Victory motorcycle fairing kits are more than just aesthetic enhancements; they represent a vital improvement in both the performance and visual appeal of these iconic machines. Designed intricately to improve aerodynamics and rider comfort, fairing kits come with a plethora of customization options that cater to individual tastes. They are engineered with high-strength materials that ensure durability in varying riding conditions, making them an essential accessory for any Victory motorcycle owner. This exploration of fairing kits will delve deeper into their aerodynamic benefits, customization potential, material engineering, and market availability, providing business owners the insights necessary to understand their value in today’s motorcycle aftermarket.

Streamlined Power: Aerodynamics and Performance with Motorcycle Fairing Kits

Across the spectrum of riding styles, from long-haul touring to spirited backroad sprinting, the fairing is more than a cosmetic shell. It is a carefully engineered system that reshapes air, shields the rider from wind pressure, and tunes the machine’s overall energy budget. A well-conceived fairing kit does more than hide cables or cover a frame; it orchestrates how air travels around the bike and over the rider’s shoulders. The result is a blend of reduced aerodynamic drag, increased stability at speed, and a quieter, more comfortable perch behind the windscreen. For riders facing long days in the saddle or high-speed highway cruising, these gains are not merely theoretical. They translate into real-world advantages: steadier handling in gusty crosswinds, less rider fatigue as the wind’s pressure is redirected rather than fought, and a measurable uptick in fuel efficiency when the engine works less against air resistance. Every contour, radius, and angle of the kit is a statement about how a machine meets its rider—quietly, efficiently, and with a clean, integrated appearance that remains faithful to the bike’s original character while extending its capability.

The core of modern fairing design rests on controlling flow. Streamlining reduces the cross-section presented to the air and helps the air rejoin behind the rider in a way that minimizes turbulence. A smooth, well-seated front fairing guides air toward the sides and over a low-profile wind deflector or integrated spoiler, if present, that helps maintain laminar flow across a broader portion of the motorcycle’s width. The rider’s body becomes a more predictable part of the aerodynamic system, which means less energy is wasted fighting eddies and separations that typically rob stability at highway speeds. When the rider is shielded from a broad, unrelenting wind pressure, a wider range of gear is usable at comfortable speeds without adding to the fatigue caused by bracing against the blast of air. This is particularly valuable on long rides where the headwinds can become taxing layers of fatigue over hundreds of miles.

Every fairing kit carries its own philosophy of how to handle air. Some designs emphasize a compact silhouette that hones airflow around the lower torso and knees, reducing the cross-sectional area presented to the airstream. Others lean toward a taller, more enveloping form, trading a touch more frontal area for better wind protection and a more stable presence at speed. Within each approach lies a spectrum of choices: the curvature of the chin, the depth of the side panels, and the profile of the upper screen. A streamlined front end can produce meaningful gains in stability and efficiency, but those gains hinge on fit and integration. If the fairing cannot wrap neatly around the bike’s existing geometry, its benefits can be offset by misalignment, added drag from gaps, or interference with other components. As a result, the most effective kits pay careful attention to the geometry of the model they are designed to fit and the way mounting points align with the bike’s substructure.

Material selection is another critical lever in the aero equation. Modern fairing kits commonly use reinforced plastics and composite materials that balance stiffness, impact resistance, and weight. The goal is to maintain rigidity under bumpy road conditions while keeping mass low enough not to burden the suspension’s travel or alter the machine’s weight distribution in a way that erodes handling. Some options incorporate metal housings in strategic areas where durability matters most, delivering a more rugged feel for riders who encounter mud, dust, and temperature extremes on adventure or touring builds. Whether the kit uses high-grade plastics, composites, or lightweight metal components, the defining trait is durability under real-world conditions: sun exposure, temperature swings, road spray, and the occasional off-road encounter should not degrade the fit or performance over time. Quality control at the manufacturing stage, including dimensional accuracy and consistent wall thickness, ensures that these materials behave predictably when mounted, and that the resulting aerodynamic form holds its intended shape across a wide range of riding scenarios.

Beyond the core shape, modern kits often incorporate features that extend customization without compromising aerodynamics. Integrated mounting points for mirrors, lighting, and even wind-deflecting elements are common. These features are designed to sit flush or near-flush with the surrounding surfaces, preserving the intended airflow paths and avoiding sharp protrusions that can unsettle the boundary layer of air in front of the rider. A true aerodynamic upgrade also considers how the rider interacts with the bike from a seating position. The upright posture of a touring rider, for instance, creates a broader wake that can induce drag; a well-designed fairing helps split that wake as cleanly as possible, decreasing drag and reducing the unnatural lift that can occur when wind pressure wraps around the rider. In this sense, fairings become a collaboration between form and function, marrying visual appeal with a measurable improvement in ride quality and efficiency.

The riding style dictates which design cues will yield the best gains. Track-oriented or sport riders often favor aggressively sculpted shapes that trim weight and minimize protrusions that could disturb airflow under high lift conditions or at high speeds. For these riders, even a modest reduction in weight and a tighter profile around the handlebars can translate into crisper steering response and more immediate feedback through the chassis. In contrast, long-distance or touring-oriented configurations prioritize comfort and wind management. They typically emphasize a wider, more protective shield for the upper body and a shape that channels air smoothly across lateral surfaces to reduce buffeting and heat buildup. The choice is not simply about aesthetics; it is a question of balancing drag reduction with rider protection, comfort, and the ability to sustain energy on lengthy rides. Skilled manufacturers recognize this balance and present kits that offer a spectrum of wind deflectors and venting strategies that can be tuned at the rider level, enabling a tailored aerodynamic package without requiring a complete redesign of the bike’s front end.

Of course, a fairing’s performance can be amplified by accessory integration that respects the aero envelope. Universal winglets, for example, can be added to certain kits to generate downforce at the front, improving high-speed stability by helping the front wheel maintain grip in gusty conditions. These winglets are not a substitute for a well-fitting main fairing; they are a complement that can enhance downforce without significantly increasing drag when properly positioned. The broader lesson is that aftermarket improvements do not have to come at the expense of efficiency. When an upgrade thoughtfully preserves the air paths that the designer calibrated, a rider gains both a sharper look and a tangible performance edge.

In the process of selecting a fairing kit, fitment and compatibility deserve close scrutiny. A guaranteed fit is not a luxury but a practical prerequisite for achieving the aerodynamic and performance goals described above. The process typically involves a catalog of models and years, with mounting points that line up with the bike’s frame and substructure. For riders who invest time in research, installation guides and support resources can make the difference between a clean, straightforward upgrade and a frustrating afternoon spent chasing misaligned panels. The quality of seals matters as well; weatherproofing and dust sealing help protect the mechanicals behind the fairing and maintain consistent aerodynamic performance by keeping surfaces free of grit that could alter airflow. A kit designed with precision tolerances will sit flush against the frame, leaving little room for vibration-induced rattles and minimizing the chance that fasteners loosen over time under the stress of vibration and heat.

Aesthetics, while important, should not eclipse the practical economies of the upgrade. A well-chosen kit offers a cohesive look that remains faithful to the bike’s design language, while delivering practical gains. The finish quality—the uniformity of color coats, the absence of visible seams, and the precision of edge treatment—contributes to the perceived and real quality of the upgrade. Color matching, UV resistance, and scratch resistance are not cosmetic niceties; they influence the long-term appearance and the usability of the kit in varied riding environments. A kit that is pre-finished or that accepts factory-grade finishes can preserve the bike’s character, while a modular option may provide more flexibility for riders who want to swap looks as seasons or preferences change. In either case, the best outcomes come from kits that align with a rider’s vision of wind management, handling balance, and the machine’s visual stance on the road.

Riders also consider the economics and practicality of aftermarket fairings. The market presents a broad range of options, from entry-level configurations to higher-end assemblies engineered for precise fit and longevity. This spectrum is not merely about price; it is about confidence, warranty, and the availability of support via installation guides or community knowledge. A well-supported kit tends to reduce the risk of misfit and, by extension, the possibility of gaps, vibration, or rattling that could compromise aero performance. Buyers are encouraged to examine guarantee terms, return policies, and the availability of replacement parts if a panel or fastener should require care after several seasons of use. The best investments are those that combine a robust mechanical fit with a durable surface finish and a clear path toward post-purchase maintenance.

In describing the broader ecosystem, it helps to think of fairing upgrades as a dialogue between rider aspiration and engineering discipline. On one hand, riders seek a clean silhouette, improved wind protection, and a nod to personal style. On the other, engineers and manufacturers translate those aims into precise geometries, chosen materials, and reliable assembly methods. The end product should feel like a single, cohesive system rather than a collection of discrete parts bolted together. When the integration is thoughtful, the fairing becomes a single aerodynamic entity, guiding air with the rider in mind and yielding a perceptible difference in how the motorcycle behaves on the road.

For those who want to explore similar design philosophies inside other brands’ aftermarket catalogs, one can browse through broad categories such as the Yamaha fairings collection to gauge how the industry translates these aerodynamic principles into tangible products. This reference point is not a substitute for a Victory-specific fitment, but it illustrates how universal considerations—airflow management, rider comfort, mounting compatibility, and finish quality—shape the development of any fairing kit. The process is remarkably similar across brands, with the lessons learned about flow control and rider interaction applicable to virtually any cruiser or sport bike seeking to elevate its aero profile without losing character or reliability. Yamaha fairings collection serves as a nearby example of how catalogs frame this balance and guide riders through a curated selection of panels that respect both the machine’s form and the air it encounters.

The marketplace remains dynamic, and the availability of options continues to expand as new materials, faster bonding methods, and smarter mounting solutions emerge. That momentum matters because aerodynamics is not static; it evolves with the riding context, the speed envelope, and the rider’s evolving priorities. A fairing kit that worked brilliantly five years ago might now be outpaced by a contemporary design that achieves cleaner laminar flow while offering lighter weight or easier installation. Yet the underlying physics stay constant: reducing drag, guiding air, and limiting buffeting produces a calmer, more efficient ride. The job of a thoughtful kit, then, is to integrate these physics into a package that fits the bike flawlessly, looks intentional, and supports the rider’s goals—whether those goals center on distance, speed, comfort, or a blend of all three.

In practice, the journey from decision to road-ready upgrade is as much a learning process as it is a purchase. Riders will compare profiles, test fit panels, and evaluate the tactile feel of mounting points and seals. They will consider the balance between added bulk and the control benefits that come from a more predictable aerodynamic field. They will anticipate maintenance needs, such as periodic checks of fasteners and the care of surface finishes in sunlit climates or dusty lanes. They will weigh the value of integrated features and how easily those features can be upgraded or reconfigured as riding preferences change. The most successful transitions are those that treat the fairing kit as part of a broader approach to bike setup—one that respects the bike’s fundamental geometry while offering a clear path to enhanced wind management, improved stability, and a refined riding experience.

As this exploration of aerodynamics and performance suggests, the advantages of a well-chosen fairing kit extend beyond mere looks. They deliver a measurable step toward efficiency and control that can alter how a rider experiences a long trip or a tight corner. The kit’s form, materials, and integration with the bike’s essential systems all play a role in shaping that experience. In the end, the goal is a cohesive system that partners with the rider’s intent and the bike’s innate behavior to produce a more confident, capable, and comfortable ride, from first dawn to last light.

External reference: https://www.ebay.com/sch/i.html?_nkw=Victory+Motorcycle+Fairing+Kit

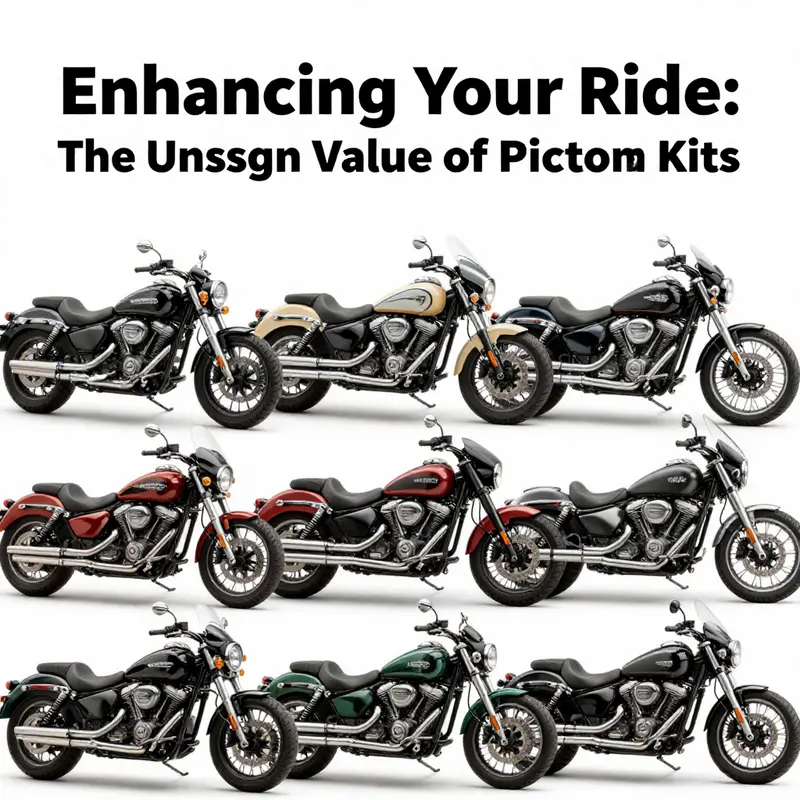

Customization and Aesthetic Expression: Crafting Identity with Victory Motorcycle Fairing Kits

Riders are often drawn to fairing kits not merely for the promise of better aerodynamics, but for the opportunity to tell a story with their motorcycle. The kit becomes a bridge between machine and rider, a surface upon which personal taste meets engineering intent. In the landscape of Victory fairing kits, this duality takes on a particular texture. The aesthetic module is not just about cosmetics; it is a deliberate, functional statement. The lines of a bike, once a baseline silhouette, can be reimagined into new proportions that emphasize speed, poise, or presence in a crowd. The kit provides a blank slate from which personal style can emerge while preserving the bike’s inherent geometry and structural integrity. The result is not a compromise but a synthesis—gloss and carbon-like textures coexisting with the bike’s original mass and center of gravity, all chosen by the rider.

The customization potential of these kits rests most vividly in the realm of graphics. Non-invasive graphics kits, decals, racing stripes, logos, and personalized emblems offer an approachable path to customization. They function as visual overlays that can evoke a classic look from a different era, an aggressive stance that screams speed, or a modern retro vibe that nods to motorsport heritage without altering a single bolt on the chassis. The advantage is twofold: the rider can express identity without the long lead times of panel replacement, and the core structure—the integrity of the fairing and the mounting points—remains untouched. In practical terms, this means riders can experiment with color schemes, contrast between matte and gloss surfaces, or the subtlety of a carbon-fiber pattern printed on the surface. The decals can be removed or revised when tastes evolve, offering flexibility that’s particularly valuable in a market where style can update as quickly as a rider’s calendar allows.

Model-specific fit remains a critical factor in achieving a cohesive aesthetic. Kit designers aim for exacting tolerances so that the front fairing, side panels, and tail sections align with the frame and seat line, producing a seamless transition from the radiator cover to the cockpit and onward along the bike’s belly. The result is a silhouette that looks as if it grew from the factory line, rather than one that was tacked on as an afterthought. This attention to fit is especially important when the rider is chasing a particular look—sleek sport-touring lines, an assertive streetfighter stance, or a minimalist, muscular profile that reveals the bike’s chassis geometry. The choice between a full fairing kit and more restrained, half-fairing variants also shapes the bike’s appearance. A complete shell can reinvent the busier lines of a touring platform into a single, aerodynamic sweep, while a more restrained fairing configuration emphasizes the bike’s frame and engine with a whispered, more timeless edge. In both cases, the alignment of mounting holes, panel curvature, and edge radii matters as much to the eye as to aerodynamic performance, and reputable kits are designed with those anatomies in mind.

Material choice is a quiet but consequential narrator in this story. High-impact plastics such as ABS, along with reinforced fiberglass composites, are commonly used because they provide a balanced mix of rigidity, impact resistance, and weight. The surface quality matters as much as the structural properties; a panel that holds paint without warping or yellowing over time contributes to the visual appeal year after year. UV resistance, color stability, and the ease of color-matching with original equipment finishes help maintain the aesthetic investment through sun, rain, dust, and road salt. The finish itself—whether a high-gloss clear coat, a satin sheen, or a textured faux-carbon effect—needs to perform as the bike ages. A well-chosen kit will not instantly look dated after a few rides in dry or wet climates; instead, it should mature gracefully, aging like the bike itself. This durability is essential when considering long-distance touring or off-road adventures, where a fairing may face more than the usual wash-and-wax routine.

Beyond weather protection and visual appeal, fairing kits can subtly influence rider comfort through wind management and ergonomic integration. A well-designed front fairing reduces wind pressure on the chest and shoulders at highway speeds, and integrated deflectors or carefully shaped edges can direct airflow to reduce buffeting. Even if a rider prioritizes aesthetics, the comfort gains from refined aerodynamics are a persuasive incentive. The way air flows over the helmet, across the shoulders, and around the torso informs how a rider perceives long days in the saddle. Not every kit emphasizes the same aerodynamic targets, but the possibility exists to tailor the wind envelope to a riding style. For touring-oriented builds, the impression of calm airflow can be as meaningful as a more aggressive look that communicates speed. The balance between form and function is never more visible than when a rider leans into a turn and notes how the silhouette seems to cling to the bike’s natural curves rather than betray them.

The broader context includes the availability of a variety of materials and finishes that help a given kit echo a rider’s preferred aesthetic. Gloss, matte, and satin finishes each convey different vibes, from showroom shine to understated sophistication. The decorative choices extend into surface textures that mimic more exotic materials, offering a tactile dimension to the visual effect. The options keep the project feeling personal rather than mass-produced. At the same time, the kits must respect the underlying engineering essentials—the fairing must not interfere with steering clearance, radiator airflow, or brake lines. A thoughtfully conceived kit can maintain or even improve legible panel gaps, a clean seam around the headlight, and a natural transition into the tank and tail. A well-executed aesthetic upgrade does more than flatter the eye; it reinforces the machine’s sense of purpose on the road and in the lineup of the rider’s personal collection of time on two wheels.

The decision to pursue a customization path through fairing kits often begins with a desire to harmonize performance cues with personal identity. A rider might be drawn to a look that echoes aerodynamic efficiency or a vintage racing lineage. In this pursuit, the graphics approach stands out for its accessibility and reversibility. Because decals and graphics overlays can be selected, revised, or swapped, a rider can refine the effect in stages. The initial installation can be straightforward—peel-and-stick artistry with simple alignment—yet the effect can be complex, offering a layered, multi-tone aesthetic that plays with light and contrast against the bike’s contours. The rider can test how a particular color interacts with the engine’s shadows, how a bright stripe refracts through a headlight cutout, or how a darker side panel fade accentuates the bike’s stance. The ability to iterate makes the customization process iterative and playful rather than an all-or-nothing commitment. If the result no longer suits the rider’s evolving taste, the graphics can be removed and replaced for a fresh look without compromising the core structure.

From the standpoint of shop and community support, the path to a new look through fairing kits reflects broader trends in motorcycling culture. Owners are more inclined to treat the body as a canvas for personal expression while preserving resale value by not requiring permanent modifications that alter structural integrity. The fairing kit becomes a reversible upgrade that can be reinstalled, swapped, or updated as styles shift with seasons or with upgrades to the bike’s performance package. The social dimension—sharing before-and-after photos, discussing fitment, color matching, and installation tips—adds another layer to the experience. The act of choosing a kit often becomes a conversation about taste, while the practical considerations—fit, durability, weather resistance—anchor the decision in real-world riding conditions. In this sense, the kit is not only about changing appearances; it is a statement about how riders want to be seen and how they want their machines to behave in the world they ride through.

A practical note on selection helps integrate these ideas into a coherent approach. Prospective buyers should assess their riding environment and the vehicle’s current geometry. A kit designed for a specific model will align better with the bike’s lines than one approached as a universal fit. The included mounting hardware, the quality of the finish, and the availability of color-matched options influence the final result as much as the price tag. The decision-making framework blends aesthetics with practical considerations: ease of installation, compatibility with accessories, and the potential for future upgrades such as light wiring or wind-deflecting features that can be added later. In expressing a rider’s taste, there is room for experimentation and professional guidance. A thoughtful installer can optimize alignment and ensure that the paint or decals do not obscure critical vents or switchgear. The goal is to harmonize the new silhouette with the bike’s existing personality, producing a look that feels inevitable as if the kit grew from factory lines rather than being an afterthought.

The narrative of customization thus folds into a broader understanding of how modern fairing kits function within a rider’s lifecycle. They are more than hinge points for the eye; they are modular platforms for ongoing expression. The same kit that reshapes a profile can also preserve or improve functional attributes such as air management and weather protection. A rider who appreciates the combination of performance and style will likely value the ability to adapt their bike’s appearance through seasons, events, or even travel itineraries. The kits invite a dialogue with the machine’s anatomy, encouraging the rider to observe how subtle changes in color, texture, and line weight influence perception from different angles and at different speeds. The effect is lasting: a bike that looks prepared for the next ride as much as a bike built to perform in a particular environment.

Within this context, the learner’s journey matters as much as the finished look. A rider may begin with a modest graphics package or a light color refresh to test the waters, then graduate to more dramatic changes that alter mass perception. The learning curve for installation—alignment checks, surface preparation, and careful edging—becomes part of the experience. As confidence grows, the rider can tackle more ambitious graphic schemes, perhaps combining multiple textures or color panels to emphasize a feature the rider loves about the bike’s geometry. The process fosters a personal relationship with the bike, a practice of tuning visuals to complement the machine’s existing shapes rather than overpower them. When done well, the result is a cohesive sculpture that appears to be a single, continuous form rather than a collage of separate elements.

The interplay of original equipment aesthetics and aftermarket graphics is a conversation about respect for design language. A well-chosen fairing kit mirrors the bike’s compass, guiding the eye toward its strongest lines and away from awkward angles. It reinforces the emotional charge that attracted the rider to the machine in the first place while providing new ways to experience the wind and the road as speed is imagined rather than simply endured. The chapter of customization thus becomes a story about owning a motorcycle as a lived experience, not merely as a mode of transport. The rider is invited to see how a kit can elevate both beauty and performance by preserving the core geometry and enabling personal expression that is both legible and durable. In the end, the aesthetic achievement will be a reflection of the rider’s ability to balance taste, practicality, and technical respect for the bike’s nervous system—the fairing.

For readers who want to explore the breadth of options, it helps to consider how graphics and finishes translate across brands and bike archetypes. The broader market demonstrates that the same design principles—fit, finish, and the ability to personalize—apply to many platforms. The lessons learned from one brand’s approach to graphics can inform decisions about another’s, particularly when a rider is seeking a look that blends modern aerodynamics with vintage flair. The idea is not to mimic a single source, but to study the principles behind how a fairing kit reads in the wind, how its surface interacts with light, and how the lines of the bike are recalibrated to celebrate form as a dynamic element of riding. This perspective helps riders resist the impulse to treat aesthetics as a static overlay and instead embrace it as an evolving part of their riding identity.

To complement this exploration, consider how different brands tackle the same design challenges. A well-chosen kit can emphasize aerodynamics while maintaining a rider’s personality. The goal is to arrive at a look that feels inevitable—the product of careful measurements, thoughtful materials, and a palette that resonates with the rider’s sense of place on the road. The craft is not about chasing a trend but about curating a lasting impression—one that can travel with the bike through sun-drenched highways, late-winter mists, or desert heat. The kit becomes a partner in the journey, offering stability and style as riding conditions shift and seasons turn. It invites ongoing adjustment, a gentle reminder that personal expression in motorcycling, like speed itself, is a practice of balance, timing, and the courage to stand out while staying true to the bike’s fundamental spirit.

The process, finally, is a dialogue between rider, machine, and environment. The kit’s value lies not only in the visual transformation but in how it preserves the bike’s original purpose while enabling a new narrative. A rider who invests in this kind of upgrade learns to read the bike differently—how the chassis supports a new silhouette, how the light catches a freshly styled contour, and how the wind becomes a collaborator rather than a force to be tamed. It is a creative discipline that respects engineering, celebrates individuality, and remains practical for daily use. As the road stretches ahead, the fairing kit stands as a quiet partner in the rider’s exploration of speed, shelter, and self-expression—an enduring reminder that a motorcycle is most compelling when its exterior mirrors the interior intention of the rider.

Internal link for related exploration: Yamaha fairings collection

External resource: https://www.victorymotorcycles.com/customization/graphics-kits

Durability and Material Engineering in Victory Motorcycle Fairing Kits

A motorcycle’s fairing is often judged by what the rider sees first—color, contour, and the way light falls across a sleek surface. But the true craft of a high-quality fairing kit rests in durability and material engineering. These kits are designed not merely to decorate a bike; they are expected to shield critical components, reduce fatigue, and stand up to the realities of long rides, rough roads, and changing climates. To understand why some kits endure where others crack or warp, it helps to look at the materials themselves, the tests those materials endure, and how those choices translate into real-world performance. The best kits are crafted from materials that balance stiffness with lightness, resist the solar assault of UV exposure, and retain color and gloss after years of sun, rain, and road spray. The result is a body that wears its strength visibly—without adding unnecessary weight or compromising the rider’s comfort or control at speed.

At the heart of durable fairing design is the material itself. Two widespread choices dominate aftermarket offerings: ABS plastic and fiberglass, each with distinct advantages and trade-offs. ABS, or acrylonitrile butadiene styrene, is prized for its resilience and impact resistance. It absorbs energy when struck by debris and resists cracking better than many simpler plastics. Modern formulations of automotive-grade ABS also incorporate UV inhibitors that help prevent yellowing and fading when the sun beats down on a fairing day after day. This is not just about appearance; color integrity matters for resale value, visibility, and brand perception. A fairing that retains its original hue under intense sunlight looks sharp, but more importantly, its edges stay crisp, and its transitions remain seamless after years on the road. In a practical sense, ABS’s workability supports precise shaping and fit. It can be molded into complex curves while maintaining surface rigidity, which ensures aerodynamic profiles remain accurate to design even after temperature fluctuations and vibration exposure. The reliability of ABS in this context is not merely theoretical; it translates into repeatable manufacturing tolerances and predictable performance across model variations.

Fiberglass offers a different equation. It tends to provide excellent stiffness-to-weight ratios and can be tailored for higher strength where impact risk is greatest. For some riders and circumstances, fiberglass’s resilience under impact and its ability to keep a surface smooth after minor abrasions make it a compelling choice. However, fiberglass requires careful resin systems, controlled layups, and protective coatings to avoid moisture ingress and to minimize micro-cracking over time. The engineering challenge with fiberglass is in the details: resin chemistry, weave orientation, and edge treatments all affect how a kit ages in the field. In either material family, the best products leverage advanced formulations and disciplined manufacturing processes to deliver predictable performance when exposed to temperature swings and road debris. That predictability, in turn, reduces the need for frequent repairs, preserving the rider’s confidence and keeping the bike looking consistent across seasons.

Beyond raw material choice, the emphasis on durability also drives weight management. Modern fairing kits strive to shave weight without sacrificing strength. Weight reduction matters for handling and for fuel efficiency, especially on long-distance tours where every marginal gain compounds across thousands of miles. The most effective kits achieve this by using optimized wall thicknesses, strategic reinforcements, and high-performance resins and plastics that maintain stiffness with less heft. When a shell weighs too much, it can impose a subtle strain on mounting hardware and fasteners, potentially amplifying flex under high-speed gusts. Conversely, a lighter, well-braced panel maintains its shape during acceleration and braking, which reduces noise, improves aerodynamics, and protects internal components from unexpected movement. This engineering balance—lightness paired with structural integrity—defines modern durability standards for fairing kits and sets expectations for riders who push their machines hard on highways, byways, or gravel stretches.

To translate material choices into ride-ready reliability, manufacturers subject fairing kits to a battery of durability tests. UV exposure is one pivotal test, given how relentlessly sunlight can degrade plastics—causing surface chalking, loss of gloss, and compromised color matching. UV-resistant formulations protect against this wear, ensuring finishes remain uniform from the first ride to the last. Impact testing is another critical measure; fairings face road debris, seasonal weather, and occasional drops. In testing, samples are subjected to controlled impacts to quantify the energy a panel can absorb before cracking or losing hollow integrity. The results guide wall thickness, layup geometry, and edge treatment so a panel can deflect or absorb energy without splintering. For riders who expect weatherproof performance, water and humidity resistance are essential as well. Absorbing moisture can cause swelling and dimensional changes, which degrade fit and seal integrity around mounting points and gaps around the engine bay. Durable kits use resins and sealants that create tight, moisture-resistant joints to protect the internal structure from corrosion and warping.

Durability also hinges on colorfastness and surface protection. A robust finish is more than cosmetic—it shields the material from the wear of wind-blown dust and chemical exposure from road grime and cleaning products. A well-engineered kit uses coatings calibrated to the underlying plastic or composite, ensuring adhesion remains strong through repeated washing and seasonal cleaning cycles. In some cases, color matching is tuned to minimize the visible impact of micro-scratches, a common fatigue point for riders who rely on frequent cleanup after backroad adventures. The aesthetic dimension—how the surface looks after a year of sun and rain—becomes a proxy for the kit’s health. A glossy, even surface suggests the materials and coatings have remained intact; a dull or uneven finish can be a signal that surface protection has begun to fail and moisture may start to creep in at the edges.

Another pillar of durability is compatibility and fit. The best fairing kits are designed with precision-fit systems that align with mounting interfaces common to a wide range of models. Precision-fit means fewer misalignments that can cause edge lifting, improper seal at the screen or wind deflectors, and unnecessary vibration. It also means the panel lines harmonize with neighboring components, reducing the risk that wind loads create micro-medges or contact points that accelerate wear. Precision sometimes involves pre-drilled mounting holes and standardized attach points; it can also involve compatible hardware selections that resist corrosion and maintain clamp strength even under temperature swings. When fit is right, the kit behaves like a single, integrated body part rather than a separate shell. Riders feel the difference as wind pressure is more evenly distributed across the fairing, reducing buffet and the fatigue that accompanies turbulently shaped wind gusts at highway speeds.

With durability and fit understood as co-dependent goals, some manufacturers pursue enhanced performance through composites and engineered laminates. Composite construction can deliver exceptional stiffness and impact resistance without the mass of metal or heavy plastics. By layering different materials—such as a core that reduces bending while outer skins provide impact resistance—these panels can be tuned for specific riding contexts, from city commuting to long-distance touring. The downside, of course, is cost and complexity. High-performance composites require specialized manufacturing steps and quality control to keep tolerances tight and to avoid voids or delamination. For riders seeking durability and longevity at a more accessible price point, automotive-grade ABS remains a reliable baseline option. It provides consistent performance, good impact resistance, and straightforward repairability, which means riders can maintain or refresh their fairings without specialized equipment.

The decision between ABS and fiberglass—or a composite blend—depends on the rider’s priorities. If low weight and ease of repair are paramount, ABS offers a pragmatic balance of durability and practicality. If extreme stiffness and impact resistance are prioritized for off-road conditions or rough roads, fiberglass or a composite approach can deliver the needed reserve without a prohibitive weight penalty. In practice, many riders opt for a hybrid strategy: use ABS for primary body panels to maximize shape fidelity and color durability, and reserve a fiberglass or composite reinforcement for areas that experience more stress, such as mounting brackets or central spine sections. This approach marries the best of both worlds—durability where it matters and manageability where it counts most during everyday riding.

Beyond raw materials, the lifecycle of a fairing kit is about more than the first ride. Long-term durability depends on maintenance practices and environmental exposure. Regular cleaning using mild, non-abrasive products helps preserve UV protective coatings and keeps the surface free from abrasive particles that could create micro-scratches. When cleaning is neglected, tiny abrasions can propagate under sun exposure, accelerating dulling and color loss. Protective waxes or sealants, when compatible with the panel material, create a temporary barrier against the elements and ease future cleaning. The choice of cleaning agents is critical; some solvents can deteriorate certain resins or soften particular plastics, compromising fit and finish. A conscientious maintenance routine extends the life of the kit, protects its color integrity, and preserves the aerodynamic profile that underpins performance benefits.

In addition to materials and maintenance, the concept of durability extends into the rider experience. Wind noise, buffering, and heat transfer are all influenced by how the fairing interacts with the rider and the air around the bike. A well-engineered fairing kit reduces turbulent wake behind the head and shoulders, which in turn lowers rider fatigue on long rides. It also serves as a protective shield for the engine and other components, intercepting road spray and debris that would otherwise risk chipping paint, nicking plastic, or loosening fasteners. Aerodynamic efficiency, reinforced by a robust material system, helps maintain stability at speed and creates a quieter, calmer cockpit for the rider. These performance benefits often compound over time; riders who demand reliability will notice that a well-chosen kit remains visually cohesive and functionally protective after thousands of miles, even in challenging weather and on imperfect pavement.

For riders who want a sense of connection between material science and the road, it helps to consider the shopping and customization experience as part of the durability story. A kit designed with attention to precise fit reduces the likelihood of squeaks, rattles, or gaps that can invite moisture and dirt. The ability to integrate wind deflectors, mirrors, or other add-ons with pre-drilled or intelligently placed mounting points is more than a convenience; it is a durability feature. When the mounting system is designed to accommodate accessories without forcing the panel to flex or shift under load, the entire assembly remains stable. That stability translates into fewer inspection points for wear and less frequent repairs, which is a meaningful advantage for riders who rely on their machines for long trips or daily commuting.

In sum, the durability and material engineering of a fairing kit are a composite of choices and outcomes. Material selection—ABS, fiberglass, or composites—sets the baseline for impact resistance, UV stability, and weight. The craft of the layup, resin systems, and edge protection determines how the kit ages under heat, moisture, and road spray. Precision-fit and thoughtful mounting interfaces translate that engineering into real-world reliability, reducing vibration, improving aerodynamics, and preserving color and gloss. The result is a kit that does more than cover the bike; it actively participates in performance and rider comfort. As the market continues to push for lighter, stronger, and more adaptable panels, the most enduring solutions will be those that balance practical durability with the subtle, constant demands of high-speed riding, long-distance touring, and daily use. For riders, that balance becomes an assurance: a fairing kit that stays true to its lines, keeps weather at bay, and supports the motorcycle’s performance through the miles ahead.

To connect this overview to broader options within the aftermarket ecosystem, riders often explore a wide array of fairing lines that emphasize compatibility and variety. For example, a comprehensive Yamaha fairings collection exemplifies how a wide range of models can share robust, well-finished shells designed for durability and precise fit. This broader marketplace perspective helps riders understand how material engineering translates across brands and Models, even as each line prioritizes its own balance of cost, weight, and performance. Yamaha fairings collection offers a tangible reference point for how the same engineering principles manifest in different shapes and mounting schemes, reinforcing the idea that durability is a universal design objective rather than a brand-specific trait.

As with any major aftermarket upgrade, informed choices come from looking at materials, testing, and the real-world behavior of the kit after miles of ride time. The path from raw polymer to a finished, durable panel involves chemistry, geometry, and a relentless focus on fit. It is this synthesis that separates a fairing kit that lasts from one that merely looks good for a season. For riders planning long trips or regular commutes through variable weather, staking a decision on material engineering—favoring UV resistance, impact strength, and precise fit—can yield a durable shell that ages gracefully with the bike. And in the end, that is the essence of durability: a kit that maintains its form and function through storms, wash cycles, and the steady passage of many miles.

External resource for further reading: ABS formulations, UV resistance, and testing in fairing materials can be explored in industry references and product listings that discuss corrosion-resistant plastics, impact testing, and lightweight design. See the following external resource for a detailed look at those material properties: https://www.alibaba.com/product-detail/ABS-Motorcycle-Fairing-Kits-for-Honda-MSX_1601468799531.html

Riding the Market: Victory Fairing Kits — Availability, Value, and Choice

A Victory motorcycle instantly reads as a statement of form and function, where bodywork is more than skin; it is a calculated balance of aesthetics, protection, and wind management. Fairing kits designed for Victory models bring a holistic approach to customization, offering front fairings, side covers, tail sections, and often integrated features like wind deflectors or mirror housings. The market for these components has grown more nuanced as riders seek both OEM fidelity and aftermarket flexibility. The result is a layered ecosystem where availability spans channels, material choices range from basic plastics to diecast aluminum housings, and pricing moves across a broad spectrum to accommodate everything from budget replacements to factory finished upgrades. Understanding this landscape means recognizing how the pieces fit together: the intention behind the kit, the year specific fit, and the value riders place on durability, weather resistance, and look as distinctive as the rider on the road.\n\nAcross the board, the market for Victory fairing kits unfolds through a multi channel network. Traditional routes such as authorized distributors and dealer networks extend into online marketplaces and independent outlets that specialize in bike plastics and body kits. The advantage for the rider is clear: a wider selection of configurations and aesthetics, from subtle refinements to bold, color matched transformations. But with more options comes the responsibility to confirm compatibility. Victory models cover several generations, and a fairing kit that fits one year may not align perfectly with another due to changes in mounting points, headlight assemblies, or instrument clusters. This shakes out in the marketplace as a mix of complete body kits, partial sets, and individual pieces, each labeled with fitment notes that must be cross checked against the specific year and model. For riders who value a seamless, factory like appearance, there is a distinct appeal to OEM quality replacements, while others chase creative, performance oriented tweaks that emphasize aerodynamics and wind management.\n\nMaterial choices are a central thread in this story. At the practical level, plastics remain the backbone of most aftermarket fairings for their light weight and impact resistance. But some entrants push beyond standard plastics into diecast aluminum housings or hybrid constructions that promise enhanced rigidity and a premium feel. A diecast aluminum shell, when paired with a weatherproof seal and IP67 rated components, offers an appealing combination of strength and rugged reliability—particularly for riders who tackle long tours or variable riding conditions. The IP67 rating, indicating comprehensive protection against dust and water immersion, is not merely a badge but a signal that a component can endure mud, rain, and repeated exposure to the elements without compromising structural integrity. This level of durability matters for fairings that shield the radiator, energy-draw utilities, and the rider from the brunt of windblast at highway speeds. In real-world riding, the benefit translates into reduced wind fatigue, more stable steering feel at high speeds, and a calmer cockpit—factors that accumulate into greater rider comfort over long stretches.\n\nThe price spectrum for Victory fairing kits mirrors the market’s breadth and the variance in materials and finish. Basic, functional components such as lower fairings or single side-cover panels tend to sit in the more accessible range, roughly within the low tens to modest hundreds of dollars per piece, depending on the exact material and whether the piece is sold as a standalone item or as part of a small pairing. In some cases, smaller pieces may be priced at roughly forty to eighty dollars, with occasional promotional pricing dipping toward the mid-thirties. When you move to more complete assemblies—the upper fairing sets, full tail sections, or comprehensive body-kit bundles—the price climbs, reflecting the added complexity of the piece, the need for precise fitment across mounting points, and the finish work required to achieve a factory-like look. For riders aiming to restore an OEM-grade appearance, full side covers in factory finishes can reach into the two-hundred-dollar range, with some contemporaries priced around two hundred and twenty-five dollars or more for a single piece depending on color matching and body line continuity. The market also includes stainless steel or other durable metal components in some segments, which may list in the mid-range for specialty pieces, typically spanning from the thirties to the seventies for individual parts. This spectrum captures both the practical budget-conscious buyer and the enthusiast willing to invest in a more robust or visually dramatic setup.\n\nA crucial dimension in the purchasing decision is model-year compatibility. Victory’s evolving lineup across years means that a fairing kit sourced for a specific generation may require careful verification to ensure fitment. A misfit can turn a simple upgrade into a frustrating retrofit, necessitating additional brackets, different mounting hardware, or even repainting to achieve color consistency. Riders who prioritize a clean, turnkey installation often gravitate toward OEM replacements or verified aftermarket kits that explicitly advertise cross-year compatibility or model-year specificity. In contrast, those who value experimentation or a unique custom look may accept a tighter fit or a minor adaptation if the kit delivers the desired aesthetics and aerodynamic benefits. The decision thus hinges on how much effort a rider is willing to invest in alignment, color matching, and potentially minor rework.\n\nThe innovation in fairing design also extends to integration options that emphasize rider comfort and performance. Some kits are conceived with wind deflectors and airflow management elements that reduce direct wind pressure on the rider’s shoulders and torso, particularly at highway speeds. Others feature pre-drilled mounting holes in lower sections to facilitate straightforward customization, enabling riders to add or remove deflectors, braces, or auxiliary mirrors with relative ease. These design choices illuminate a broader trend: fairing kits are increasingly treated not just as static coverings but as modular systems that can be tailored to a rider’s climate, riding style, and comfort thresholds. Such modularity speaks to a market that rewards thoughtful, user-centric design, where the combination of parts can be tuned to produce a more stable front-end behavior, less vibration-induced fatigue, and a more predictable ride in gusty conditions or on uneven pavement.\n\nFrom a procurement standpoint, the buying journey is marked by diligence and cross-checking. The demand for a harmonious finish—where paint, texture, and gloss align with existing bodywork—pushes some buyers to seek OEM-grade replacements or color-matched components by year. But the breadth of the market also makes non-OEM options attractive, especially when price sensitivity is a factor or when a rider is pursuing a temporary or experimental aesthetic. The decision framework often weighs several factors: the importance of color and finish fidelity, the potential need for repainting to achieve color consistency with the rest of the motorcycle, the availability of hardware and mounting instructions, and the level of after-sale support offered by the seller. Returns and warranty policies become particularly salient in this space, given the potential for fitment discrepancies and the specialized nature of fit. A seller with clear fitment notes, documented compatibility data, and reasonable return terms reduces uncertainty and provides a safety net for a purchase that might otherwise feel risky when dealing with a model-year-specific component.\n\nAs riders navigate these decisions, the practicalities of sourcing extend beyond the vehicle’s immediate assembly. Shipping times, packaging integrity, and the condition of the components upon arrival influence the overall value of the purchase. Fairings, being relatively fragile during transit, benefit from durable packaging, careful bracing, and protective coatings that minimize surface damage. Likewise, the hardware that accompanies the fairing kit—fasteners, brackets, grommets—needs to be consistent with the kit’s mounting requirements. In many cases, a complete kit is preferred to ensure that all necessary components are available in a coherent set, reducing the risk of missing parts and minimizing the time spent sourcing individual items later. Conversely, for riders who are updating a single area of the bike—perhaps replacing a damaged lower fairing panel—part-by-part purchases can be a cost-efficient approach, provided one confirms precise fitment and finishing.\n\nThe broader ecosystem of suppliers and marketplaces adds another layer to the landscape. While one can find a wide array of parts across major online marketplaces, dedicated distributors and reputable retailers that emphasize quality control, fitment verification, and color-matching services offer an additional level of reassurance. For the rational buyer, value can be found not only in the price tag but in assurance: a guarantee of fit, a guarantee of finish, and a predictable delivery experience. From a long-term perspective, the total cost of ownership includes not only the initial purchase price but the potential savings in time and labor when the kit fits with minimal modification and the color match remains consistent over time. In the end, the market’s richness—its many channels, its spectrum of materials, and its array of configurations—gives riders tangible choices for shaping the appearance and aerodynamics of their Victory machine while preserving or enhancing its ride quality.\n\nFor readers who want a broader sense of how fairings and body kits are treated across the motorcycle aftermarket, a general catalog of fairings in related brands can offer perspective on design language, mounting philosophies, and finish options. This broader view helps frame Victory specific decisions within the wider ecosystem of sport and touring bike customization. The catalog demonstrates that the basic principles—fitment accuracy, finish quality, and ease of installation—are consistent across brands, even as the exact mounting geometry and color codes differ. It also underscores a practical truth: the market rewards clarity. Clear fitment notes, transparent pricing, and a robust return policy reduce friction and help riders align their expectations with the realities of aftermarket and OEM alternatives. The pursuit of a harmonious integration—where the fairing lines echo the bike silhouette, where the color and gloss align, and where the installed package contributes to a more comfortable, efficient ride—remains at the heart of choosing a Victory fairing kit.\n\nFor readers who wish to explore a broader spectrum of aftermarket options beyond Victory, a curated collection of related fairings can be informative. This broader collection provides a contextual backdrop for how different brands address similar aerodynamic and cosmetic challenges, and it helps riders calibrate expectations about fitment standards, finish quality, and the level of hardware provided with each kit. Internally, this context can help readers assess whether a Victory kit represents the best alignment of price, fit, and finish for their goals. An extended look at related catalogs also highlights the importance of selecting a supplier who can offer accurate fitment guidance and reliable customer support—critical factors when a rider is investing in a component that drastically alters the bike’s silhouette and ride dynamics.\n\nExternal resource: a practical overview of market dynamics and sourcing practices for fairings in the motorcycle aftermarket can be found in widely used marketplace listings and supplier databases. These external references illustrate the breadth of available options and the spectrum of price points riders can expect when shopping for fairings across brands and generations. External resource: https://www.ebay.com/sch/i.html?nkw=Victory+Motorcycle+Fairings+Body+Kits&sacat=0&rt=nc&LHTitleDesc=0&osacat=0&_odkw=Victory+Motorcycle+Fairings

Final thoughts

Victory motorcycle fairing kits play a crucial role in enhancing both the functional and aesthetic attributes of these bikes. By improving aerodynamics, offering customization options, and providing durable solutions crafted from high-quality materials, they not only elevate a rider’s experience but also represent a lucrative opportunity for businesses within the motorcycle aftermarket sector. As the market continues to grow, staying informed about the benefits and features of fairing kits will allow business owners to cater effectively to the evolving demands of motorcycle enthusiasts.