Yamaha motorcycle fairing kits are a crucial aftermarket modification enhancing both performance and style. These kits, designed for various Yamaha models, improve aerodynamics, comfort, and customization options for riders. In a market driven by speed and personalization, understanding the role of fairing kits can provide business owners with insights into consumer needs and evolving trends. This article will explore the aerodynamic benefits and performance enhancements offered by these kits, delve into customization aspects that enhance aesthetic appeal, and examine market trends and economic impacts, empowering business owners to make informed decisions in this competitive landscape.

Streamlined Power: Aerodynamics, Weight, and the Performance Promise of Yamaha Fairing Kits

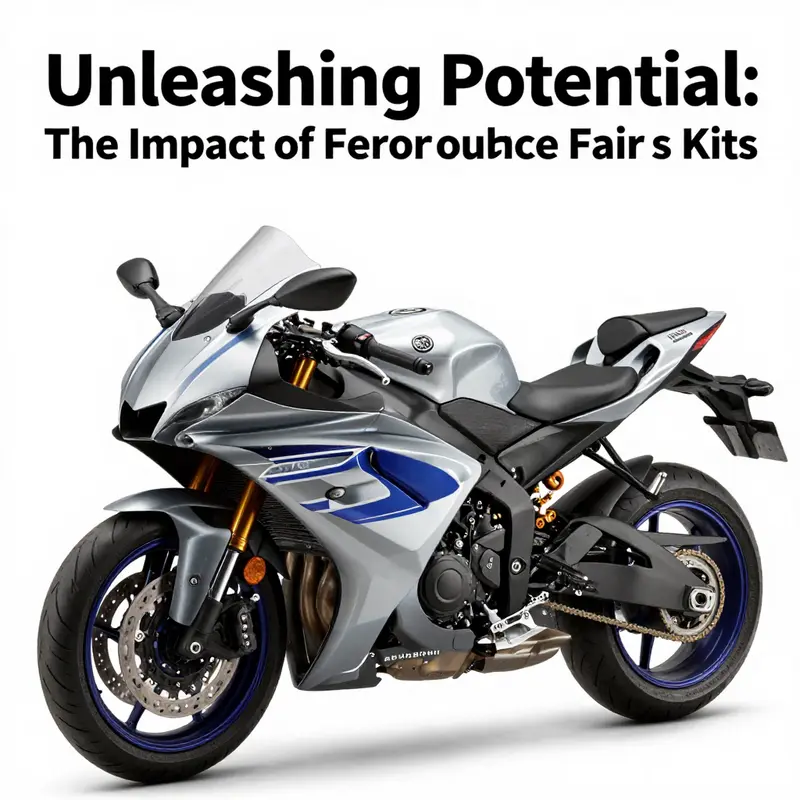

A motorcycle’s silhouette is more than a line on a page; it is a carefully crafted instrument for steering air and momentum. Yamaha fairing kits embody this truth by turning outward aesthetics into a precise engineering proposition. They are not mere covers; they are aerodynamic components that help a machine breathe more efficiently, slice through wind with less resistance, and carry the rider toward performance gains felt on track and street. The essence of these kits rests on three intertwined principles: weight reduction, streamlined shaping for improved aerodynamics, and modular design that invites personalization without sacrificing fit or safety. When these elements align, the rider experiences not only a faster-feeling machine but a more balanced one—eager to respond to throttle, steady at high speeds, and less fatigued on long rides. The discussion here centers on how such kits translate into real-world outcomes, from the workshop bench to canyon roads or a tachometer-spinning session on a circuit. The material choices behind modern fairing kits begin with a simple trade-off: weight versus strength. High-strength ABS plastic has emerged as a standout for many applications because it marries lightness with durability and heat resistance. A fairing assembled from ABS can shave weight by as much as twenty percent compared with traditional metal or older composite constructions, while resisting corrosion and environmental wear that can shorten the life of a panel exposed to rain, sun, and grit. For riders who value efficiency, that reduction matters. Even a modest drop in weight translates into less rotational inertia for the bike’s front end, a subtle but real improvement in suspension compliance and steering feel, especially at higher speeds or during long sweeping sections of road. In addition, ABS’s resilience against heat and sun exposure helps preserve fit and finish, so seams stay tight and gaps stay consistent after months of weather cycling. It is this balance—lightweight, durable, and stable under heat—that makes ABS a practical baseline for a wide spectrum of Yamaha fairing kits, from street-oriented packages to more aggressive, performance-focused designs.

Shaping Speed and Style: Customizable Yamaha Fairing Kits for Performance and Personality

When riders seek to define not just how a bike moves, but how it speaks, they often turn to fairing kits as a practical canvas. Yamaha motorcycle fairing kits sit at the intersection of form and function, offering more than cosmetic changes. They are a thoughtfully engineered upgrade that can reshape aerodynamics, wind protection, weight, and the bike’s visual language. A fairing kit in this sense is both a performance tool and a personal statement, a way to tailor a machine to the rider’s priorities—whether that means crisp, race-inspired lines on a track, smoother highway wind protection on long tours, or a distinctive street presence that turns heads at every corner. The aesthetics are powerful because they are not just about color; they carry the geometry of the bike, the tension of its lines, and the rider’s own sense of identity into the riding experience. In this way, customization becomes a narrative rather than a mere swap of panels, weaving taste, intention, and practical riding needs into one cohesive package.

The visual impact of a finished kit can be immediately striking. A well-chosen color and finish can transform the silhouette, making a familiar model look modern, aggressive, or refined, depending on the rider’s preference. A blue-finished or similarly bold choice can dramatically elevate a bike’s visual presence, helping it stand out in any setting. Yet the appeal goes beyond color alone. The materials used in modern fairing kits—ranging from ABS plastic to fiberglass and carbon fiber reinforced composites—offer distinct textures, reflectivity, and depth of finish that influence how light plays across the bike’s contours. These materials also carry functional implications. Lightweight construction reduces overall mass, aiding handling and fuel efficiency. When the fairings are up to 20% lighter than traditional metal variants, the impact is felt not only in acceleration and braking stability but also in how a rider negotiates corners and tucks in for the next bend. The choice among materials is thus a balance sheet of tradeoffs: stiffness, impact resistance, finish quality, and price all feed into a final decision that mirrors the rider’s priorities as they ride the clock, not just the track.

Functionally, the shape of a fairing kit is designed to optimize airflow around the bike at speed. Aerodynamic efficiency matters most in the ranges where wind forces begin to influence stability, engine cooling, and rider fatigue. A well-designed kit channels air to reduce drag, smooths turbulent streams around the rider’s torso, and can even lower wind noise to create a calmer cockpit at highway velocities. For touring riders, this translates into a more relaxed ride on long days in the saddle, with less fatigue and more comfortable highway mileage. For sport-oriented riders, subtle gains in stability at the edge of grip can translate into stronger confidence through high-speed sweeps and in aggressive lean angles. These performance gains are not merely theoretical; precise fitment and panel alignment affect the effectiveness of the airflow, so many manufacturers prioritize OEM-like fitting accuracy. Some claims emphasize installation in under 30 minutes, which reflects a broader trend toward streamlined, user-friendly upgrades that respect the rider’s time and the integrity of the bike’s original geometry.

Another layer of customization lies in modularity and interchangeability. Many modern kits are designed with modular panels or interchangeable sections that let riders swap colors or finishes without a full teardown. A single base fairing can be re-skinned with a different color or texture, enabling owners to refresh the bike’s look as tastes evolve or seasons change. This modular approach also supports preventive maintenance and repair, since individual panels can be replaced or upgraded without tearing into the entire assembly. The conceptual elegance of modular fairings is matched by practical advantages for daily use and long-term ownership, making the investment feel more flexible and resilient over time.

The practical considerations of sourcing a fairing kit are as important as the aesthetics for most riders. The most reliable options come from regions with established tooling capabilities and a history of producing model-specific fitments. Guangdong Province in southern China has emerged as a pivotal manufacturing cluster in this space, where skilled tooling, advanced composites processing, and efficient export logistics create a robust supply network. In this ecosystem, keepers of the craft emphasize precision fitment to ensure seamless installation and alignment with existing mounting points. The result is a kit that adheres to the bike’s original geometry, preserving the intended riding dynamics while still delivering a new look. For riders, this translates into confidence during installation and predictable performance afterward, a rare combination in aftermarket upgrades where fit can sometimes be an Achilles’ heel.

Within this manufacturing milieu, riders encounter a spectrum of materials and finishes. ABS plastic offers a balance of impact resistance and cost, while fiberglass provides a stiffer, sometimes lighter alternative with responsive shaping for a clean, track-ready profile. Carbon fiber reinforced composites promise premium stiffness-to-weight ratios and a distinctive surface sheen, appealing to those chasing a high-end, performance-first aesthetic. The choice of material is hardly incidental; it interacts with weight, aerodynamics, and the finish quality that a rider expects to endure through miles of road or track debris. Each material has a narrative of its own, from how it handles heat and UV exposure to how it responds to paint and clear coats, all culminating in a finished piece that must withstand the rigors of daily riding without sacrificing the shine that first drew the eye.

The process of selecting a kit often begins with a rider’s vision—what line, what color, what level of coverage they want over the bike’s front profile. It then moves through a sequence of practical questions about material choice, finish, and compatibility with the bike’s mounting points and windscreen. Precision fitment is more than a selling point; it is a safety and usability feature. When panels align with factory fasteners and gasket lines, the installation feels clean and professional, and the rider can ride with the assurance that nothing will rub, click, or loosen under vibration. The best kits offer a straightforward, well-documented installation pathway, with clear guidance on surface preparation, mounting torque ranges, and recommended fasteners. This is not merely about ease; it’s about preserving the integrity of the bike’s hardware and ensuring that the upgrade remains reliable after thousands of road miles or a few hundred laps on a track.

The decision to pursue a fairing upgrade is rarely about a single benefit. It is about the overall package: a ride that looks and feels right, a geometry that remains stable at speed, and a surface finish that resists road grit and sun fade. The aesthetics serve as an invitation to look again at the bike, while the functional gains invite the rider to push a little harder and go a little farther. The interplay between style and performance is a key driver of the enthusiast market, where riders want something personal, expressive, and technically sound at the same time. This is the space where design language meets engineering discipline, where color meets contour, and where a kit becomes part of the machine’s ongoing story rather than a one-off modification.

For readers who want to explore a model-specific range and see how options align with their particular Yamaha chassis, a convenient reference point exists within the broader ecosystem of model-focused catalogs. The Yamaha fairings collection presents a curated set of pieces designed to fit particular model families with high fidelity. This resource provides a sense of how the industry translates factory geometry into aftermarket versatility, preserving the lines and stance that riders recognize while expanding customization possibilities. The balance between fidelity to the original design and the urge to personalize is delicate, but when executed well, the result is a bike that feels both familiar and excitingly new. In the end, the most satisfying fairing upgrade blends alignment, weight, finish, and personal taste into a coherent whole.

When approaching a fairing upgrade, riders should also consider the broader marketplace and the responsibilities that come with modifying aerodynamics and protective structures. Quality control, safety standards, and environmental considerations all shape what can be trusted on the street or the track. A well-made kit will pass through at least a basic level of quality assurance, including consistent wall thickness, properly cured composite surfaces, and robust sealing against moisture intrusion. Finishes should be smooth, free of surface porosity, and capable of accepting coatings that are resistant to UV exposure and road chemicals. In addition to fit and finish, riders may want to confirm that the kit complies with relevant safety standards and environmental guidelines, a practical step that safeguards both rider and vehicle for the long term. These checks are not merely bureaucratic; they reflect a mature market that values reliability alongside style and performance. They are the quiet undercurrent that makes the exuberant act of personalizing a bike into a confident, repeatable practice rather than a one-off aesthetic play.

For those who crave practical examples of what this fusion of aesthetics and performance can look like, it is useful to imagine a scenario in which a rider updates a sport-oriented platform with a kit that emphasizes clean lines, tight panel gaps, and a finish that mirrors engineering precision. Picture a profile that remains calm at cruising speeds yet reveals a sharper silhouette as the pace climbs, the windscreen and fairing forming a cohesive shield that channels air with minimal disturbance. The rider benefits from reduced wind fatigue, more stable handling in gusty conditions, and the psychological boost of riding a machine that feels new and tailored. The kit’s lightweight construction supports nimble steering and responsive throttle behavior, while the modular nature of the panels allows for future tweaks without an overhaul. This is the essence of a well-chosen fairing upgrade: it respects the bike’s character, honors the rider’s vision, and enhances the experience of riding itself.

In practice, the journey from concept to finished build is a dialogue between vision and realism. Riders weigh the allure of high-end materials against budget realities, balancing long-term durability with the immediacy of a new look. They assess how finishes will age under sun exposure, how easily the kit can be repaired if a panel is dinged, and how the new form integrates with accessories such as windscreens, fenders, and cowls. The end result is not merely a fresh coat of color but a reimagined relationship with the bike—one where the rider feels more connected to the machine, more aligned with its silhouette as it slices through air, and more expressive in its stance as it rests at a stoplight or roars into a corner.

To ground these reflections in a practical step, consider that model-specific fitment and careful packaging are fundamental to a satisfying upgrade. The market rewards kits that deliver predictable install processes and consistent results across different units. When a kit slides into place with minimal modification, the rider retains confidence in the engineering that went into the original bike and gains assurance that the upgrade will behave as intended under load and vibration. Such confidence is hard-won and highly valued, and it fuels the sense of ownership that makes the kit more than a purchase—it becomes a contribution to the bike’s evolving personality.

For readers seeking direct access to a broader range of model-aligned options, the Yamaha fairings collection provides a navigable framework for exploring how different configurations align with various riding needs. This resource helps to anchor the imagination in the reality of fitment and engineering fidelity, showing how a single base platform can yield multiple expressions depending on the rider’s aims and preferences. The dialogue between imagineered design and tested practicality is what keeps the market dynamic: new finishes, new textures, and refined shaping that respond to how riders actually use their machines on the road and on the track.

As this exploration deepens, it becomes clear that the appeal of Yamaha fairing kits extends beyond mere appearance. The aesthetic choices harmonize with engineering realities, and the result is a product line that invites experimentation while respecting the bike’s core dynamics. The best kits allow riders to honor the bike’s lineage—its geometry, its stance, and its character—while giving them the freedom to redefine its visual and tactile personality. In the end, the upgrade is a dialogue with the road, a way to tune not just the bike’s surface but its relationship with speed, air, and the rider who inhabits it. The blend of customization potential with tangible performance gains makes fairing kits a compelling avenue for riders who view their machines as expressions of both intention and artistry.

To learn more about model-specific options and to explore additional context about how these kits are positioned within the broader market, readers can explore the Yamaha fairings collection. This resource helps anchor the conversation in practical possibilities and supports riders as they translate intention into a tangible upgrade. Yamaha fairings collection.

External reference: https://www.aliexpress.com/item/1005005478529262.html

Riding the Edge: Market Dynamics, Materials, and the Economy of Yamaha Fairing Kits

In 2026 the world of motorcycle customization has moved beyond simple estética. Riders are seeking a balanced blend of performance, protection, and price, and fairing kits have emerged as a focal point for that balance. The market for these kits is not a single stream of chrome and color but a multifaceted current that pulls from aftermarket ingenuity, evolving materials science, and the realities of global manufacturing and consumer budgets. The result is a landscape where choice matters as much as style, and where the value of a fairing kit is defined not just by how it looks, but by how it behaves on the road or the track. The first and most obvious shift is consumer perception. Riders no longer buy a fairing kit purely for appearance. They weigh it as an instrument of aerodynamics, wind protection, weight reduction, and even fuel efficiency. The argument has grown more nuanced: a well designed kit can reduce drag and weight enough to produce measurable gains in acceleration and handling. In practice, these gains may be subtle in street riding yet meaningful on a circuit where every tenth of a second and every degree of lean angle count. This is why the market has seen a pronounced tilt toward materials and designs that maximize performance while preserving or enhancing aesthetic appeal. The chorus of buyers is increasingly composed of two groups: those who want a practical upgrade to protect the bike and rider on daily commutes and weekend tours, and those who chase track readiness and a race inspired look. The overlap between these groups has become larger as modular designs and more sophisticated finishes allow riders to tailor their setup with ease and without professional help. The economics behind this shift are equally important to understand. In a market that once centered on factory parts, consumers now routinely compare genuine manufacturer pricing with a spectrum of aftermarket options. The price delta between OEM and aftermarket becomes a decisive factor, especially for riders who want premium looks and protection but must manage a finite budget. The data from 2026 shows a clear democratization of access. Genuine kits can exceed the high end of the market’s pricing, while high quality aftermarket alternatives begin in the mid hundreds and offer competitive fitment and finish. The gap between cost and value tightens when riders factor in the long term. A kit that is lighter and better sealed can contribute to reduced fatigue over long rides and potentially improved fuel economy. These benefits compound over time, especially for riders who accumulate many miles or push their bikes on demanding roads and tracks. The story of aging, weathering, and maintenance also plays a central role. As with any composite structure that sits exposed to the elements, fairings must resist UV degradation, moisture ingress, and micro-cracking from road debris. Carbon fiber reinforced composites have carved a niche here. They bring stiffness and weight reduction to the table, elements that are becoming essential for performance minded riders. Yet carbon fiber carries a premium price and a distinct risk profile. The upfront investment is higher, and the maintenance mindset is different. A crack in a carbon panel can be more expensive to repair than a similar damage to a fiberglass part, and the way the panel absorbs impact is different from traditional ABS or fiberglass. This reality has created a tiered market where buyers weigh the cost against the performance dividends and their own risk tolerance. The market’s maturity is reflected in design philosophy as well. Minimalism has gained ground among riders who value efficiency and practicality. A leaner silhouette that preserves ground clearance during aggressive leans and reduces overall weight aligns with contemporary riding styles. This design approach suits commuters and touring riders who want protection without the bulk of full race oriented fairings. On the other end of the spectrum, sport oriented kits persist, offering enhanced wind deflection, streamlined shapes, and aggressive lines. These options are favored by track riders and those who want a race ready aesthetic. The tension between minimalism and full coverage is not simply about looks; it is about real world use. Improperly sealed panels can trap moisture, leading to corrosion and fogging, which detracts from both performance and safety. The best kits address this by focusing on fitment and integrative seals that resist moisture and debris while maintaining easy access for maintenance. The fitment problem has historically been a critical barrier to satisfaction. Recent advances in mold technology and precision engineering have materially improved the OEM like fit that aftermarket producers strive to replicate. The promise of a quick install, sometimes pitched as setup in under 30 minutes, holds weight for riders who want to minimize downtime and get back on the road or track quickly. This is not just about speed of installation; it is about predictable fit that aligns with a rider’s expectations and tools. Consumers increasingly expect modular panels and interchangeable color options. The modular approach lets riders switch looks without recourse to a full replacement or professional bodywork. It also opens up the possibility of seasonal styling: the bike can wear a new look for different events or riding moods. Materials and manufacturing methods drive these modular capabilities. ABS plastic remains a baseline, valued for its balance of cost, impact tolerance, and ease of fabrication. Fiberglass offers a lower cost alternative with reasonable weight characteristics and ease of repair. Carbon fiber, while the most exotic and light, demands careful handling, skilled fabrication, and a willingness to pay a premium. In practice, this creates a spectrum of products that meet different constraints — from budget daily riders to serious enthusiasts who chase performance on the strip. The supply chain behind these products reveals a global pattern that coaches the market’s price and availability. A number of high quality options originate in manufacturing hubs that specialize in composites, precision molding, and rapid export logistics. Guangdong province stands out as a center of activity, where skilled technicians, advanced tooling, and an efficient distribution network converge. This regional specialization helps explain the wide array of choices available to buyers around the world. The geography of production also has implications for pricing dynamics and lead times. When a rider in one country seeks a kit, the interplay between localized distribution networks and international logistics determines how quickly a purchase can be fulfilled and whether a kit arrives with the finish and calibration promised by the seller. For buyers seeking certainty, several suppliers emphasize model specific fitment. The promise of precise OEM fitment can be a decisive selling point for riders who want a near factory look and feel. It is a reminder that performance and protection do not have to come at the expense of reliability. As with any investment, the decision calculus for fairing kits includes not only the upfront price but ongoing considerations. The life cycle of a fairing kit is linked to the climate and riding conditions in which the bike operates. Maintenance routines, including careful cleaning, inspection for cracks, and prompt repairs, extend the life of a kit and preserve its performance benefits. The economic complexity of the market is also shaped by consumer choice between premium materials and more accessible options. The availability of lower cost injection molded kits versus higher end hand finished sets reflects a broader shift in consumer expectations. Riders are increasingly willing to buy in at the lower tier when the product design, finish, and fit are solid enough for daily use. That willingness, in turn, stimulates suppliers to diversify their offerings, creating a broader spectrum that can accommodate different budgets while maintaining overall quality. In this ecosystem, decision making is guided not only by price but by a holistic assessment of value. A kit’s weight reduction translates into measurable handling improvements and potential efficiency gains. The degree to which a kit reduces drag impacts acceleration and stability at speed, an effect that matters on the highway and on the track. Yet the benefits are not uniform across all models. The same degree of weight reduction might yield more noticeable gains on a lighter chassis or a bike with older aerodynamics, and less pronounced effects on a modern platform with already optimized fairing contours. Riders weigh these factors against installation effort, maintenance demands, and the potential for weather related drawbacks such as moisture catching and seal degradation. The market’s growth is moderated by environmental and safety considerations as well. The push toward sustainable manufacturing and responsible disposal of composite materials informs buyer choices. Some suppliers highlight compliance with environmental standards and the use of recyclable components or paints that minimize volatile organic compounds. These elements increasingly shape the reputational calculus around a brand and its products. Simultaneously there is a cultural dimension to the market that mirrors broader shifts in motorcycle culture. The idea of customization has evolved from a display of personal flair to a functional statement about confidence, performance, and ownership experience. In this sense fairing kits are less of a one time accessory and more of a modular system that can be repeatedly adapted as the rider gains experience, toggles between street and track use, and experiments with different visual identities. The interconnection between design, material science, and economics is why this chapter treats fairing kits not simply as accessories but as a window into how riders negotiate risk, reward, and identity. When a rider considers a new kit, the calculation extends beyond the cost and the look. It includes how the kit integrates with maintenance practices, how it holds up to the weather, and how it interacts with performance expectations under variable riding conditions. The market has responded with a mix of guidance sources, customer reviews, and professional installation services that help buyers navigate these decisions. A willingness to exchange some time for the promise of better performance is becoming part of the rider mindset. To close the loop, the market’s evolution is guided by a simple but powerful dynamic: riders seek more value, not just more style. They understand that a fairing kit can influence weight, aerodynamics, and protection, and that these factors combine to affect the rider’s experience. They also recognize that the economics of scale — the way materials, labor, and logistics are organized — shape the price and availability of options. The result is a vibrant, evolving ecosystem where design ingenuity, material science, and careful budgeting come together to redefine what a fairing kit can do. For those seeking a tangible entry point into this ecosystem, the Yamaha fairings collection offers a canvas of opportunities to explore how form meets function in emerging ways. Yamaha fairings collection invites riders to survey options that balance affordability with performance and protection, and to imagine how a single accessory can influence a ride, a season, and even a market segment. As riders experiment with different combinations and as suppliers refine their processes, the chapter of fairing kits expands beyond aesthetics into a narrative about economy, skill, and the evolving meaning of customization. External research supports these observations, underscoring the ongoing negotiation between OEM reliability and aftermarket innovation that shapes rider choices and market dynamics. External reference: How to Choose Yamaha R3 Fairings: OEM vs Aftermarket

Final thoughts

Yamaha motorcycle fairing kits are essential for riders seeking both performance enhancements and customized looks. By understanding the intricate balance between aerodynamics and aesthetics, business owners can tap into a lucrative market opportunity. Emphasizing high-quality materials and distinctive designs can set offerings apart. As the market evolves, aligning product strategies with the latest trends and consumer preferences will ensure sustained growth and success in the motorcycle accessories industry.