursue post-purchase. The wholesale pricing window of forty to eighty dollars allows for efficient stocking and straightforward-margin strategies for retailers, while still enabling manufacturers to pursue innovation investments and quality control enhancements. The downstream effects include not only sales of the fairing itself but a more robust ecosystem of compatible components, coatings, and finishing options that sustain consumer interest and engagement over time. As a result, the fairing market supports a broader spectrum of business models—from one-off customization projects to scalable production runs—each contributing to the sector’s overall productivity and profitability. The confluence of durable construction, weatherproofing, and customizable appeal creates a compelling case for fairings to be central to the motorcycle’s total cost of ownership, ongoing ownership experience, and resale economics.

For readers curious about specific pathways to diversification and growth, consider the breadth of available platform options within the aftermarket. While the general principles apply across brands and models, certain platforms have established reputations for readily compatible fairing lines that can be integrated with multiple chassis configurations. This ease of integration helps retailers diversify their offerings without sacrificing quality, enabling them to reach broader rider segments and to experiment with new design themes, materials, and finishing techniques. The resulting economic effect is a more fluid market where experimentation is rewarded with quicker feedback loops, shorter product development cycles, and a faster route from concept to consumer. The end result is a more responsive industry capable of translating rider desires into tangible products with measurable demand, stronger margins, and greater brand loyalty.

For those exploring practical buying paths or enrichment through choice, a curated reference point can be found in the Honda fairings collection, which serves as a representative example of how a widely adopted, compatible line can catalyze broader market activity. This example illustrates how standardized compatibility, combined with high-quality materials and protective features, can drive both consumer satisfaction and business performance. As the market continues to evolve, the fairing category’s economic impact will likely be felt through a blend of scale-driven efficiencies and distinctive, customer-driven design choices that push the entire ecosystem toward higher performance and greater value. In this sense, the fairing is not merely an accessory; it is a strategic instrument in the instrumented growth of the motorcycle market, a driver of brand differentiation, and a barometer of consumer aspiration that foreshadows where the industry will head next.

External perspectives tend to corroborate this outlook. Market research forecasts point to a sustained, healthy expansion of the motorcycle fairing segment, with drivers including increased demand for protection in varied climates, rising interest in aerodynamic tuning, and a growing appetite for personalized styling. The synergy of function, durability, and customization suggests that fairings will continue to occupy a central role in the aftermarket economy, reinforcing value across the entire supply chain—from raw materials to finished goods, from distributors to end users. For a broader frame of reference on market dynamics and future forecasts, see Market Research Future’s analysis of the motorcycle fairing market. https://www.marketresearchfuture.com/reports/motorcycle-fairing-market-1684

In sum, while a single component may seem modest in isolation, the fairing’s cumulative impact on the motorcycle industry is substantial. It shapes rider expectations, informs product development, and anchors pricing, margins, and aftersales activity. The 11.7 percent CAGR projected for 2025–2030 signals that the market recognizes the fairing’s potential to elevate performance and perception in equal measure. As brands and retailers continue to align their offerings with the evolving preferences for durability, protection, and customization, fairings will solidify their status as a cornerstone of the motorcycle economy—an understated yet potent engine driving growth, resilience, and enduring rider engagement.

Internal link: For readers exploring established lines and proven compatibility across popular platforms, the Honda fairings collection offers a representative example of how standardized design language can support broad market appeal. See the collection here: Honda fairings collection.

A Shield on the Highway: Rider Experience, Durability, and the Community Conversation Around a Classic Cruiser Fairing

A fairing on a cruiser-class silhouette is more than a style statement or a single part in a long maintenance list. It is a shield that shapes every mile ridden, every gust battled, and every decision a rider makes about comfort, access to weather protection, and visual cohesion with the bike’s lines. When we talk about a well-made fairing in this space, the discussion moves beyond mere aesthetics to a practical philosophy: protect the rider, optimize airflow, and endure the conditions of day-long journeys where weather can switch from inviting to menacing in a heartbeat. The fairing in focus embodies this philosophy through a diecast aluminum housing that delivers robust structural integrity. That choice of material translates into a shell that resists flexing under wind loads and road irregularities, preserving the alignment of mounting points and ensuring that adjacent components—windscreens, turn signals, and mounting brackets—stay true over the life of the bike. In a world where a small misalignment can introduce wind noise or create vibration paths, the rigidity of a diecast construction becomes a meaningful rider benefit, helping to maintain a calm cockpit and predictable handling as speeds rise or as headwinds push pressure against the bike’s face. The same piece of hardware tells another part of the story: durability that carries through the weather, the atmosphere, and the occasional encounter with debris on a highway stretch. The fairing’s housing is the backbone of the whole assembly, and its design signals a deliberate choice to balance strength with weight and to keep the appearance of a clean, unbroken profile along the bike’s front end. In weather, strength matters, too, and that is where the IP67 waterproof design enters the narrative with practical seriousness. The IP67 standard speaks a language riders understand: electronics ought to survive in rain, splashes, and damp environments without failure, and the rider’s experience should remain uninterrupted by moisture intrusion. The result is a fairing that serves not only as a shield but as a dependable companion on days crowded with uncertain skies, muggy commutes, or sudden downpours on a cross-country leg. The practical implications extend to the bike’s electrical architecture—headlights, indicators, and any ancillary sensors that ride closer to the fairing’s surface. When those elements stay dry and secure, the rider gains a quiet confidence, the kind that reduces cognitive load and preserves attention for the road ahead rather than the fear of a sudden short circuit or fogged lens. In terms of value, market dynamics reflect a similar balance of form and function. The fairing discussed here is positioned in a price range that supports wholesale dynamics and volume sales, with a typical spread that invites riders, riding clubs, and retailers to consider bulk orders for fleets, tours, or dealer programs. The range—priced accessibly depending on quantity—signals a demand that is not purely about a single consumer purchase but about a broader ecosystem that can supply riders with replacement parts, upgrades, or aesthetic choices without breaking a travel budget. This is where the aftermarket narrative starts to take shape. Riders who tour frequently or who keep a meticulous eye on the condition of their gear often see value in the ability to refresh or customize the look while preserving, or even enhancing, airflow patterns and protection. The fairing’s integrated design makes it easier for installation and alignment to follow a precise standard, reducing the friction that can come with incompatible hardware or misaligned mounting points. It is exactly this balance—clear protection, dependable waterproofing, and predictable fit—that helps explain why the community eyes a well-made fairing not only as a component, but as a statement of reliability for long-haul journeys. Within enthusiast forums and rider groups, conversations about this kind of part tend to orbit around a shared repertoire of concerns and praise: fit and finish, the ease of installation, and how well the piece integrates with the bike’s overall silhouette. Riders often note that a well-executed fairing aligns with the bike’s aesthetics, joining air management with visual flow so that the front end reads as a single, cohesive unit rather than a two-piece assembly grafted onto a chassis. That alignment matters, not just for the eye, but for the sense of cohesion it gives on the road. When the wind is coming hard from the side, a properly contoured surface can help redirect flow and reduce buffeting for the rider’s helmet and upper body, a subtle but tangible uplift in comfort on longer stretches where fatigue is a close rival to concentration. Yet community feedback is rarely monolithic. Enthusiasts recognize the strength that a railing of aluminum can bring, but they also consider the cost of maintenance and the realities of damage and repair. If a fairing is scuffed or grazed in a parking lot mishap, the prospect of replacement often becomes a real consideration, and that is where the economic argument intersects with usability. In a market where replacement parts can carry a premium, riders may weigh the immediate cost of a new piece against the long-term reliability and the ease of repair, especially in regions where service centers are sparse. The aftermarket ecosystem here rises to meet that need, offering alternatives that promise lighter weight or different aesthetics without sacrificing the backbone characteristics that matter most to riders: weather resistance, mounting reliability, and the ability to maintain a clean, integrated look after years of use. The ongoing dialogue among riders tends to reveal a pragmatic optimism: they value a fairing that blends into the bike’s lines, functions reliably in a range of weather scenarios, and accepts customization without undermining core protection. Some enthusiasts pursue off-the-shelf refinements, such as additional deflectors or vents that redirect air to manage cooling and reduce noise, while others experiment with finishes that evoke carbon fiber or other textures that visually communicate performance and precision. The openness of this community to modification is a strength, yet it is balanced by caution about legal compliance and safety. Changes that alter wind flow or lighting or that use unverified fasteners can, in some jurisdictions, tip into concerns about roadworthiness or regulatory compliance. As a result, even the most enthusiastic builders tend to emphasize compatibility and safety alongside aesthetics and speed. The design ethos at the heart of a high-quality fairing is a quiet, persistent confidence: a product intended to be felt, not noticed as a stray element. The rider experiences comfort and stability as the default, with the fairing presenting a curated combination of protection and style that complements the bike’s architecture rather than fighting against it. This is the kind of experience that translates to long trips, to overnight rides, to the calm in the helmet when the wind gusts pick up, and to the sense of reassurance that comes from a piece of equipment that behaves consistently when the weather turns and the road demands more from rider and machine alike. In the wider market, the potential for further refinement remains; discussions about new materials, modular assemblies, and even more robust sealing systems persist in forums and owner groups. The forward-looking rider understands that durability does not mean stagnation; it means preparing for new scenarios, improving on proven approaches, and ensuring that each component can be upgraded without discarding the entire system. Carving out space for lighter weight composites, exploring more efficient attachment schemes, or adding modular sections for different climates could further elevate the rider’s confidence and extend the mileage that a single fairing can cover. For those who want to dip a toe into broader customization while preserving the mechanical core, there is a path that blends proven reliability with fresh aesthetics. The online ecosystem offers a spectrum of options, including compatible aftermarket kits and colorways that harmonize with a bike’s existing palette. To explore a broader universe of compatible kits, readers can view the Honda fairings collection, a representative example of the diverse approach to fitment and style across the market: Honda fairings collection. This entry point underscores the way aftermarket offerings can complement factory setups, making it possible for riders to tailor the front end without sacrificing the fundamental protection and structural integrity that the original design is meant to deliver. The community’s voice, then, is not simply a chorus of praise or criticism; it is a living dialogue about how a single component can influence the travel experience, how it can be rebuilt and refreshed as technology evolves, and how riders adopt, adapt, and carry forward a tradition of durable, well-integrated fairing design. The chapter of a rider’s journey that begins with a shield on the highway often ends up weaving a broader story of how design philosophy, material science, and user feedback converge to shape product development, aftermarket ecosystems, and the culture around cruising. In that sense, this fairing is less a product than a persistent partner in the rider’s ongoing dialogue with the road. External resource: https://www.victorymotorcycles.com/forum/

Final thoughts

The exploration of Victory Motorcycle Fairing reveals its integral role in enhancing the overall riding experience through its design, functionality, and market versatility. Understanding its durable construction and economic influence highlights the promise it holds for business owners in the motorcycle accessories market. User feedback reinforces its standing, confirming that Victory Motorcycle Fairing not only meets but exceeds rider expectations. Embracing these insights can empower business strategies and position offerings for greater success.